Coatings rolling contact fatigue tester

A rolling contact fatigue and testing machine technology, which is applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of insufficient test efficiency and achieve high-efficiency testing, convenient operation, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

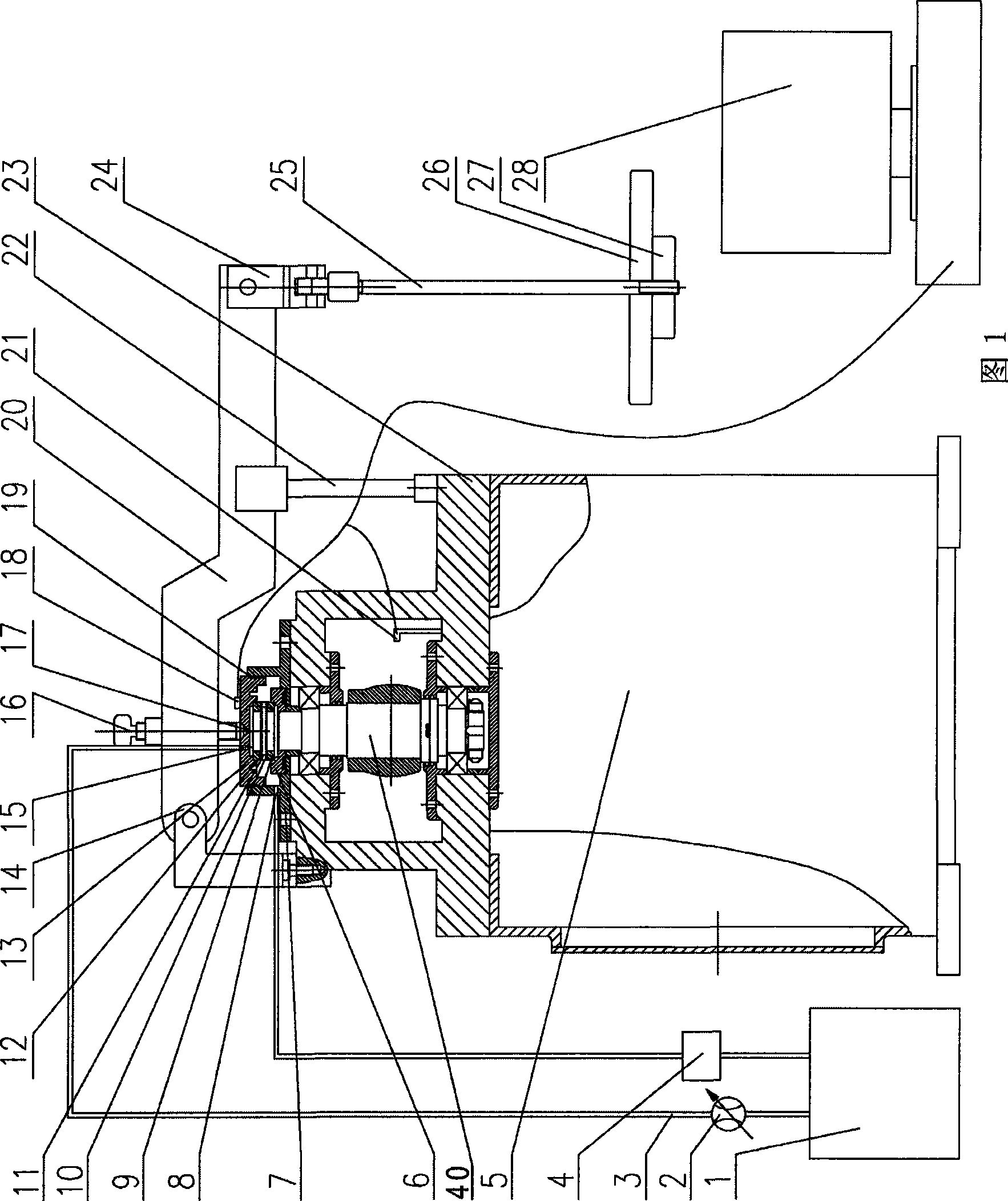

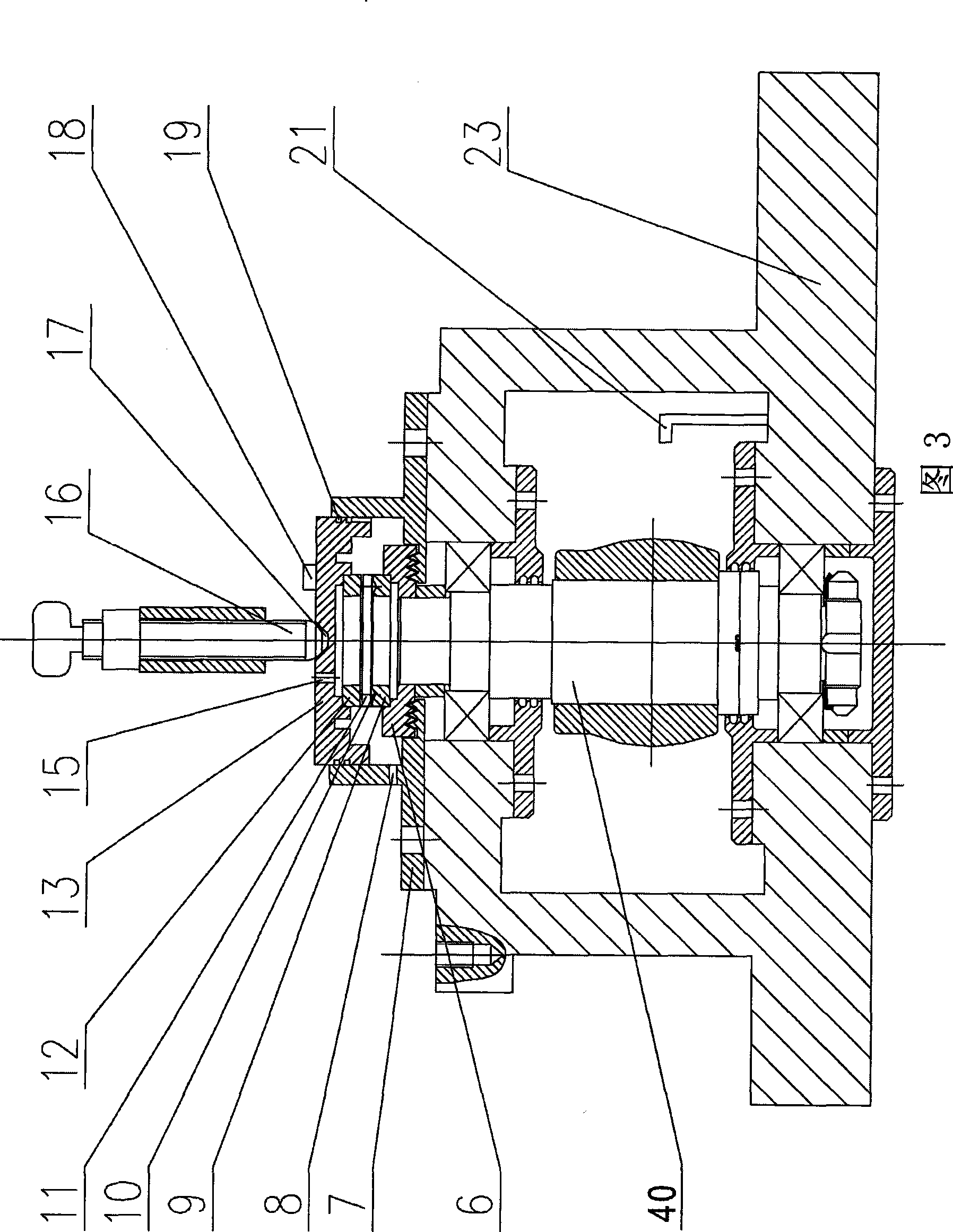

[0021] As shown in Figures 1-3, the coating rolling contact fatigue testing machine of the present invention includes a base 23 fixed on the frame 5, a transmission mechanism installed on the base 23, a test device, a loading mechanism, a lubrication system, and information collection and control systems, of which:

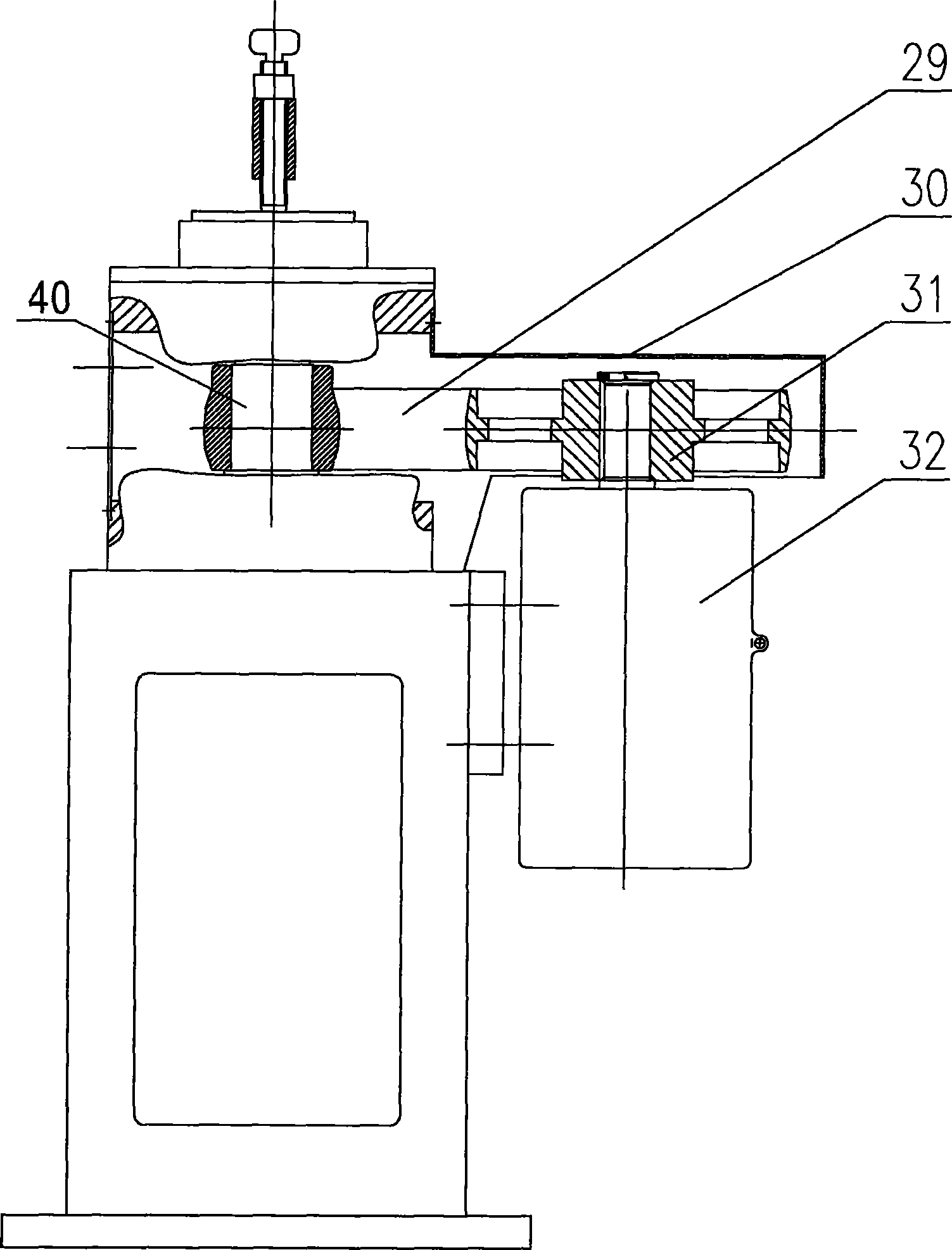

[0022] The transmission mechanism includes a motor 32 and a transmission shaft 40. In this embodiment, the motor 32 is a variable frequency motor. The motor 32 is installed on one side of the base 23, and the transmission shaft 40 is installed on the base 23. A belt 29 connects the large pulley 31 on one side of the motor 32 and the transmission shaft 40, so that the rotation of the motor 32 can drive the transmission shaft 40 to rotate.

[0023] The test device is installed on the transmission shaft 40 above the base 23, and includes a test chamber 7, in which a lower flat washer placement frame 6, a lower flat washer 9, a cage 11, an upper flat washer are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com