Piston oil-return structure of horizontal opposed piston two-stroke internal combustion machine

A two-stroke internal combustion engine and horizontally opposed piston technology, which is applied to pistons, piston rings, mechanical equipment, etc., can solve the problems of increased oil consumption and difficulty in oil return, and achieve the effect of controlling oil consumption and overcoming difficulties in oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

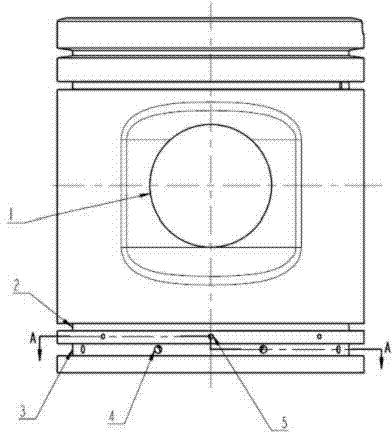

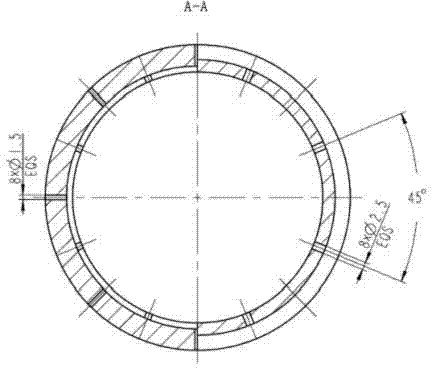

[0022] A piston oil return structure for a two-stroke internal combustion engine with horizontally opposed pistons, including two air rings on the head of the piston, a piston pin hole, a third air ring, and an oil ring; a third air ring is arranged below the piston pin hole. There is an oil ring under the third air ring, and the three are arranged in sequence from top to bottom; on the circumference of the bottom of the oil ring groove, there are more than two oil return holes evenly; the piston under the third air ring On the circumference of the outer circle, there are also more than two oil return holes evenly provided with another group of oil return holes used to assist the oil return holes on the circumference of the bottom of the oil ring groove; The boxes are connected.

[0023] There are 8 oil return holes on the circumference of the bottom of the oil ring ring groove, and the hole diameter is 2.5mm; there are 8 oil return holes on the outer circumference of the pist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com