Endurance testing machine for wheel bearing

A hub bearing and durability technology, applied in the field of testing machines, can solve problems such as dynamic adjustment force overshoot, two-way loading force interference, bearing fatigue damage, etc., and achieve the goal of solving dynamic adjustment force overshoot, rapid adjustment, and accurate test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

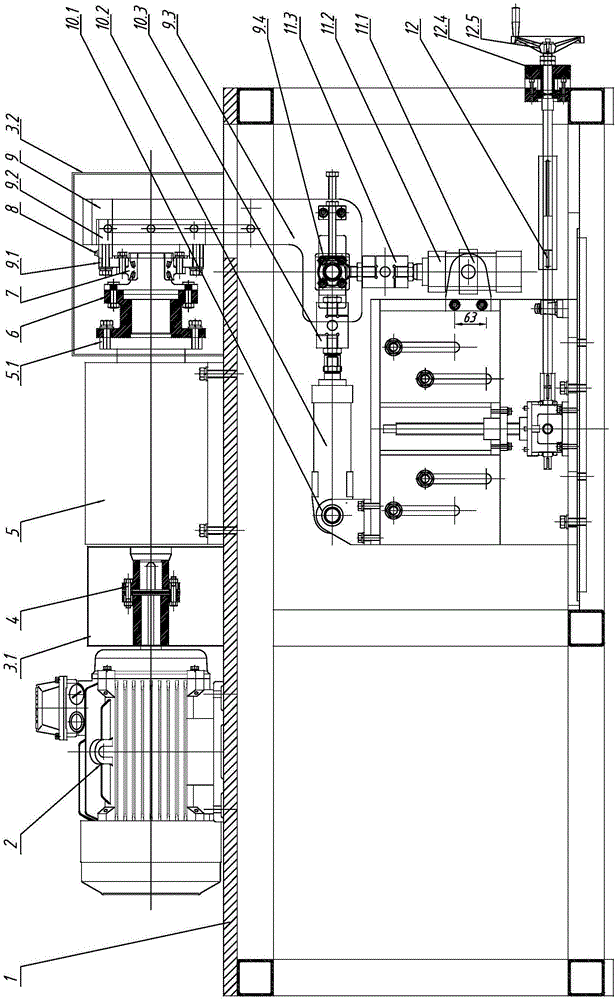

[0020] Such as Figure 1 to Figure 6 As shown, the hub bearing durability testing machine provided by the invention consists of two parts, the mechanical part and the electrical system.

[0021] The mechanical part is composed of a working platform 1, a drive system, a hydraulic loading system, a hydraulic central station and a protection system, etc.

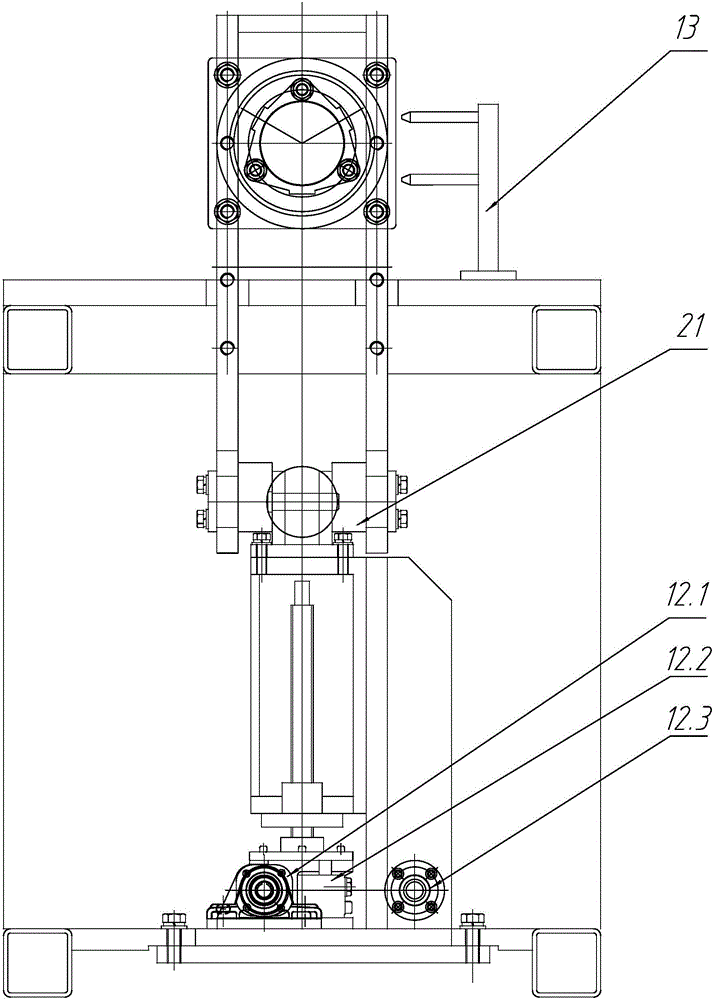

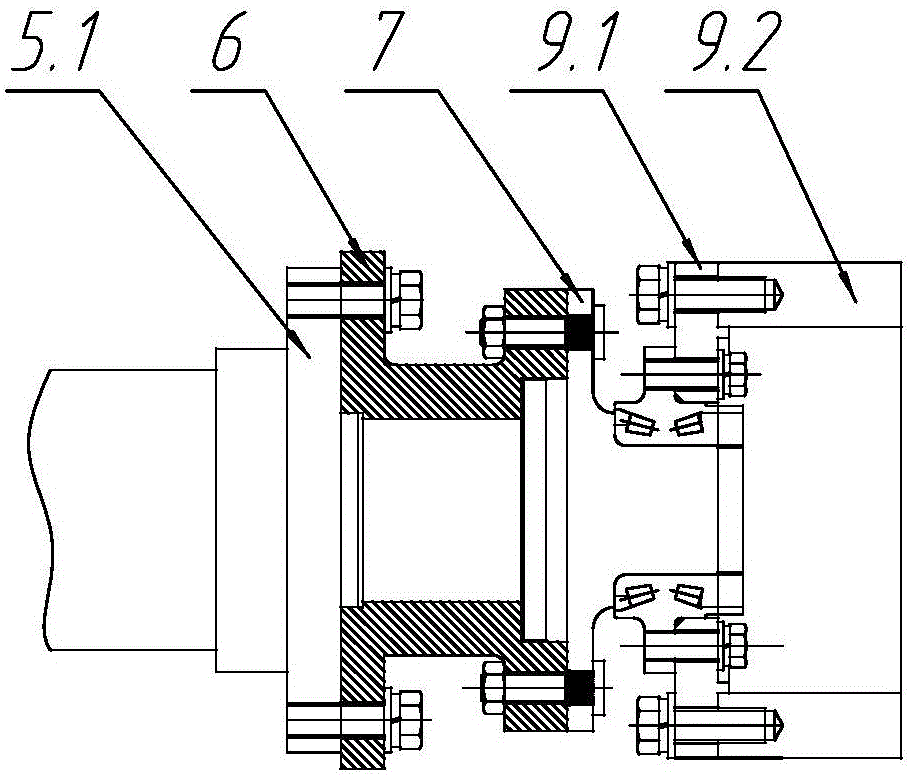

[0022] Depend on figure 1 As shown, the driving system includes an AC frequency converter, a variable frequency speed regulating motor 2, a coupling 4, and a main shaft bearing seat 5; the hydraulic loading system includes an L-shaped loading device 9, an axial loading mechanism 10, a radial loading mechanism 11, and a loading The device position adjustment mechanism 12 forms.

[0023] The L-shaped loading device 9 is used to connect the test piece 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com