Friction wearing part test apparatus for connecting rod small end bushing of engine

An engine connecting rod, friction and wear technology, applied in the field of engine connecting rod small end bushing testing, can solve the problems of connecting rod small end bushing wear, frequent engine accidents, etc., to reduce the test cost, easy to implement, and simple in structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

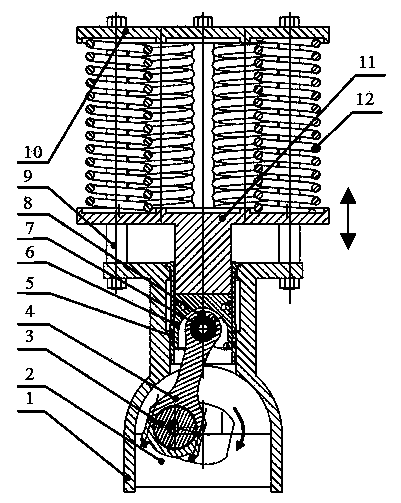

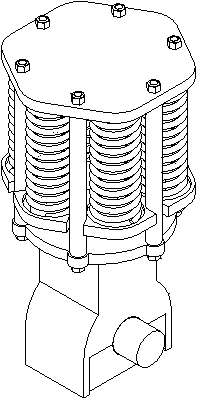

[0015] Such as figure 1 As shown, a test device for friction and wear parts of engine connecting rod small end bushing, including body 1, bearing cap 2, crankshaft 3, connecting rod 4, cylinder liner 5, test piston 6, piston pin 7, small end bushing 8 , Support rod 9, spring limit plate 10, moving plate 11 and spring group 12. Among them, the engine body 1, bearing cap 2, crankshaft 3, connecting rod 4, cylinder liner 5, test piston 6, piston pin 7, and small head bushing 8 are the common basic structures of the engine, and the crankshaft 3 is made in the supporting structure composed of the engine body, etc. The rotating motion drives the piston 6 to reciprocate up and down. Among them, the test piston needs to be improved on the basis of the commonly used piston of the engine, and the combustion chamber at the top is removed, so that the top of the piston can be evenly stressed, and it is closer to the state of the whole machine.

[0016] The present invention is improved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com