Fatigue endurance test device and method for a multi-link rear suspension axle housing assembly

A fatigue-durability and testing device technology, applied in measurement devices, vehicle testing, mechanical component testing, etc., can solve the problem of load road spectrum data that cannot directly measure the loading position, and weaken the durability testing of multi-link axle housing assemblies. Influence, weaken the influence and other issues, to achieve the effect of saving test costs, shortening the development cycle, and ensuring no distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

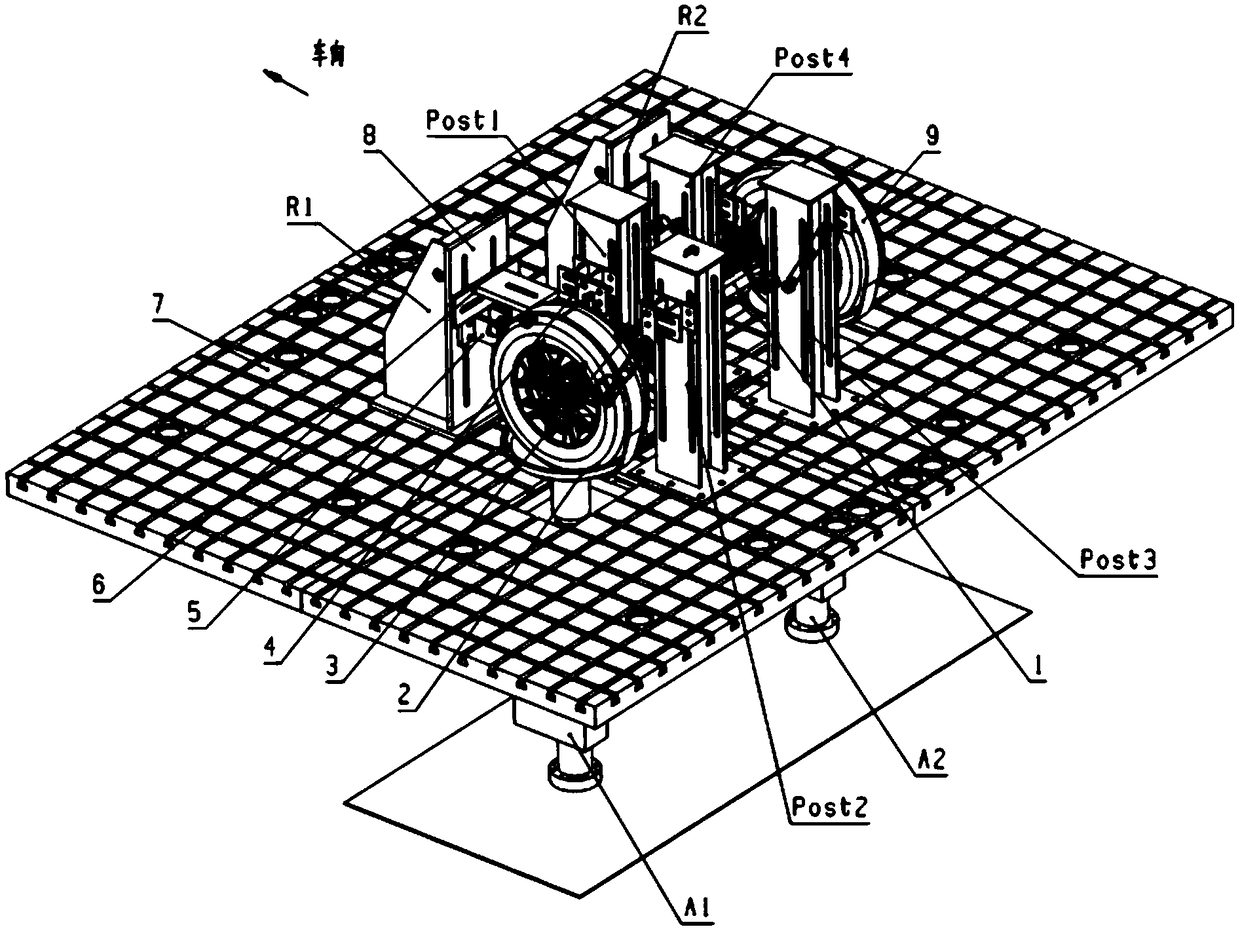

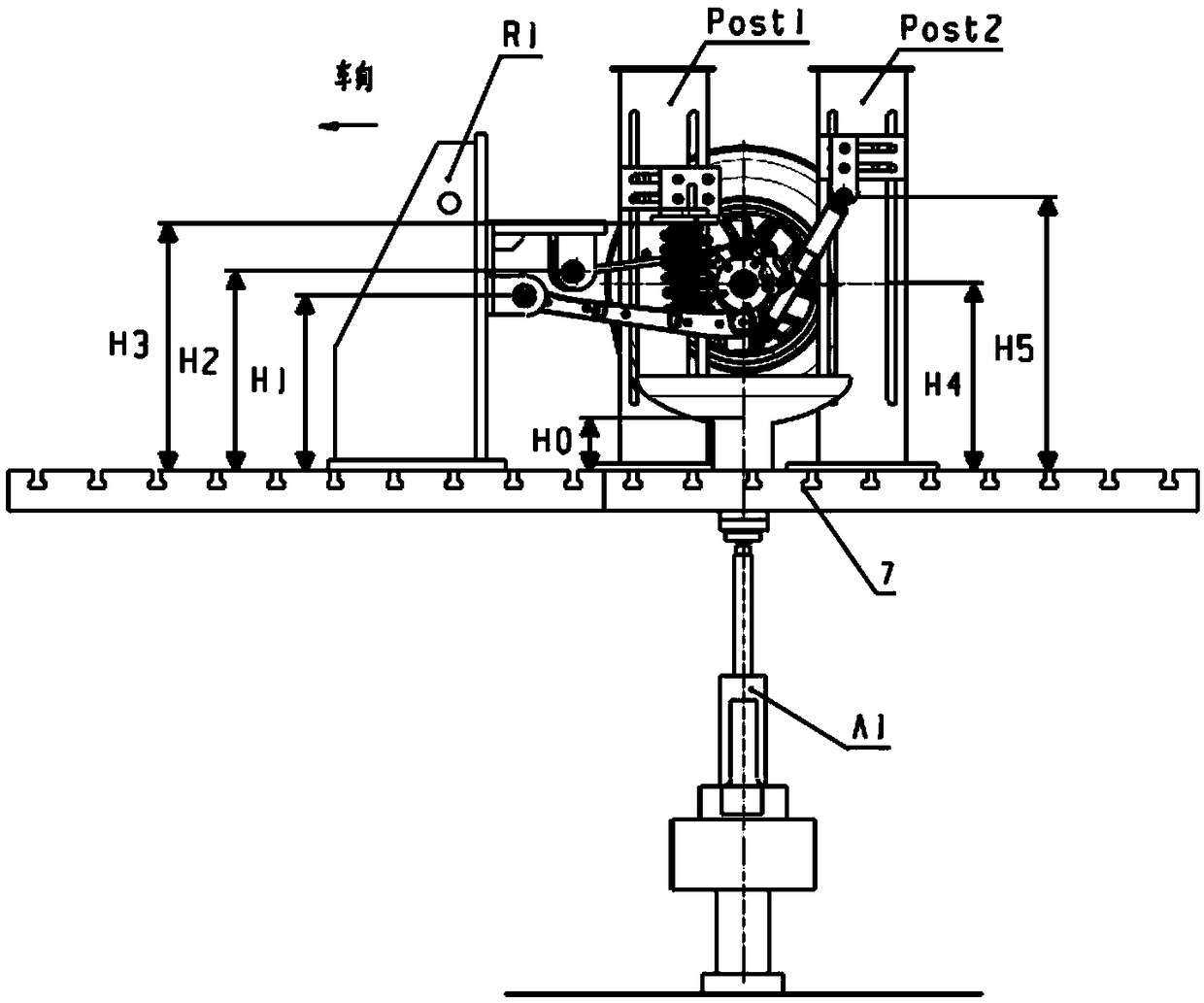

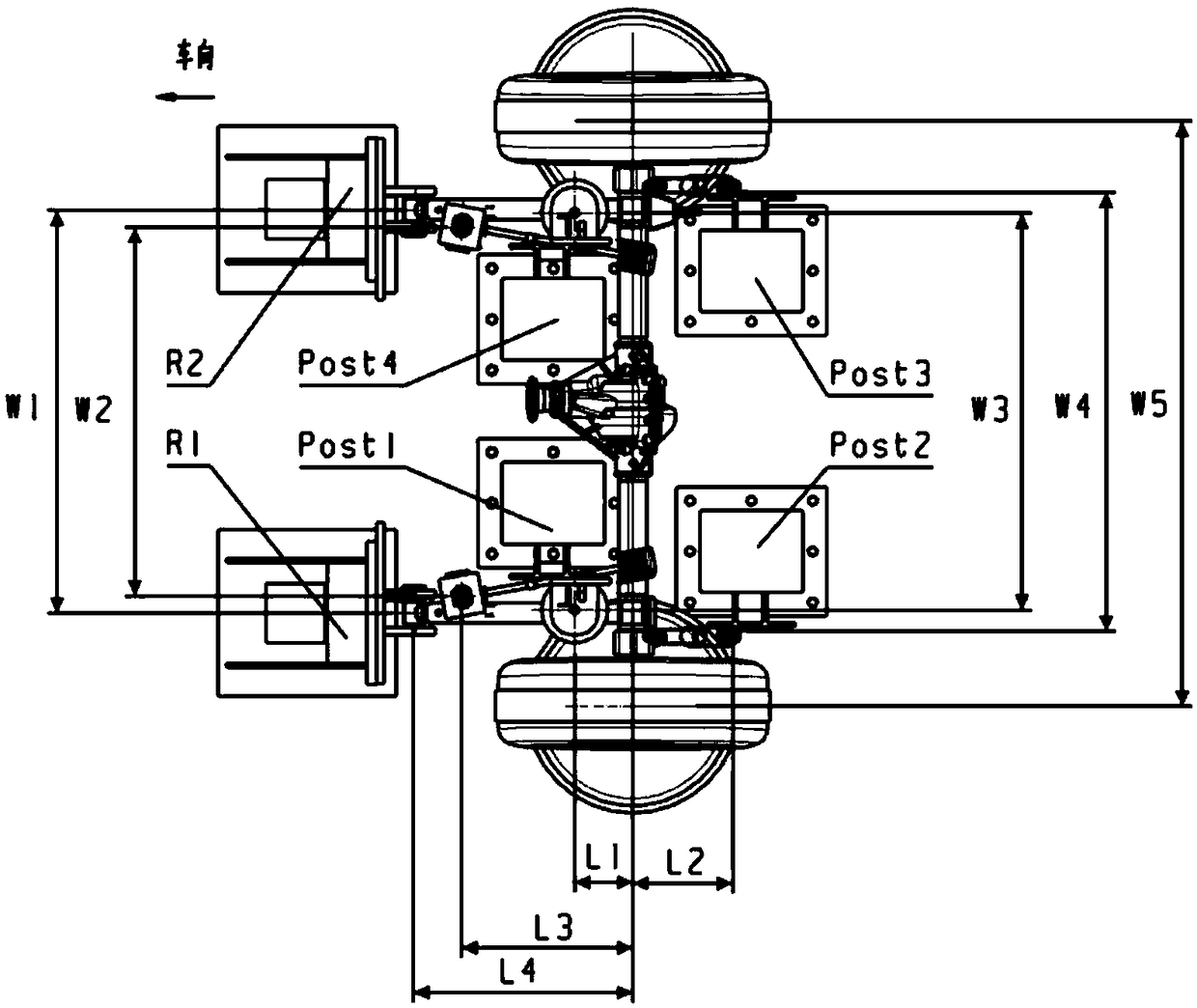

[0058] The invention provides a fatigue durability test device for a multi-link rear suspension axle housing assembly. The structure of the device is as follows figure 1 , figure 2 , image 3 As shown, the fatigue durability test device includes: a multi-link rear suspension assembly 1, an actuating supporting component 2, a shock absorber fixing component 3, a spring fixing component 4, a lower control arm fixing component 5, and an upper control arm fixing Part 6, iron floor 7, horizontal reaction seat 8, belt 9. The tires of the multi-link rear suspension assembly 1 are placed on a pallet and fixed by belts 9. The left and right sets of horizontal reaction seats 8 are fixed on the iron floor 7, and the lower control arm fixing part 5 is fixed on the horizontal reaction seat. 8 The upper and lower control arms are fixed on the lower control arm fixing part 5; the same horizontal reaction seat 8 also fixes the upper control arm fixing part 6, and the upper control arm is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com