Inorganic anti-radiation building coating and preparation method thereof

A technology for architectural coatings and radiation protection, applied in radiation-absorbing coatings, fire-resistant coatings, alkali metal silicate coatings, etc., can solve the problems of limited application, easy oxidation of carbon black, etc., to improve the application range, and not easy to absorb dust , Long-term effective electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

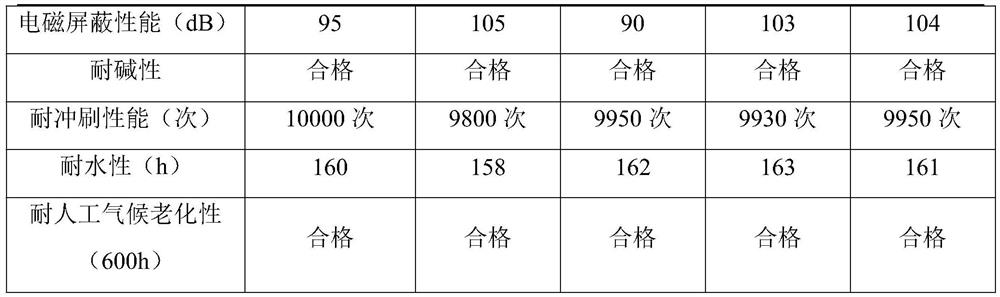

Examples

preparation example Construction

[0033] The preparation method of hydrophobic silica sol is as follows: the influence of the four factors of the modulus of potassium silicate solution, reaction temperature, reaction time and the amount of silicon-acrylic emulsion on the hydrophobic effect of the coating is determined by the method of orthogonal experiment, and the hydrophobicity of the preparation is obtained. The optimal synthesis process of silica sol: the modulus of potassium silicate solution is 5.5, the reaction temperature is 50°C, the reaction time is 15 minutes, and the addition amount of silicon acrylic emulsion is 25%; Viscosity, film-forming properties and mechanical properties were tested, and the optimum percentages of zinc powder content were obtained as 40% and 50%; the infrared spectrum of the potassium silicate base material after adding the silicon-acrylic emulsion showed that potassium silicate There are groups in the solution, which improves the mechanical properties of the coating such as ...

Embodiment 1

[0048] The preparation method for preparing the inorganic anti-radiation exterior wall coating according to the following steps comprises the following steps:

[0049] Step 1: Weigh the raw materials according to the following parts by weight:

[0050] 55 parts of hydrophobic silica sol, 8 parts of sepiolite, 10 parts of wollastonite, 7 parts of aluminum hydroxide, 5 parts of microwave absorber, 5 parts of inorganic mineral pigment, 10 parts of filler, 0.1 part of dispersant, defoamer 0.2 parts, thickener 0.4 parts.

[0051] Add the microwave absorber and dispersant to the hydrophobic silica sol, and grind to obtain the mixed solution A; grind by ball milling, the grinding speed is 1000r / min, and the grinding time is 2 hours.

[0052] The microwave absorber is coated SiO 2 layer of carbon black with an average particle size of 20 nm.

[0053] Step 2: Add sepiolite, aluminum hydroxide, and wollastonite into mixed solution A, disperse fully after soaking to obtain mixed solut...

Embodiment 2

[0057] The preparation method for preparing the inorganic anti-radiation exterior wall coating according to the following steps comprises the following steps:

[0058] Step 1: Weigh the raw materials according to the following parts by weight:

[0059] 58 parts of hydrophobic silica sol, 9 parts of sepiolite, 12 parts of wollastonite, 8 parts of aluminum hydroxide, 8 parts of microwave absorber, 6 parts of inorganic mineral pigment, 13 parts of filler, 0.2 part of dispersant, defoamer 0.2 parts, thickener 0.4 parts.

[0060] Add the microwave absorber and dispersant to the hydrophobic silica sol, and grind to obtain the mixed solution A; grind by ball milling, the speed of grinding is 1500r / min, and the grinding time is 1.5 hours.

[0061] The microwave absorber is coated SiO 2 layer of carbon black with an average particle size of 30nm.

[0062] Step 2: Add sepiolite, aluminum hydroxide, and wollastonite into mixed solution A, disperse fully after soaking to obtain mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com