Vehicle door lock endurance test bench and its testing method

A technology of durability test and test method, applied in the direction of machine/structural component test, measuring device, instrument, etc., to achieve high economic benefit, good versatility, and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

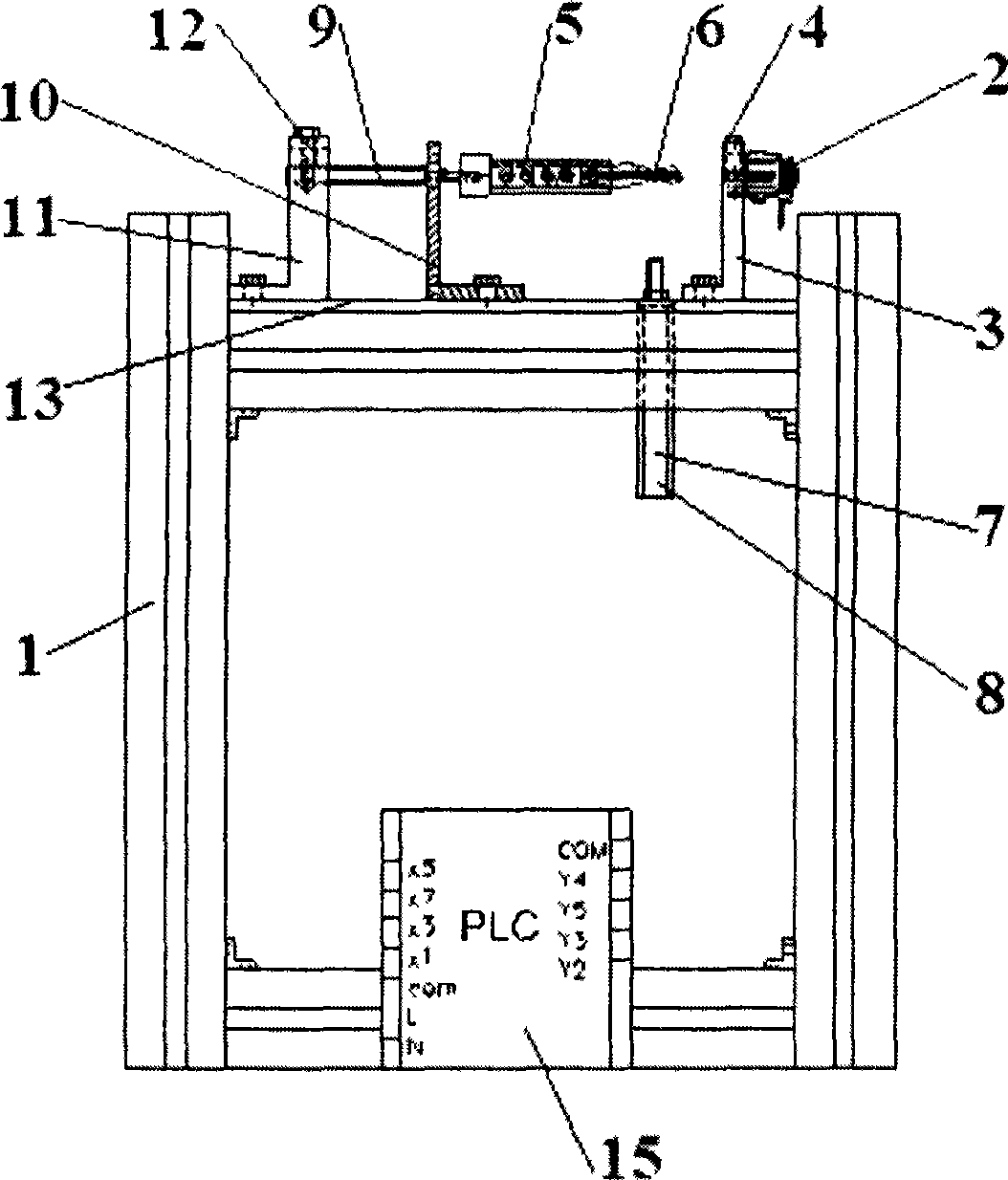

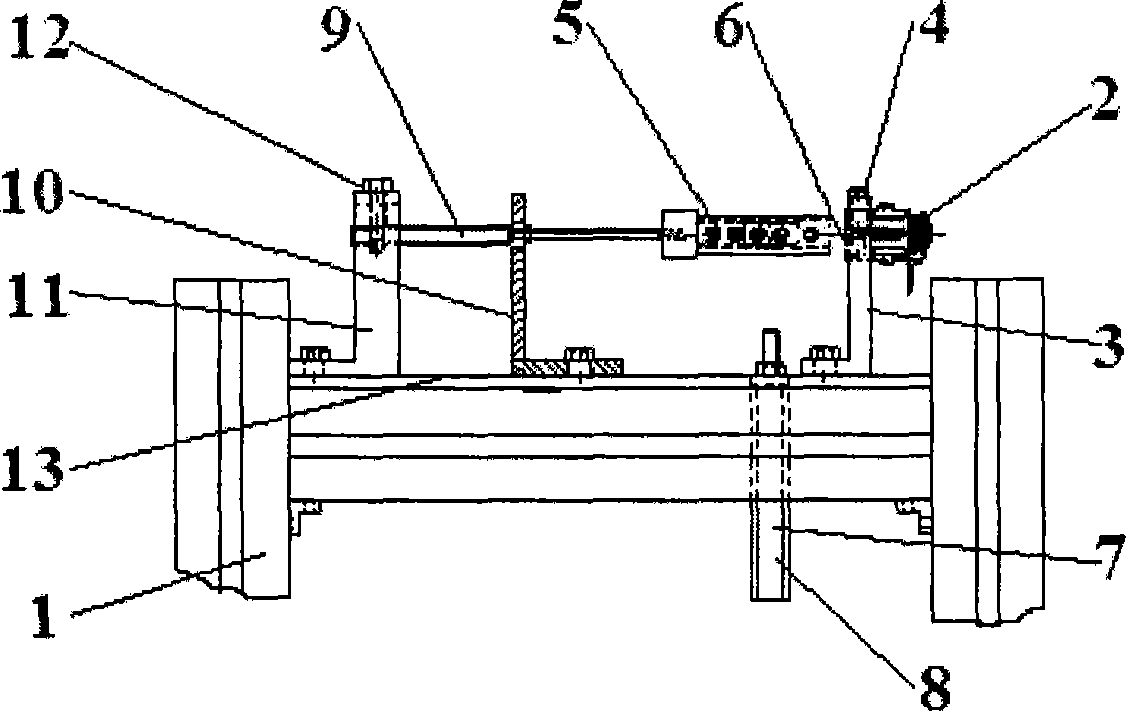

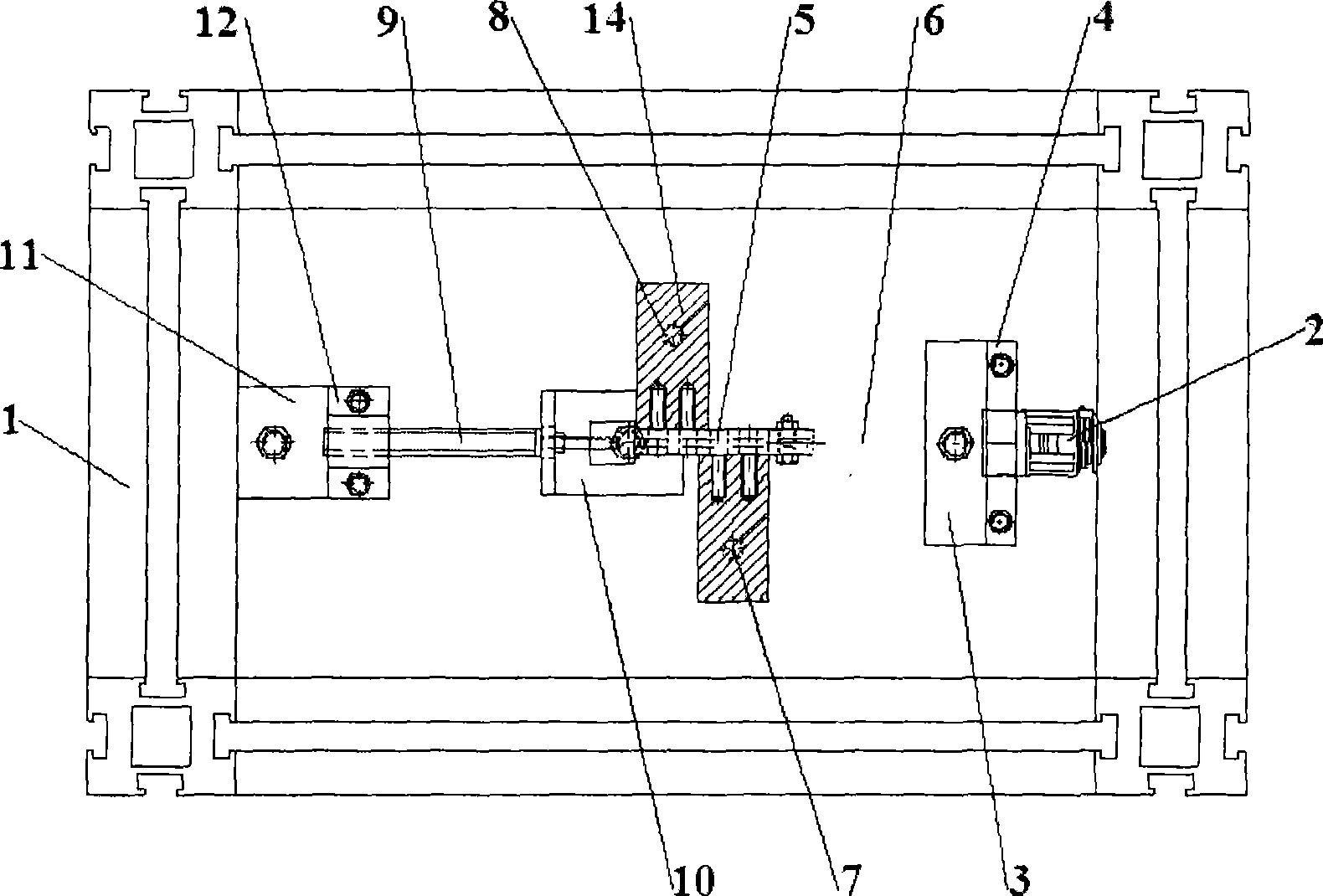

[0036] The key advance and retreat cylinder 9 of the present invention is fixed on the test bench body 1 through the cylinder front end fixing seat 10 and the cylinder rear end fixing seat 11 .

[0037] The key advance and retreat cylinder 9 is fixed on the cylinder rear end fixed seat 11 by the cylinder clamp block 12 . Cylinder front end fixed seat 10, cylinder rear end fixed seat 11 and lock cylinder fixed seat 3 and key rotary cylinder 7 and key rotary cylinder 8 are all fixed by test bench backing plate 13. And the test bench backing plate 13 is horizontally fixed on the test bench body 1 . The test bench backing plate 13 is a steel piece, which can withstand greater force than the aluminum alloy test bench body 1 .

Embodiment 2

[0039] The electrical control part of the durability test bench of the present invention is controlled by a PLC controller 15 . The actuator of the entire test bench adopts PLC programming technology, which can flexibly compile different programs to meet the test requirements stipulated by different standards. Finally, the purpose of controlling the movement of the cylinder 7, the cylinder 8 and the cylinder 9 is achieved, so that it can test the durability of the automobile door lock cylinder.

Embodiment 3

[0041] The key forward and backward cylinder 9 , the key rotary cylinder 7 , and the key rotary cylinder 8 described in the present invention are respectively controlled by solenoid valves, and the solenoid valves are controlled by the PLC controller 15 .

[0042] The solenoid valve is controlled by the PLC controller 15, and the solenoid valve respectively controls the key rotation cylinder 7, the key rotation cylinder 8 and the key advance and retreat cylinder 9 to realize the insertion of the key and the rotation of the key with the lock cylinder, and finally achieve the purpose of locking the car door. Core 2 was tested for durability performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com