Endurance testing device of automobile sliding door traveling wheel arms and locking combining pieces

A technology of durability test and wheel arm, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems of high cost, many influencing factors, and lack of pertinence, so as to speed up technology development Cycle time, saving development costs, and highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

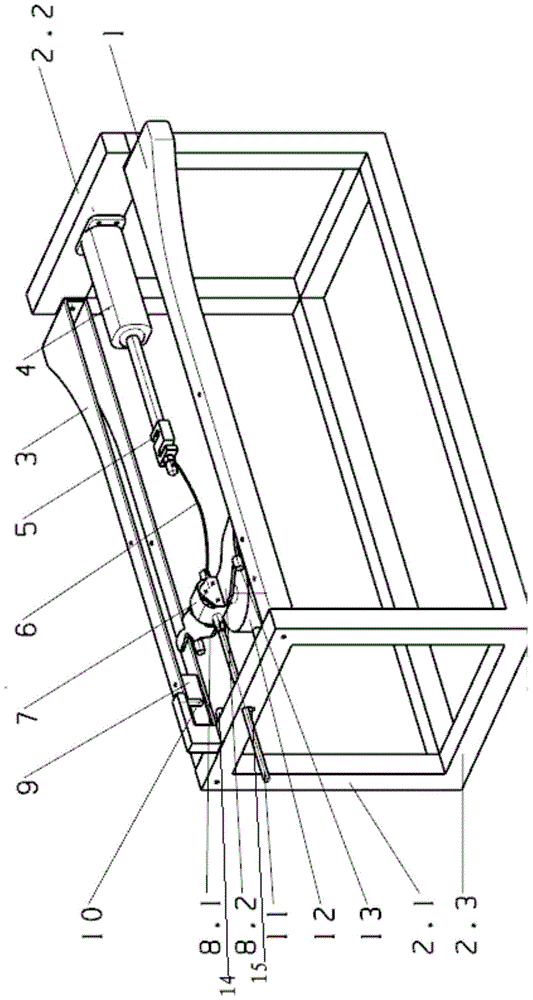

[0023] Such as figure 1 The shown durability test device for a wheel arm and a stop assembly of an automobile sliding door of the present invention includes a stand 2, and the stand includes a front frame 2.1, a rear frame 2.2, and a bottom frame 2.3 vertically arranged and parallel to each other. The two ends of the guide rail 1 are respectively fixedly connected to the bottom of the front frame 2.1 and the rear frame 2.2; the two ends of the left guide rail 3 are respectively fixedly connected to the top of the left end side of the front frame 2.1 and the rear frame 2.2; the two ends of the right guide rail 1 are respectively fixedly connected to the front frame 2.1 and the top of the right end side of the rear frame 2.2; the left guide rail 3 and the right guide rail 1 are horizontally symmetrically arranged and parallel to each other. A guide hole 15 per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com