Adjustable-assembly parameter endurance testing device for electromagnetic relay

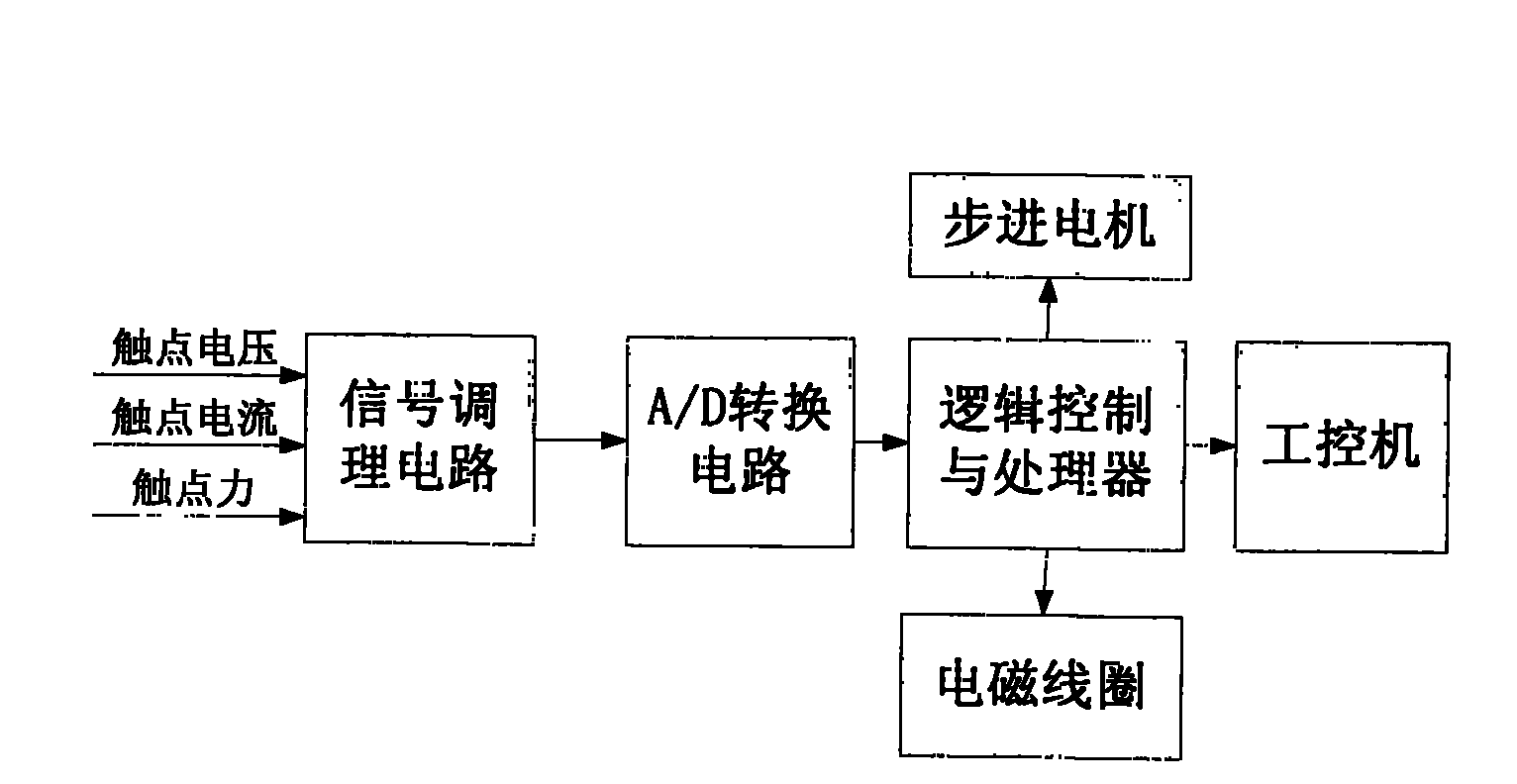

A technology of electromagnetic relay and life test, applied in circuit breaker test and other directions, can solve the problems of studying the influence of electromagnetic suction and mechanical reaction force on electrical life, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

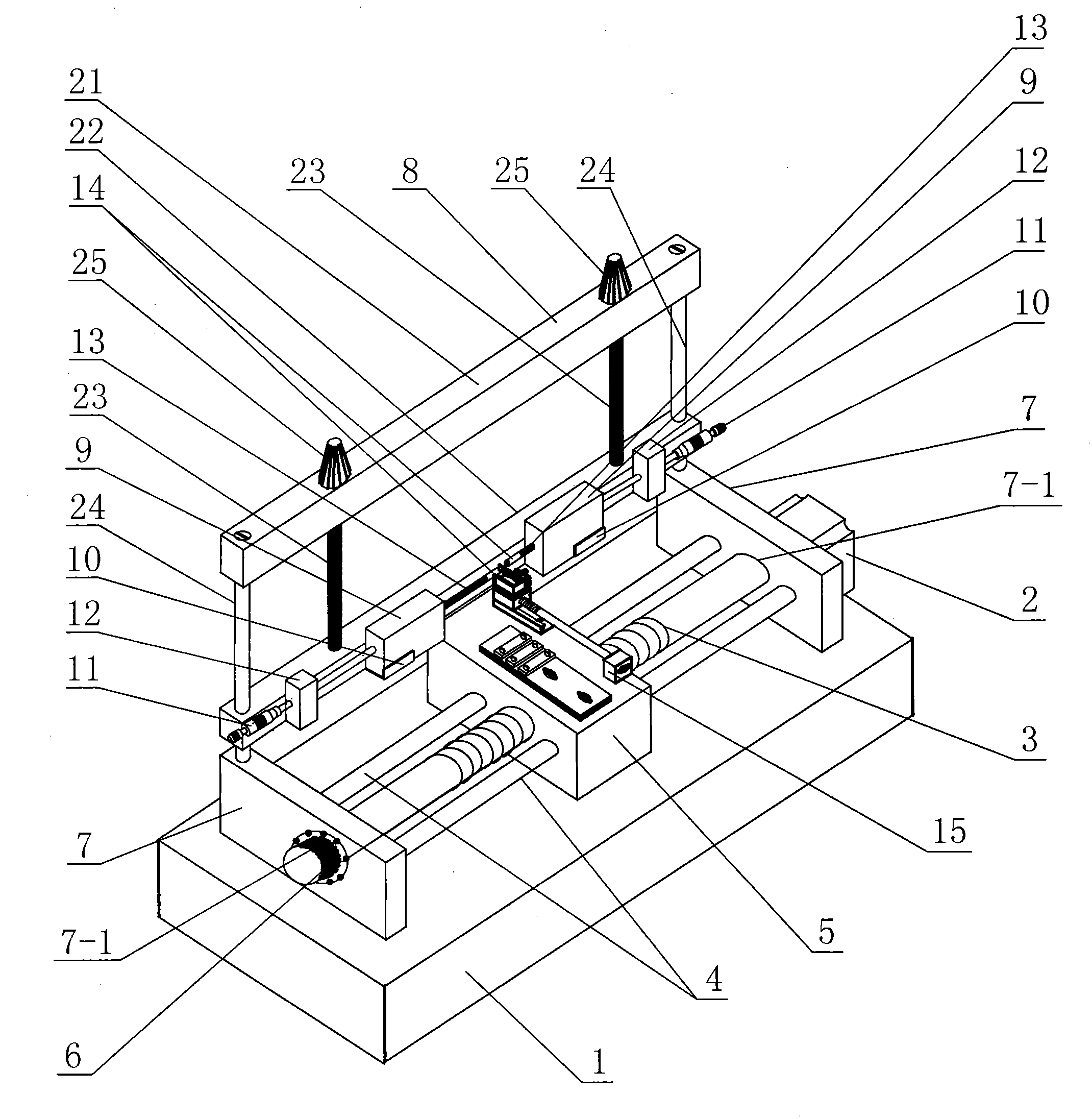

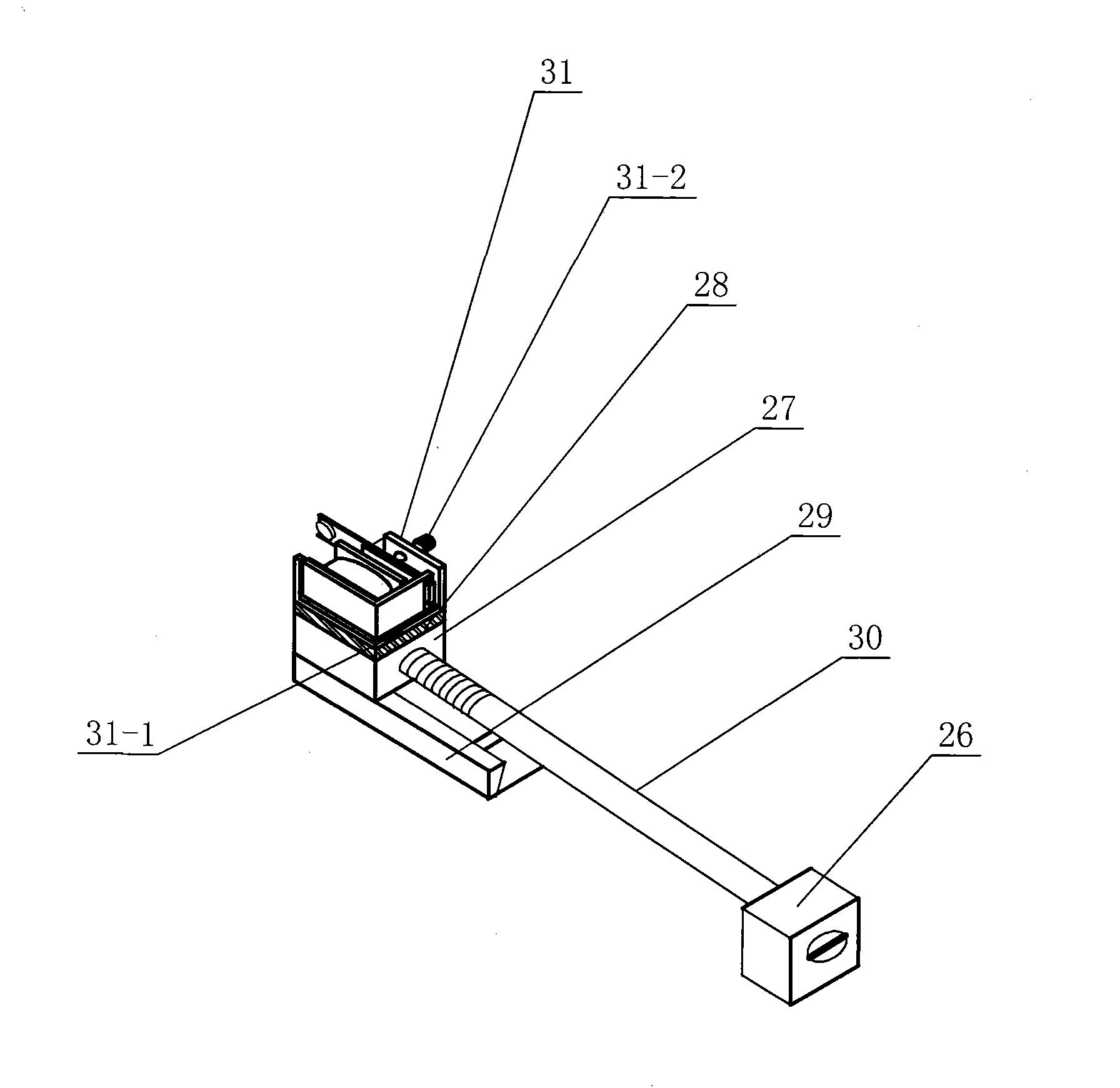

[0007] Specific implementation mode one: as Figure 1~2 As shown, the electromagnetic relay life test device with adjustable assembly parameters in this embodiment consists of a base plate 1, a stepping motor 2, a first lead screw 3, two horizontal guide rails 4, an adjustment block 5, an adjustment knob 6, and two vertical plates 7. Vertical adjustment device 8, two pressure sensors 9, two sensor brackets 10, two differential devices 11, two fixed blocks 12, two insulating rods 13, two static contacts 14 and moving contacts The adjustment device 15 is composed of the two vertical plates 7 that are relatively parallel and fixed on the upper end surface of the bottom plate 1, and the two vertical plates 7 are correspondingly opened with first through holes 7-1, and the first lead screw The two ends of 3 are correspondingly worn in the first through holes 7-1 of the two vertical plates 7 and are connected with the two vertical plates 7 in rotation. The adjustment knob 6 is insta...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 As shown, the vertical direction adjustment device 8 in this embodiment is composed of a first crossbeam 21, a second crossbeam 22, two second lead screws 23 and two vertical guide rails 24, and the two vertical guide rails 24 The upper ends are affixed to the two ends of the first crossbeam 21 respectively, and the lower ends of the two vertical guide rails 24 pass through the second crossbeam 22 and are affixed to the upper end faces of the corresponding vertical plates 7. The lower ends of the lead screws 23 pass through the first beam 21 and are screwed to the second beam 22 . With such a design, the heights of the two static contacts 14 on the vertical adjustment device 8 can be adjusted. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 As shown, the vertical adjustment device 8 in this embodiment further includes two adjustment handles 25 , and one adjustment handle 25 is provided on the upper end of each second lead screw 23 . With such a design, the second lead screw 23 can be rotated conveniently. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com