Condition Monitoring System for Radial Bearings of Tubular Hydrogenerator Units

A condition monitoring system and radial bearing technology, applied in the field of monitoring systems, can solve problems such as inability to judge, temperature rise, and serious problems, and achieve the effects of ensuring real-time and synchronization, flexible module combination, and small system size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

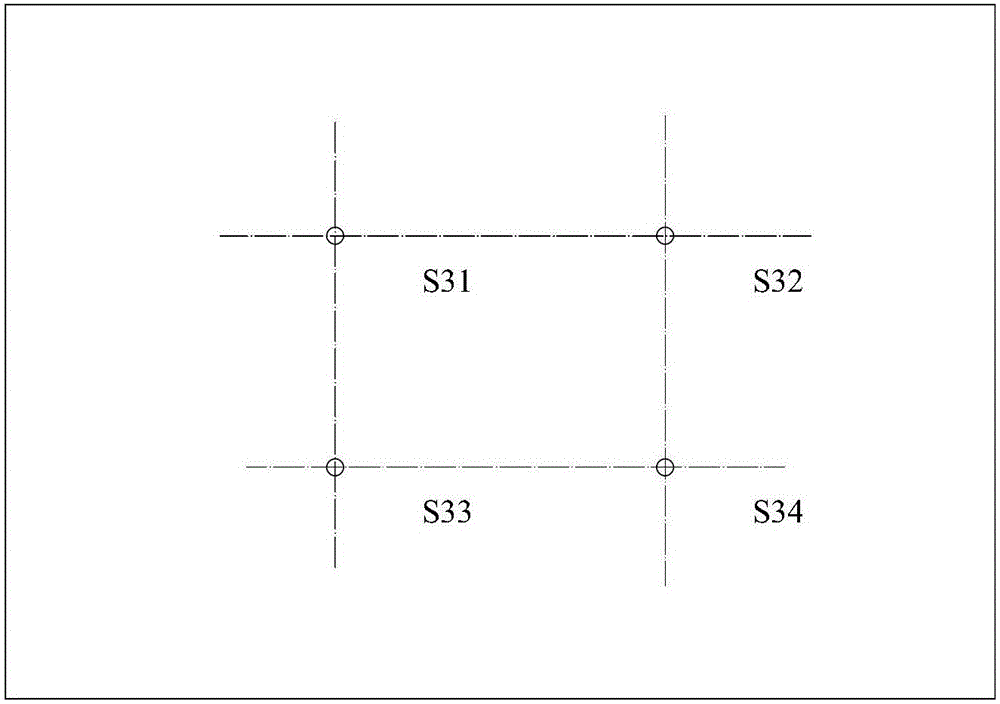

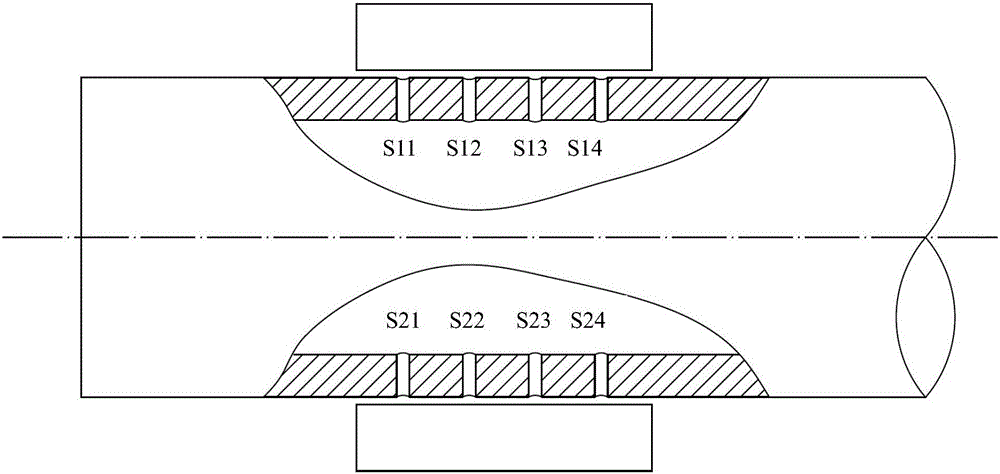

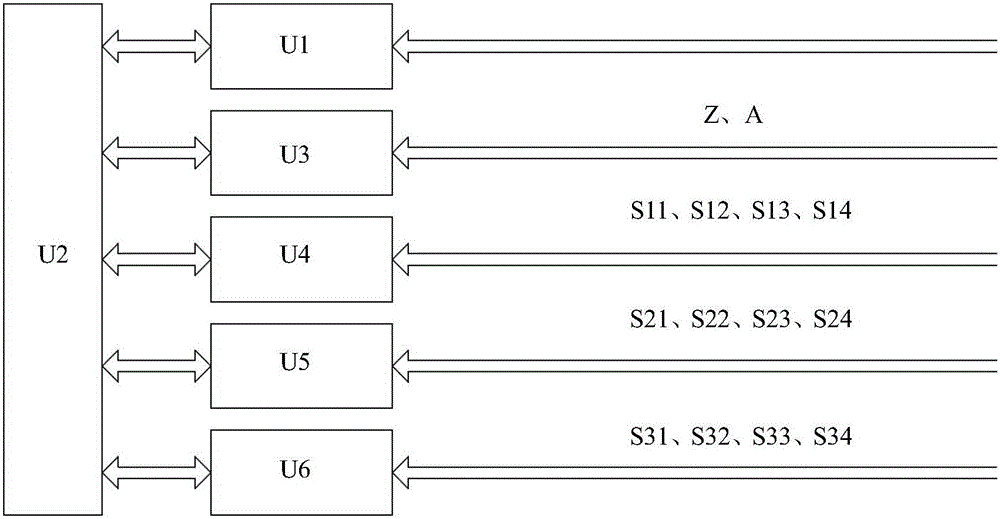

[0015] The oil film temperature sensor is installed on the bearing pad of the radial bearing, and 4 oil film temperature sensors are arranged on each bearing pad, the positions are as follows: figure 1 shown. The oil film pressure sensor is installed on the rotating shaft, and 4 measuring points are evenly distributed along the axial direction within the size range of the contact between the rotating shaft and the bearing bush to ensure that each sensor is within the range of the bearing bush. The oil film thickness sensor is also installed on the rotor, on the circumference of the rotating shaft The direction is distributed axisymmetrically with the oil film pressure sensor, and the layout of these two sensors on the shaft is shown in figure 2 shown. When the rotating shaft rotates once, the oil film pressure sensor and the oil film thickness sensor will sweep each thrust pad respectively, and at the same time, the photoelectric encoder will send a trigger pulse signal at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com