Patents

Literature

134 results about "Endurance testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Endurance Testing means testing of an application or software with a significant load extended over a long period of time, to evaluate how the system behaves under sustained use. This type of testing is performed at the last stage of performance run cycle.

Insulation gas voltage endurance testing method and testing device

InactiveCN1700029AFast measurementReduce cost of measurementTesting dielectric strengthEngineeringAtmospheric pressure

The invention relates to a measuring method and device of insulation gas pressure resistance measurement, which has a sealing container, manufactured by insulation material and can take on over 1MPa air pressure, wherein a pair of measuring electrode is posited inside the container. It has the following steps: first cleaning the container and sealing it, adjusting and measuring the distance of the electrodes, heating, drying and purging it in air draft, then inputting test gas into the container, placing the measuring electrodes on high-voltage test circuit, exerting high voltage to the electrodes and graduate increasing until it disruptive discharging then measuring instantaneous discharge voltage.

Owner:何平安

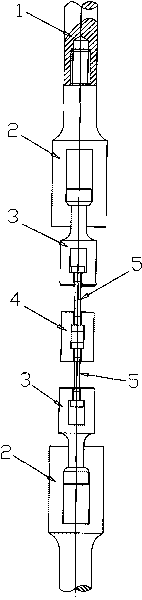

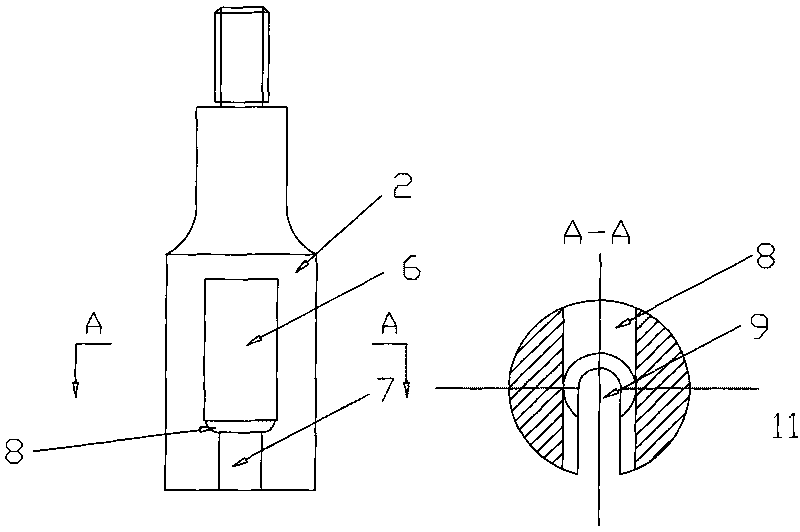

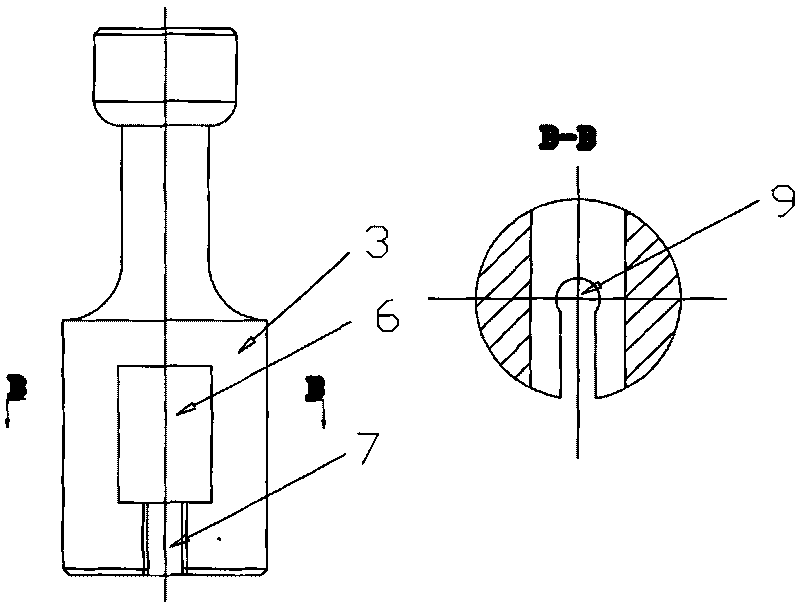

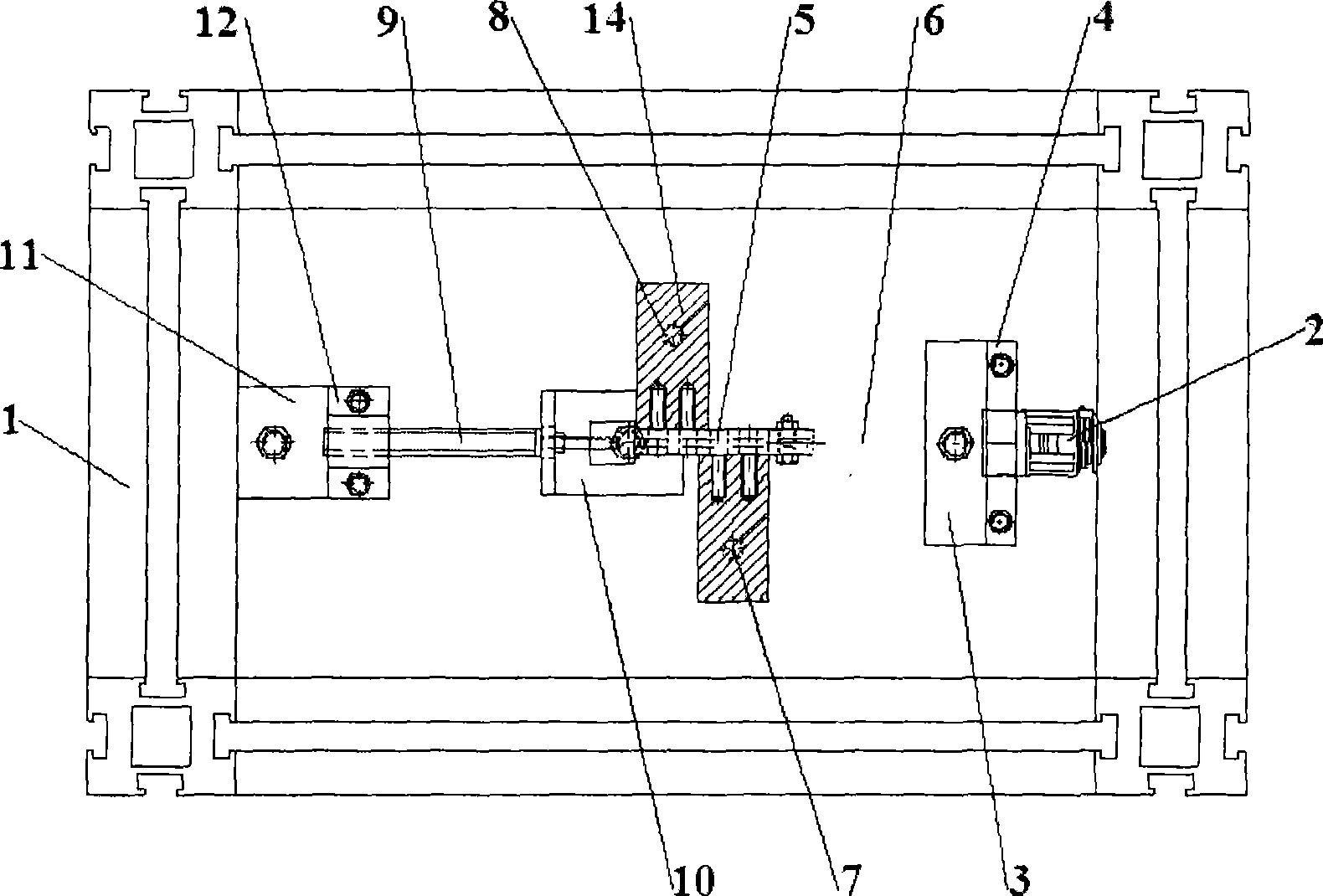

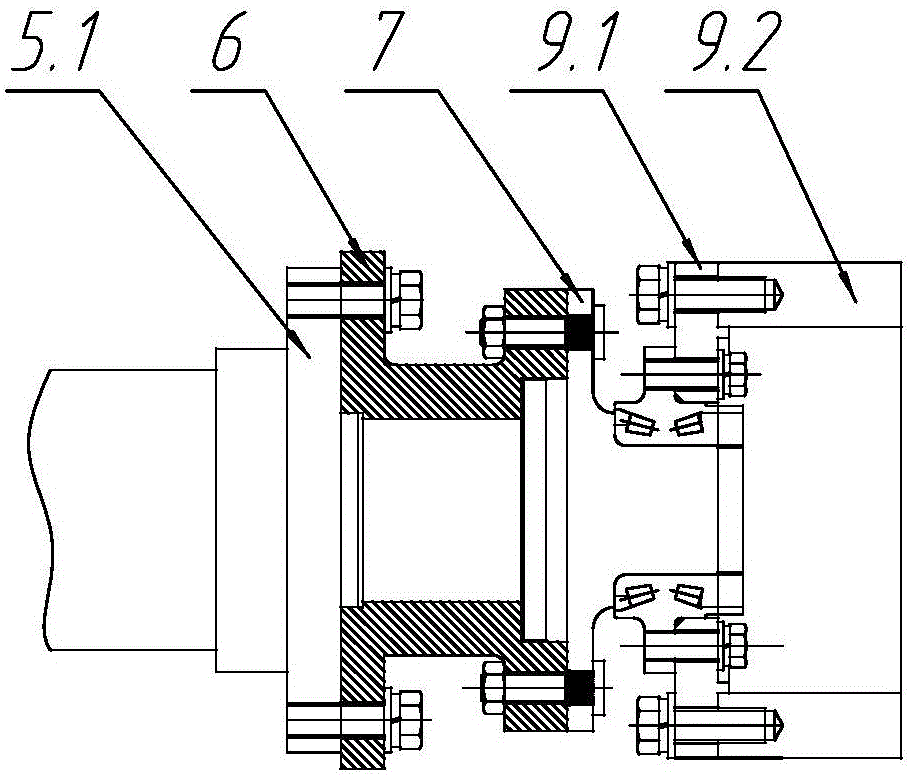

Anti-adhesive shoulder fixture for improving efficiency of endurance test

ActiveCN101706391AMeet tooling requirementsGuaranteed concentricity requirementsMaterial strength using tensile/compressive forcesTest efficiencyAlloy

The invention discloses an anti-adhesive shoulder fixture for improving the efficiency of an endurance test, which aims to provide a novel test fixture structure to improve the efficiency of the endurance test, prevent the adhesion and the tripping between a specimen and a fixture and between the fixture and a pull rod of a testing machine, and ensure the authenticity and the reliability of the test. The technical scheme of the anti-adhesive shoulder fixture has the following key points that: the fixture adopts a shoulder type structure to prevent the adhesion and the tripping between the specimen and the fixture and the adhesion and the tripping between the fixture and the pull rod of the testing machine; a shoulder type serial connector is designed, and two specimens are connected in series and are synchronously tested on one testing machine so as to improve test efficiency; a shoulder large pull head adopts K002 high-temperature alloy, and the shoulder fixture and the shoulder type serial connector adopt directional high-temperature alloy DZ22 or single crystal high-temperature alloy DD3 to improve the applicable test temperature of the fixture to 1200 DEG C; and the fixture has simple operation and quick and convenient clamping, ensures the concentricity, and is applicable to different models of endurance testing machines produced by different testing machine manufacturers.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

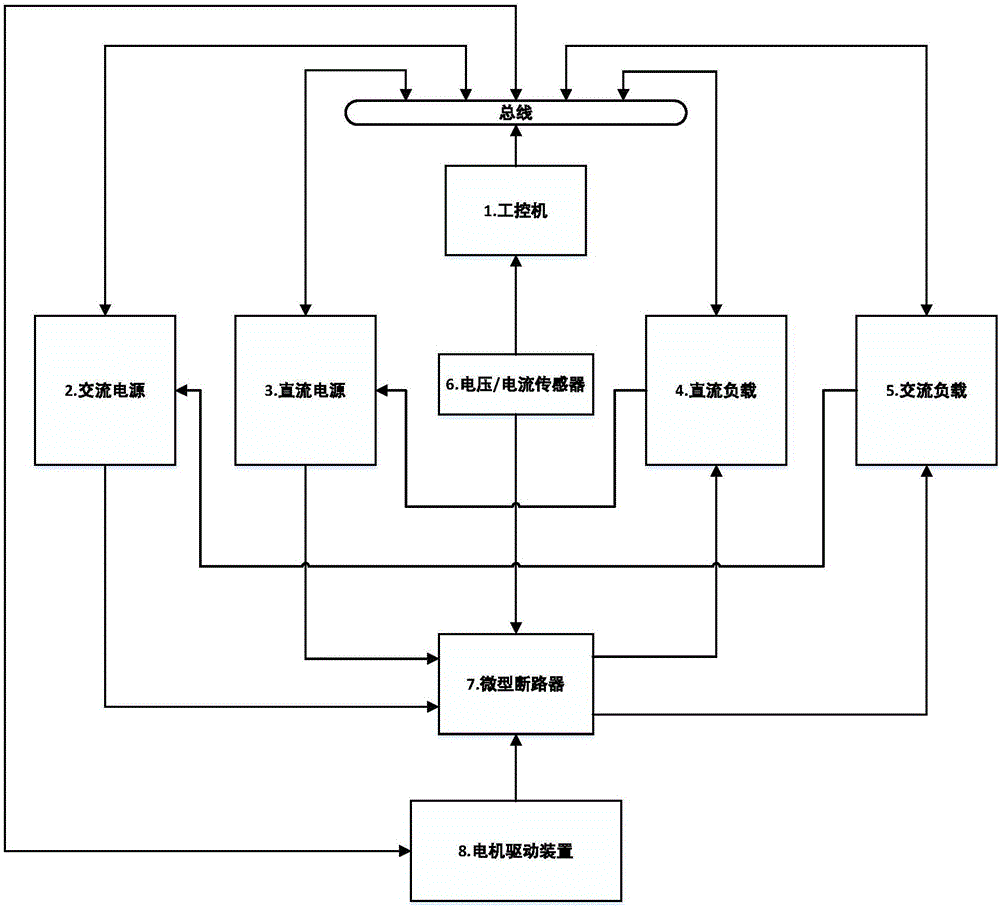

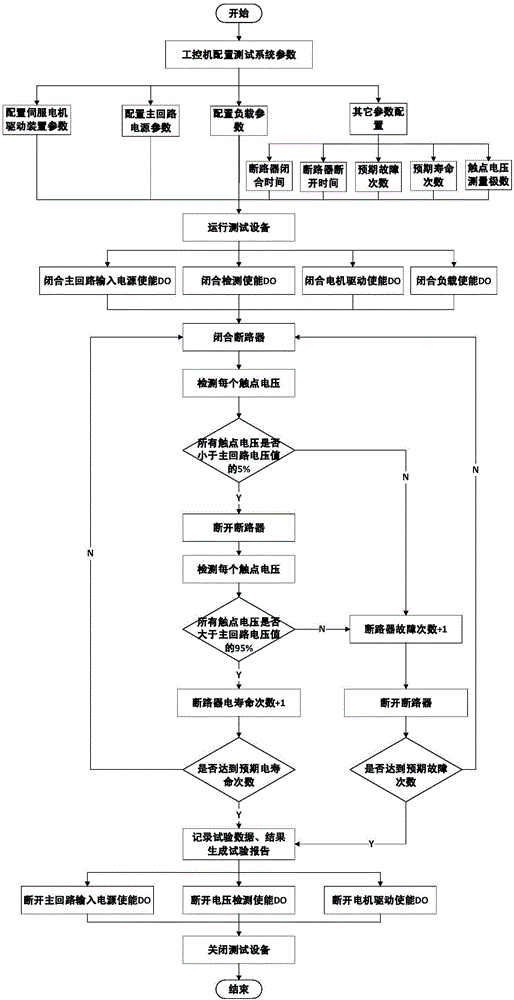

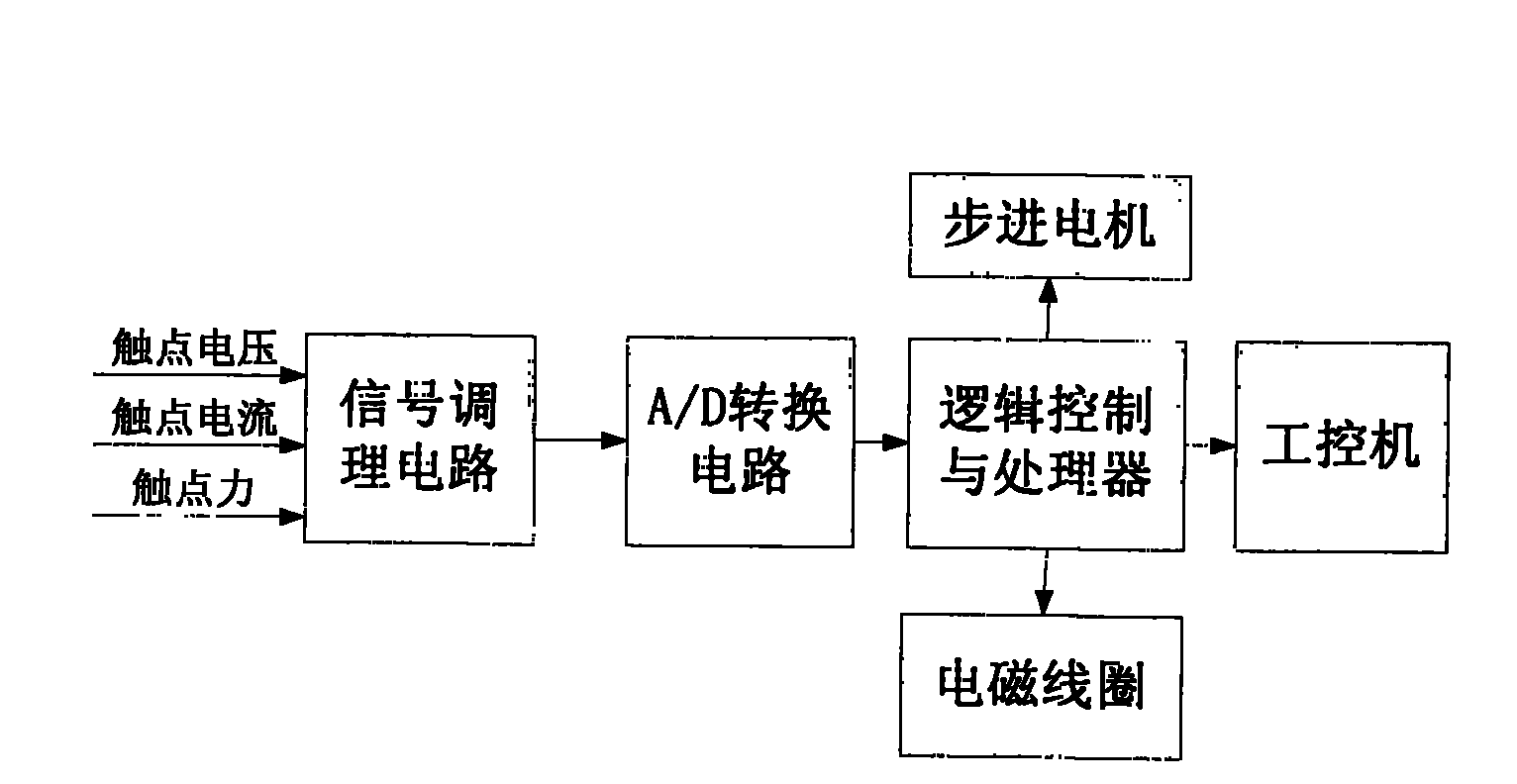

Miniature circuit breaker electric endurance testing system and method

InactiveCN106772014ARealize fully automatic controlSimple and fast operationCircuit interrupters testingEngineeringAlternating current

The invention relates to a miniature circuit breaker electric endurance testing system and method. The miniature circuit breaker electric endurance testing system mainly comprises an alternating-current output power source, a direct-current output power source, an alternating-current load, a direct-current load, a voltage and current sensor and an industrial personal computer, wherein the industrial personal computer can send commands to the alternating-current power source, the direct-current power source, the alternating-current load and the direct-current load through buses; the alternating-current power source and the direct-current power source can automatically set output voltage of a main circuit to a miniature circuit breaker according to the commands; the alternating-current load and the direct-current load can be automatically matched with circuit impedance to determine testing main circuit current required by testing the miniature circuit breaker; the industrial personal computer sends a command to a motor driving device to control a manipulator of the motor to circularly switch on and off the tested miniature circuit breaker; the voltage sensor can collect voltage between a movable contact and a fixed contact of the miniature circuit breaker and send the voltage to the industrial personal computer to be analyzed and processed; thus, automatic testing of breaker electric endurance is achieved. The testing method is convenient, further improves reliability and accuracy for judging testing results, greatly improves work efficiency and reduces labor cost.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

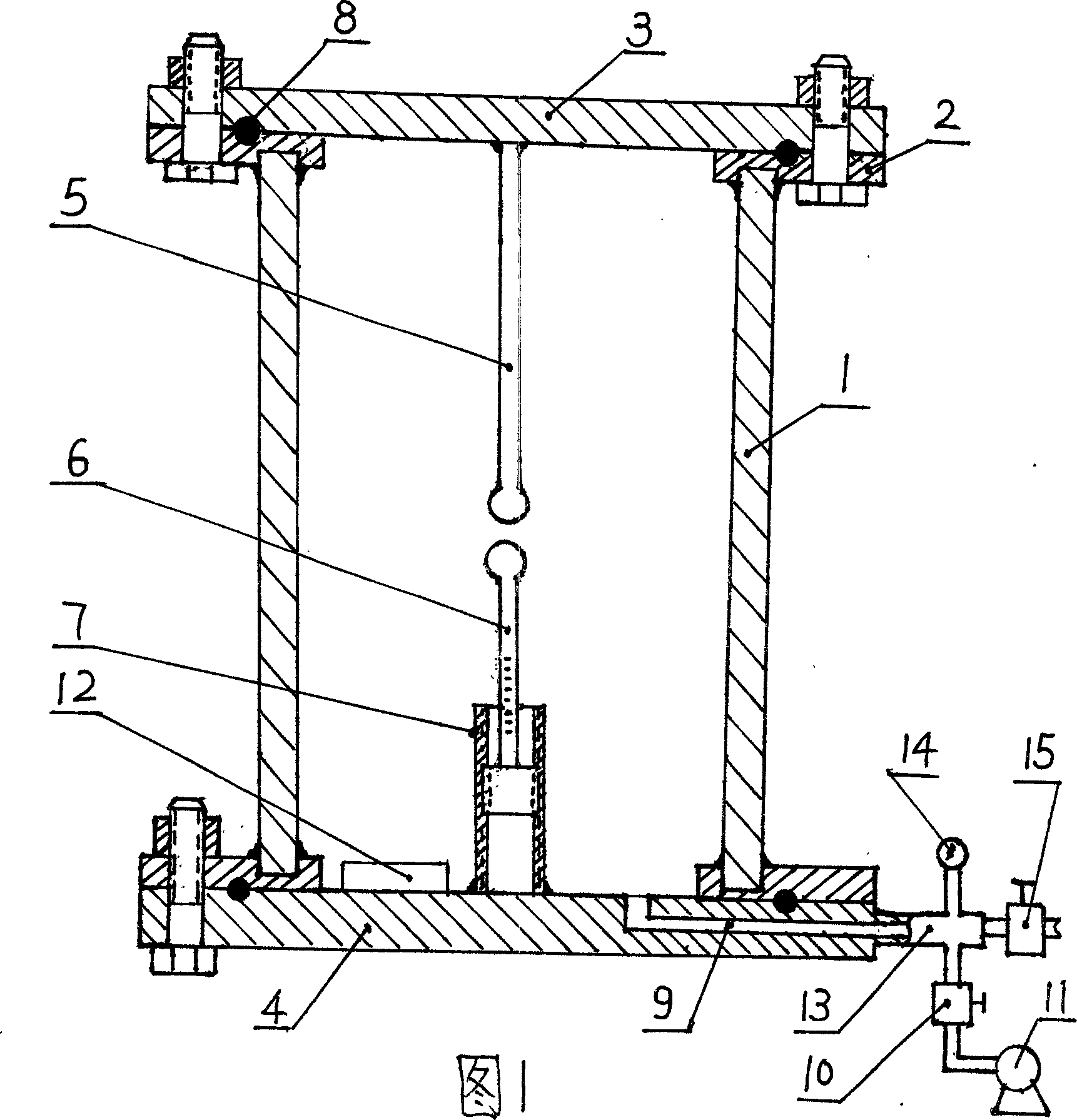

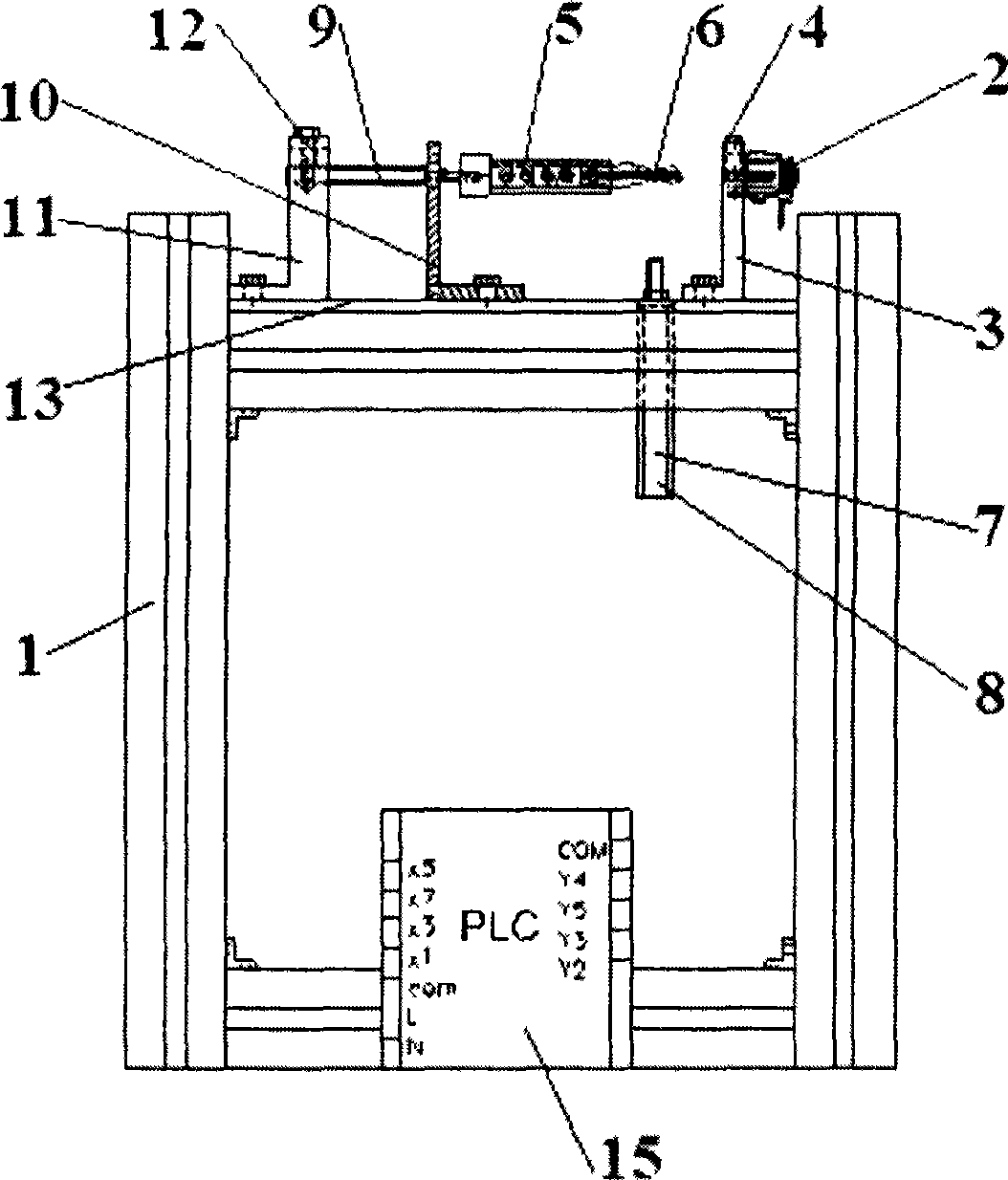

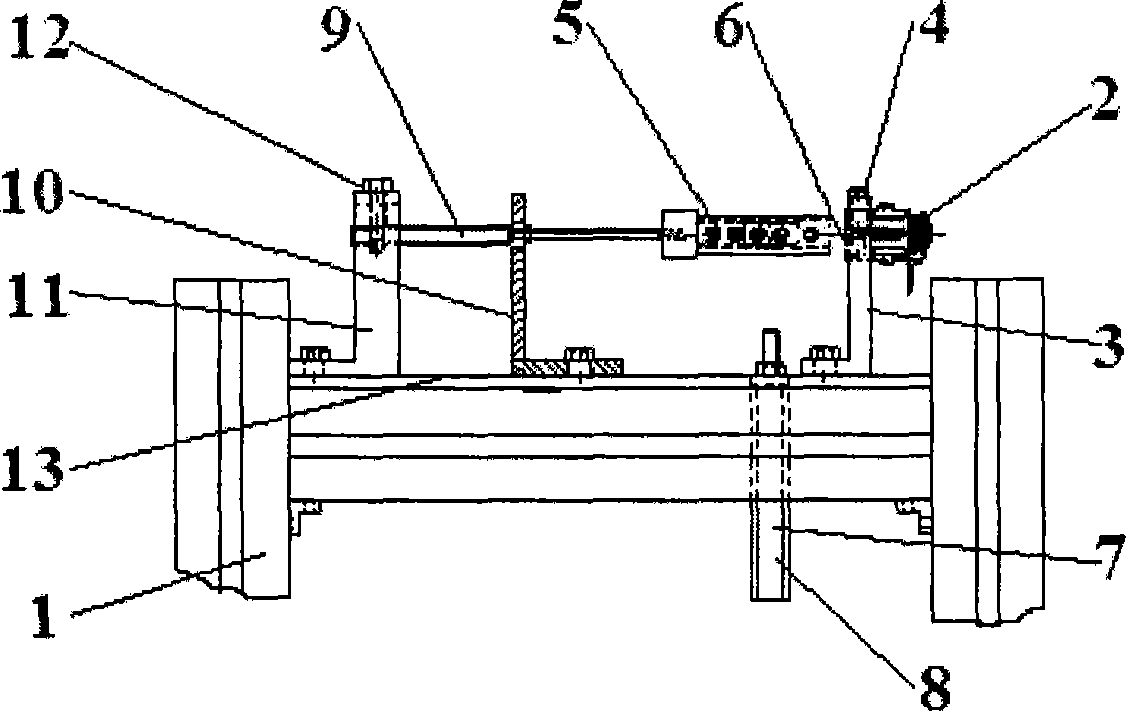

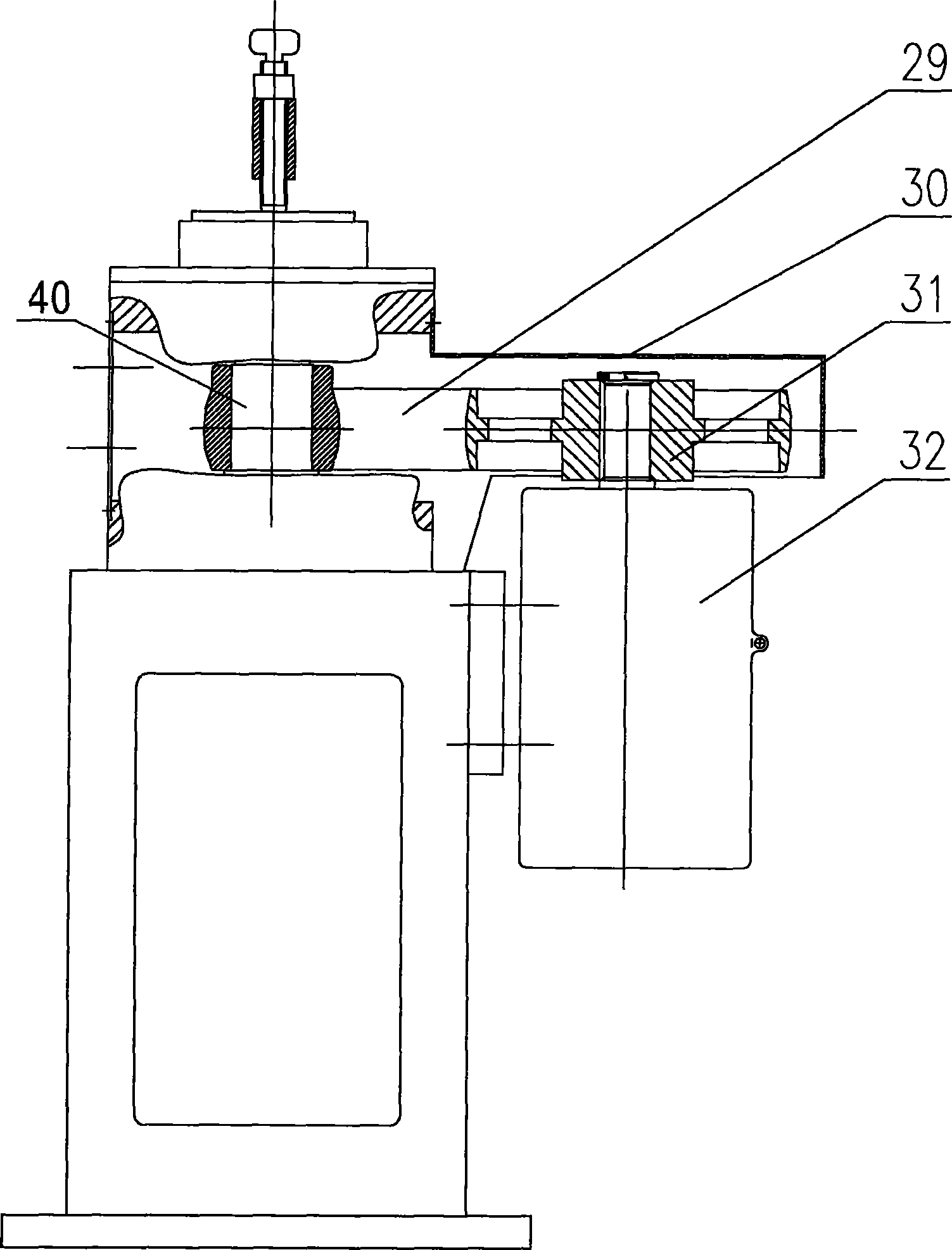

Vehicle door lock endurance test bench and its testing method

InactiveCN101430253ASimple and fast operationOperation time savingStructural/machines measurementEconomic benefitsTest bench

The invention discloses an endurance test bed for a lock cylinder of a vehicle door. The mechanical part of the endurance test bed comprise a test bed body, a lock cylinder fixed seat, a lock cylinder key fixed block; the lock cylinder is fixed on the lock cylinder fixed seat by a lock cylinder fixture block, a key in-out cylinder is provided, and the lock cylinder key is fixed on a piston rod of the key in-out cylinder, the two sides of the lock cylinder key fixed block are respectively provided with a key rotating connecting block which protrudes outwards, and two key rotating cylinders are provided to push the two key rotating connecting blocks respectively so as to drive the lock cylinder key to make rotary motion in two directions. The technical proposal helps realize the endurance performance test of the lock cylinder of the vehicle door by high-precision pneumatic components in conjunction with programmable control of a PLC controller. The test bed has simple operation, time saving property, low labor intensity, good versatility and high economic benefit; and the test conditions can be set as required, and the obtained test data are accurate and truly reflect the endurance performance of the lock cylinder in service use.

Owner:CHERY AUTOMOBILE CO LTD

Coatings rolling contact fatigue tester

InactiveCN101393096ASimple structureEasy to operateUsing mechanical meansInvestigating abrasion/wear resistanceRolling contact fatigueControl system

The invention relates to a coat rolling contact endurance testing machine, which comprises a tester, a loading mechanism, a driving mechanism, a lubrication system, and an information acquisition and control system. The coat rolling contact endurance testing machine has a simple structure, convenient operation and high reliability; in addition, because the testing machine is provided with a plurality of rolling elements, the testing machine has a plurality of contact points and can realize a high efficient test; besides; and through detecting vibration signals and monitoring the surface condition of the coat or a fraction pair, when micro-cracks are generated, the testing machine can pause the test and save the failure moment.

Owner:EAST CHINA UNIV OF SCI & TECH

Remote-control key endurance testing device

InactiveCN102841312AHigh precisionEasy to determine the degree of pressingCircuit interrupters testingRemote controlMechanical engineering

The embodiment of the invention discloses a remote-control key endurance testing device which relates to the field of automobile accessory testing apparatus and is used for solving the problem of lower testing result accuracy caused by the fact that the pressing in-place degree in the traditional remote-control key endurance test is hard to determine. According to the embodiment of the invention, due to the fact that a push rod is movably connected to a limiting bracket main body by a connecting shaft and the push rod can rotate along the connecting shaft under the drive of a driving device, and meanwhile, due to the fact that a limiting bolt is arranged in a bolt hole of a second part of the push rod, when a remote-control key is in a pressed state, the tail part of the limiting bolt supports against a protruding part of the limiting bracket to limit the downward rotating displacement of the push rod, in this way, the depth of a pressure pillar which downwardly presses a key to be tested under the drive of the push rod is determined accurately, so that the pressing in-place degree of the key to be tested can be determined easily, and the higher accuracy of a remote-control key endurance test result can be ensured. The embodiment of the invention is mainly used for the automobile accessory testing apparatus.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

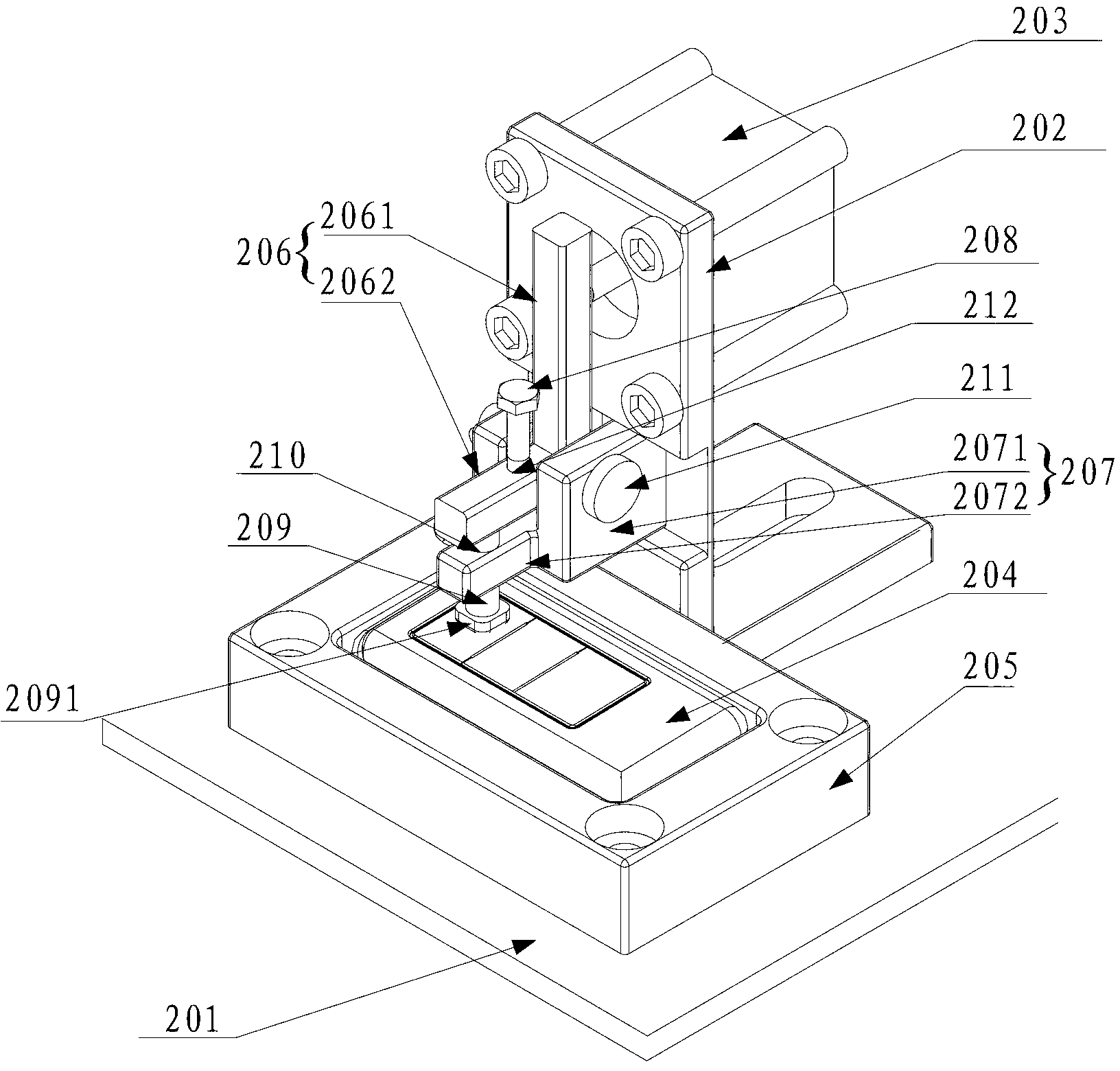

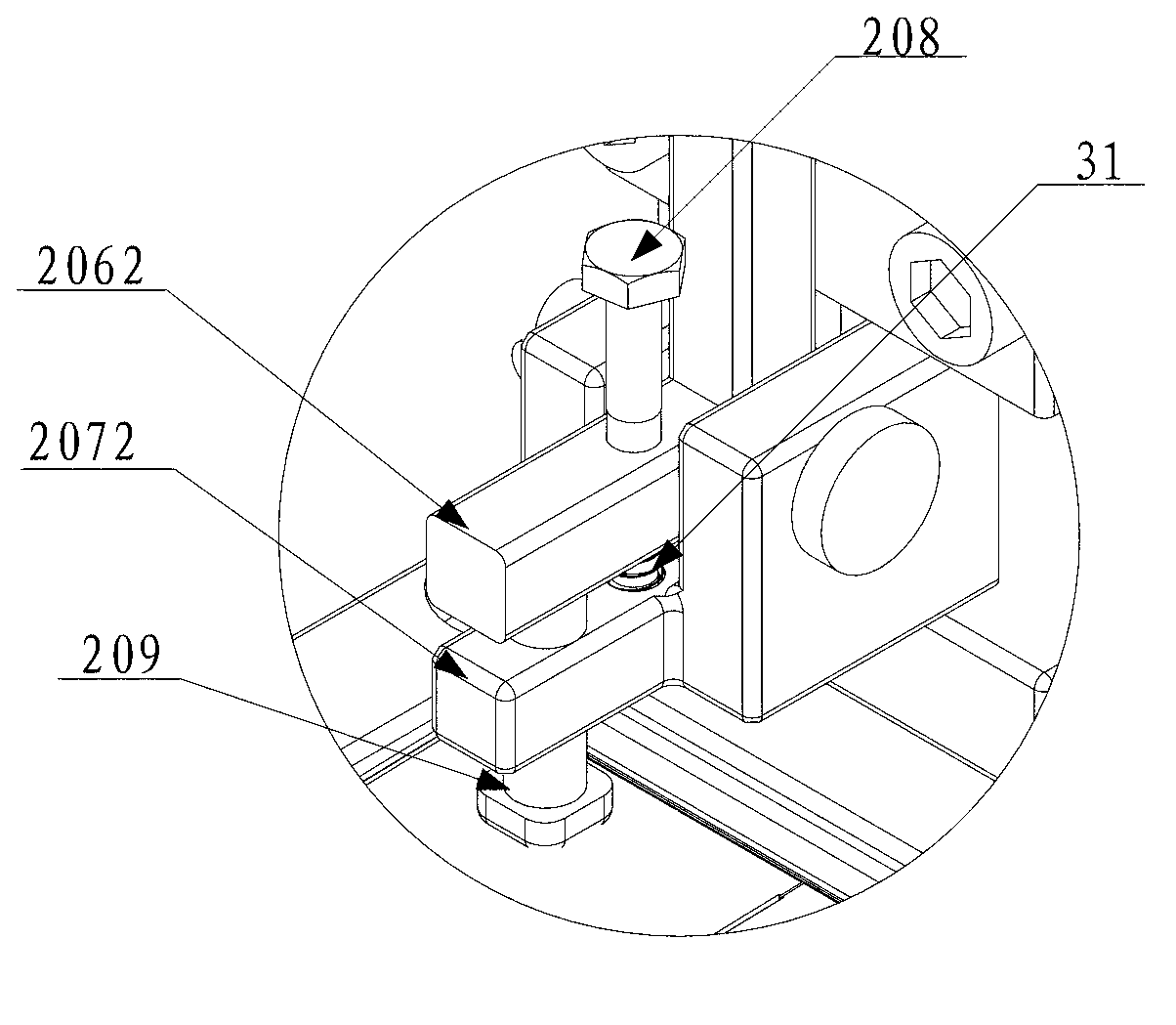

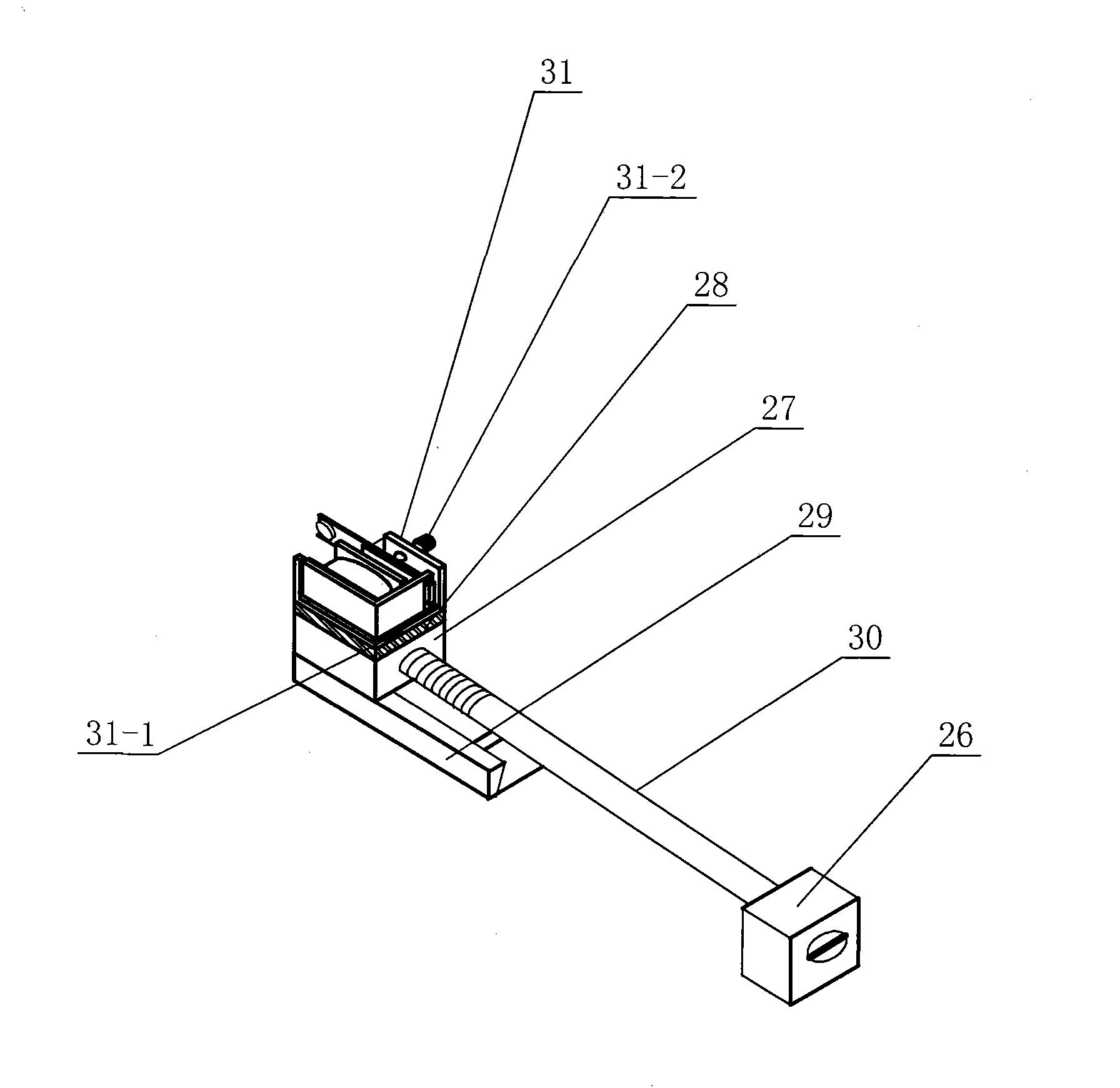

Adjustable-assembly parameter endurance testing device for electromagnetic relay

InactiveCN101806860ASimple structureEasy to operateCircuit interrupters testingElectricityEngineering

The invention discloses an adjustable-assembly parameter endurance testing device for electromagnetic relays and relates to an endurance testing device for the electromagnetic relays. The invention solves the problem that it is impossible to research the influences of the traditional endurance testing device for the electromagnetic relays on the matching relationship between an electromagnetic attraction force and a mechanical counter force and on the electrical endurance by changing an assembly parameter. Adjusting blocks are arranged on a first screw by threaded connection; the lower end of a vertical adjusting device is fixedly arranged on upper end faces of two vertical plates and is positioned on the same side of the two vertical plates; two fixing blocks are symmetrically arranged on the front side wall of the vertical adjusting device; two sensor supports are symmetrically fixed on the front side wall of the vertical adjusting device and are positioned between the two fixing blocks; and two pressure sensors are positioned on the two sensor supports and are in sliding connection with the sensor supports respectively. The device makes it is possible to research the influences of the device on the matching relationship between the electromagnetic attraction force and the mechanical counter force by changing the assembly parameter and on the electrical endurance of the electromagnetic relays.

Owner:HARBIN INST OF TECH

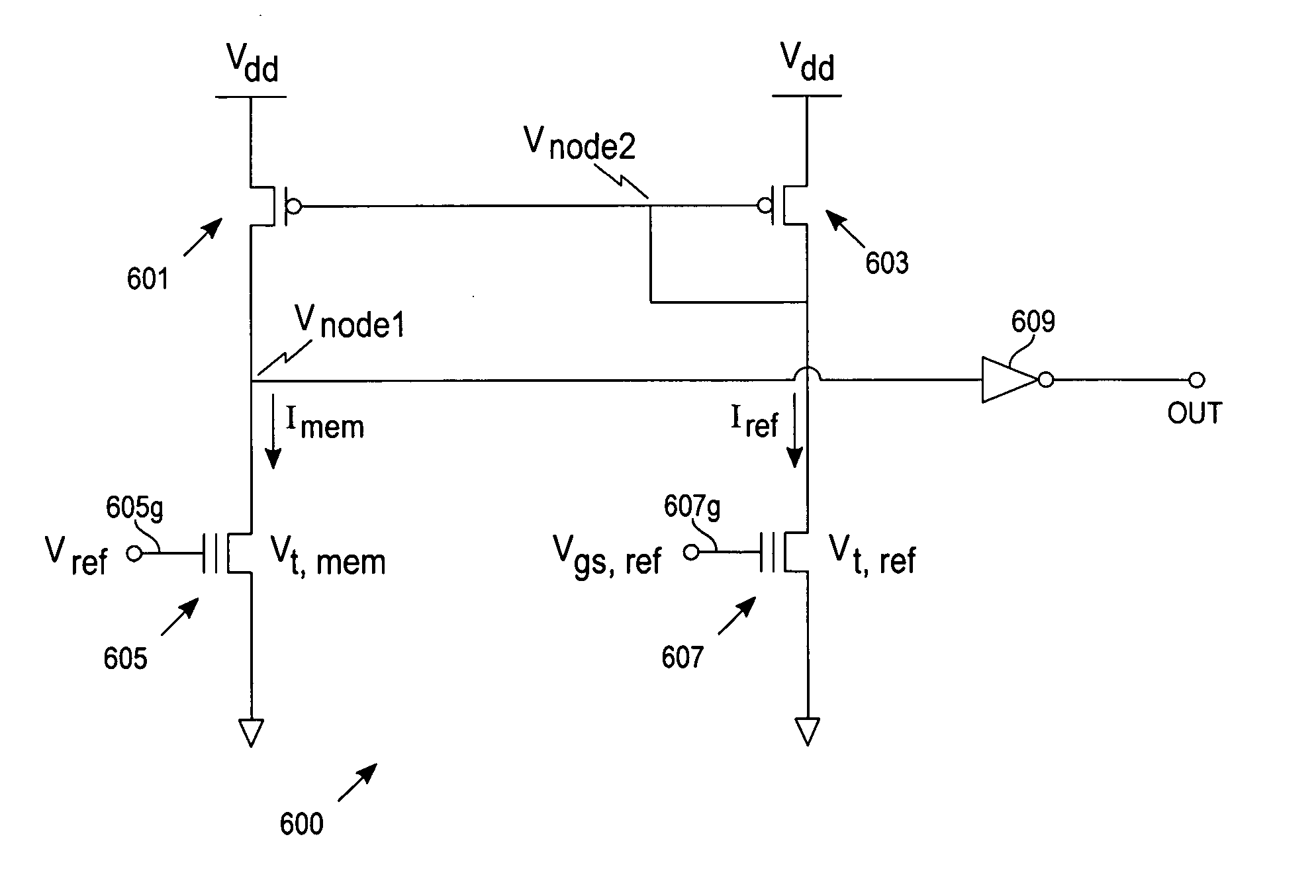

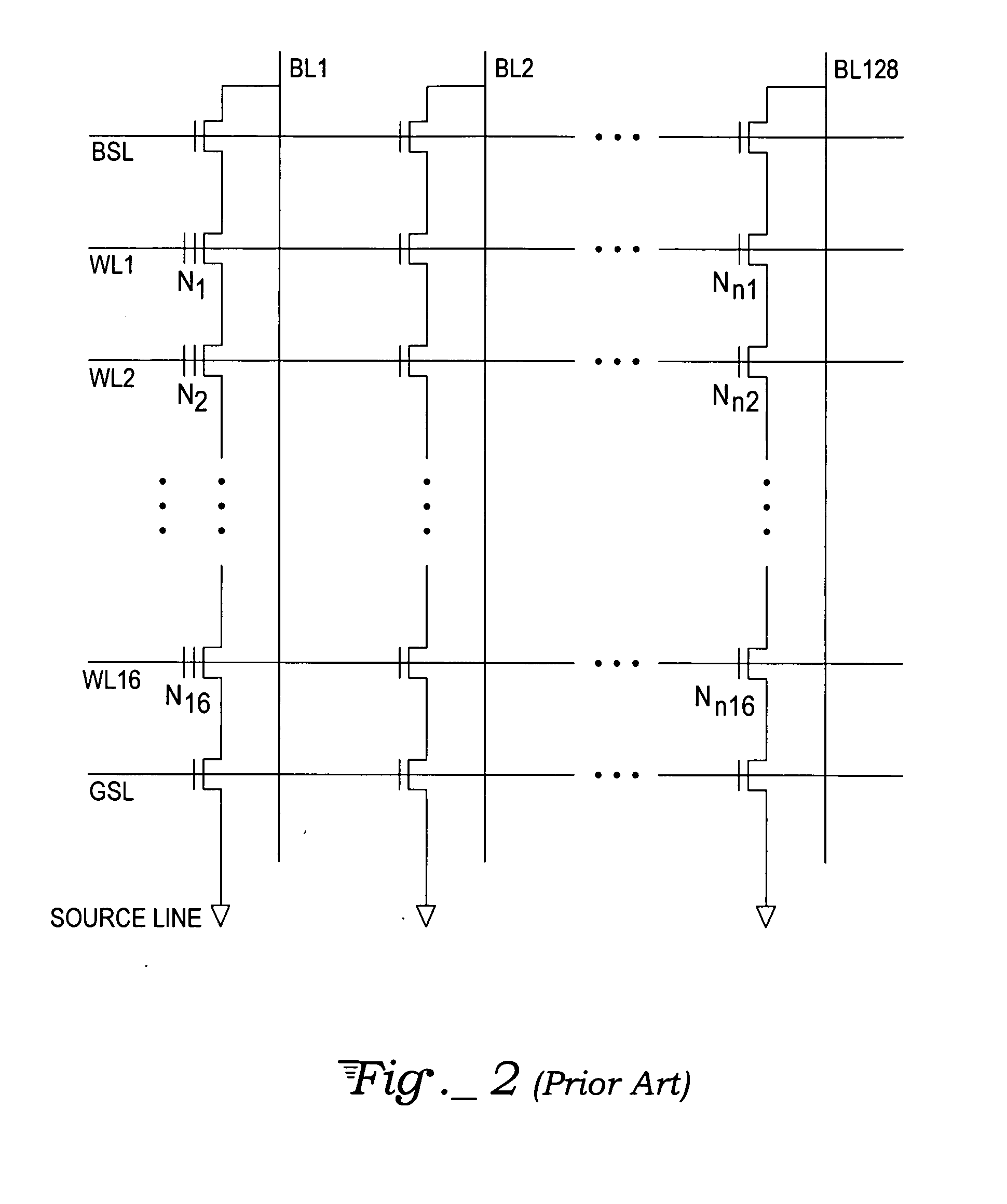

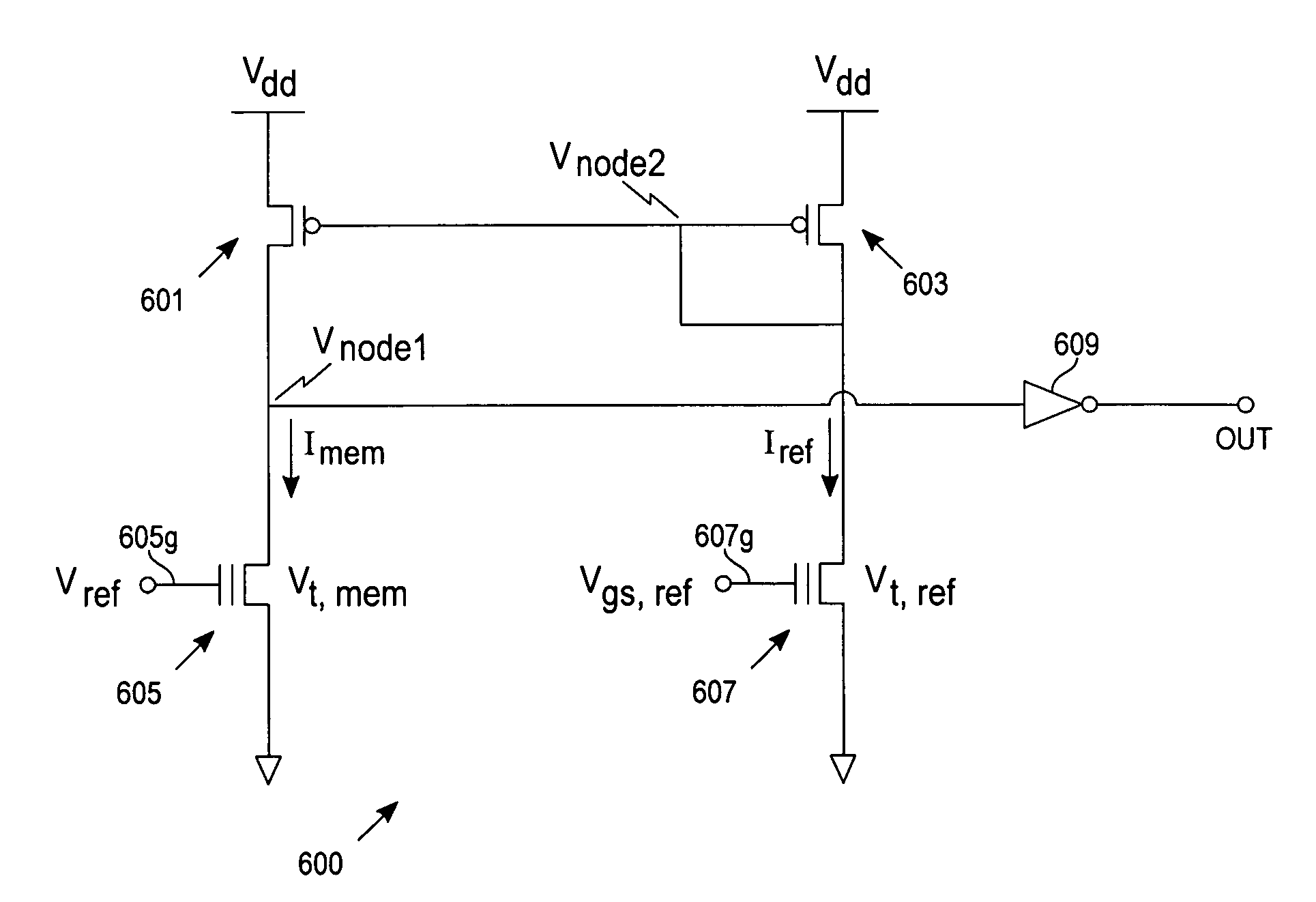

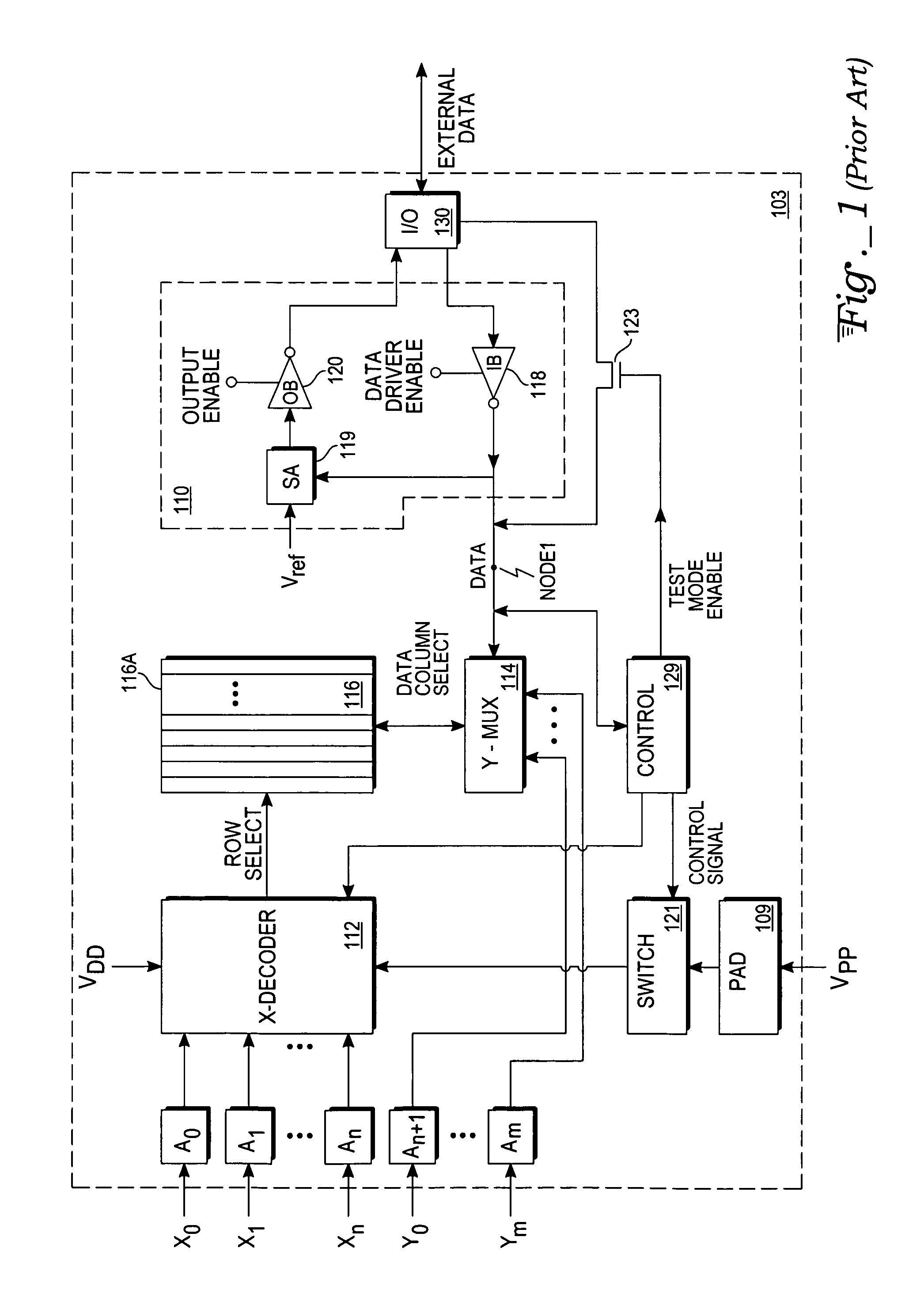

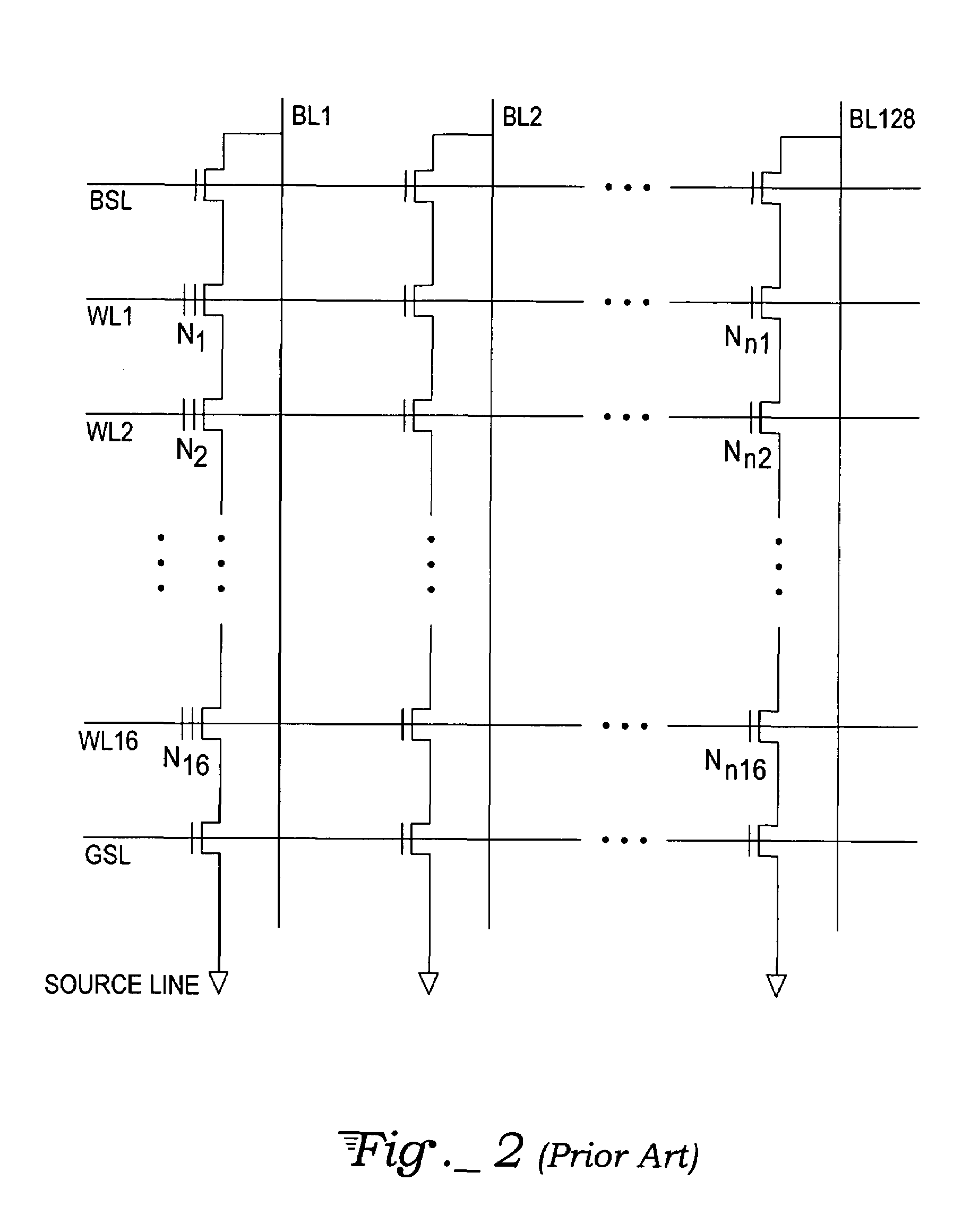

Indirect measurement of negative margin voltages in endurance testing of EEPROM cells

InactiveUS20070237013A1High voltageEndurance or longevity of the cellRead-only memoriesDigital storageEngineeringPositive power

An electronic test structure and method for testing non-volatile memory cells. The structure includes a first transistor coupled in series to a floating gate transistor whereby a source of the first transistor is coupled to a positive power supply voltage and a source of the floating gate transistor is coupled to a power supply ground. A gate of the first transistor is further coupled to a source of the first transistor. A second transistor is coupled in series with a memory cell with a source of the second transistor coupled to a positive power supply voltage and a gate of the second transistor is coupled to the drain of the first transistor.

Owner:ATMEL CORP

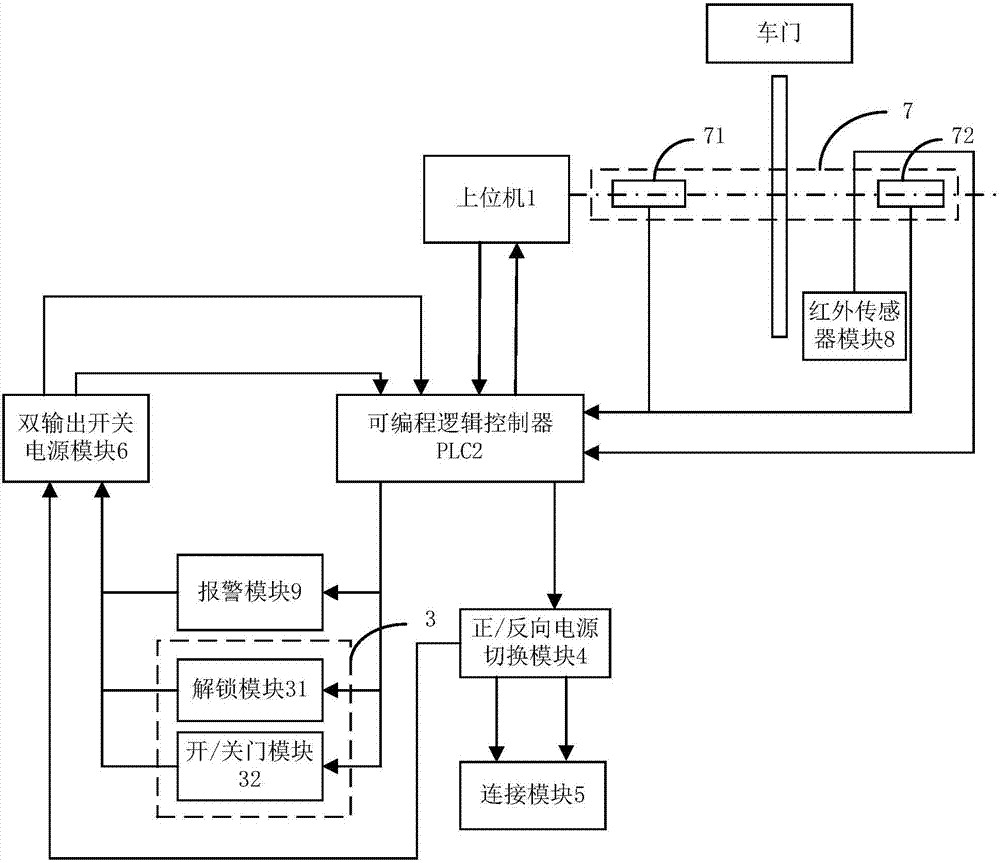

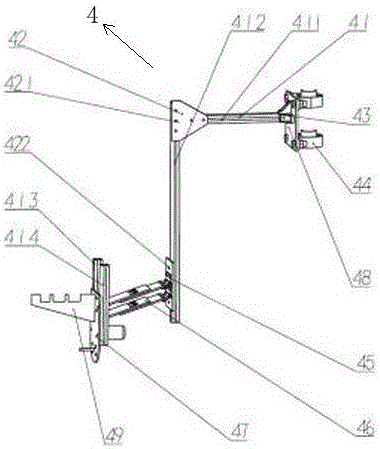

Comprehensive endurance testing device for electric window glass lifter and door opening/closing

InactiveCN106989936ATimely exposure of design flawsVehicle testingMachine part testingProgrammable logic controllerState parameter

The invention discloses a comprehensive endurance testing device for an electric window glass lifter and door opening / closing, and provides a relatively complete applicable scheme for comprehensive endurance testing of an electric window glass lifter and door opening / closing. The comprehensive endurance testing device for an electric window glass lifter and door opening / closing is characterized in that a host computer sends operation parameters to a programmable logic controller PLC, and the PLC executes the preset action according to a host computer command and transmits the operation state parameters to the host computer for monitoring of the host computer; the host computer and the PLC performs bidirectional communication through USB-RS485; a laser bijection sensor module and an infrared sensor module provided by the comprehensive endurance testing device can perform a performance test on the electric window glass lifter and door opening / closing at the same time, and perform matching design optimization on each component of the door system; during the sample car developing stage, by performing a comprehensive endurance test on the electric window glass lifter and door opening / closing in the door system, the comprehensive endurance testing device for an electric window glass lifter and door opening / closing can timely expose the design defect in the door system so as to gain the time for the subsequent rectification and reform from the angle of being relatively more close to the using habit of a user.

Owner:JIANGLING MOTORS

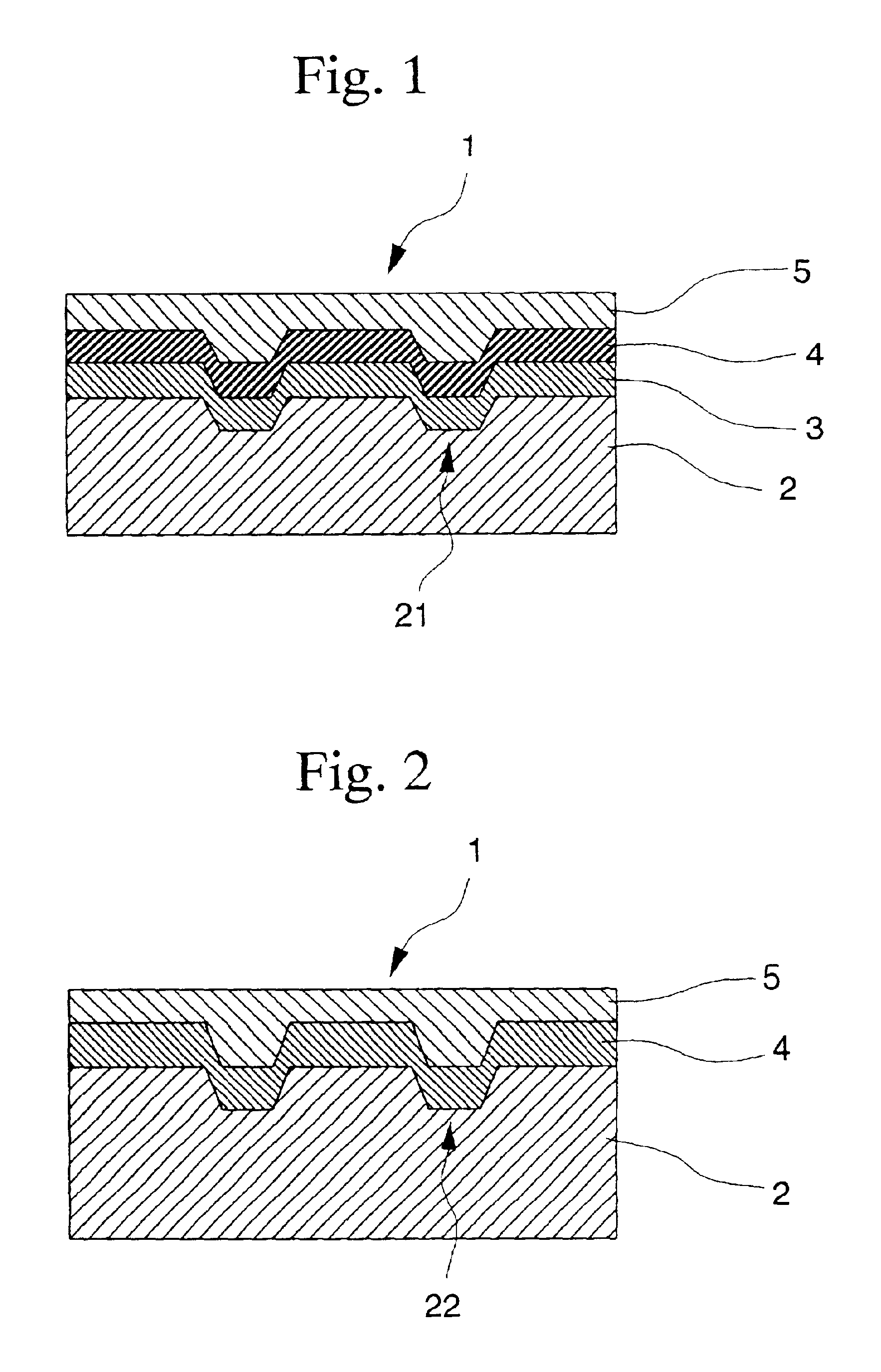

Ultraviolet-curable composition and optical recording

InactiveUS6924017B2Increased durabilityLayered productsRecord information storageUV curingHigh humidity

The present invention provides an ultraviolet-curable composition having satisfactory protective performance even in endurance testing at high temperature and high humidity in an optical recording medium having for its reflective film Ag or a metal and / or alloy having Ag for its main component, and an optical recording medium in which it is applied. A cured film of an ultraviolet-curable composition, for which the pH value of a 1 wt % methanol solution of said ultraviolet-curable composition is within the range of 4.5 to 6.8, is coated onto a reflective film in the form of a protective film.

Owner:DAINIPPON INK & CHEM INC

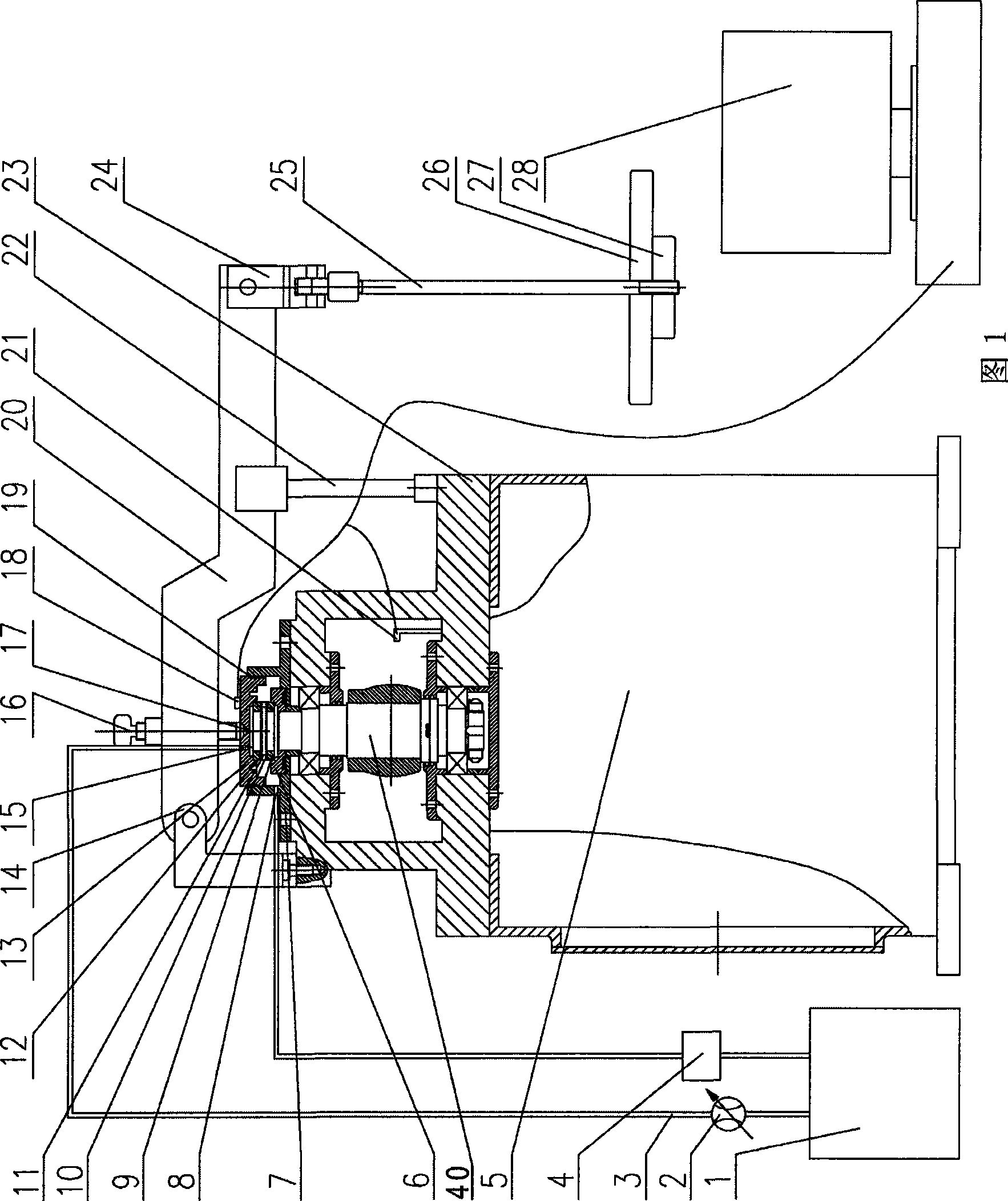

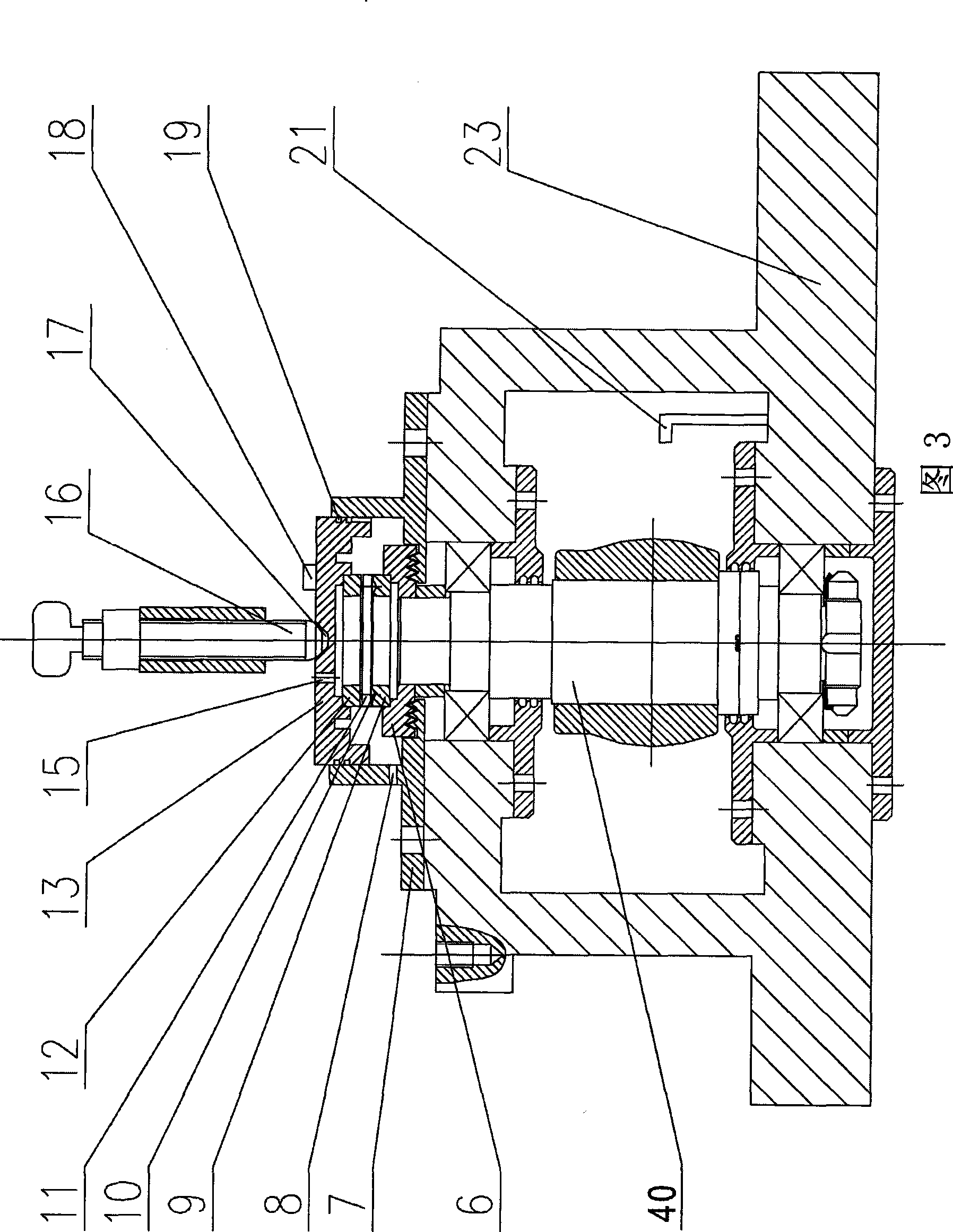

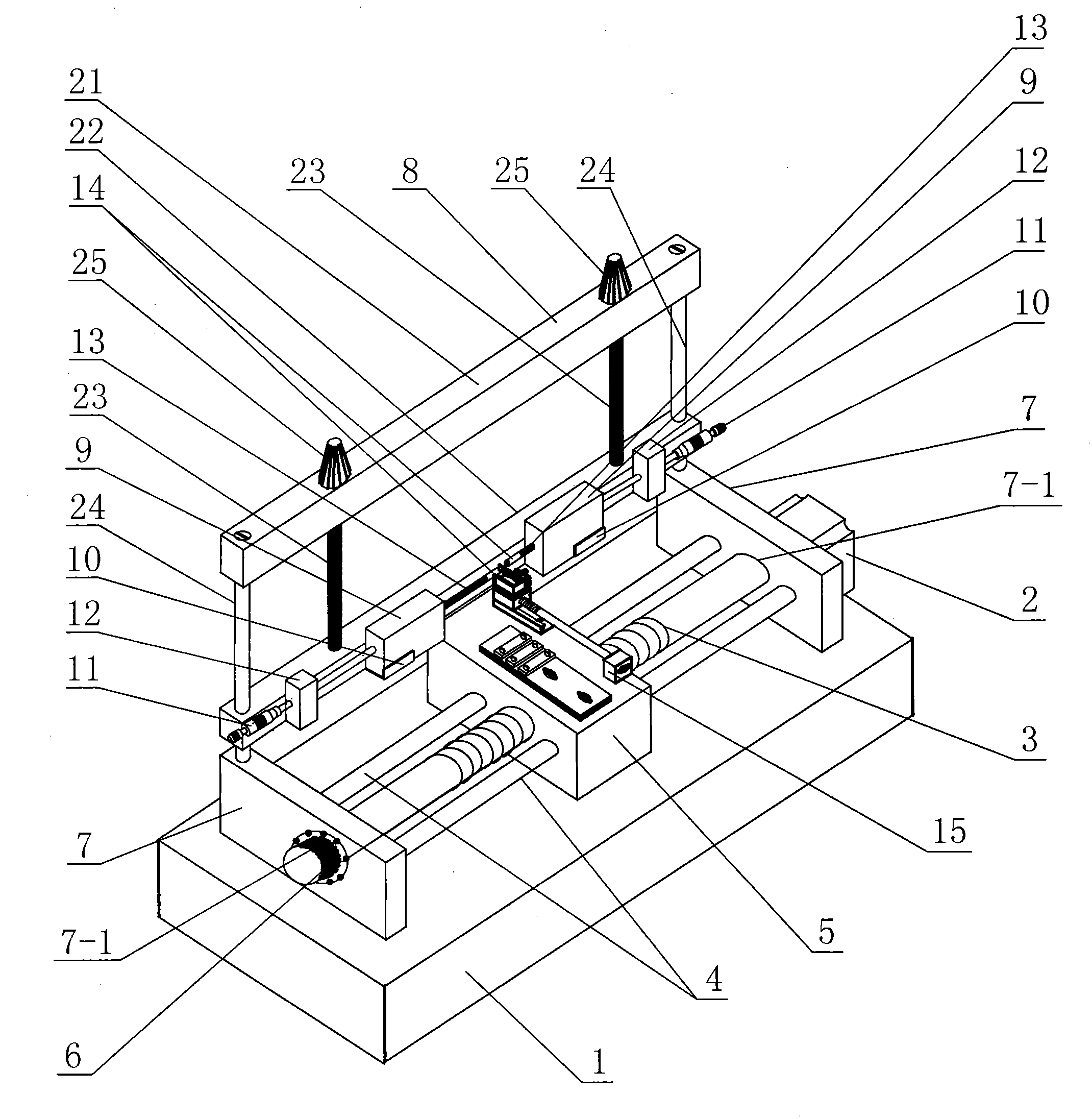

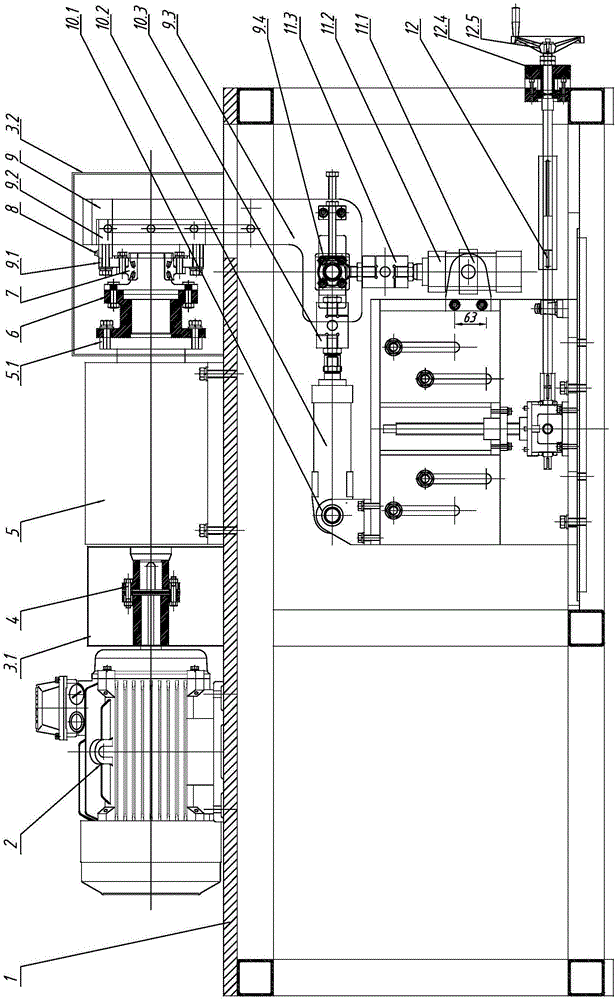

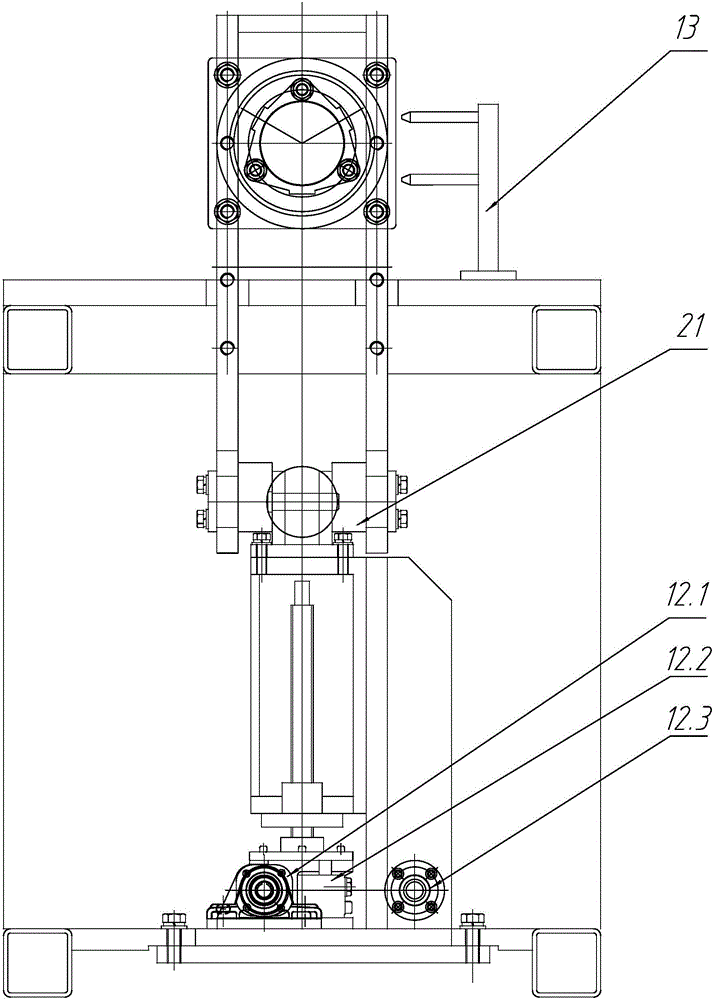

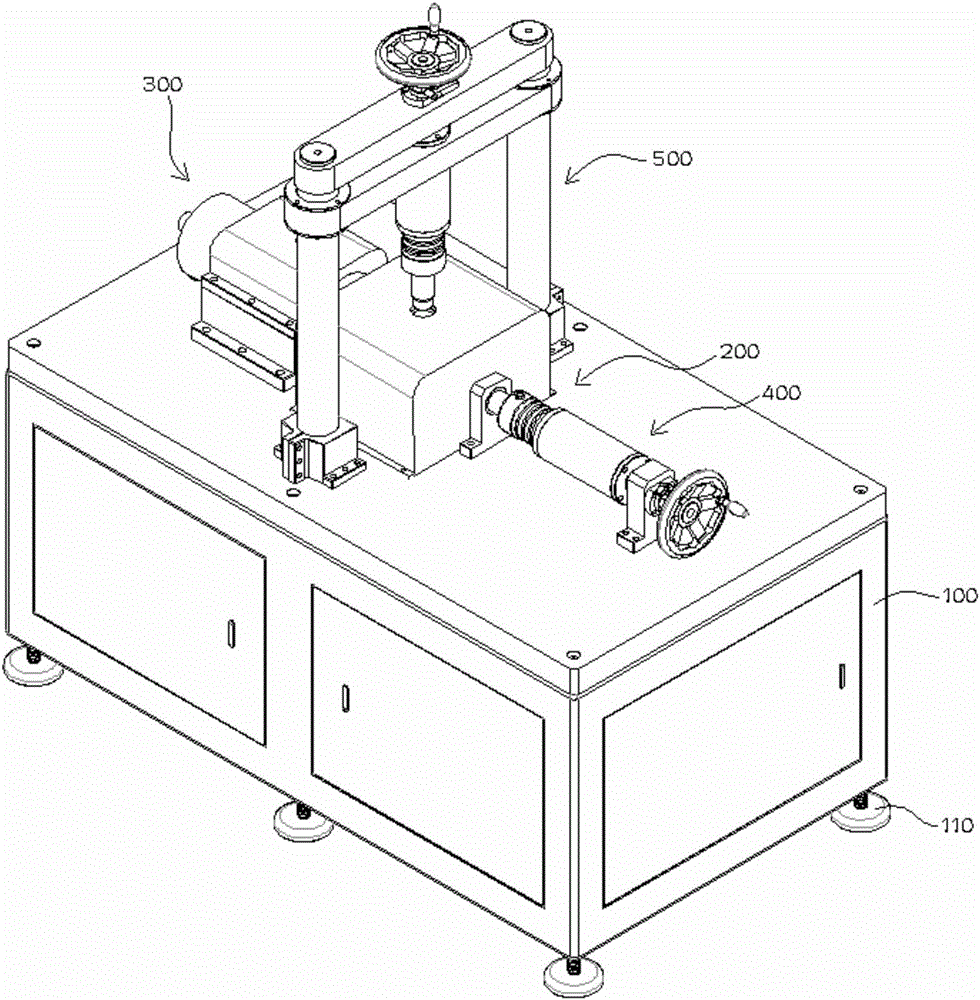

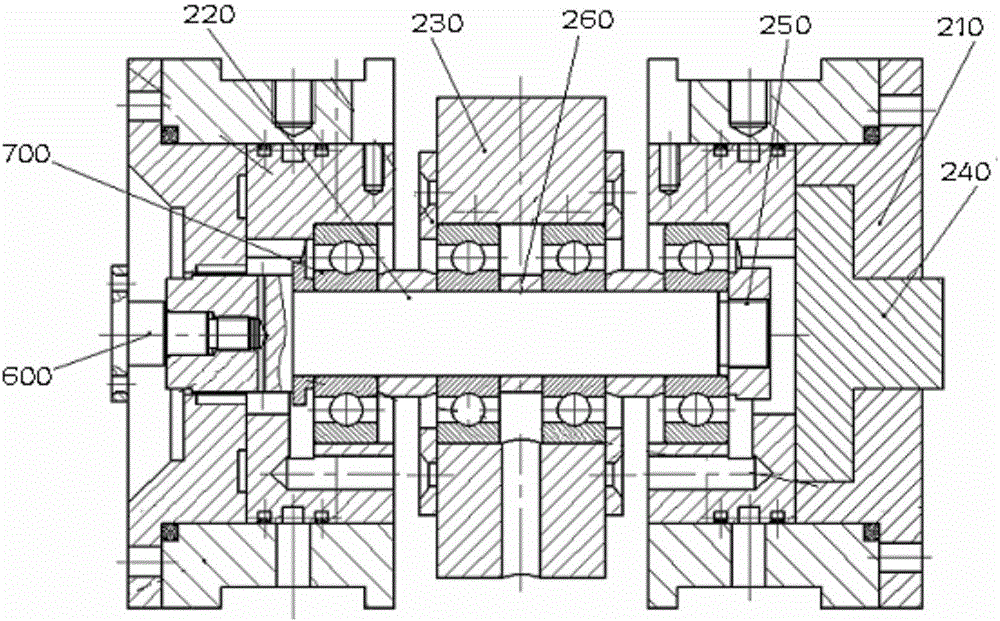

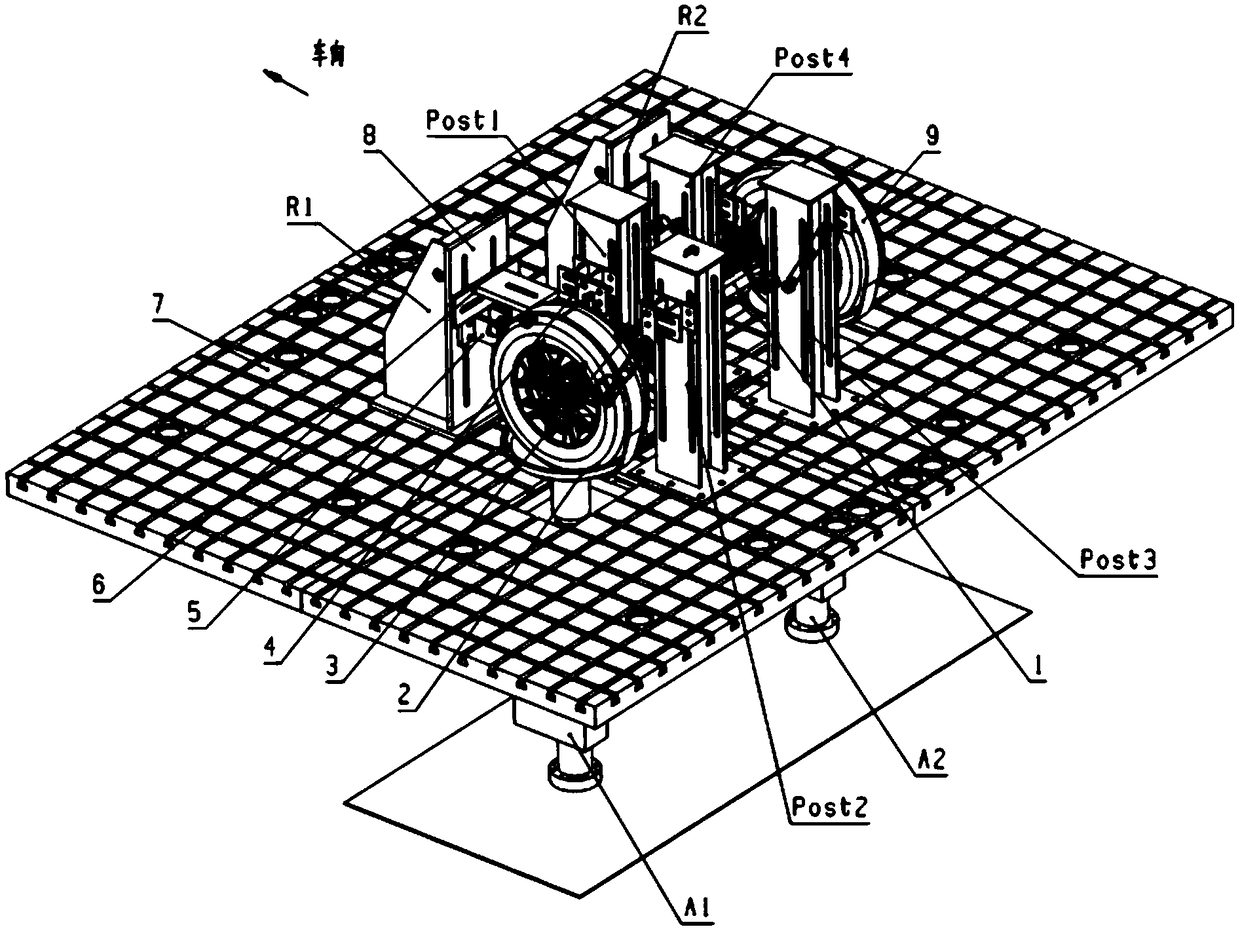

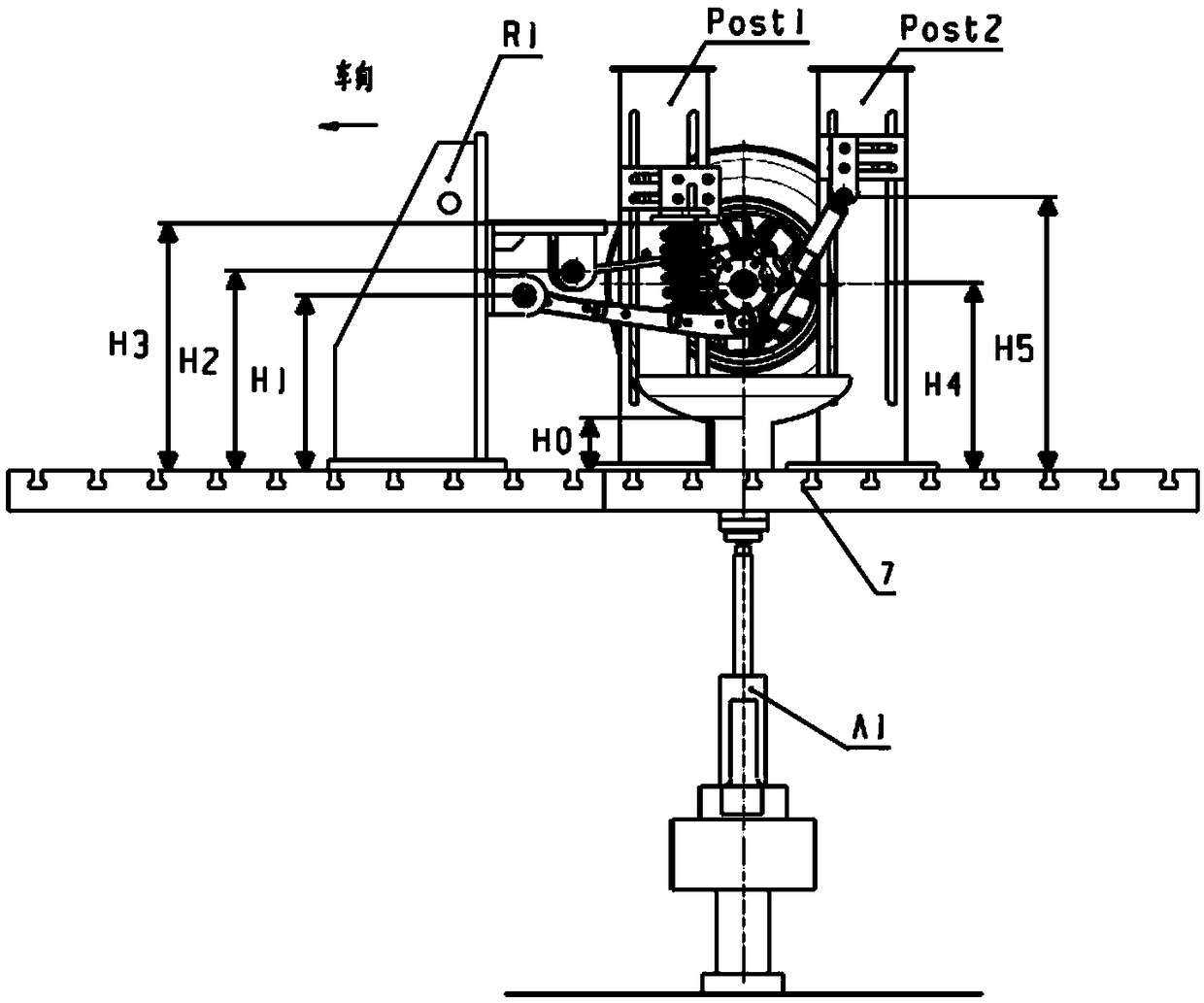

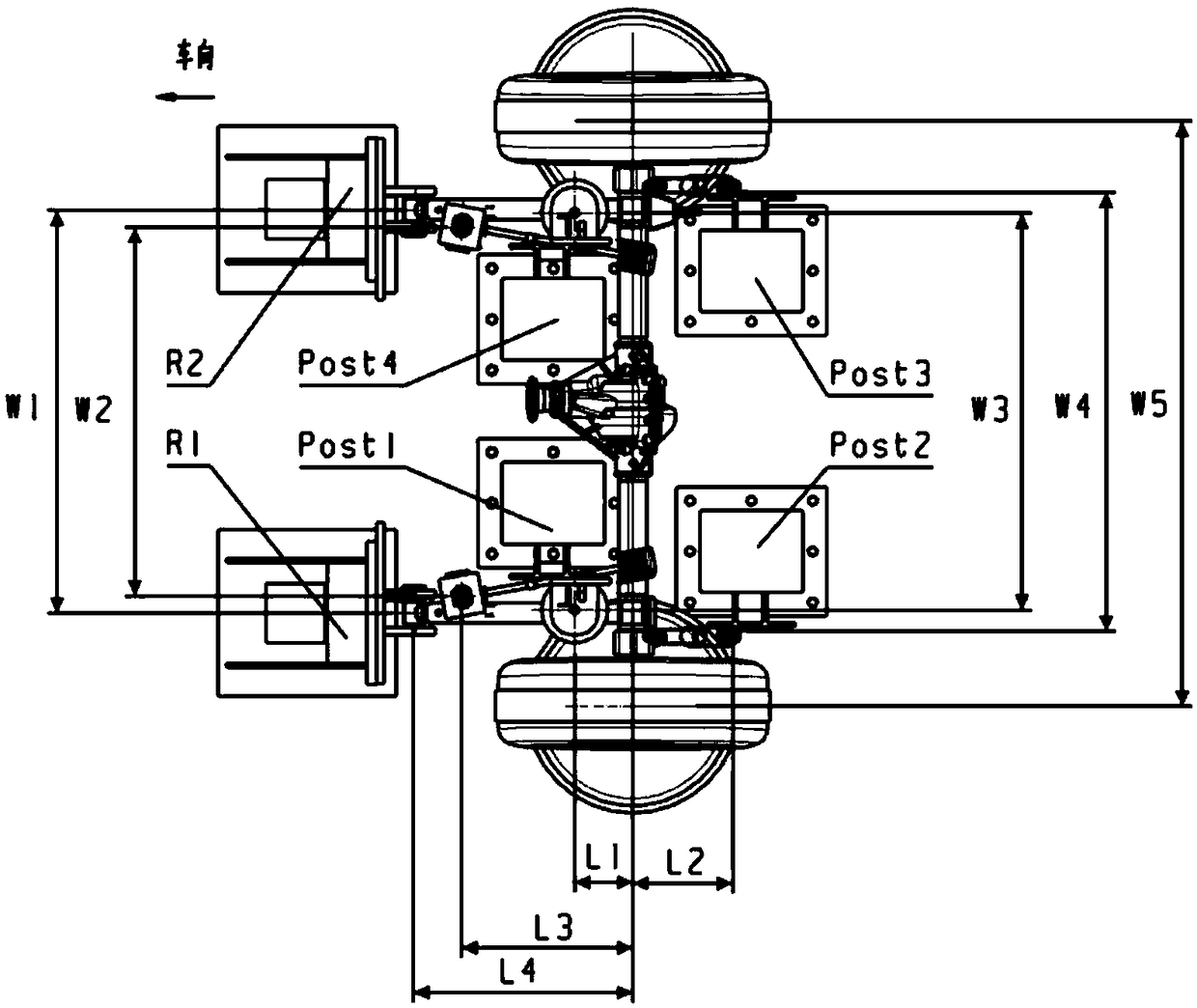

Endurance testing machine for wheel bearing

InactiveCN105738111ASolve the two-way loading force interferenceSolve the adjustmentMachine bearings testingEngineeringFlange

The invention relates to an endurance testing machine for wheel bearings, and provides a testing machine capable of testing the endurance of a wheel bearing by simulating the real entrucking conditions of the wheel bearing. The endurance testing machine comprises a working platform, and a driving system and a hydraulic loading system installed on the working platform, wherein the driving system comprises a motor, a main shaft driven by the motor, a main shaft flange fixed on the end portion of the main shaft and a bi-flange connection disc connected with the main shaft flange, and the hydraulic loading system comprises an L-shaped loading device, an axial loading mechanism, a radial loading mechanism and a loading device position adjusting mechanism. The L-shaped loading device comprises two parallel L-shaped loading plates, of which the upper ends are connected with a tool rack with a test piece connecting flange, and lower ends are connected with a bi-lug loading base. The bi-lug loading base is connected with the axial loading mechanism and the radial loading mechanism, and the axial loading mechanism and the radial loading mechanism are installed on the loading device position adjusting mechanism.

Owner:ZHEJIANG JINDUN TECH CO LTD

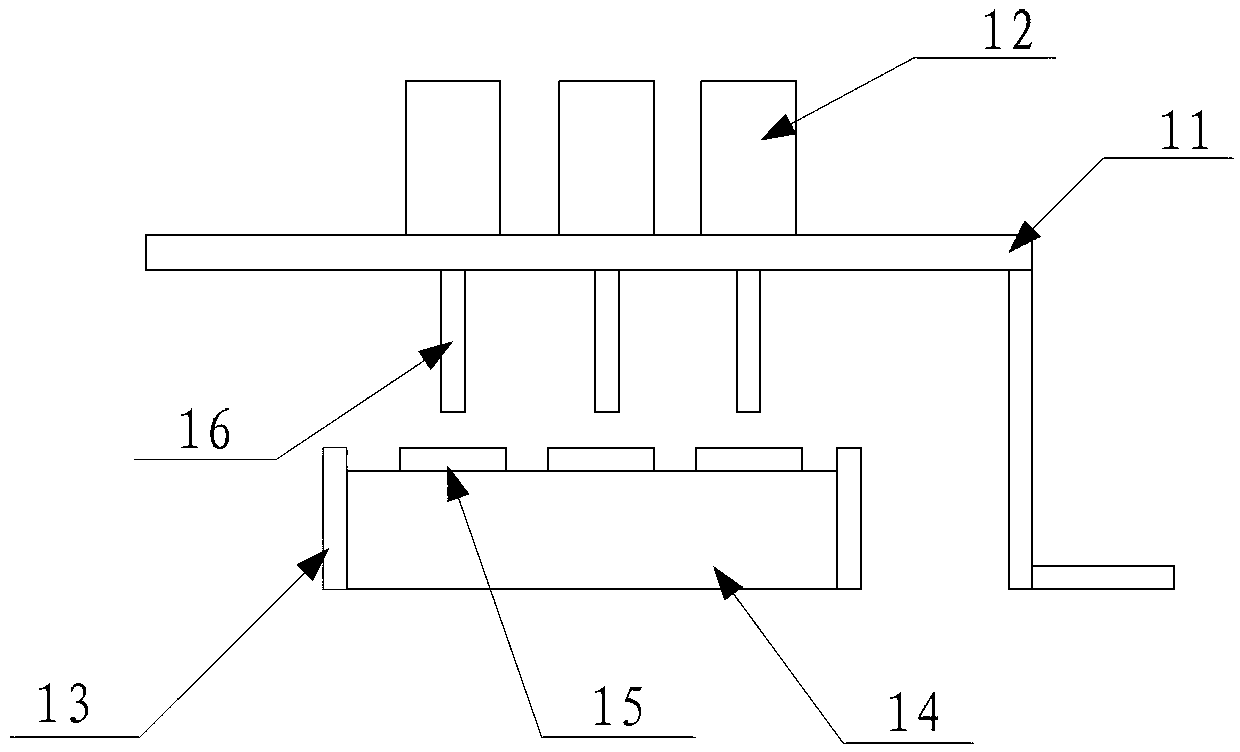

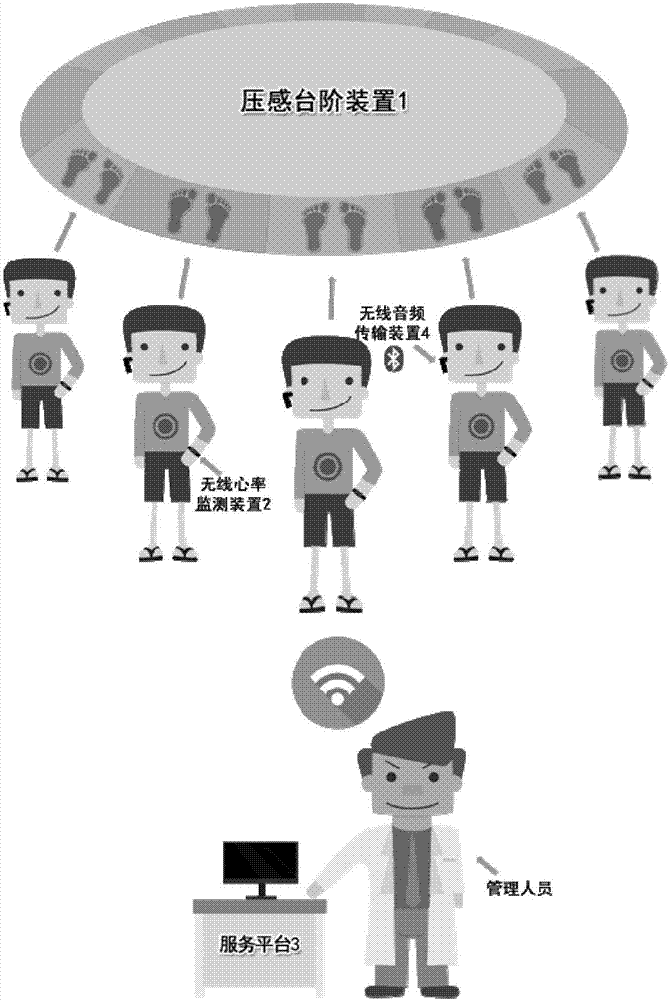

Group heart and lung endurance testing and personalized training device and method based on pressure-sensing steps

InactiveCN107887030AHigh precisionSuitable for group testingPhysical therapies and activitiesHealth-index calculationPressure senseHeart rate device

The invention relates to a group cardiovascular endurance testing and personalized training device and method based on pressure-sensing steps. The device comprises a pressure-sensing step device, a wireless heart rate monitoring device, a service platform and a wireless audio transmission device. The pressure-sensing step device is formed by a step device and a pressure sensor. The pressure sensorcollects users' pressure distribution data signals of walking up and down the steps in testing or training, pressure distribution statistical data is obtained through statistics, and the pressure distribution statistical data is wirelessly uploaded to a service platform. The wireless heart rate monitoring device collects and uploads real-time heart rate data of users in the testing or training. The service platform collects and stores basic information of the users, receives the data uploaded by the wireless heart rate monitoring device and the pressure-sensing step device, carries out cardiovascular endurance assessment according to uploaded data and gives a training guide plan, the training guide plan comprises a beat frequency and a training time, and the beat frequency is then converted into beat audio. The wireless audio transmission device receives the beat audio, and the beat audio is outputted to the users to guide the user training.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

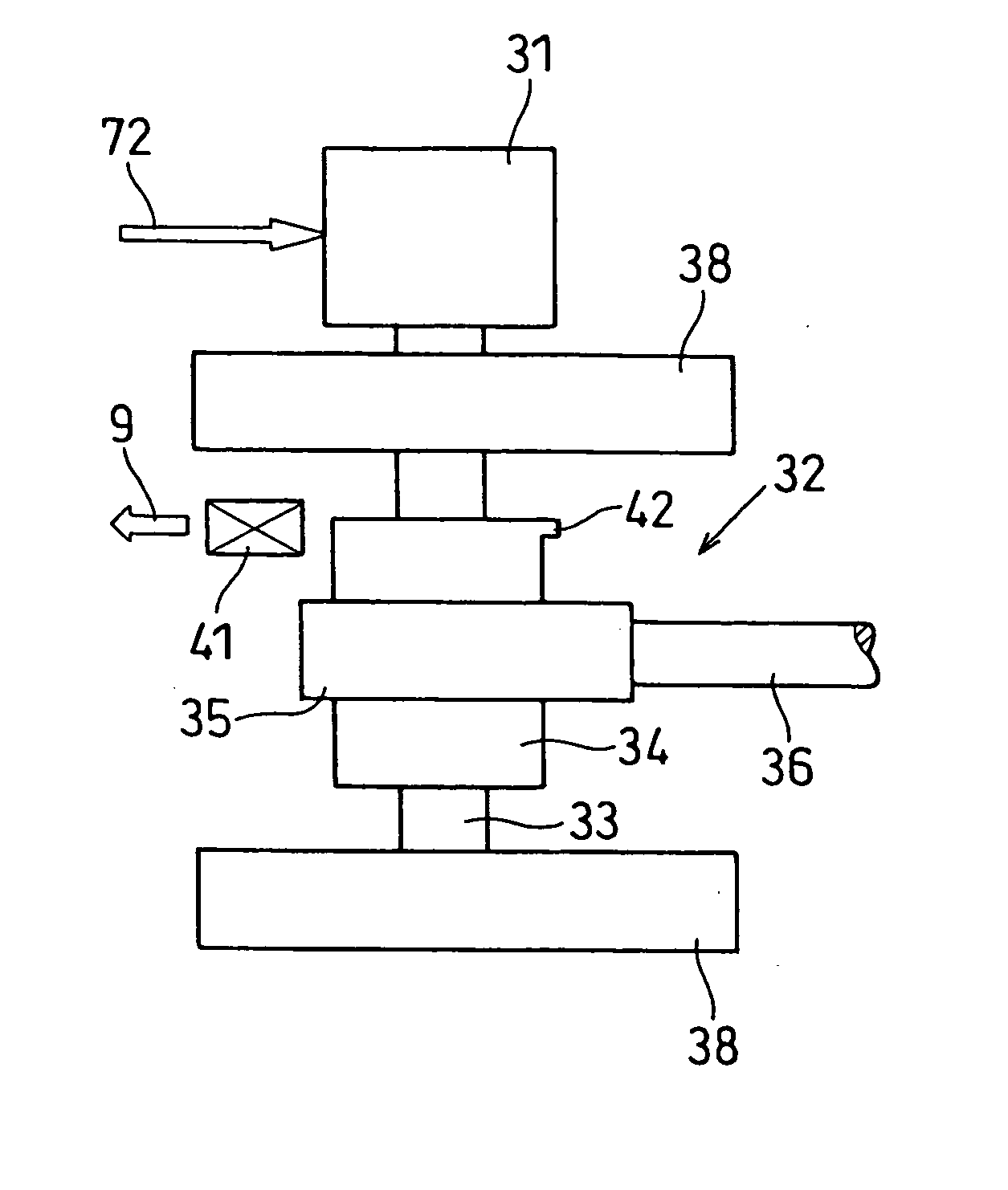

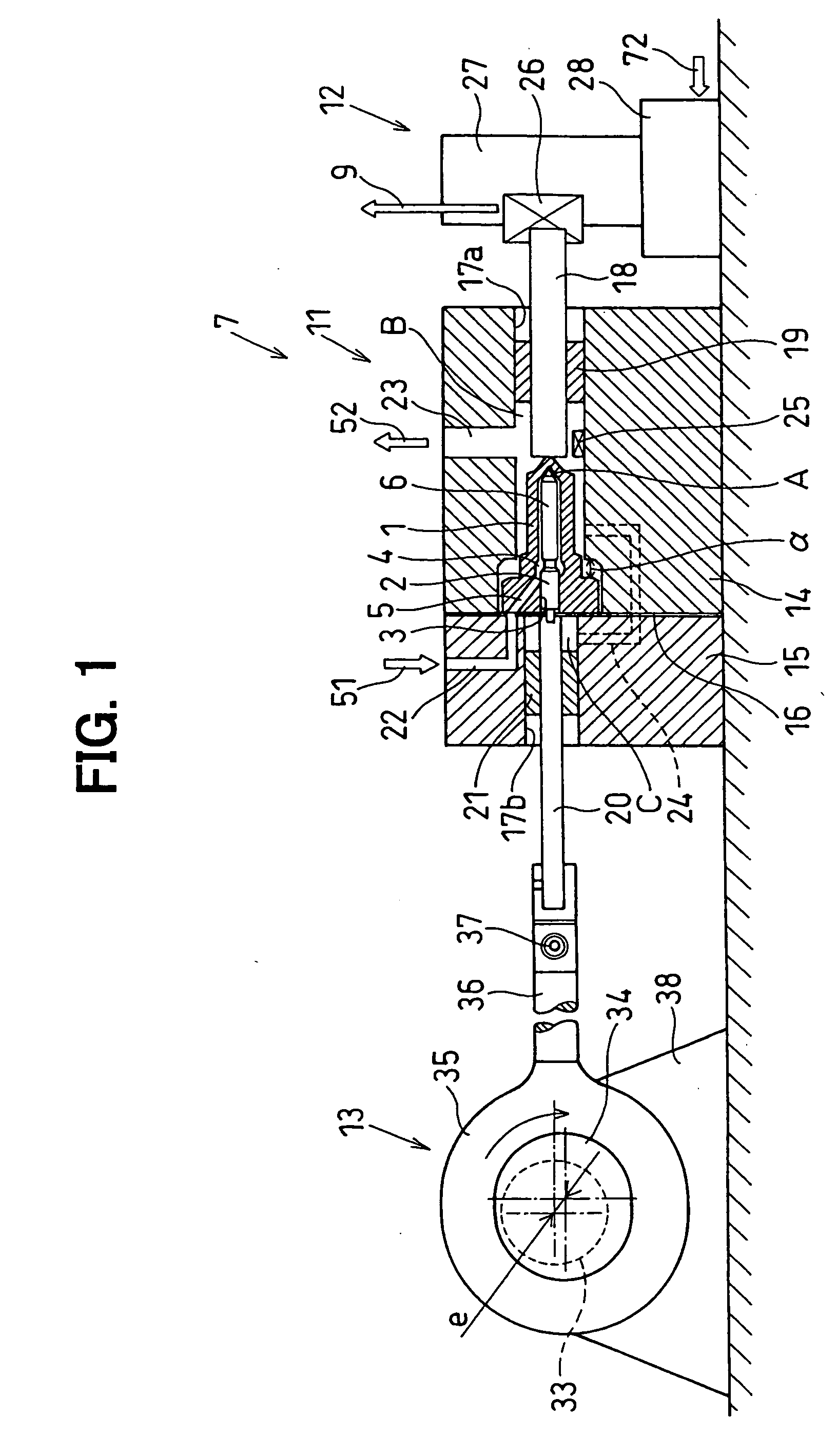

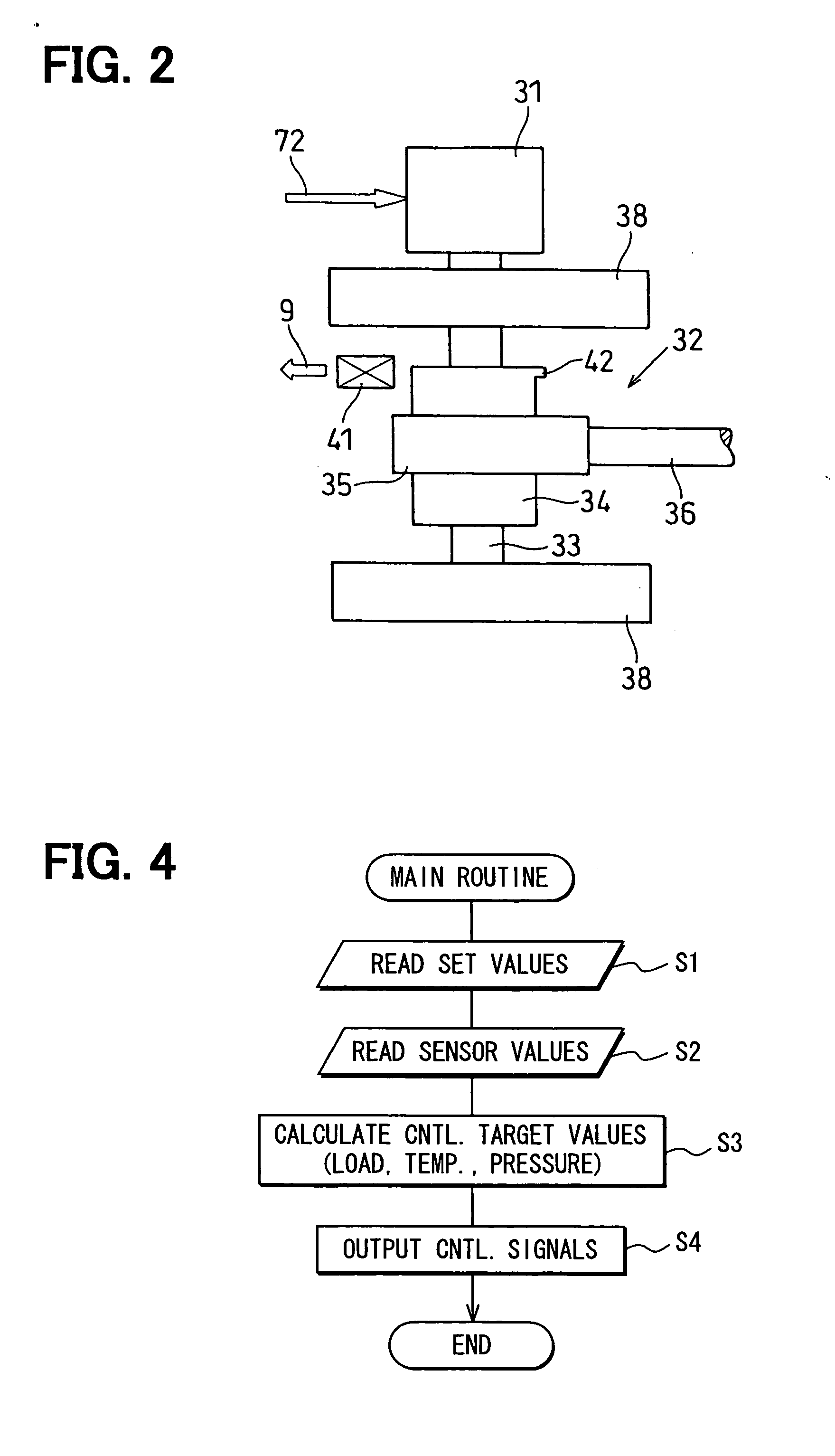

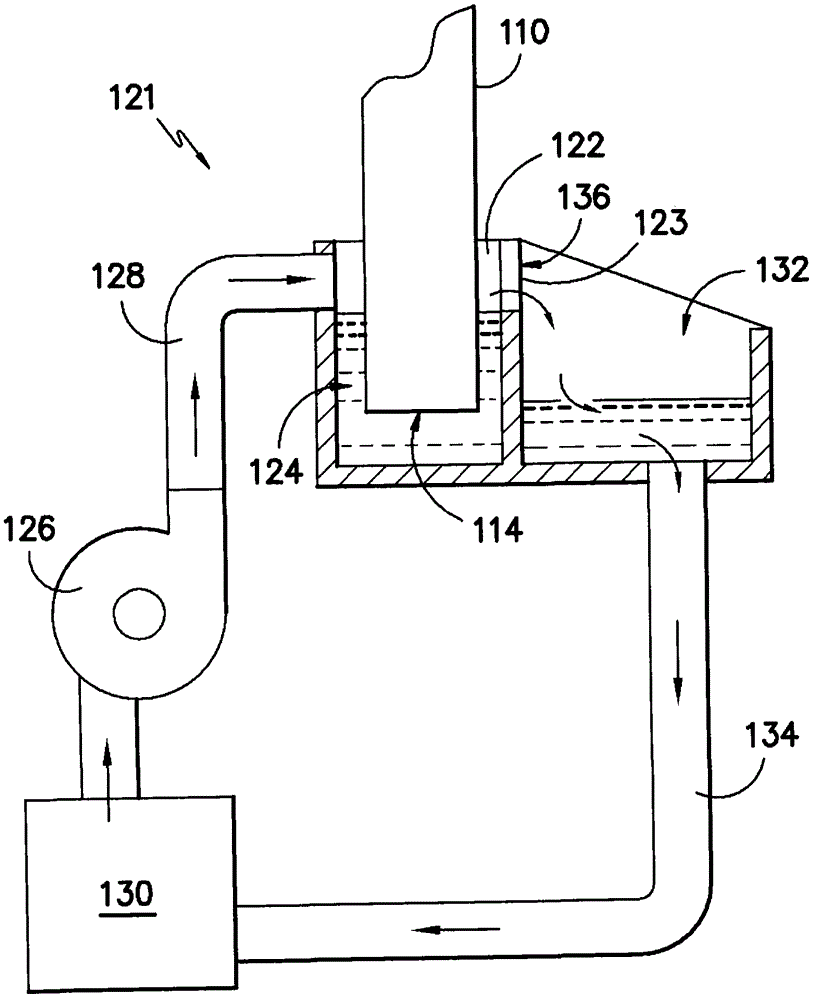

Endurance testing apparatus

InactiveUS20060219024A1Low costShorten the timeForce measurementStructural/machines measurementReciprocating motionBiomedical engineering

An endurance testing apparatus, which is for performing an endurance test of a contacting / separating portion in which a first member and a second member repeats contacting with and separating from each other, has a contact load generator and a testing medium fluid supply means. The contact load generator reciprocates the second member relative to the first member to generate a contact load acting between the first member and the second member repeatedly. The testing medium fluid supply means supplies a testing medium fluid to the contacting / separating portion to expose the first member and the second member to the testing medium fluid.

Owner:DENSO CORP +1

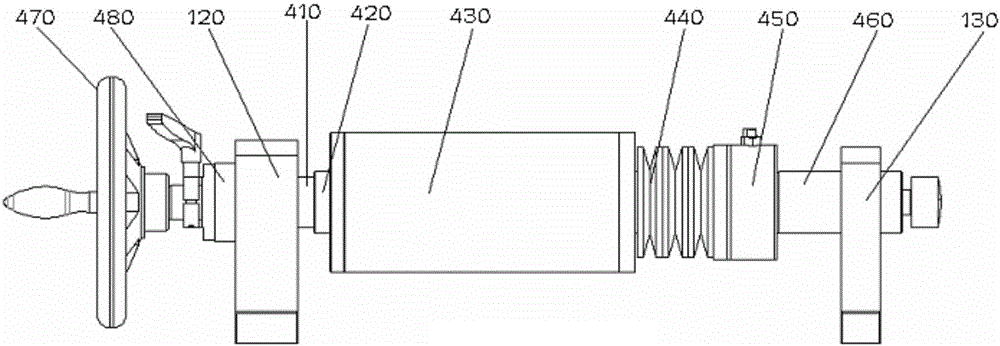

Electric automobile driving motor bearing high temperature high speed high load endurance testing apparatus

InactiveCN105973604ATest accurateAccurate technical parametersMachine bearings testingBall bearingCar driving

The invention discloses an electric automobile driving motor bearing high temperature high speed high load endurance testing apparatus which includes: a workbench; a heater box which is arranged on the workbench and is provided therein with a testing shaft which is provided with at least one to-be-tested deep groove ball bearing thereon; a driving apparatus which can drive the testing shaft to rotate and is arranged on one side of the heater box; an axial loading apparatus which can supply axial load to the to-be-tested deep groove ball bearing and is arranged on the other side of the heater box; a radial loading apparatus which supplies radial load to the to-be-tested deep groove ball bearing and is arranged above the heater box; a PLC control system which can control the heater box and the driving apparatus to work. According to the invention, the whole testing process is simple, can simulate working environment inside the electric automobile driving motor, can accurately test technical parameters of the deep groove ball bearing, and provide great convenient to operation workers.

Owner:CIXING GROUP

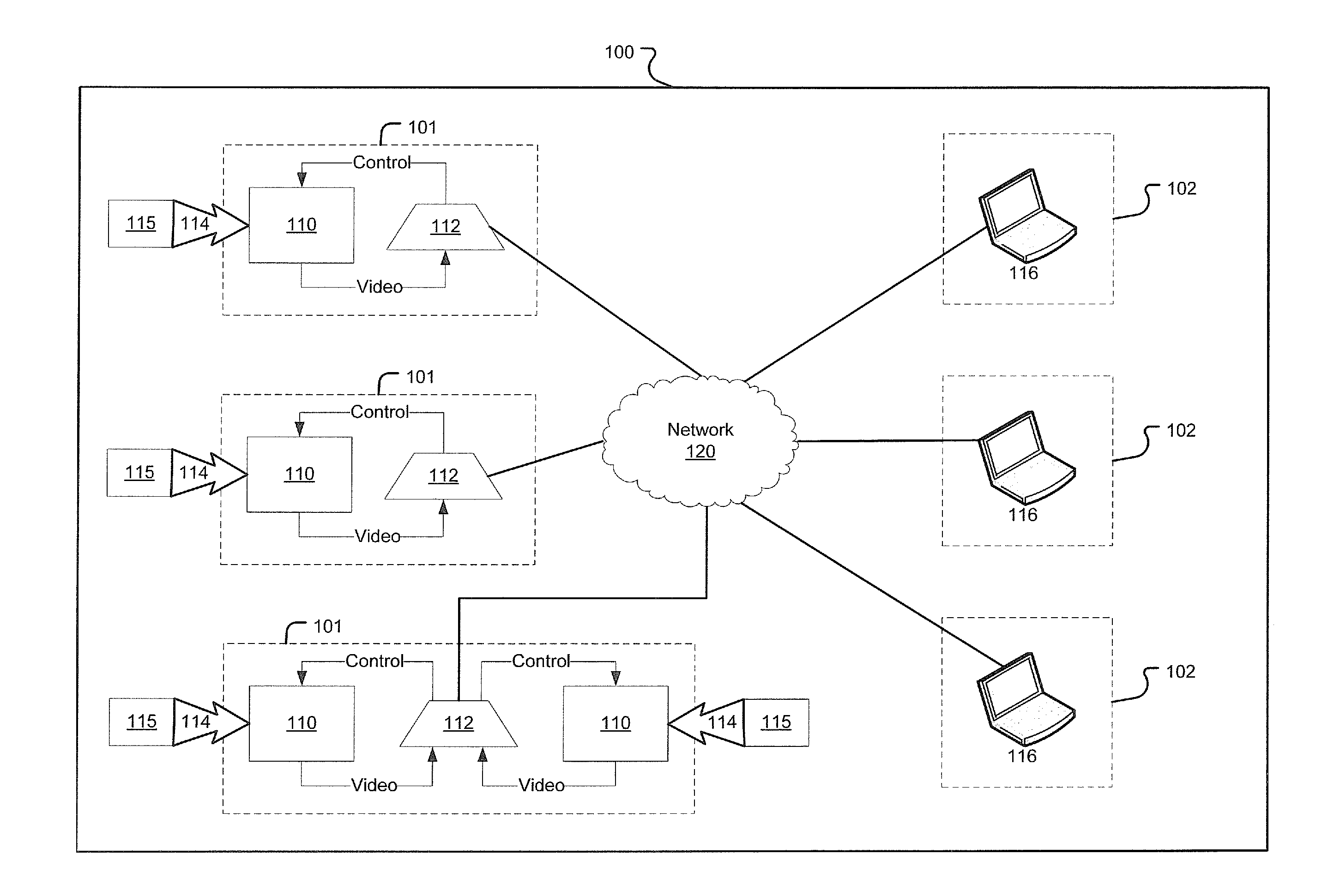

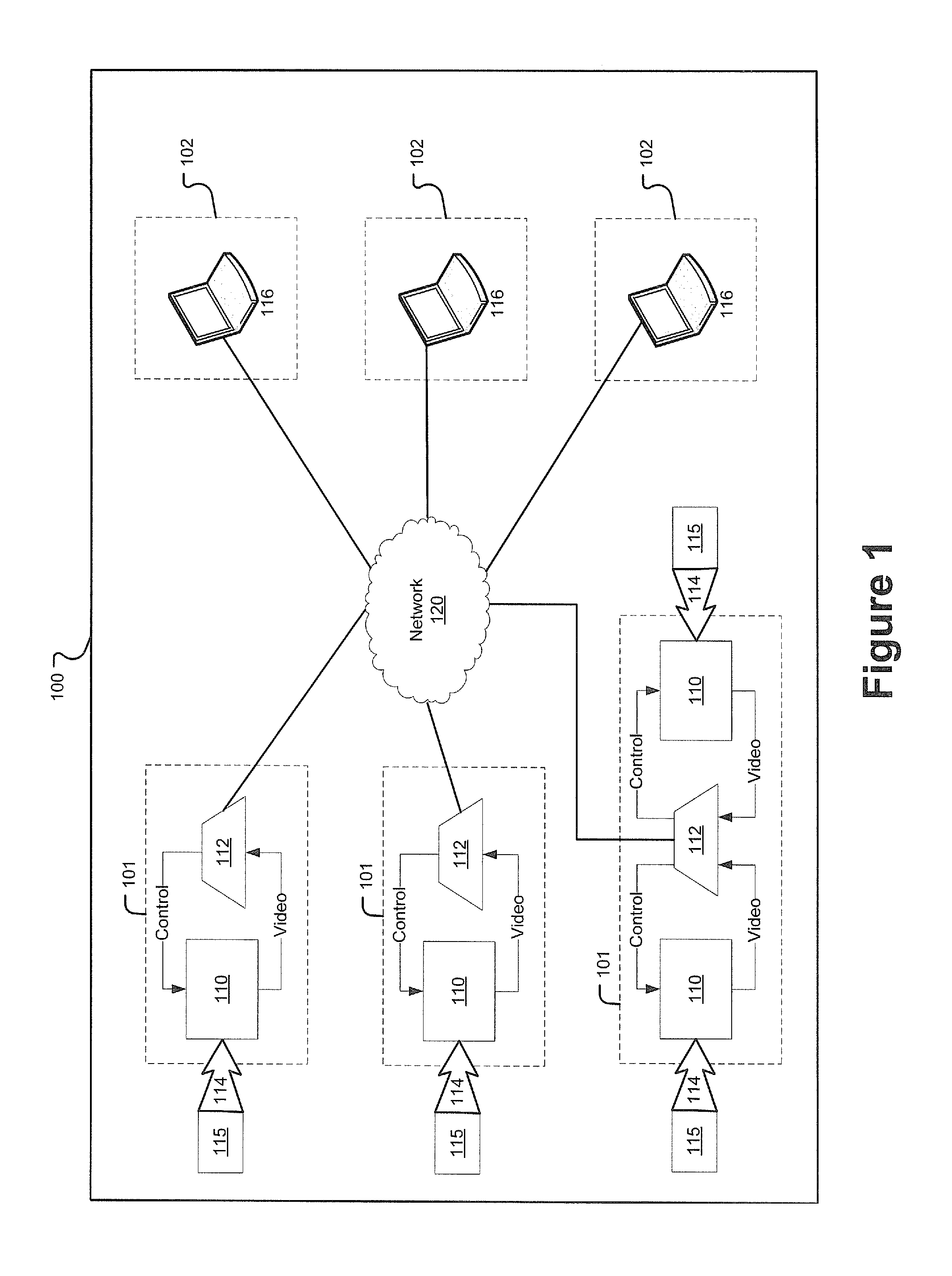

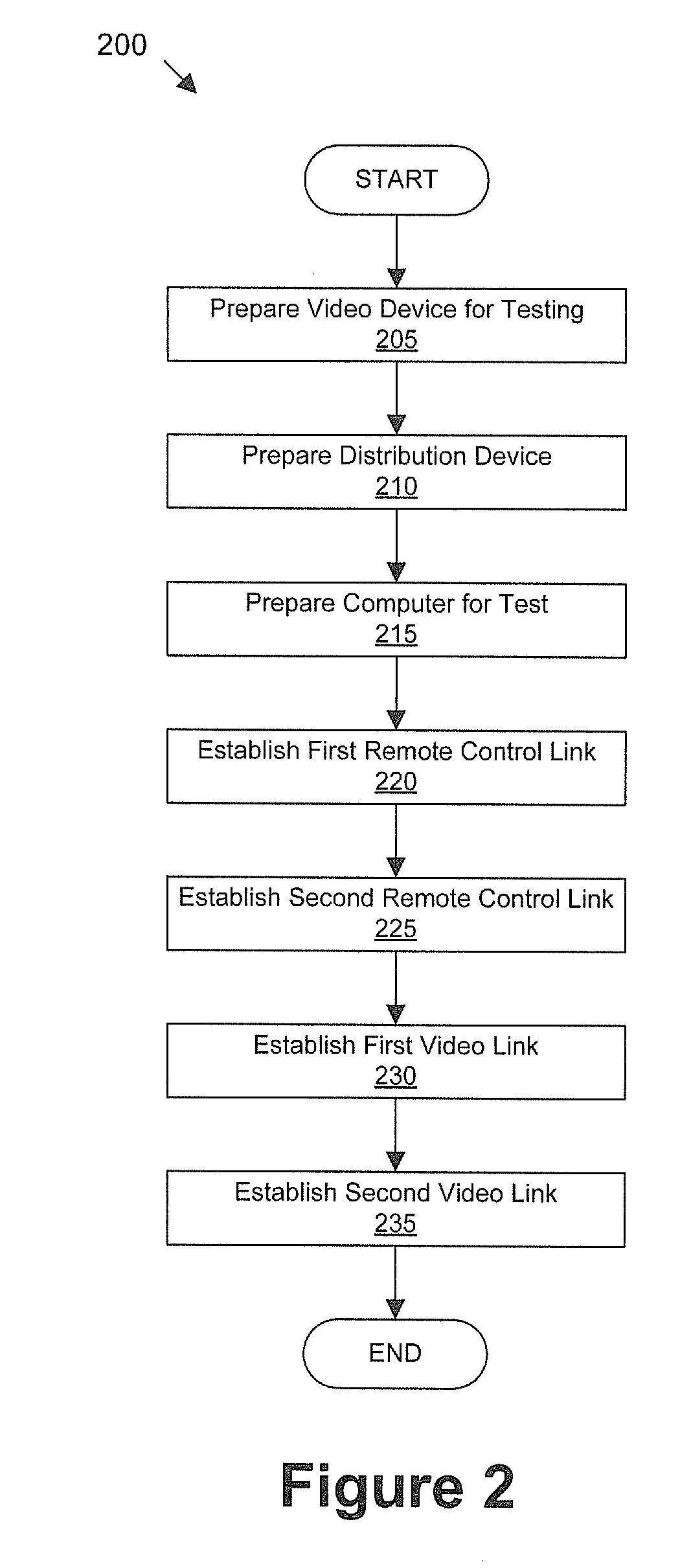

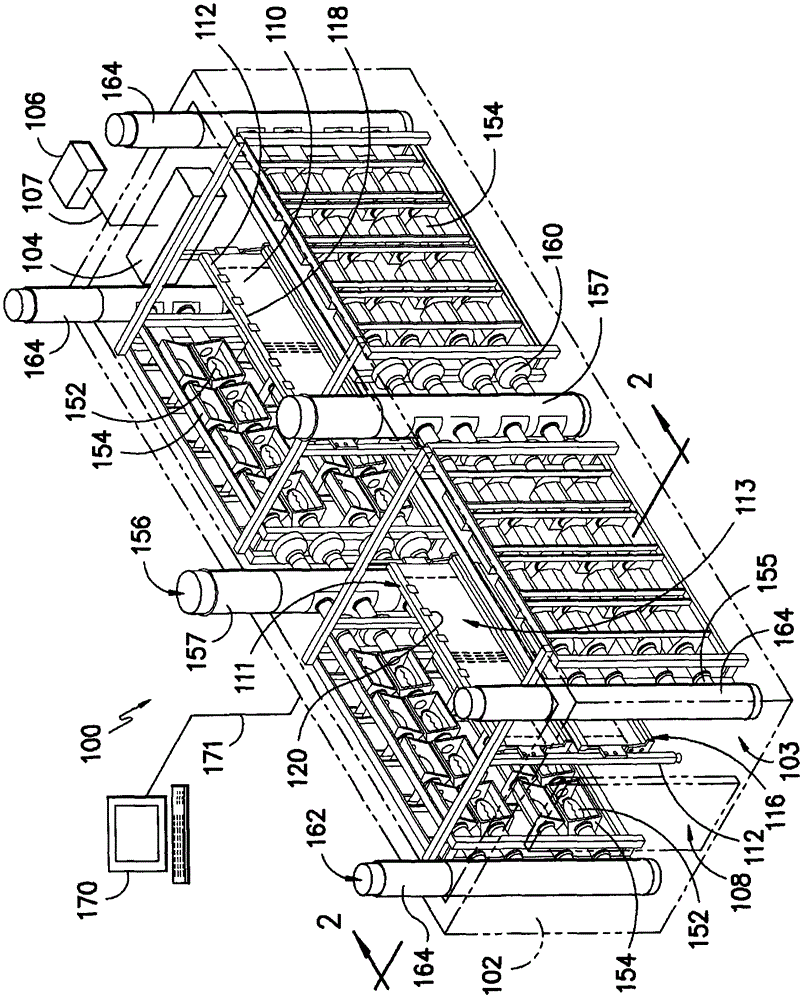

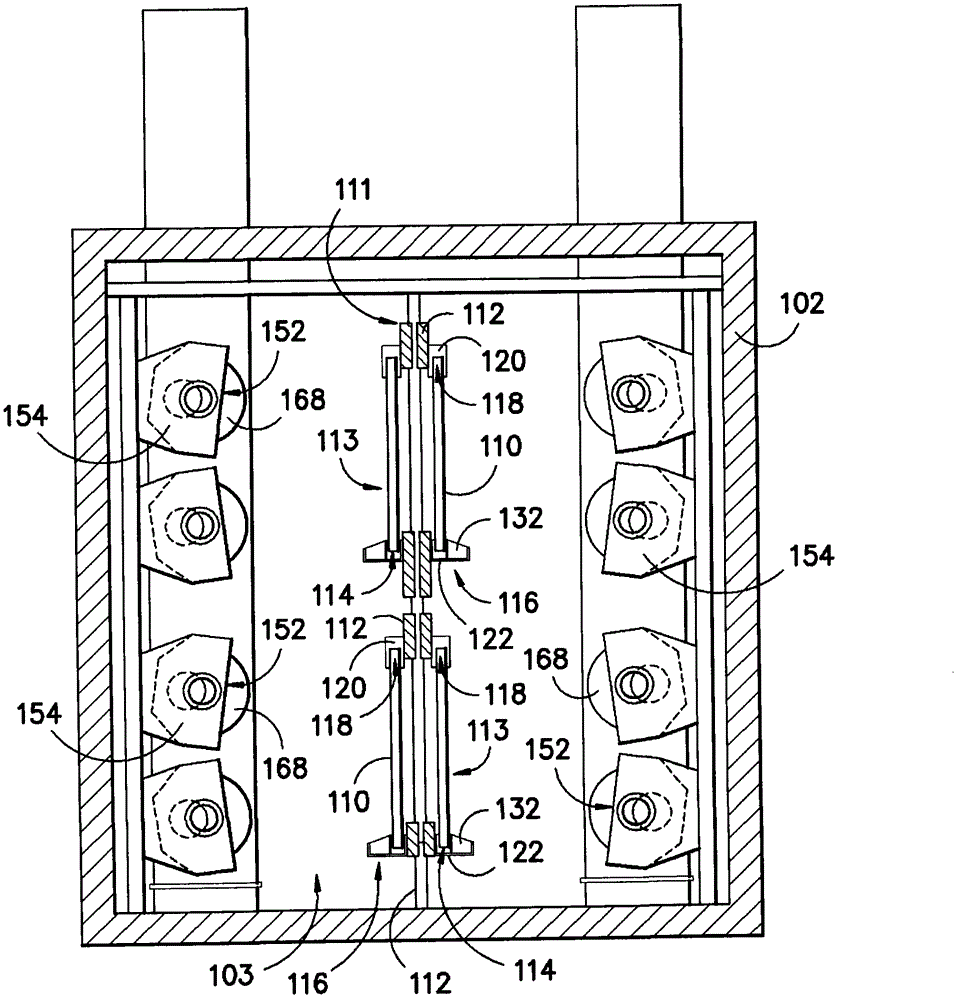

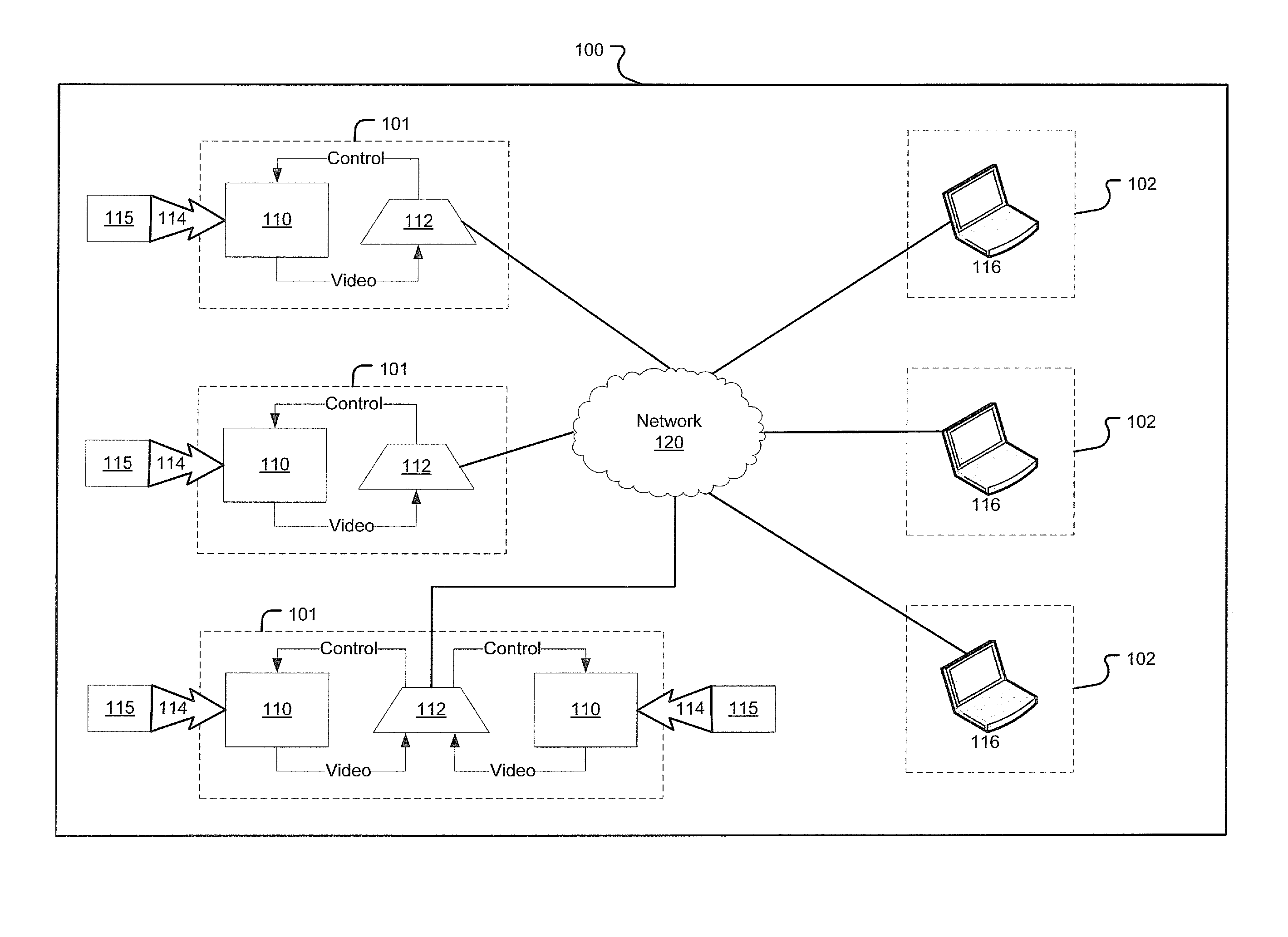

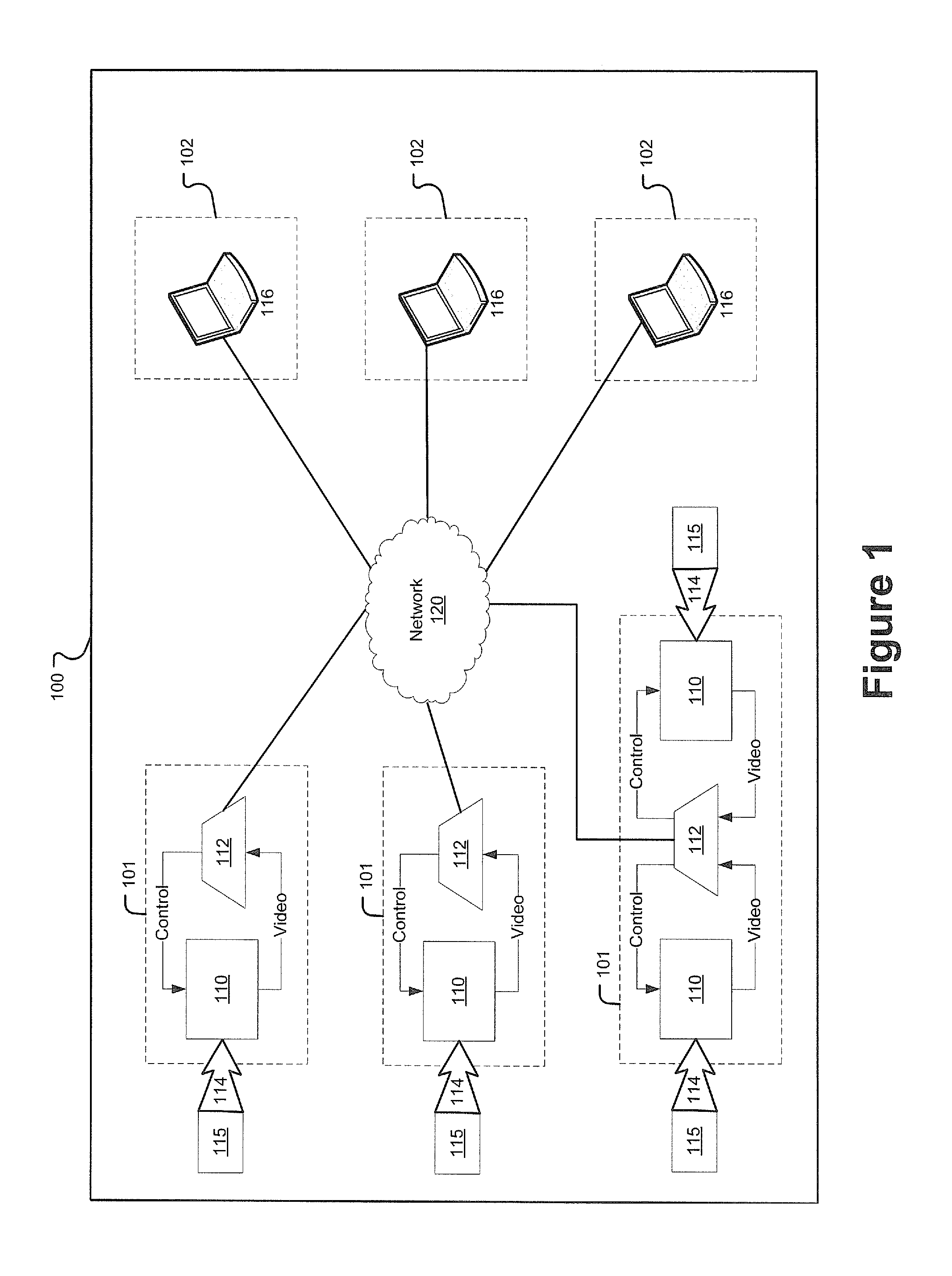

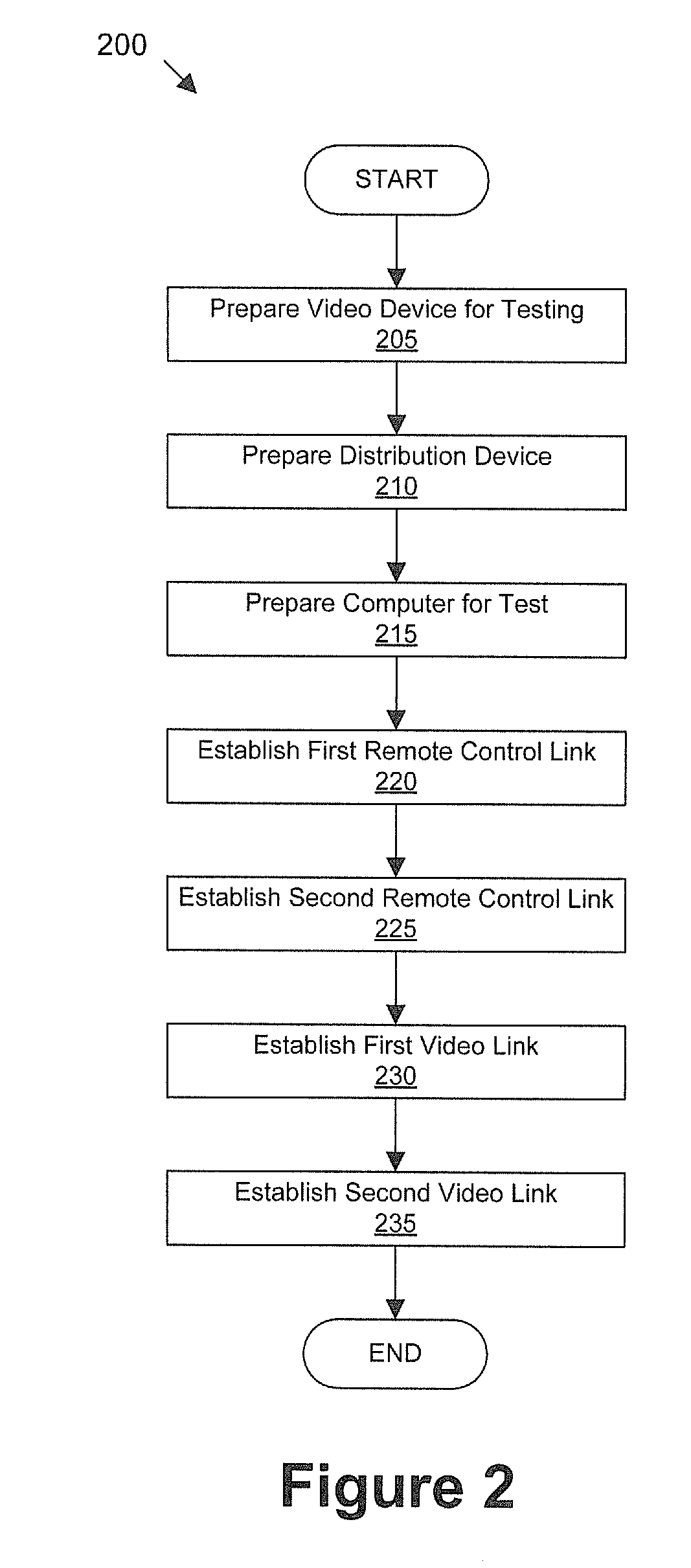

Endurance testing of a content processing device

A content processing device is configured to selectively receive a media signal from a media signal provider. A distribution device is configured to selectively receive a media signal from the content processing device, and to selectively provide one or more command signals to the content processing device. A computer is configured to selectively receive the media signal from the distribution device, and to selectively provide commands to the distribution device. The distribution device is further configured to provide the received one or more commands to the content processing device via the one or more command signals.

Owner:VERIZON PATENT & LICENSING INC

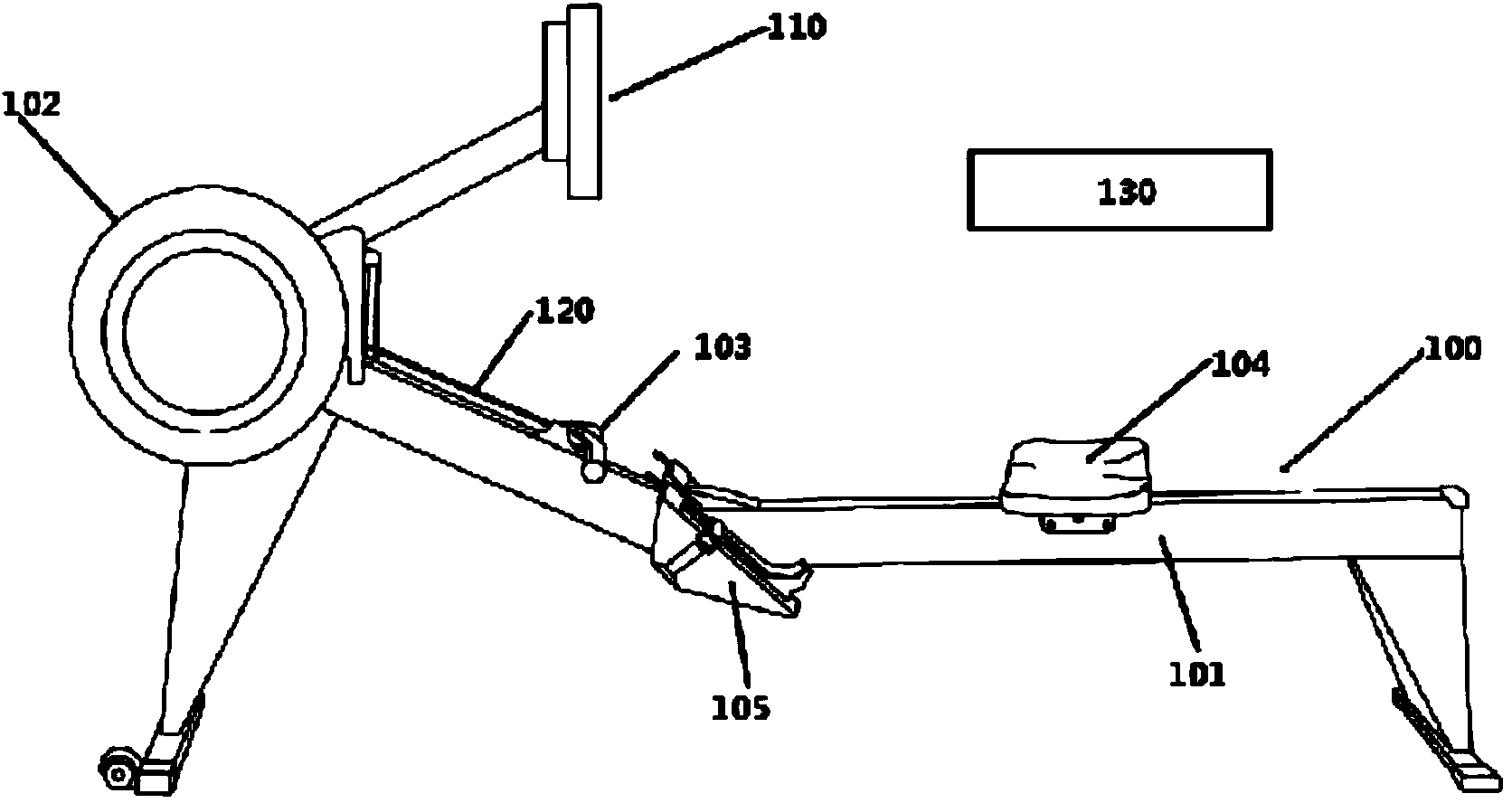

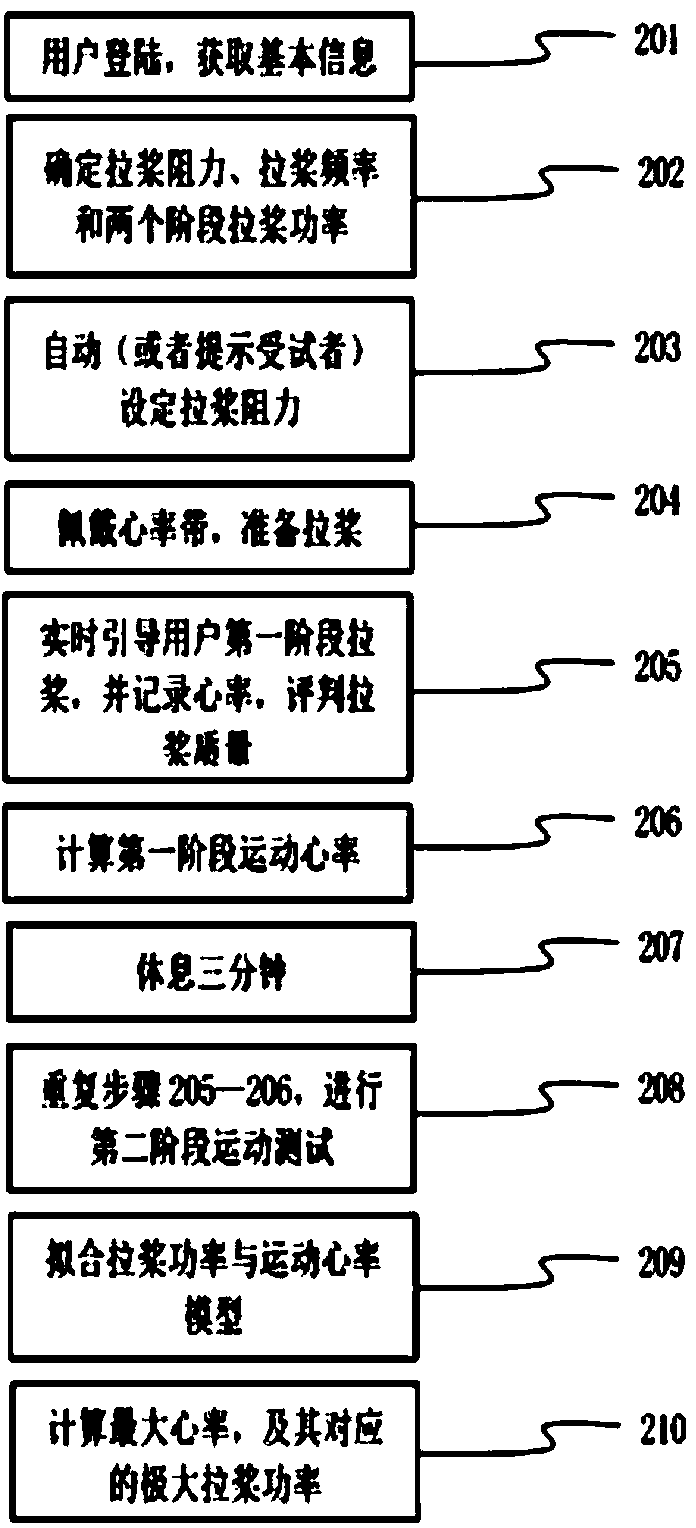

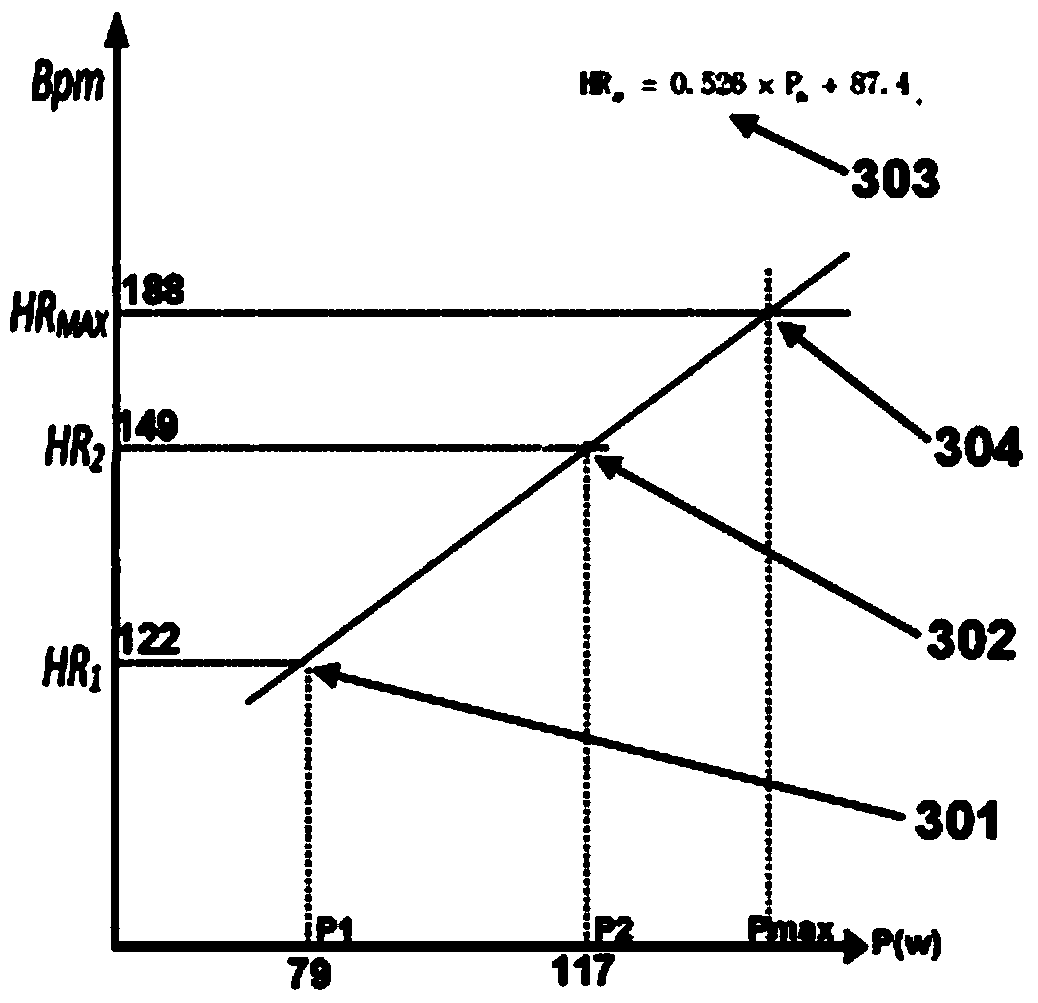

Rowing machine-based cardiorespiratory endurance testing method

InactiveCN104305986AEasy to master the test methodHighly corporatedSensorsSport apparatusPersonalizationHigh heart rate

The invention discloses a rowing machine-based cardiorespiratory endurance testing method, and is applicable to cardiorespiratory exercise capacity testing in nationwide fitness programs. More specifically, a testing system consisting of a rowing machine body, a testing analysis platform, a pull data acqusition module and a heart rate acqusition module is utilized to guide a subject to finish two groups of stable continuous pull actions with same pull resistance and pull frequency and different pull powers in a set time so as to monitor heart rate response of the subject in real time, establish a linear model between the stage movement heart rate and the pull power and calculate the pull power corresponding to the highest heart rate of the subject to serve as an evaluation index of the cardiorespiratory endurance. Whole-course real-time guide is realized by using sound, light and video signals, the exercise limit is not required to be reached, the method is suitable for a broader crowd of people and is safer, the testing result can objectively reflect the weakness of the cardiorespiratory endurance, a personalized and differentiated fitness plan can be made for the subjects, the exercise effect is improved and scientific guidance is provided.

Owner:HEFEI NORMAL UNIV +1

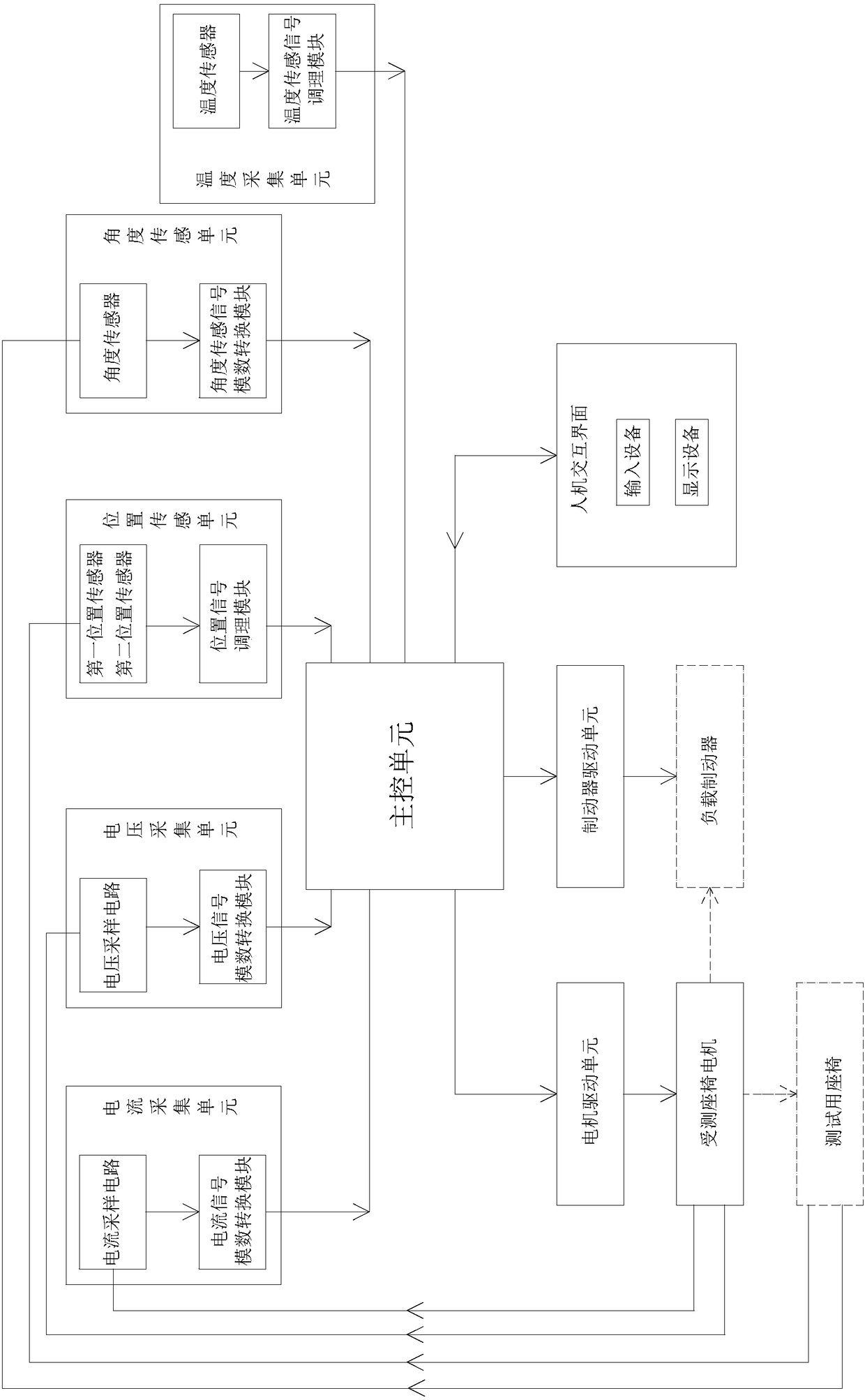

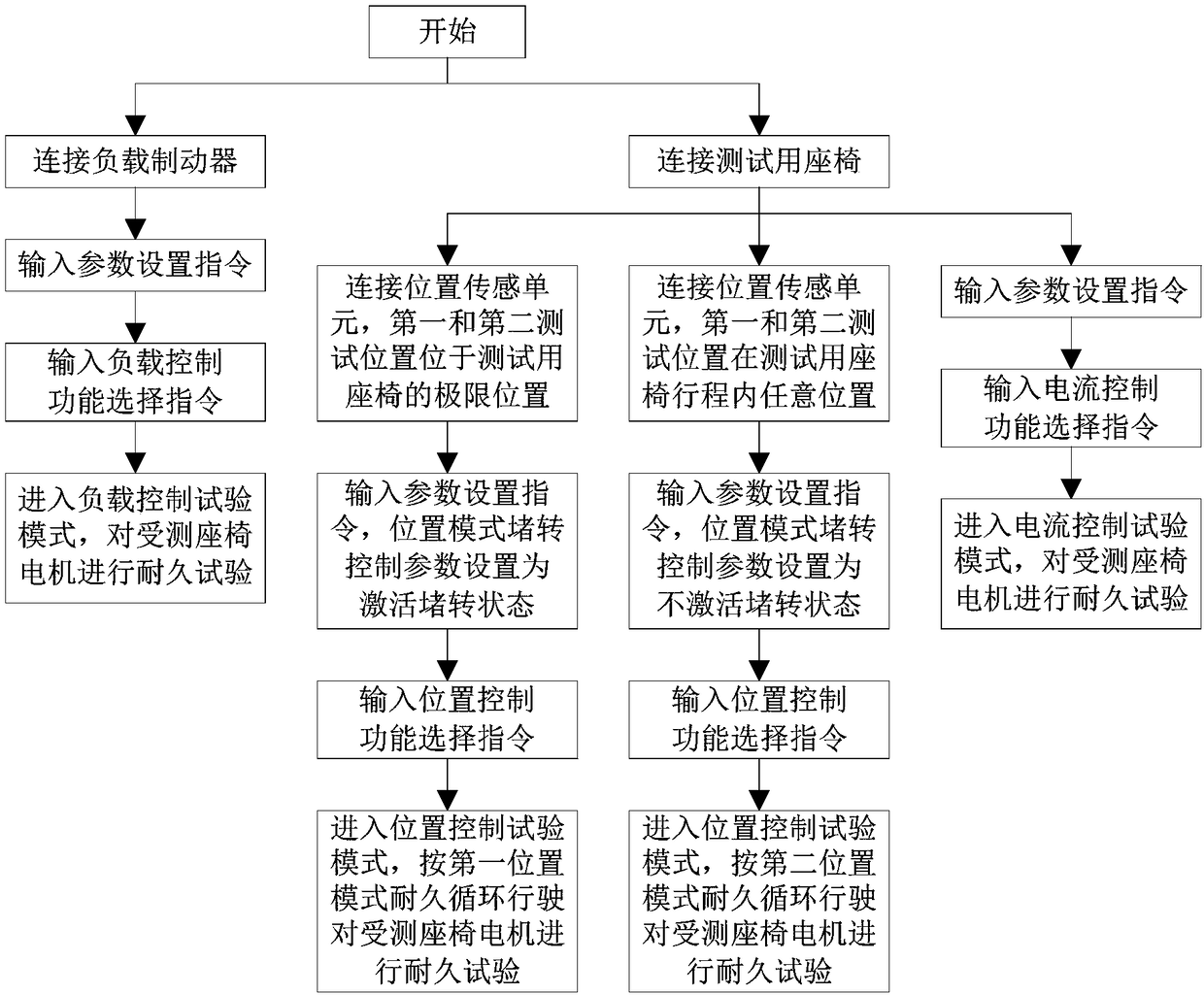

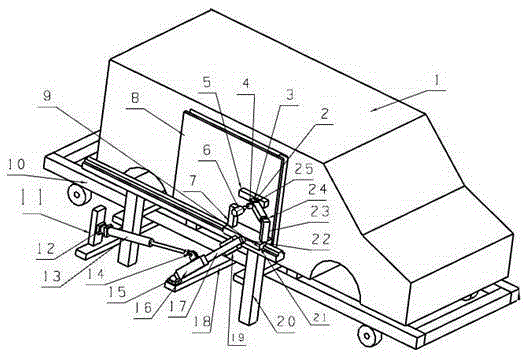

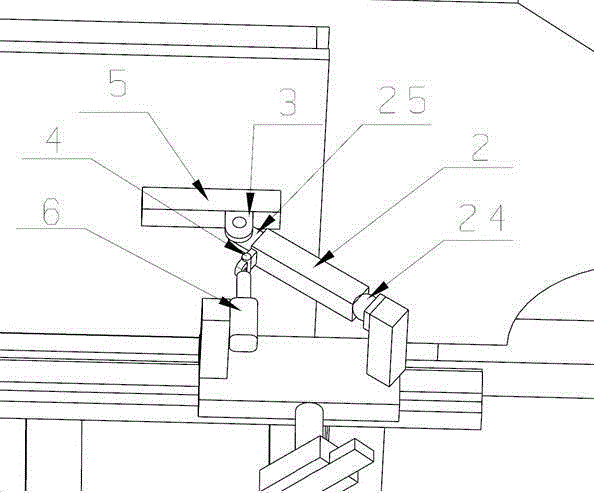

Endurance test control system and method of seat motor

ActiveCN108375731AEndurance cycle in various formsFlexible settingsDynamo-electric machine testingControl systemElectric machine

The invention discloses an endurance test control system and method of a seat motor. The control system is composed of a main control unit, a motor drive unit, a current collection unit and a brake drive unit. The main control unit is able to enter one of a load control test mode, a position control test mode and a current control test mode. According to the control method, on the basis of an endurance test standard formulated by an automotive manufacturer for a tested seat motor, endurance testing is carried out on the tested seat motor by using a load braking device or a testing seat based on a test mode corresponding to the endurance test control system according to the situation conforming to the endurance test standard requirement best. The endurance test control system and method conform to different endurance test stands and test conditions formulated by most of the automotive manufacturers for the tested seat motors; adaptability to the actual working condition of the endurancetesting process is high; and the universality is improved.

Owner:GAC COMPONENT CO LTD

Testing device for endurance of closing and opening of external unlocking door of automobile sliding door

The invention provides a testing device for endurance of closing and opening of an external unlocking door of an automobile sliding door, belonging to the endurance testing device field. The invention comprises a testing stand rack, a power device fixed on the testing stand rack, a control system, a sliding device, and an external unlocking door-opening device. The testing stand rack is used for fixing a testing vehicle; the external unlocking door-opening device is fixed on the sliding device; the power device is connected to the sliding device; the control system is used for controlling the power device to provide power and controlling the external unlocking device to unlock. The beneficial effects of the invention are that: the structure is simple, reliable and practical, the integral vehicle test is fully realized and the accuracy of the test data is guaranteed without disassembling and damaging the parts on the test vehicles, the invention is applicable to various types of the vehicles and stable in performance and reliable in test data accuracy, the operation is simple and maintenance is easy, and the invention will not damage the test sample vehicle and reduces the test cost.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Thermal endurance testing apparatus and methods for photovoltaic modules

InactiveCN102721622AWeather/light/corrosion resistanceMaterial thermal analysisInterior spaceHeat resistance

Apparatus and methods for testing the thermal endurance of a glass substrate of a photovoltaic module are provided. The apparatus generally includes, in one embodiment, a testing chamber defining an interior space having an interior atmosphere. A refrigeration unit is operably positioned with the testing chamber to control the interior atmosphere's temperature. A mounting system is positioned within the interior space of the testing chamber and configured to hold the photovoltaic module while exposing the glass substrate of the photovoltaic module. An edge cooling system is positioned in relation to the mounting system such that the photovoltaic module held by the mounting system has a first side edge in contact with the edge cooling system. A light system is also positioned within the interior space of the testing chamber to illuminate the glass substrate of the photovoltaic module.

Owner:PRIMESTAR

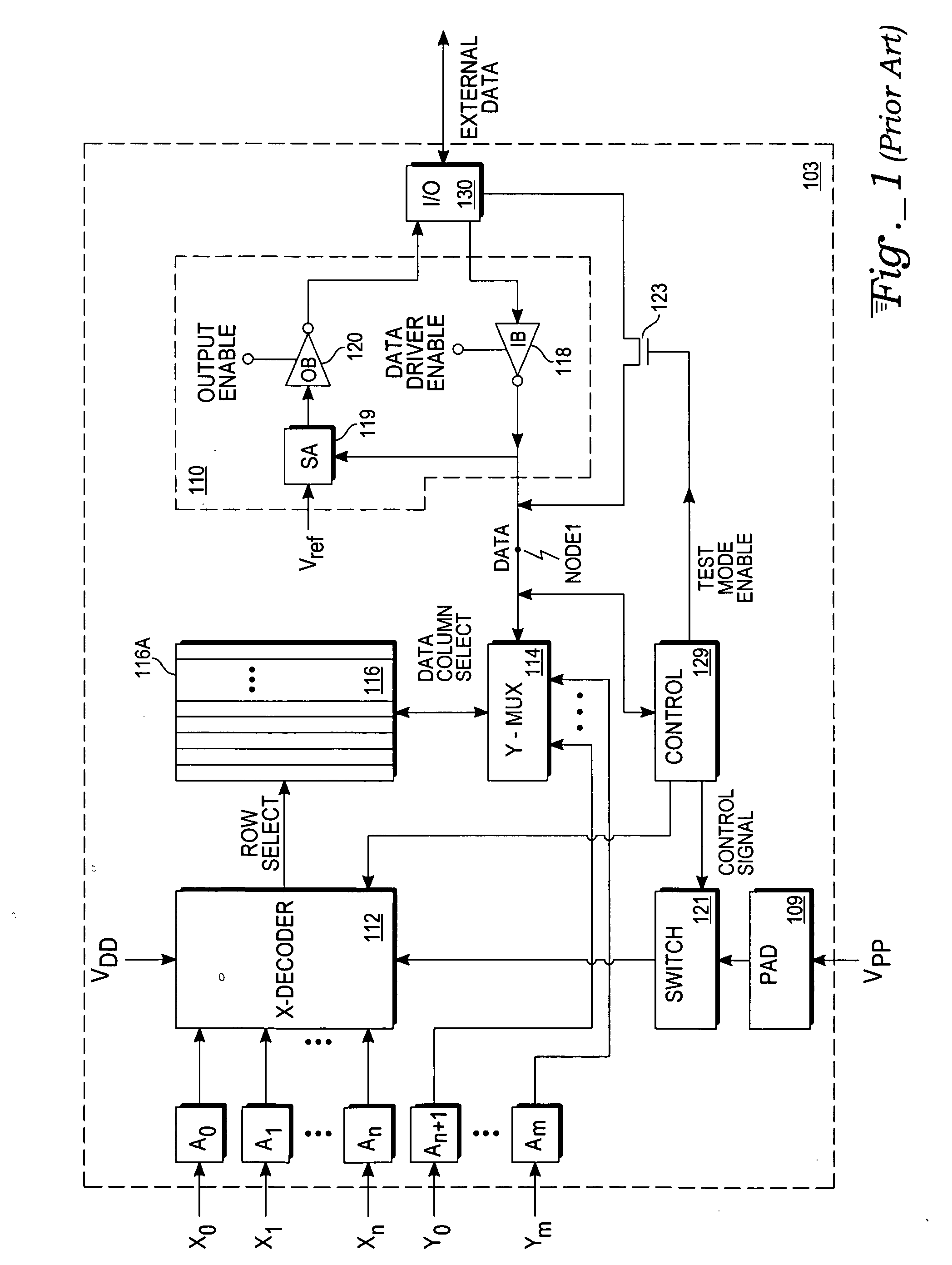

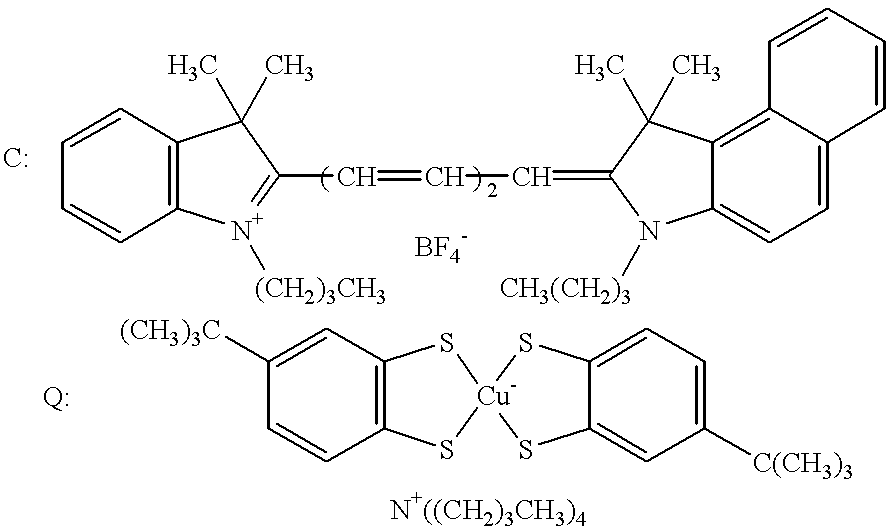

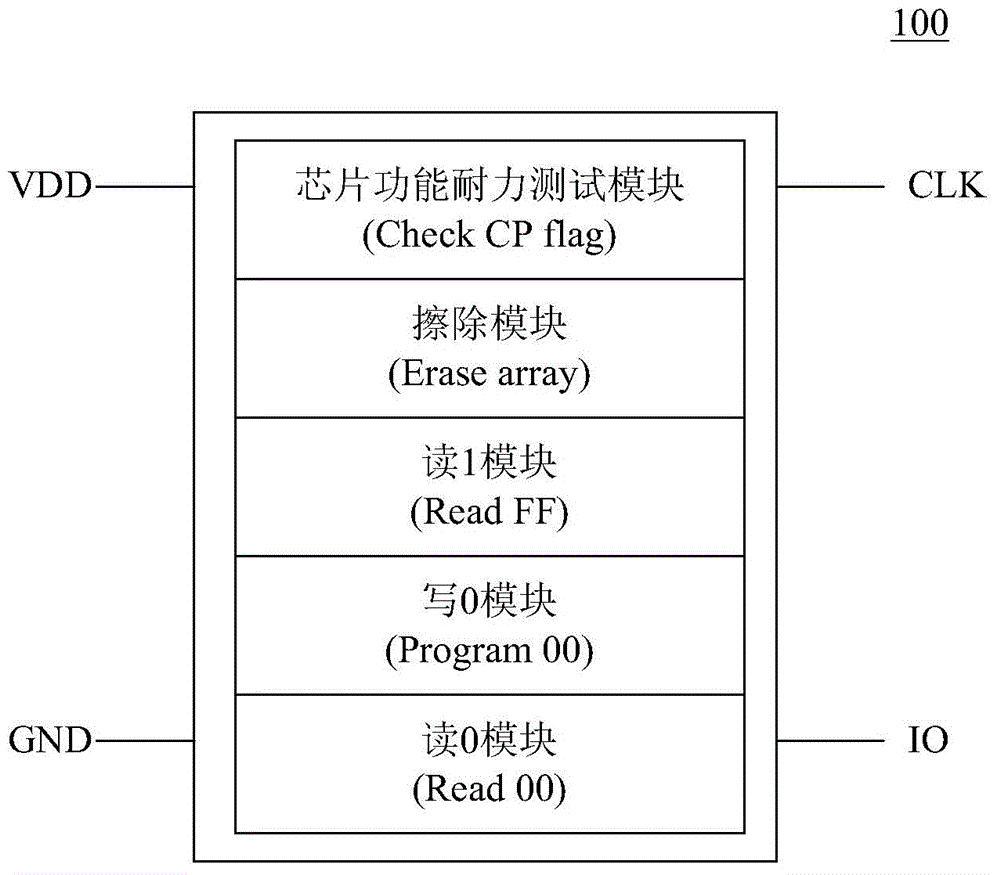

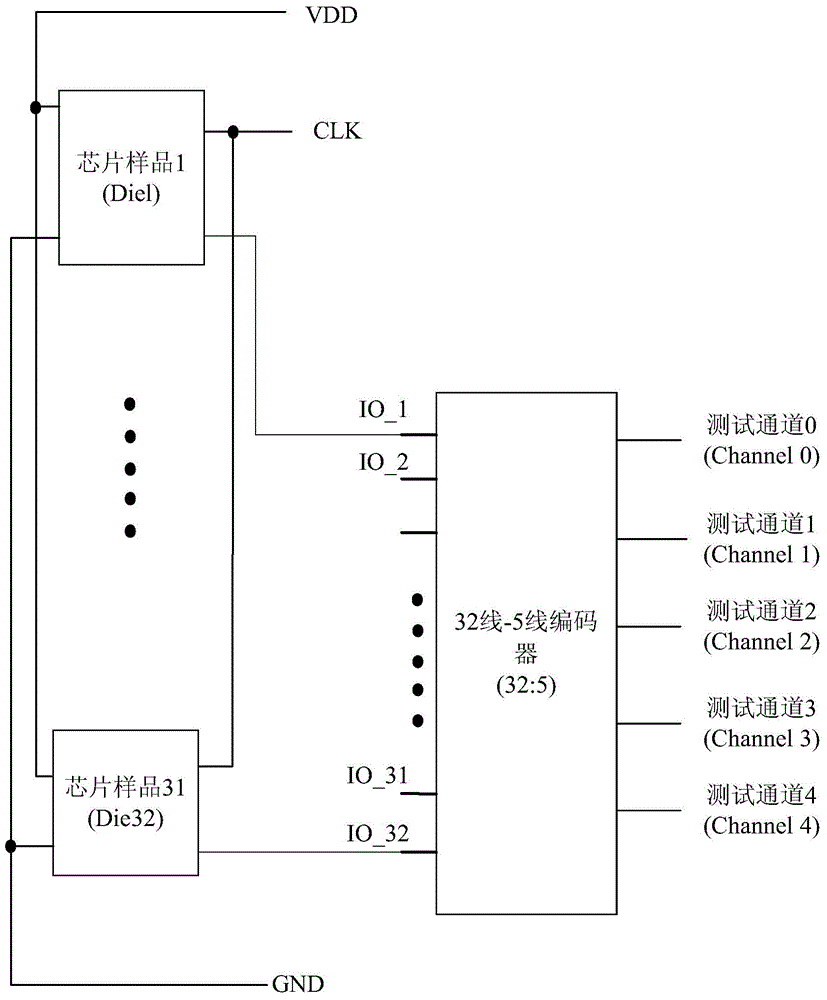

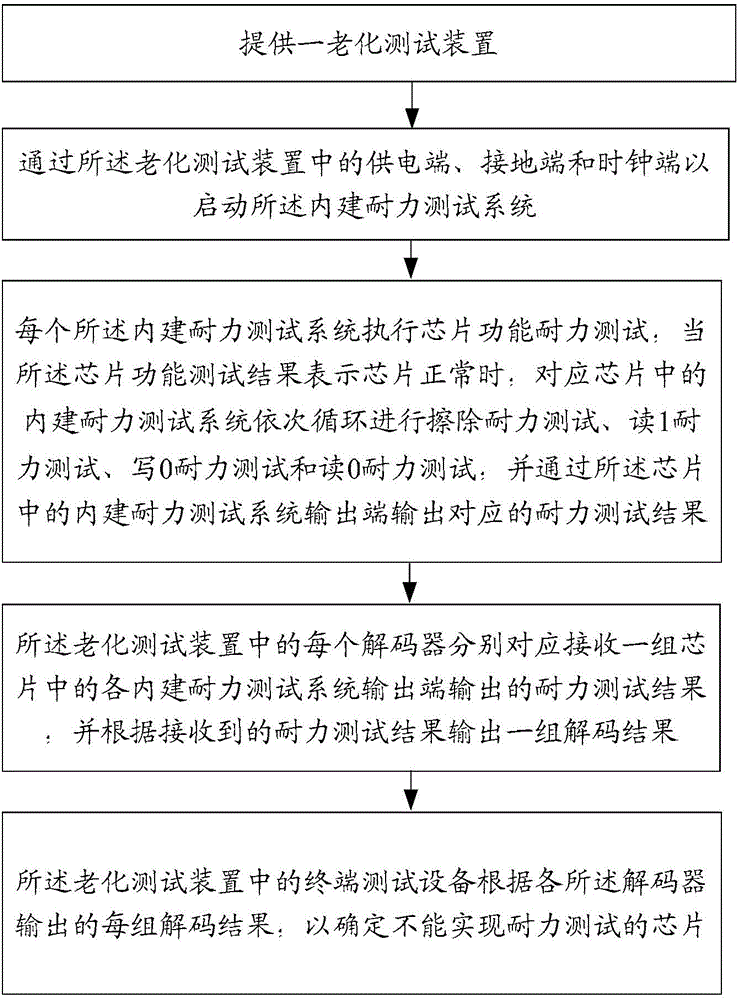

Built-in endurance test system, aging test device and corresponding endurance testing method

ActiveCN103336237AEasy to packReduce packaging costsIndividual semiconductor device testingTest equipmentTest board

The invention provides a built-in endurance test system, an aging test device and a corresponding endurance test method. The built-in endurance test system comprises a power supply end, a grounding end, a clock end and an output end; the built-in endurance test system is started through the power supply end, the grounding end and the clock end, and carries out the endurance test to a chip and outputs the endurance test results through the output end; the aging test device comprises a whole machine test plate, at least a group of chips, the built-in endurance test system, a decoder and terminal test equipment, wherein the chips are arranged on the whole machine test plate; the built-in endurance testing system is integrated in each chip; the decoder is used for receiving the endurance test results output by the built-in endurance test system; the terminal test equipment is used for determining the chips which can not realize the endurance test according to the decoding results output by the decoder, so as to solve the problems that the sample quantity is less, the endurance test period is long, whether the reading kinetic energy of a chip sample is invalid or not can not be judged automatically, and the test cost is expensive during endurance test of each batch chips.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Indirect measurement of negative margin voltages in endurance testing of EEPROM cells

InactiveUS7336540B2High voltageEndurance or longevity of the cellRead-only memoriesDigital storageEngineeringPositive power

An electronic test structure and method for testing non-volatile memory cells. The structure includes a first transistor coupled in series to a floating gate transistor whereby a source of the first transistor is coupled to a positive power supply voltage and a source of the floating gate transistor is coupled to a power supply ground. A gate of the first transistor is further coupled to a source of the first transistor. A second transistor is coupled in series with a memory cell with a source of the second transistor coupled to a positive power supply voltage and a gate of the second transistor is coupled to the drain of the first transistor.

Owner:ATMEL CORP

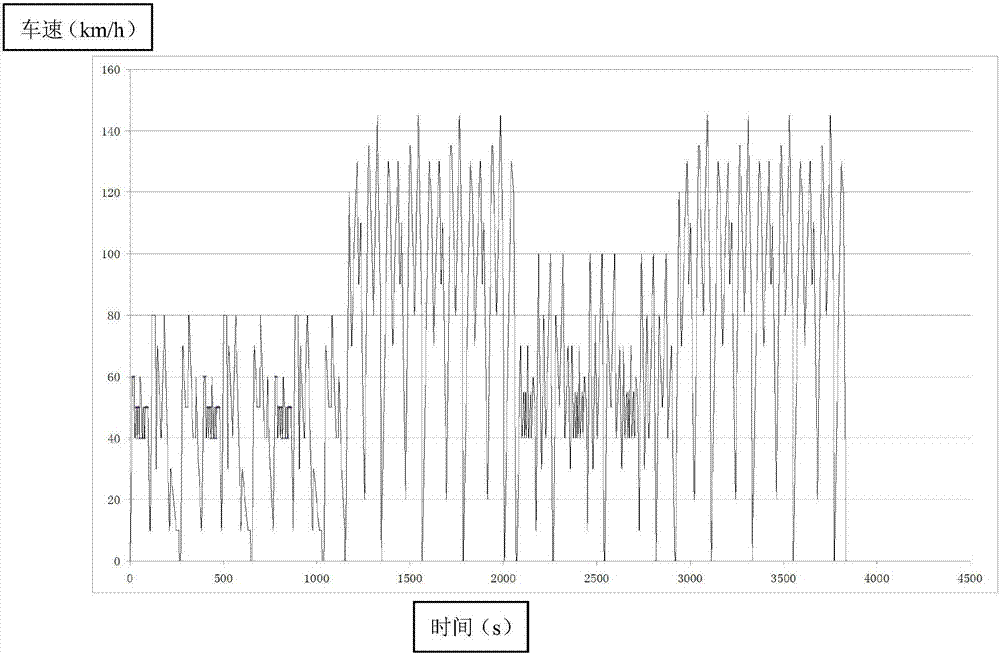

DCT finished vehicle gearshift cycle endurance testing method

InactiveCN107966295ATo achieve the purpose of special verificationLow costMachine gearing/transmission testingTest requirementsStatic checking

The invention provides a DCT finished vehicle gearshift cycle endurance testing method, which comprises the steps of: step 1, performing static checking and dynamic evaluation on a DCT transmission ofa finished vehicle before the test; step 2, in the test phase, running the finished vehicle according to a set working condition curve on a chassis dynamometer till a test requirement is met, and recording data in the test process; step 3, and finally performing dynamic evaluation on the DCT transmission of the finished vehicle again, dismantling a transmission box, and checking an internal damage situation. The DCT finished vehicle gearshift cycle endurance testing method aims at the finished vehicle provided with the DCT, performs the static and dynamic evaluation before the test, then runsthe finished vehicle according to the specific cycle curve on the chassis dynamometer till the test requirement is met, and finally performs dynamic evaluation and dismantles the transmission box, soas to achieve the purpose of conducting special item verification on the DCT, thus the DCT is not limited to constraints of road conditions, the DCT can be subjected to rapid special item verification in a targeted manner, and the DCT finished vehicle gearshift cycle endurance testing method has the advantages of low cost, short verification cycle, problem focusing and the like when compared withroad tests.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

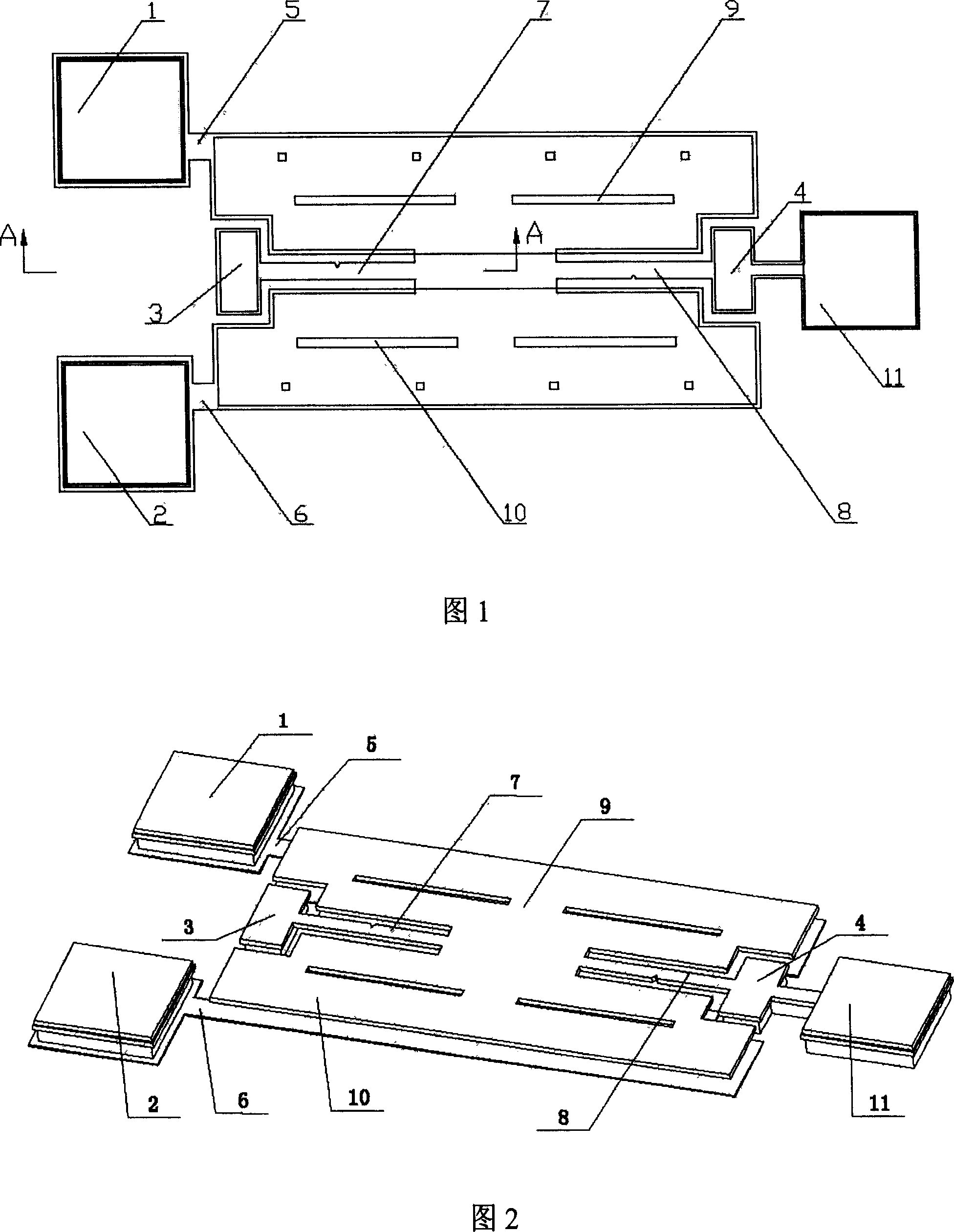

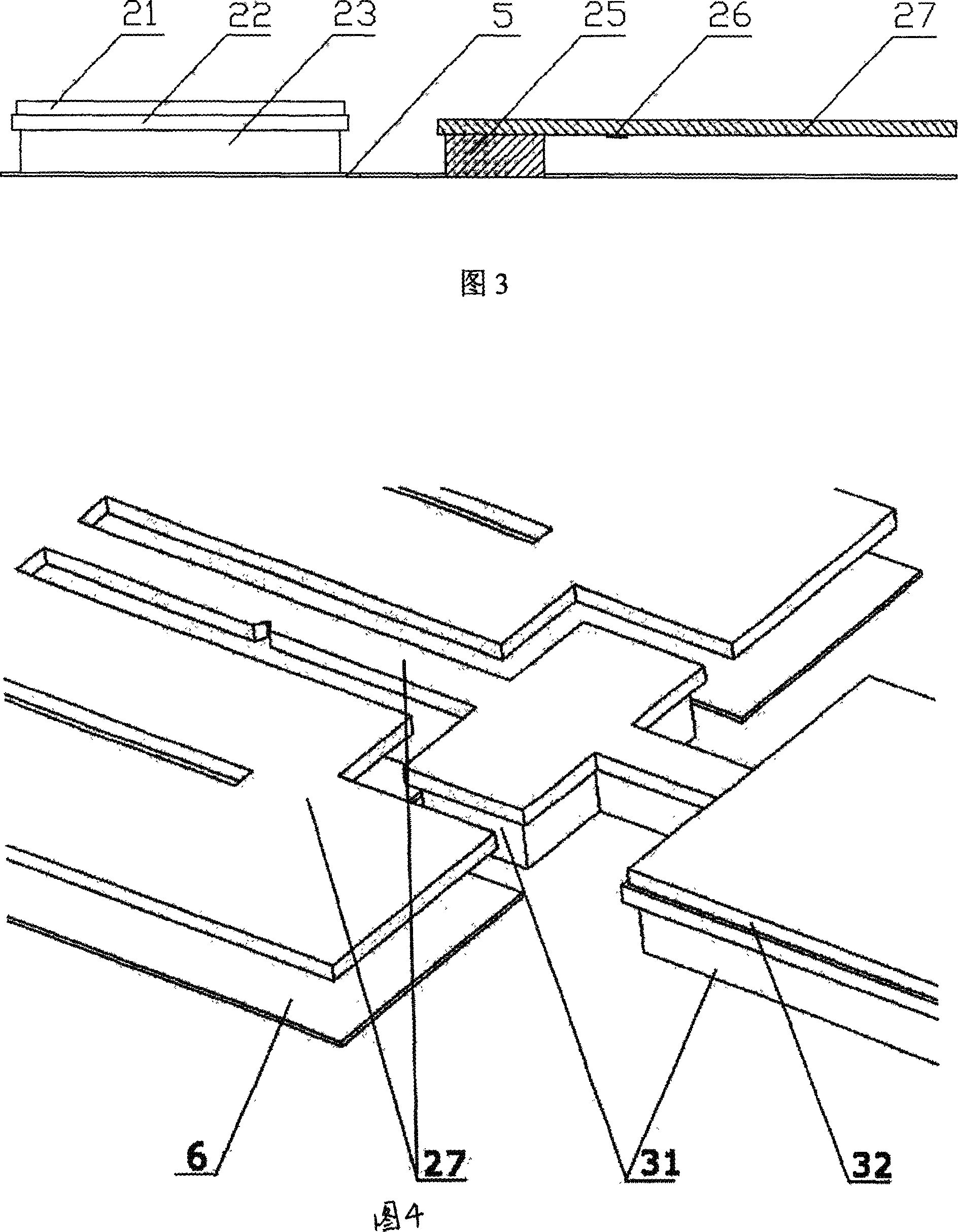

Fatigue endurance test device and method for a multi-link rear suspension axle housing assembly

ActiveCN108931382AShorten the development cycleLow costVehicle testingMachine part testingControl armMulti link

The invention relates to a fatigue endurance testing device and method for a multi-link rear suspension axle housing assembly. A tire of a multi-link rear suspension assembly is arranged and fixed ona tray on the top of an actuating support member. A left horizontal reaction force seat and a right horizontal reaction force seat are fixed on an iron floor, and upper and lower control arm members are fixed on the horizontal reaction force seats to fix an upper control arm and a lower control arm respectively. Four columns are fixed on the iron floor, wherein spring fixing parts are fixed on twoof the columns, and springs are fixed on the spring fixing parts and are adjusted in height through sliding grooves. Shock absorber fixing parts are fixed on another two columns, and shock absorbersare fixed on the shock absorber fixing parts and are adjusted in height through sliding grooves. The fatigue endurance testing device and method realize durability testing of the shock absorbers, thesprings, the upper and lower control arms and other components and can provide real and reliable experimental data for design and fatigue service life analysis of a multi-link axle housing assembly, thereby reducing the development cycle of the multi-link axle housing assembly, saving cost, etc.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

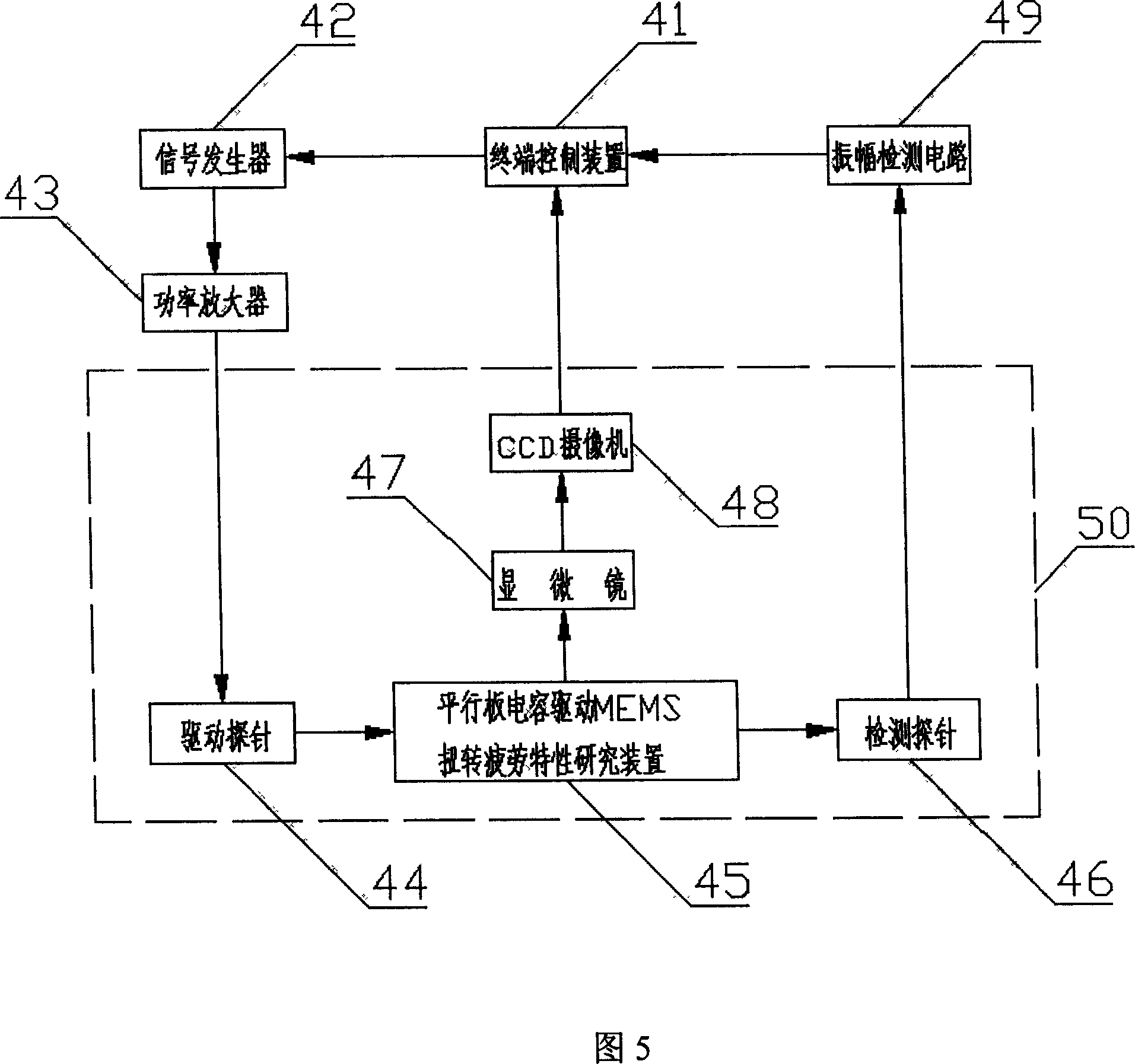

Endurance testing apparatus of micro-structure crankle driven by parallel plate capacitance

InactiveCN1963444ATo overcome the shortcomings of only horizontal driveOvercoming Vertical Electrostatic DriveStructural/machines measurementMaterial strength using steady torsional forcesMicro structureParallel plate

This invention relates to one parallel board capacitor drive micro structure fatigue test device, which comprises three electrodes, wherein, the drive one connected to alternating current to form parallel board drive tank through electrode bottom electrode layer and first hanging board to realize hanging board vertical drive; electrode bottom layer and second hanging parallel board form parallel capacitor sensor to get test distance changes between hanging board and bottom electrode; the third electrode is connected to earth.

Owner:BEIJING UNIV OF TECH

Endurance testing of a content processing device

A content processing device is configured to selectively receive a media signal from a media signal provider. A distribution device is configured to selectively receive a media signal from the content processing device, and to selectively provide one or more command signals to the content processing device. A computer is configured to selectively receive the media signal from the distribution device, and to selectively provide commands to the distribution device. The distribution device is further configured to provide the received one or more commands to the content processing device via the one or more command signals.

Owner:VERIZON PATENT & LICENSING INC

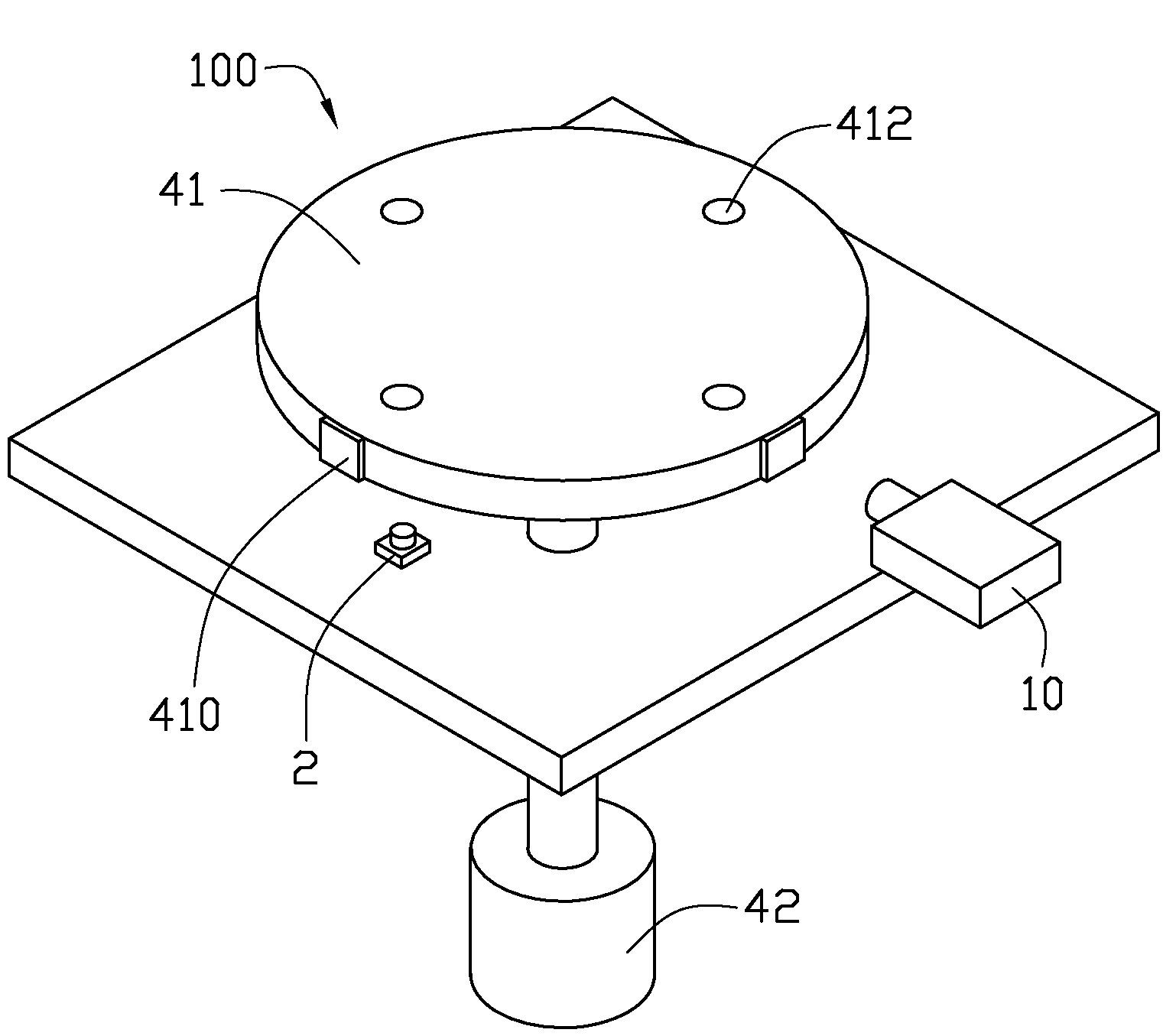

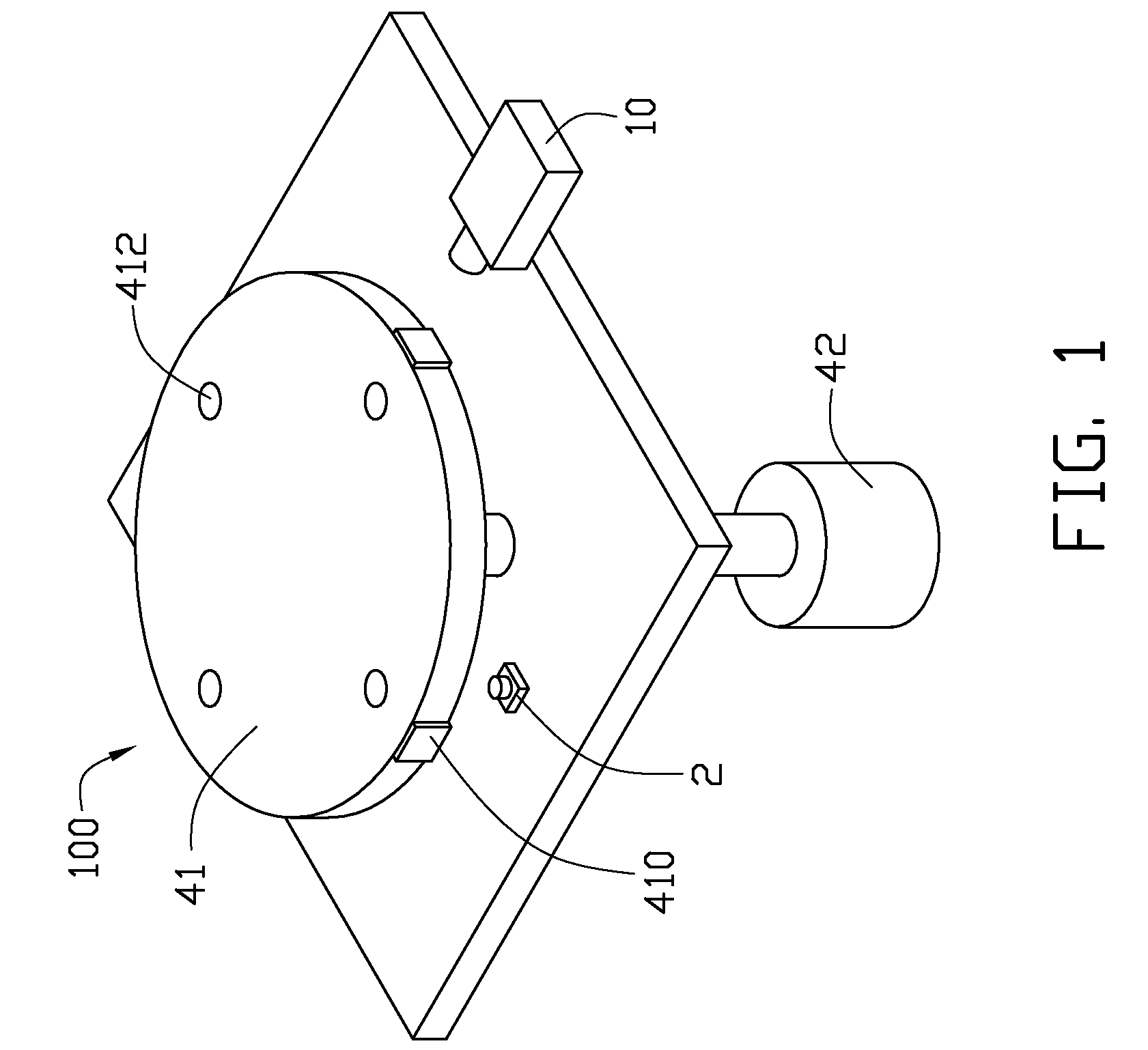

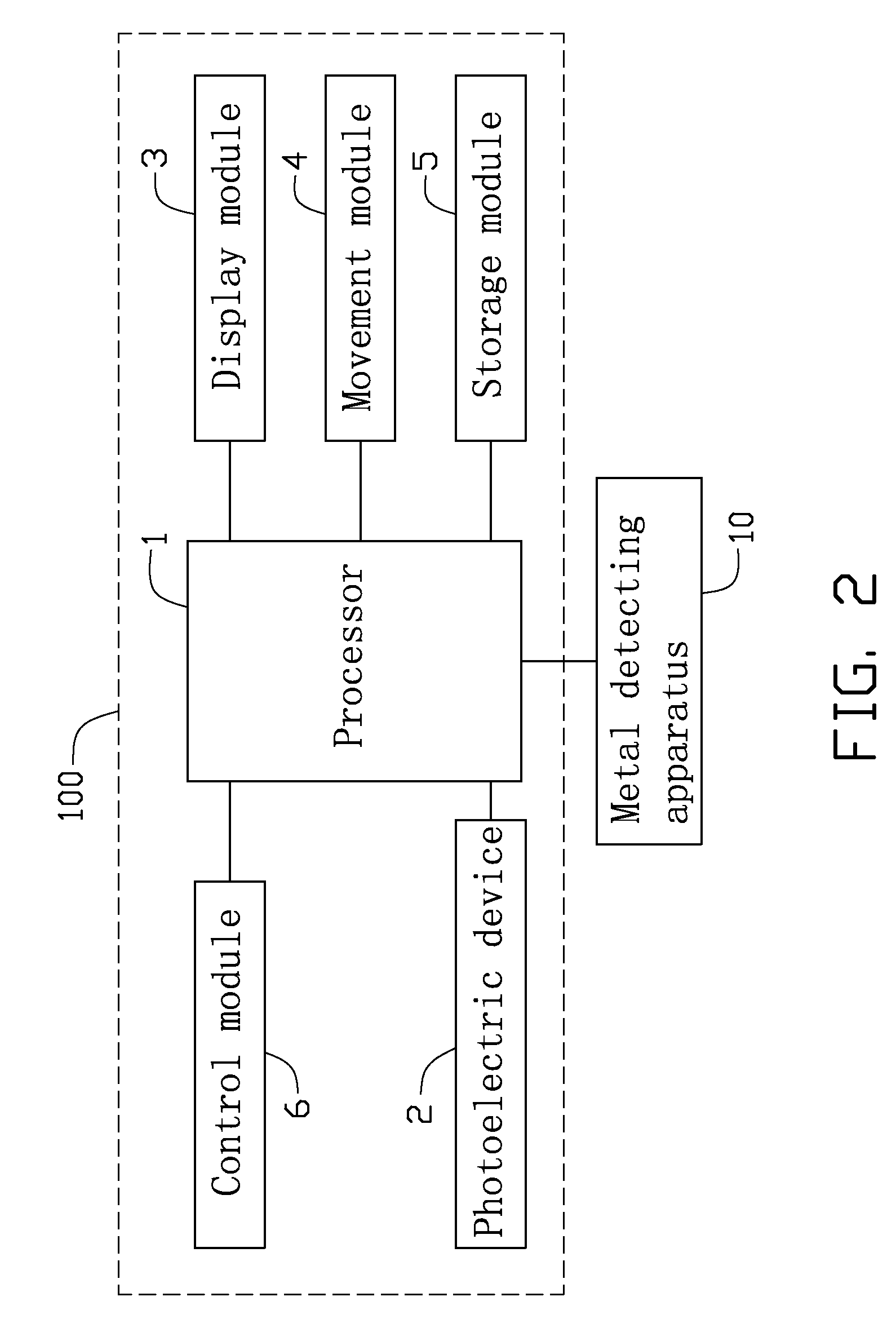

Endurance testing system and method

An endurance testing system is configured to test endurance of a first detecting apparatus. The endurance testing system includes a second detecting apparatus, a movement module, a processor, and a storage module. The movement module includes a first inductive object and a second inductive object. The processor is connected to the first and second detecting apparatuses, and the movement module, for controlling the movement module and counting a first number of times the first detecting apparatus detects the first inductive object, and a second number of times the second detecting apparatus detects the second inductive object. The storage module is connected to the processor, for storing the first and second numbers of times from the processor. The first detecting apparatus fails the testing upon the condition that the first number of times is not equal to the second number of times.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

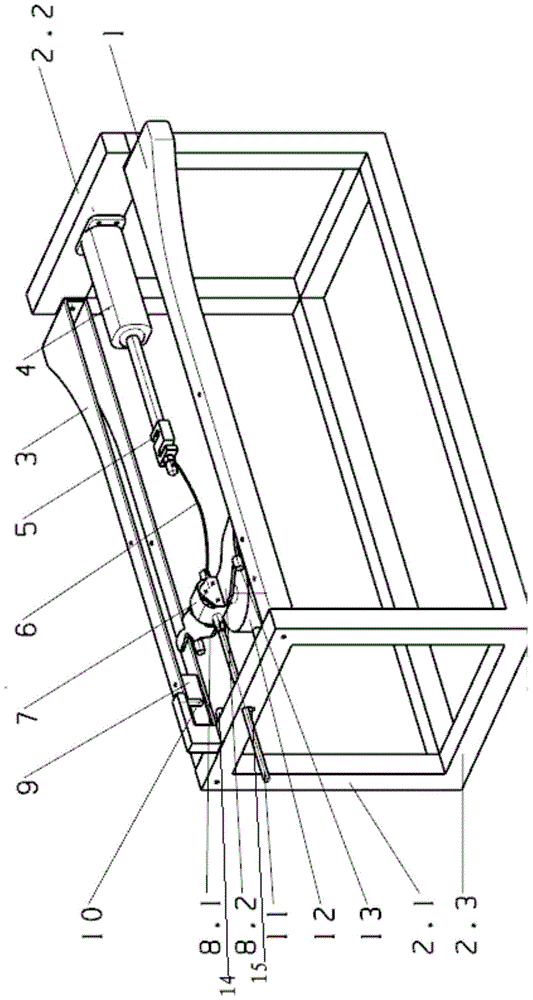

Endurance testing device of automobile sliding door traveling wheel arms and locking combining pieces

The invention provides an endurance testing device of automobile sliding door traveling wheel arms and locking combining pieces. The endurance testing device of the automobile sliding door traveling wheel arms and the locking combining pieces comprises a left guiding rail and a right guiding rail, wherein the left guiding rail and the right guiding rail are horizontally and symmetrically fixed to a table frame and are mutually parallel to each other. The left traveling wheel arm and the right traveling wheel arm are symmetrically arranged at the two ends of a connecting rod and are connected with the left guiding rail and the right guiding rail respectively in a sliding mode; one end of an actuator is fixedly connected with the center of the table frame, the other end of the actuator is connected with a force sensor, a connecting rope and a guiding rod in sequence, the actuator is coaxially arranged with the connecting rod, and a heavy article is hung below the connecting rod; the left guiding rail and the right guiding rail are respectively provided with one locking combining piece and the left traveling wheel arm and the right traveling wheel arm are respectively provided with locking rubber matched with a locking block; a photosensitive sensor senses whether the locking rubber reaches the position where the locking rubber is in contact with each locking block or not. The endurance test device of the automobile sliding door traveling wheel arms and the locking combining pieces is simple in structure, can simulate the actual motion condition when a sliding door is in actual operation, avoids the situation that the whole sliding door serves as a tested object, and the durability and the reliability of the locking combining pieces and the traveling wheel arms can be rapidly verified.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Endurance testing device for sliding door positioner

InactiveCN104677642ASimple structureEasy maintenanceVehicle testingMachine part testingActuatorForce sensor

The invention provides an endurance testing device for a sliding door positioner. The endurance testing device comprises a test car, an actuator support, an actuator, the positioner, a force sensor, a clamping device and a sliding door, wherein the test car is provided with a sliding rail; the sliding door is provided with a traveling wheel arm; the traveling wheel arm is embedded into the sliding rail and can move in the sliding rail; the positioner is arranged on one end of the sliding rail; the actuator is arranged on the actuator support; the clamping mechanism and the force sensor is arranged on one end of a cylinder rod of the actuator; the clamping mechanism clamps the sliding door. The endurance testing device provided by the invention has the beneficial effects of simple structure, convenience in installation, adjustment and maintenance, and low cost.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

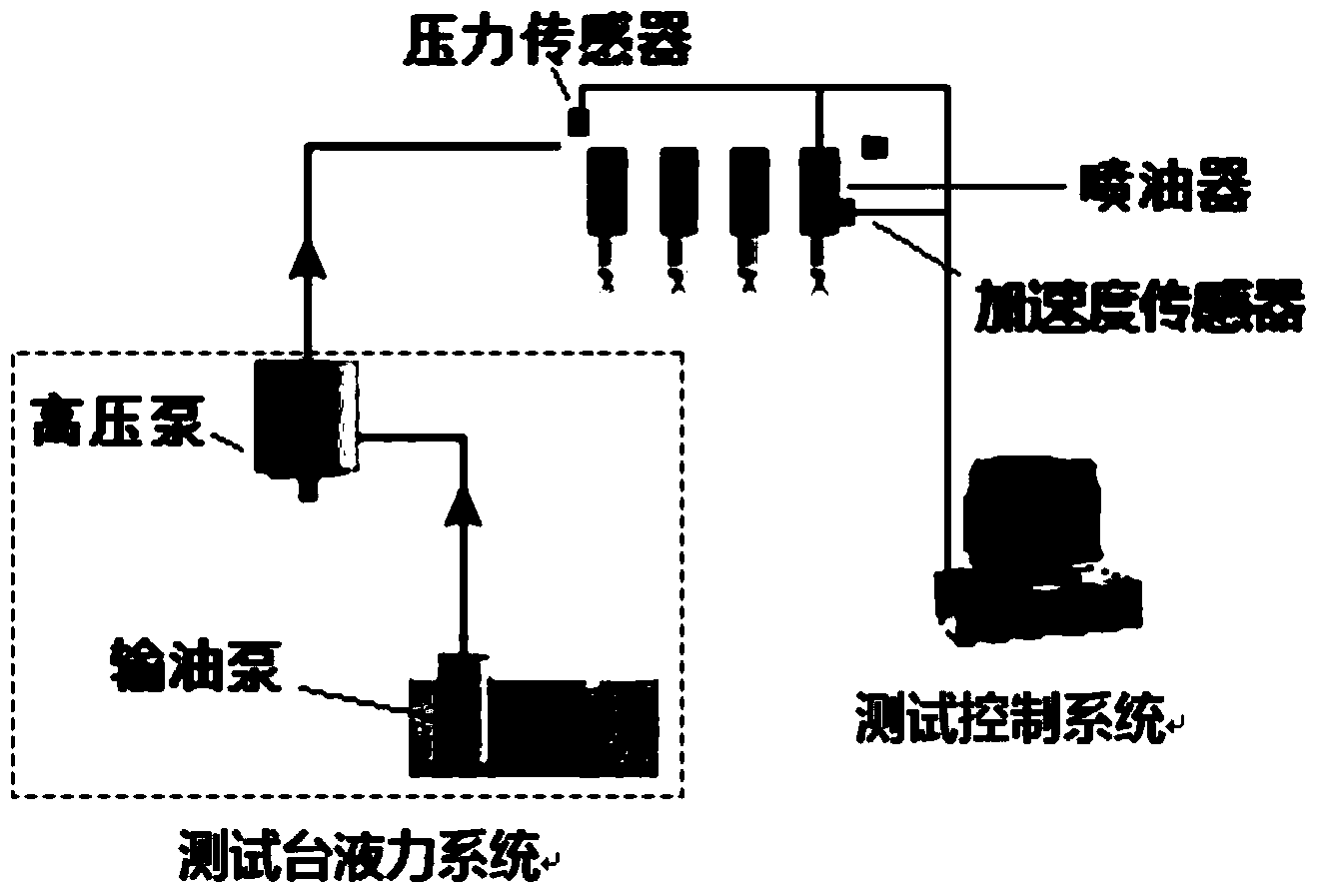

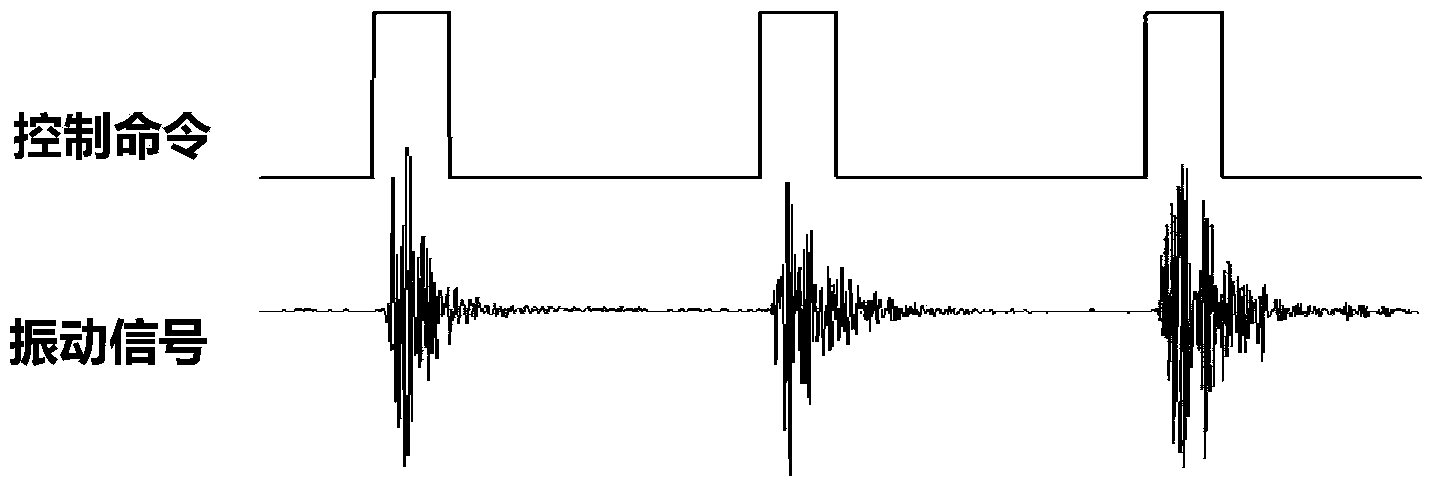

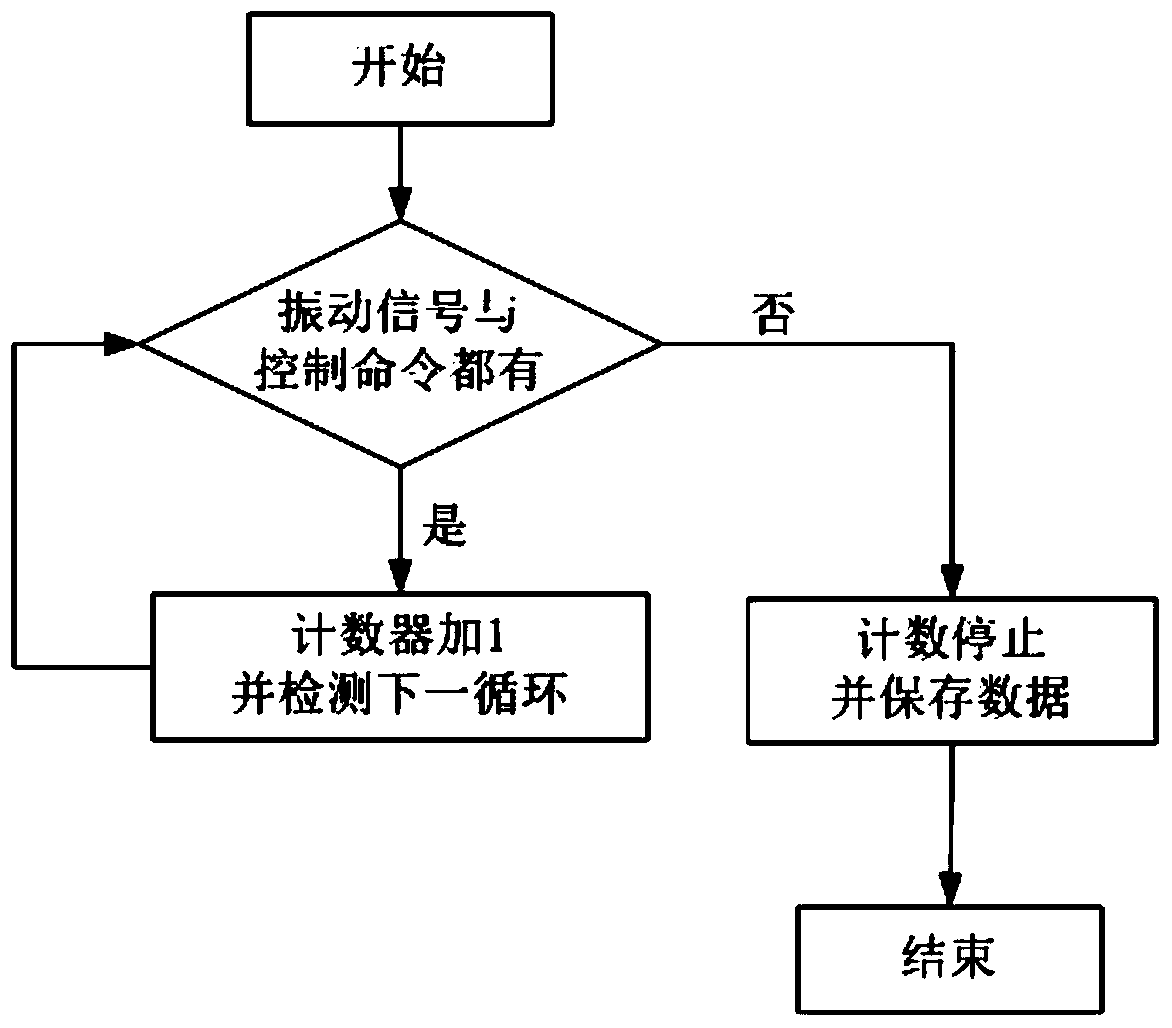

Count method for engine oil atomizer endurance test

InactiveCN103967678AEarly detection of faultsAccurate countEngine testingFuel injection apparatusEngineeringAcceleration Unit

The invention discloses a count method for an engine oil atomizer endurance test. The count method comprises the following steps that an acceleration sensor is arranged on an oil atomizer, the oil atomizer is in rigid connection with the acceleration sensor, vibration signals in the start process of the oil atomizer are sensed by the acceleration sensor and transmitted to a control unit of a test system, and the number of times of the vibration signals is monitored and counted so that the atomization processes of the oil atomizer can be counted. A test method can directly and accurately count the number of times of atomization, measurement is accurate, the method is easy to implement, and operation is easy.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

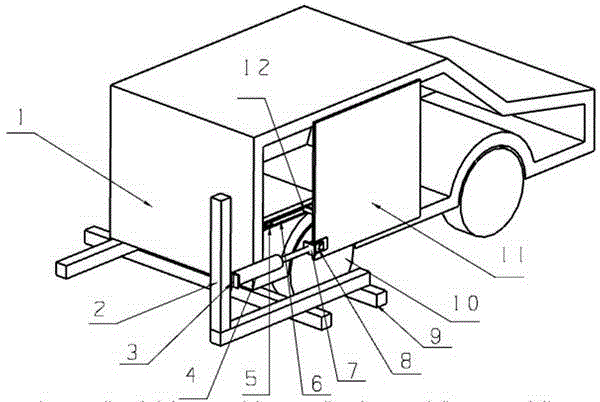

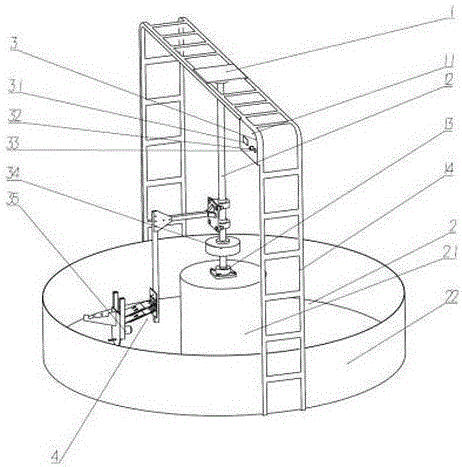

A Mars rover wheel endurance testing stand

The invention discloses a Mars rover wheel endurance testing stand composed of a rack, a soil tank, a control system and a transmission system. The rack is arranged on the soil tank; the control system is fixedly arranged on the upper end of the rack; the upper end of the transmission system is fixedly arranged on the rack; and the lower end of the transmission system is arranged on the soil tank. Before the test, a model wheel is mounted on a motor shaft; the wear test, working time and working energy consumption under different conditions are simulated by changing the angle between the wheel and the soil tank, the load size and the rotating speed to obtain durability test results. The working time and working power consumption are displayed on a display panel in real time, and an endurance test result is obtained. The Mars rover wheel endurance testing stand of the invention is simple to operate, and is safe and reliable. The Mars rover wheel endurance testing stand can examine the durability of a Mars rover wheel under different road conditions, realizes an effect of multiple test conditions, increases test diversity and can output data such the test rotary speed, the test time and energy consumption through a data collector so as to facilitate recording.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com