DCT finished vehicle gearshift cycle endurance testing method

A technology of durability test and complete vehicle, applied in the direction of machine gear/transmission mechanism test, etc., can solve problems such as lack of pertinence, inability to simulate shifting conditions, and inability to verify the performance of dual-clutch automatic transmissions in advance, and achieve a short and low verification period. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing:

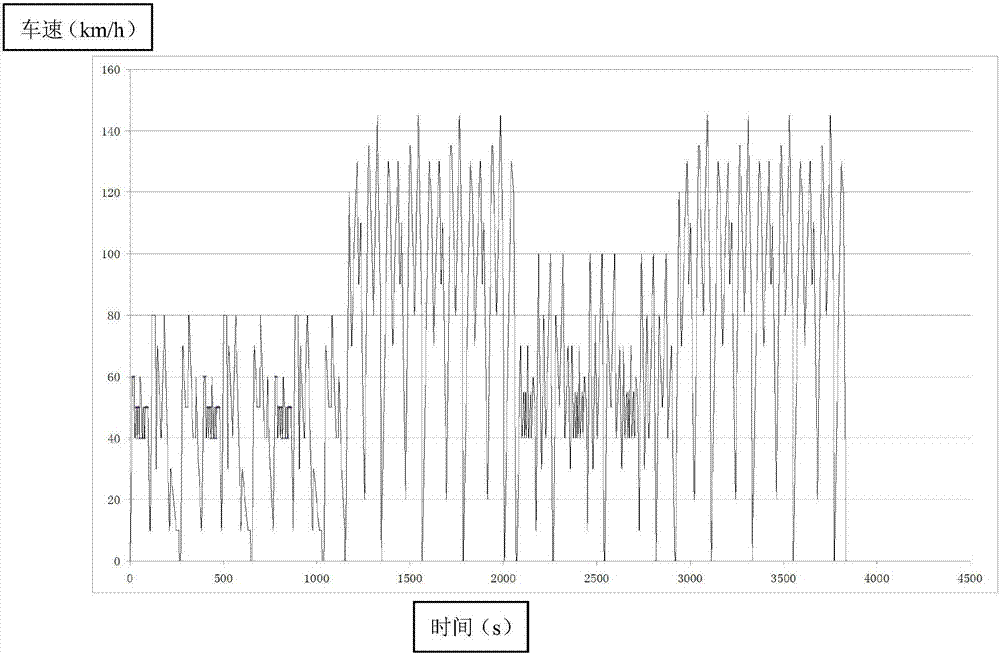

[0014] The DCT vehicle shift cycle durability test procedure is as follows:

[0015] Step 1, Static inspection and dynamic evaluation of the vehicle DCT transmission before the test

[0016] (1) Static inspection: During the static inspection, it is necessary to test and record data such as the controller software version of the DCT transmission of the vehicle, the voltage value of each gear position, and the voltage value of the installation position of the shift fork.

[0017] (2) Dynamic evaluation: Carry out on a flat road, adopt D gear, step on the accelerator to accelerate, so that the test sample car rises to the highest gear, and then release the accelerator to make the test sample car coast by inertia, and the speed changes from high to low, so that the test The sample car is lowered from the highest gear to the first gear in turn, and check whether the transmission is out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com