Count method for engine oil atomizer endurance test

A counting method and fuel injector technology, which can be used in engine testing, machine/structural component testing, engine components, etc., can solve problems such as inaccurate counting, and achieve the effect of accurate counting and accurate measurement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

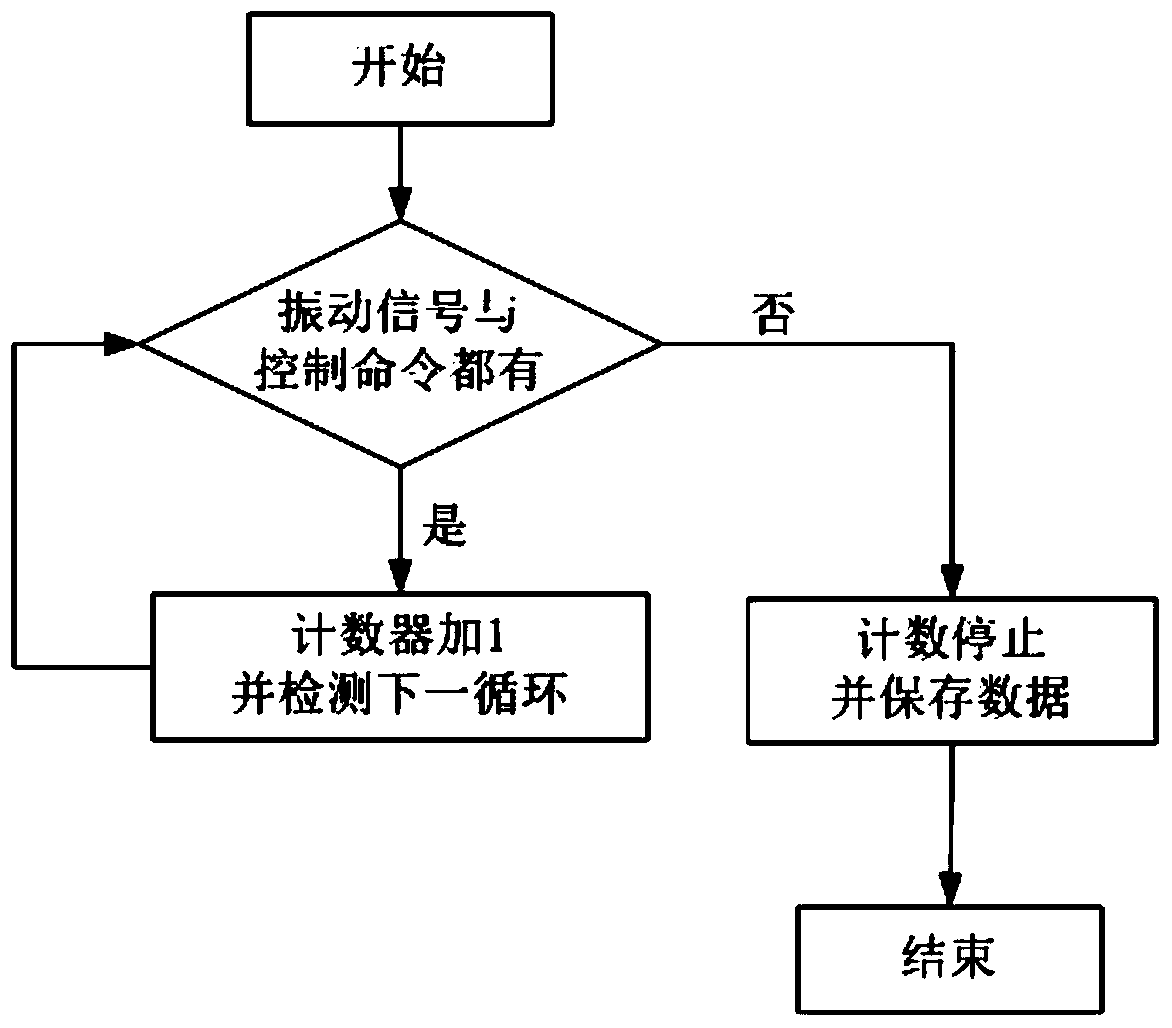

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

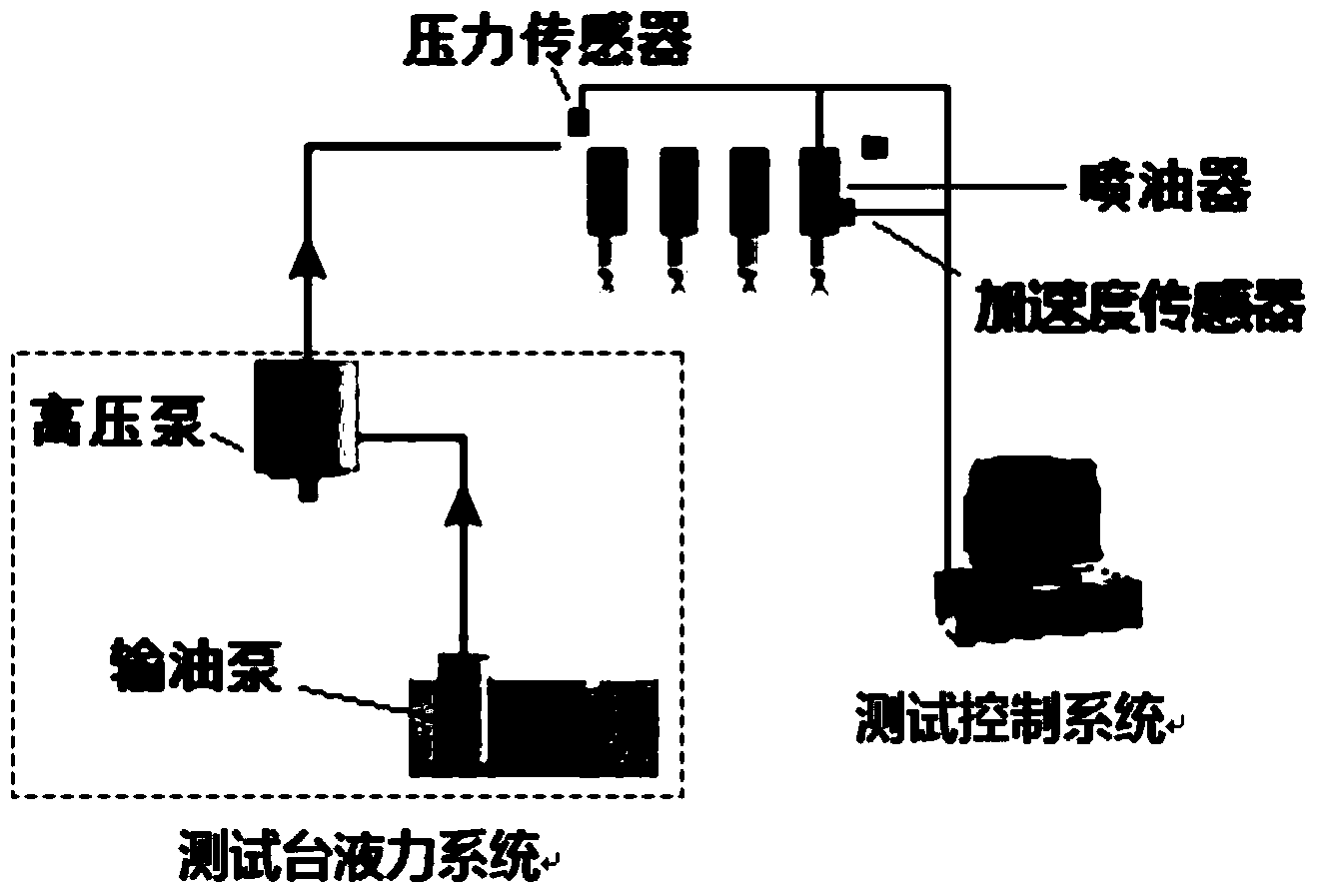

[0016] exist figure 1 In , the system composition of the engine injector durability test of the present invention is given in schematic form, including: the tested injector, the hydraulic system of the test bench, the acceleration sensor and the test control system, etc. During actual operation, an acceleration sensor is arranged on each injector to be tested. The acceleration sensor is rigidly fixed on the fuel injector or a fixture rigidly connected with the fuel injector.

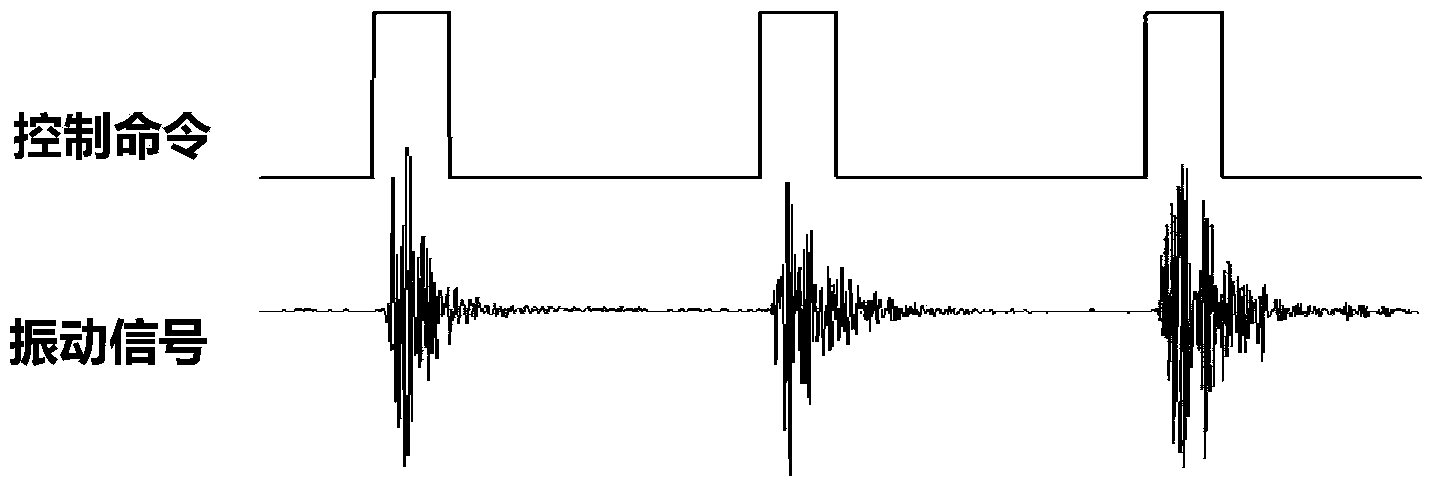

[0017] The hydraulic system of the test bench provides the required test conditions for the tested injector, such as fuel oil, pressure, etc., and ensures the accuracy and stability of the test conditions under the joint action of pressure sensors and a series of actuators. The injector under test executes the injection command under the control of the test control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com