Patents

Literature

31results about How to "In line with the actual working status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

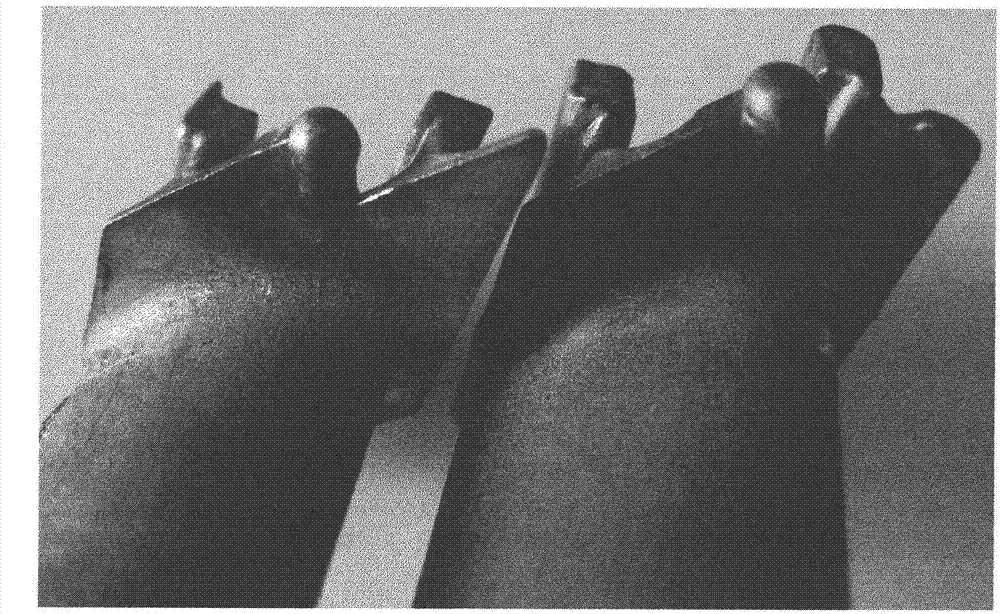

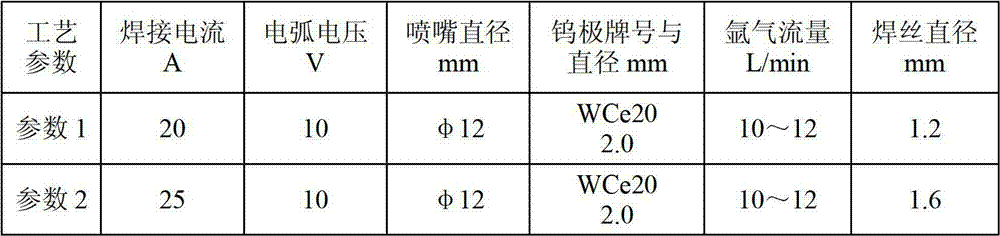

Method for overlaying wear-resistant layer of blade shroud of turbine working blade

InactiveCN102107314APromote maturityExtend working lifeArc welding apparatusPower flowWear resistant

The invention discloses a method for overlaying a wear-resistant layer of a blade shroud of a turbine working blade. In the method, manual tungsten electrode argon arc welding is used, and the specific process parameters meet the requirements that: welding wires are selected from a T800 cobalt-based wear-resistant alloy welding wire which is researched according to a B50TF193 standard of AmericanGeneral Electric Company and an S-6 cobalt-based wear-resistant alloy welding wire which is researched according to an American metal society standard AMS5788; the diameters are phi 1.6mm and phi 1.2mm respectively; a mark and the diameter of a tungsten electrode are WCe20 and phi 2.0mm; the diameter of a nozzle is phi 12mm; welding current is between 20 and 25A; and the flow rate of protective gas is between 10L / min and 12L / min. By the method, the condition of incomplete penetration or over-melting of a Z-shaped gear switching part R is avoided, the problem of overheating of welding is also solved, and the occurrence probability of welding cracks is greatly reduced or avoided. The method completely meets the requirements of the wear-resistant layer in a high-temperature working state after welding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

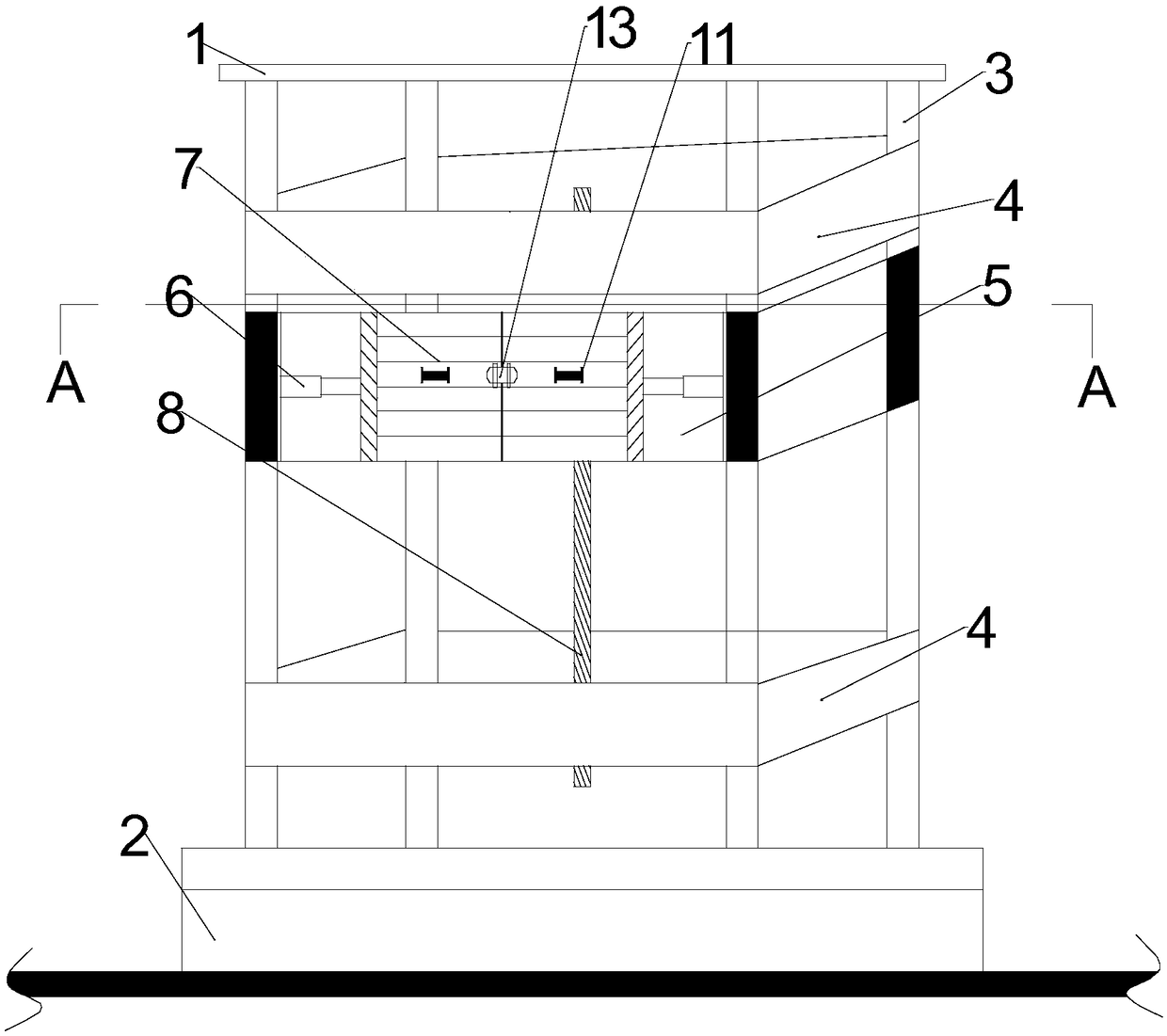

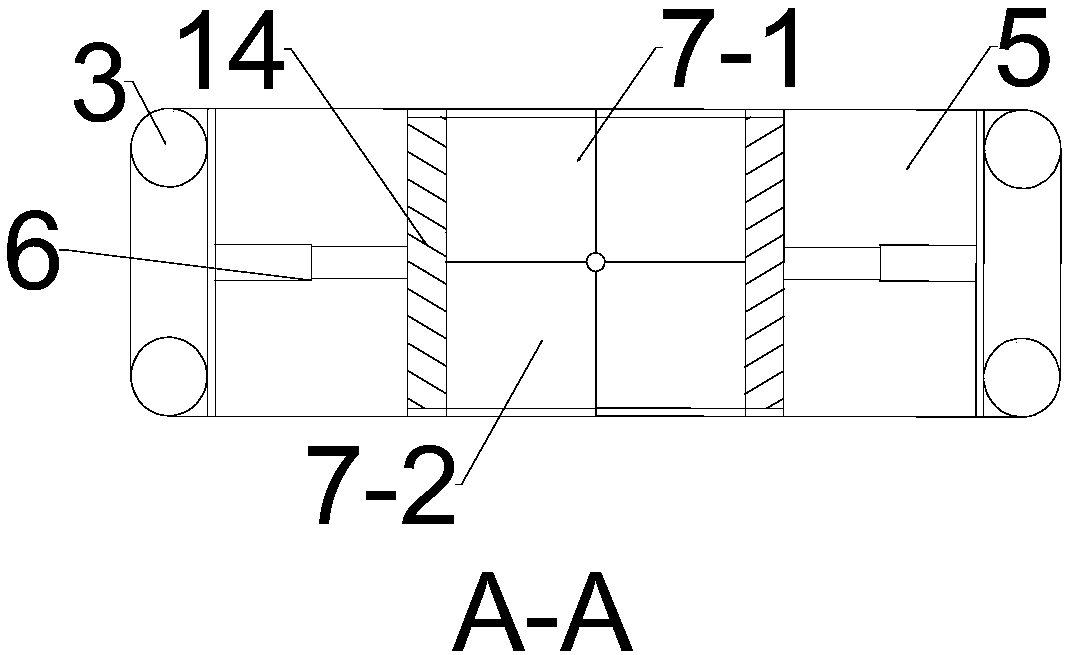

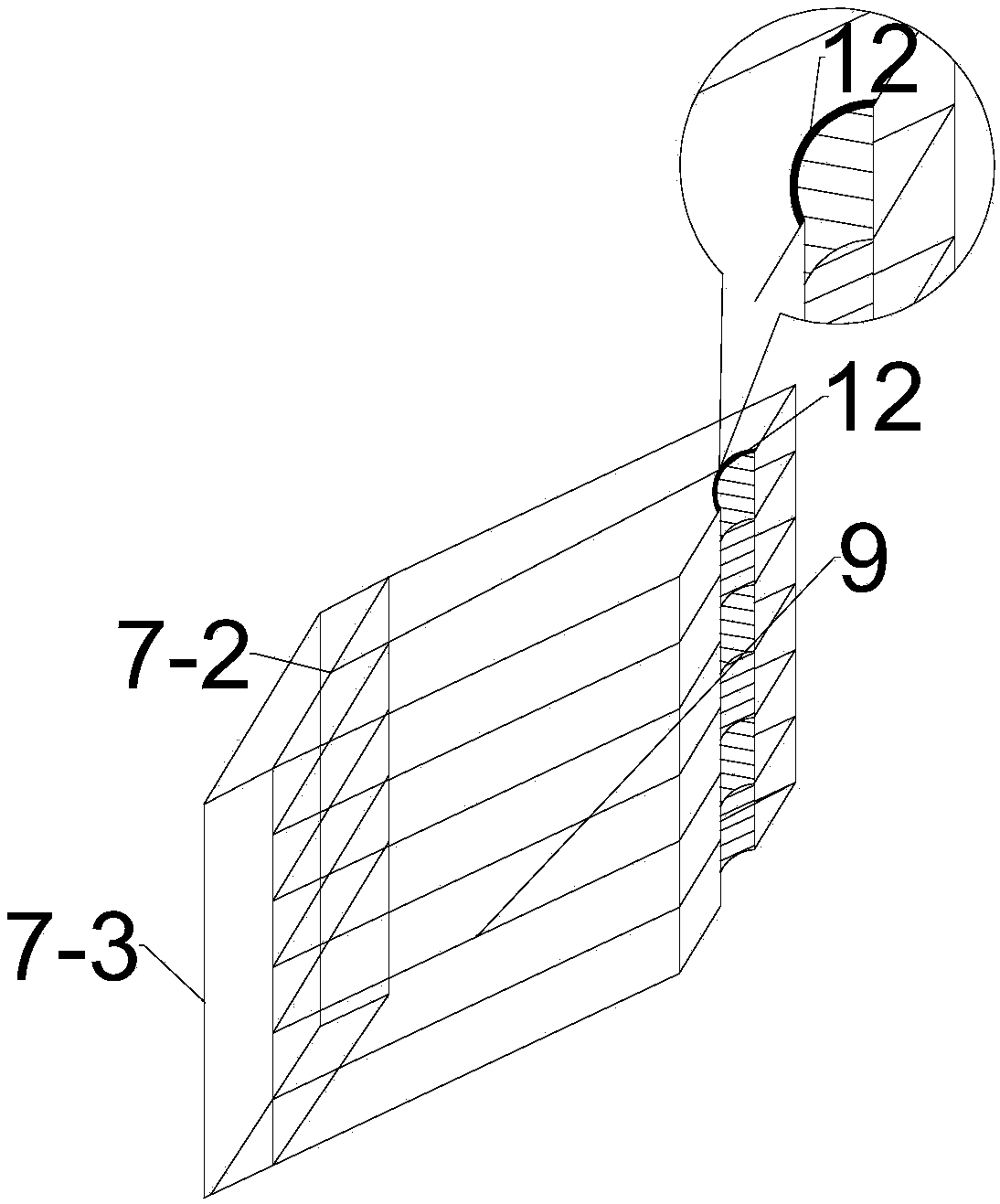

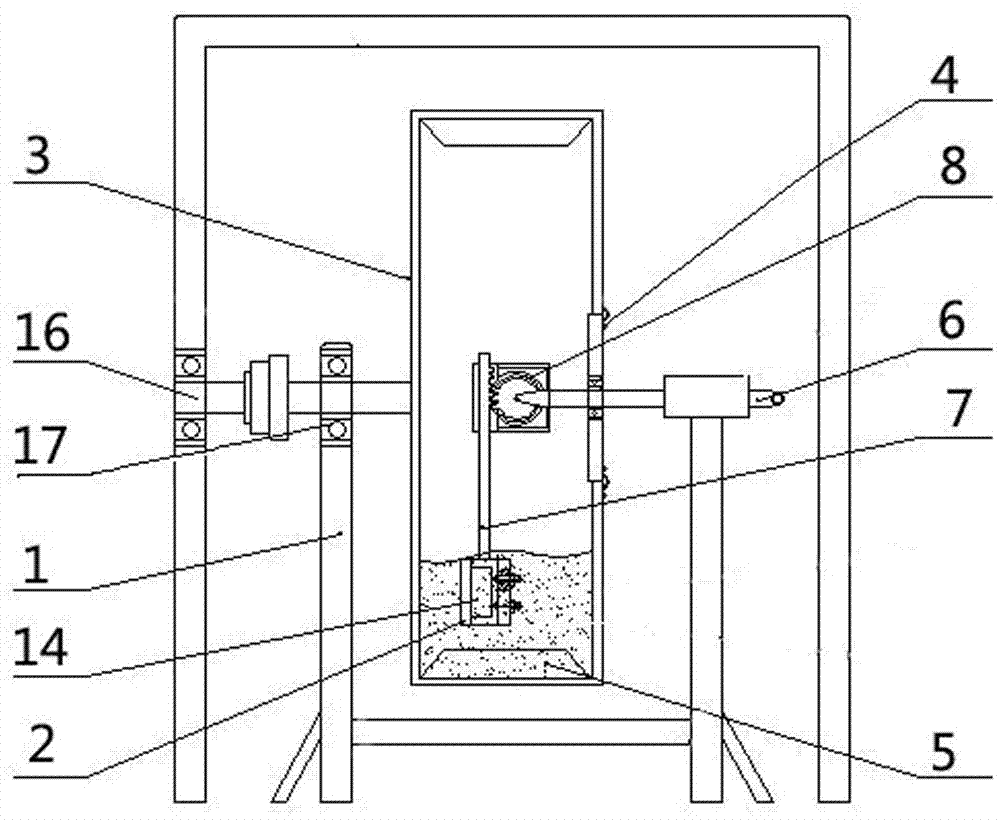

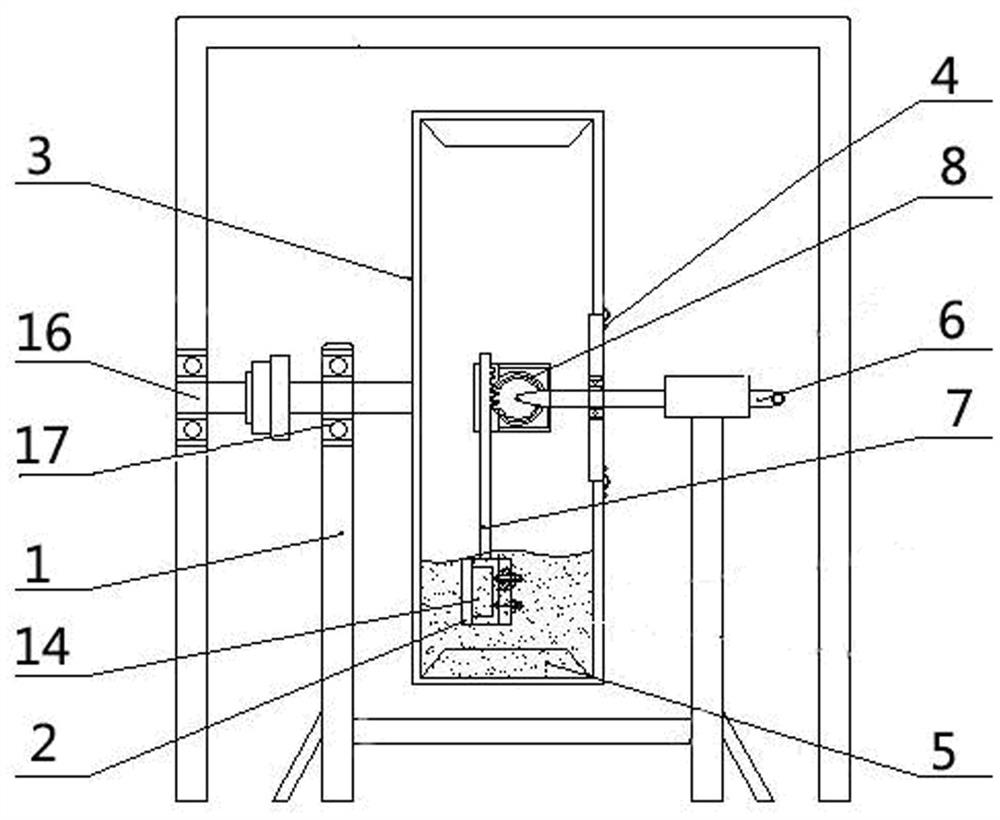

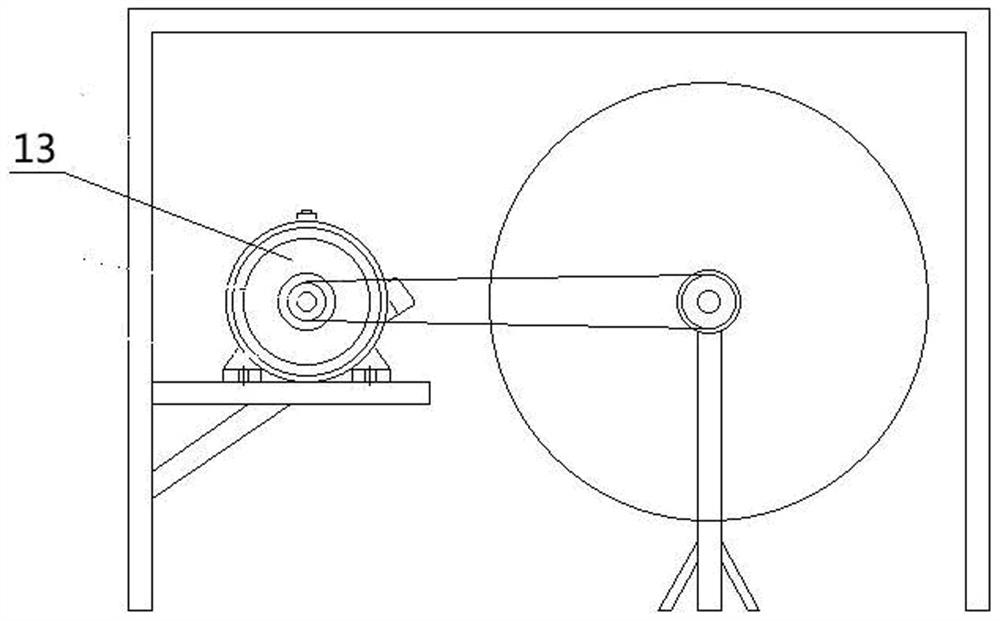

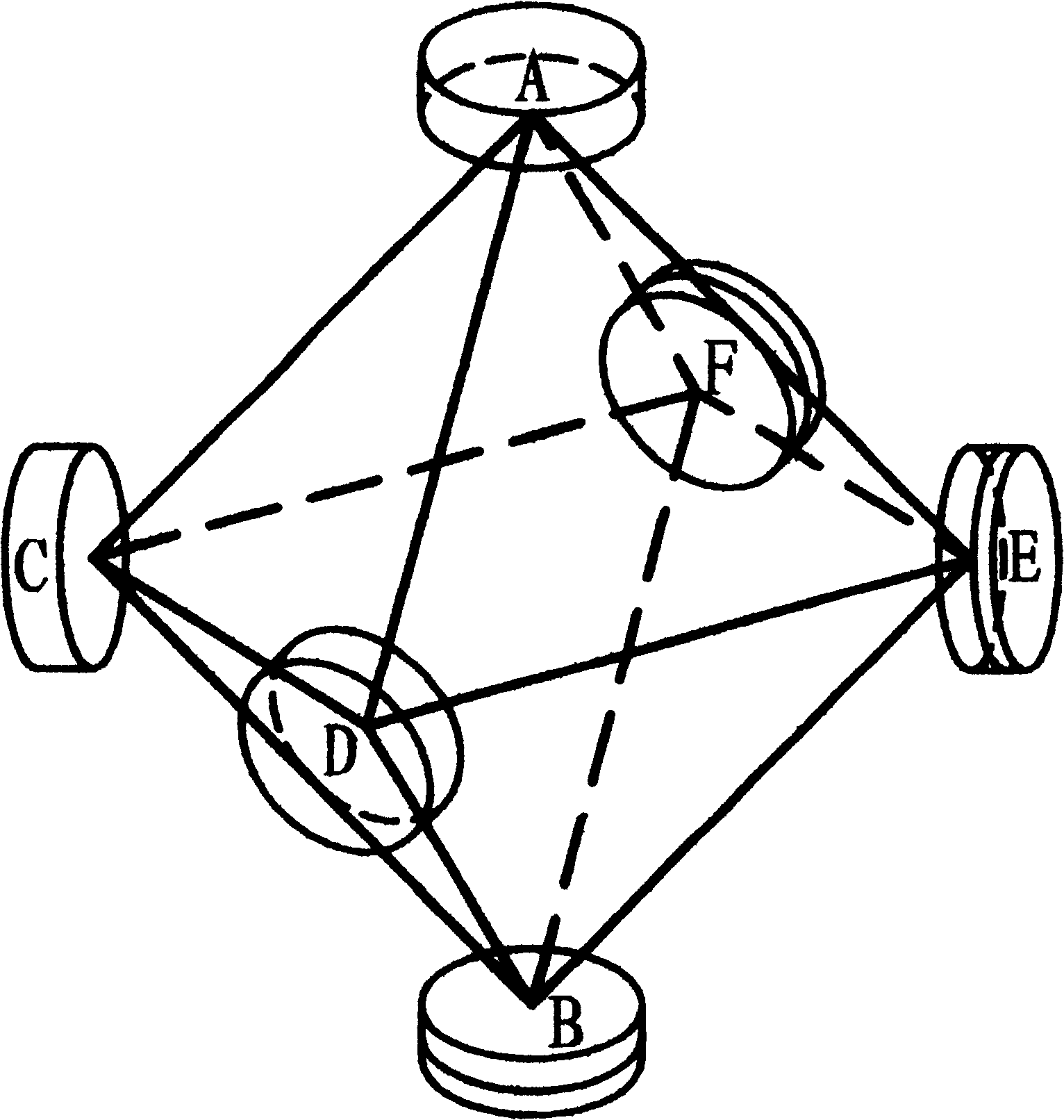

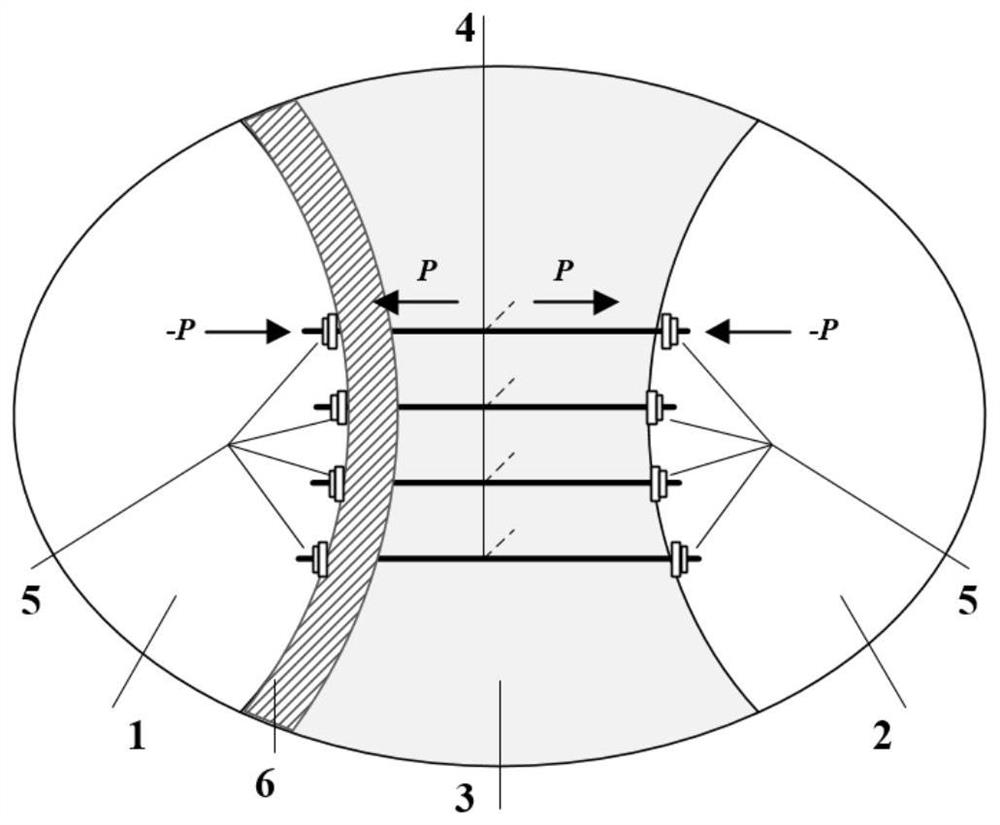

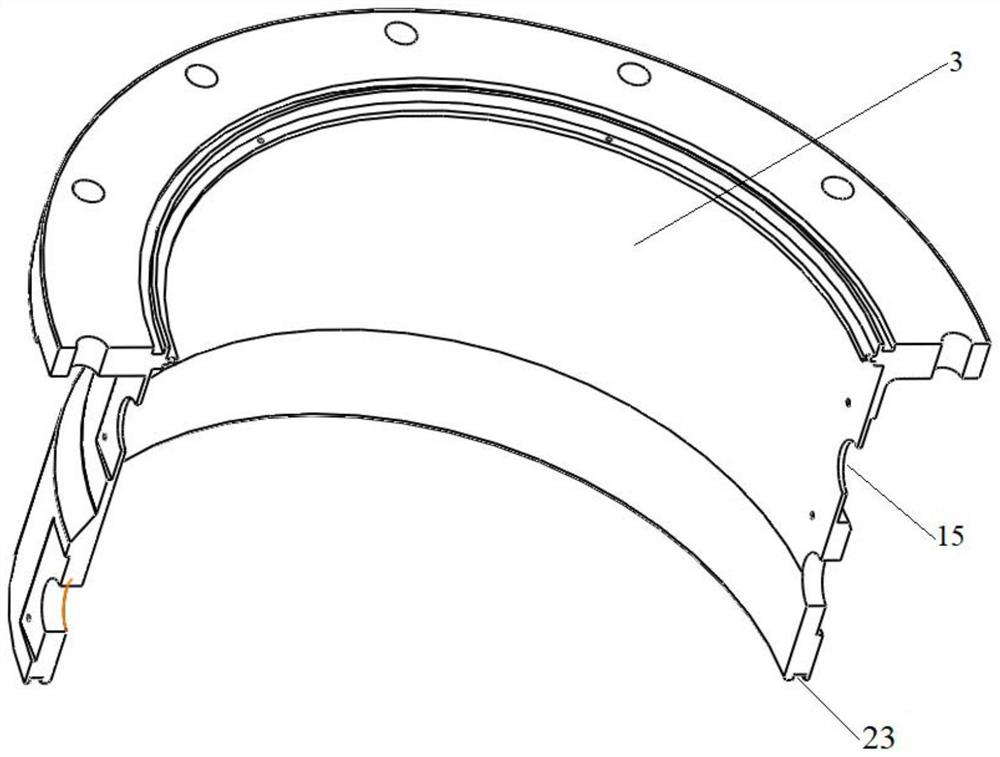

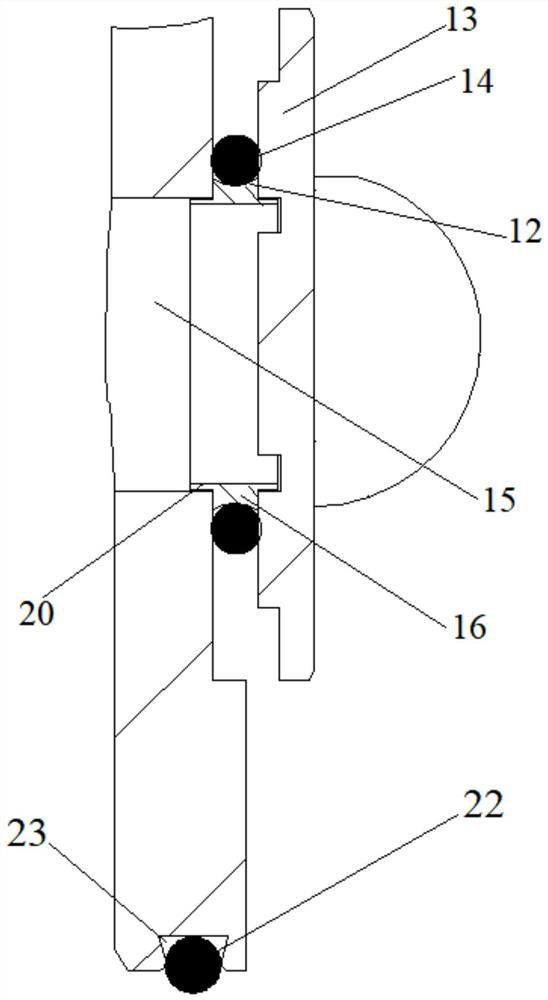

Device and method for testing work performance of anchor rod cable capable of simulating rock layer fracture and separation on basis of electromagnetic effects

ActiveCN108106936AHigh precisionIn line with the actual working statusMaterial strength using tensile/compressive forcesElasticity measurementMassive gravityWork performance

The invention provides a device and a method for testing work performance of an anchor rod cable capable of simulating rock layer fracture and separation on basis of electromagnetic effects. The device and the method are applicable to the technical field of roadway simulation for field test of anchor rod cable work performance. The device comprises a top seat and a base, wherein a plurality of hydraulic upright posts are arranged between the top seat and the base; clamping devices are arranged on the plurality of hydraulic upright posts; an electromagnet block is arranged between two groups ofpulling block-shaped clamping bodies. By using the attraction force and the repulsion force of the electromagnet block bodies, the layered electromagnet block bodies generate layer separation or fracture effects in the loading process; the mutual effect of the field surrounding rock and anchor rod cable test pieces is simulated; each performance parameter of the work state of the anchor rod cabletest piece is accurately recorded; positive guidance significance on the field work guidance is realized.

Owner:CHINA UNIV OF MINING & TECH

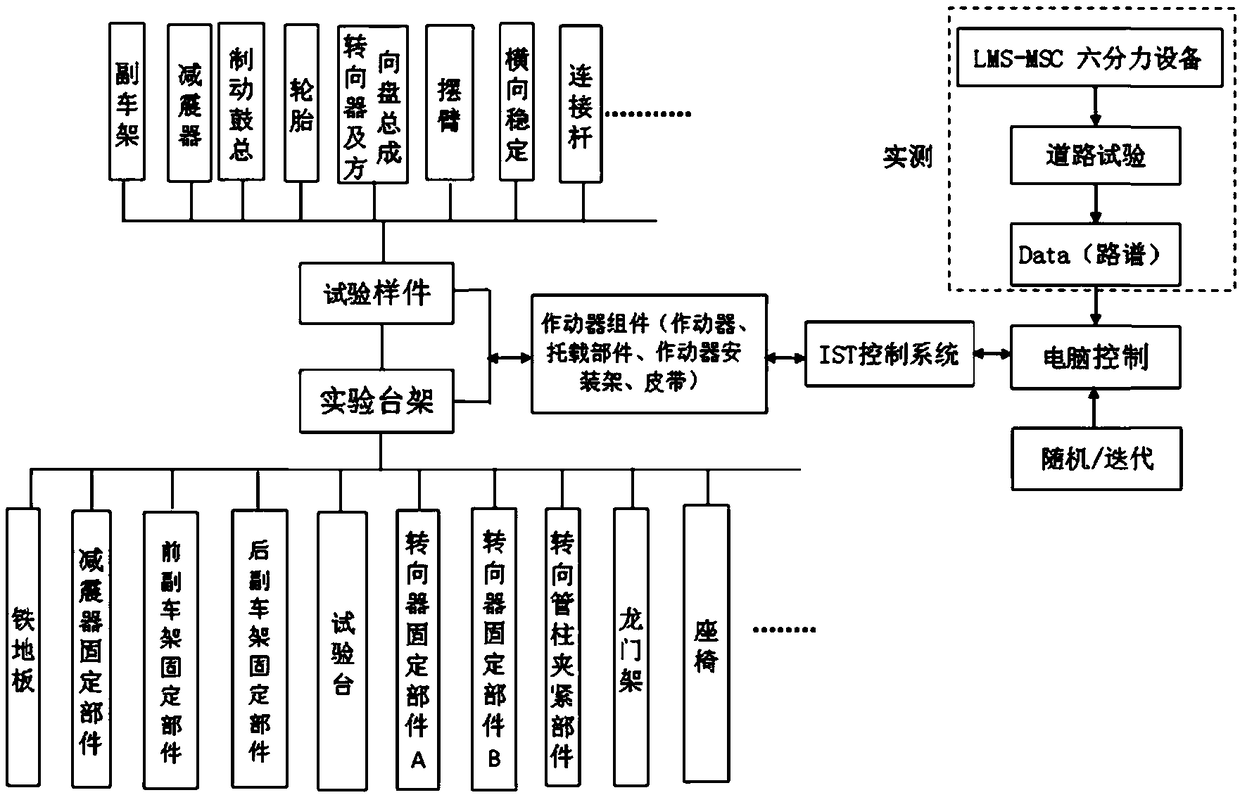

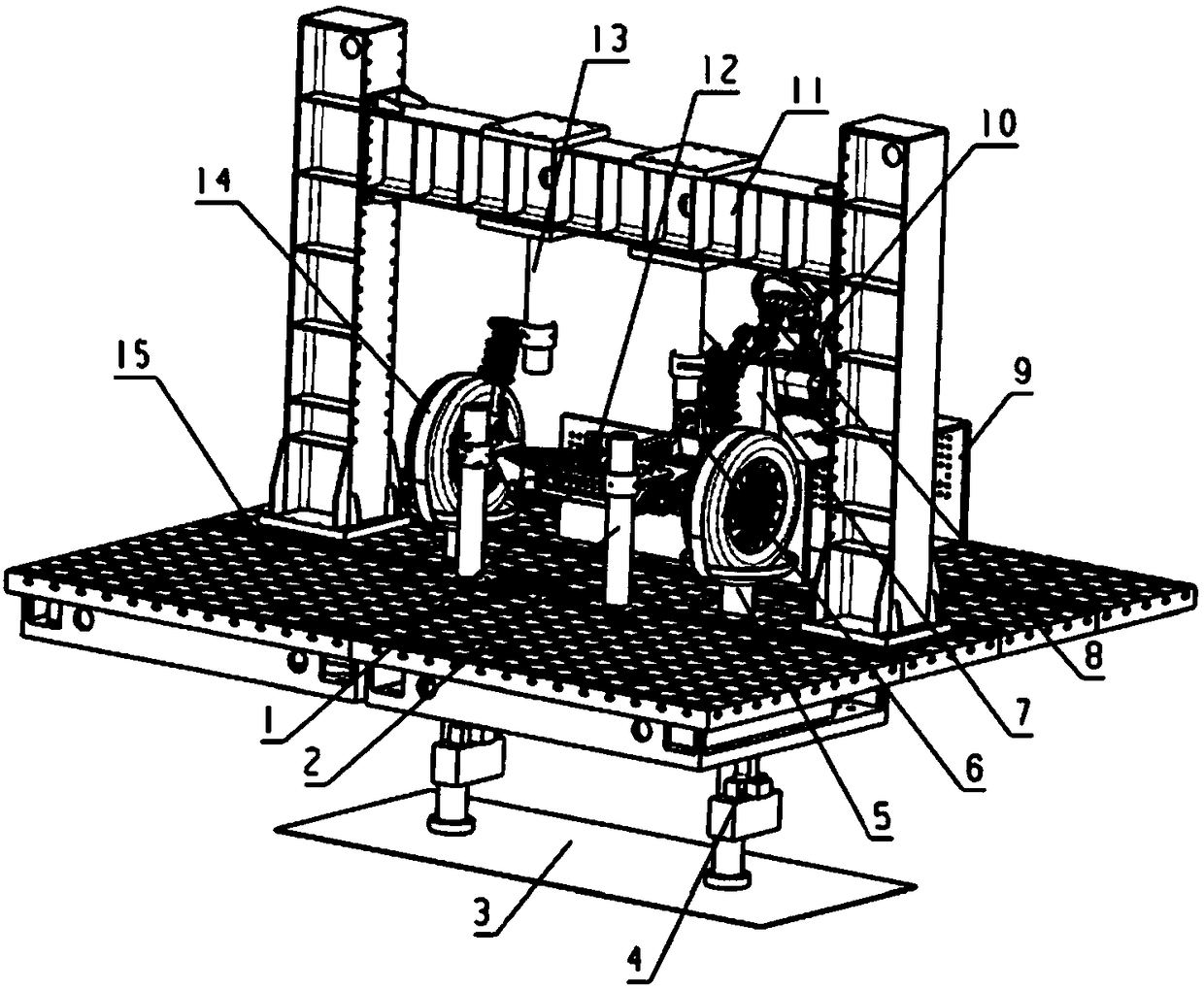

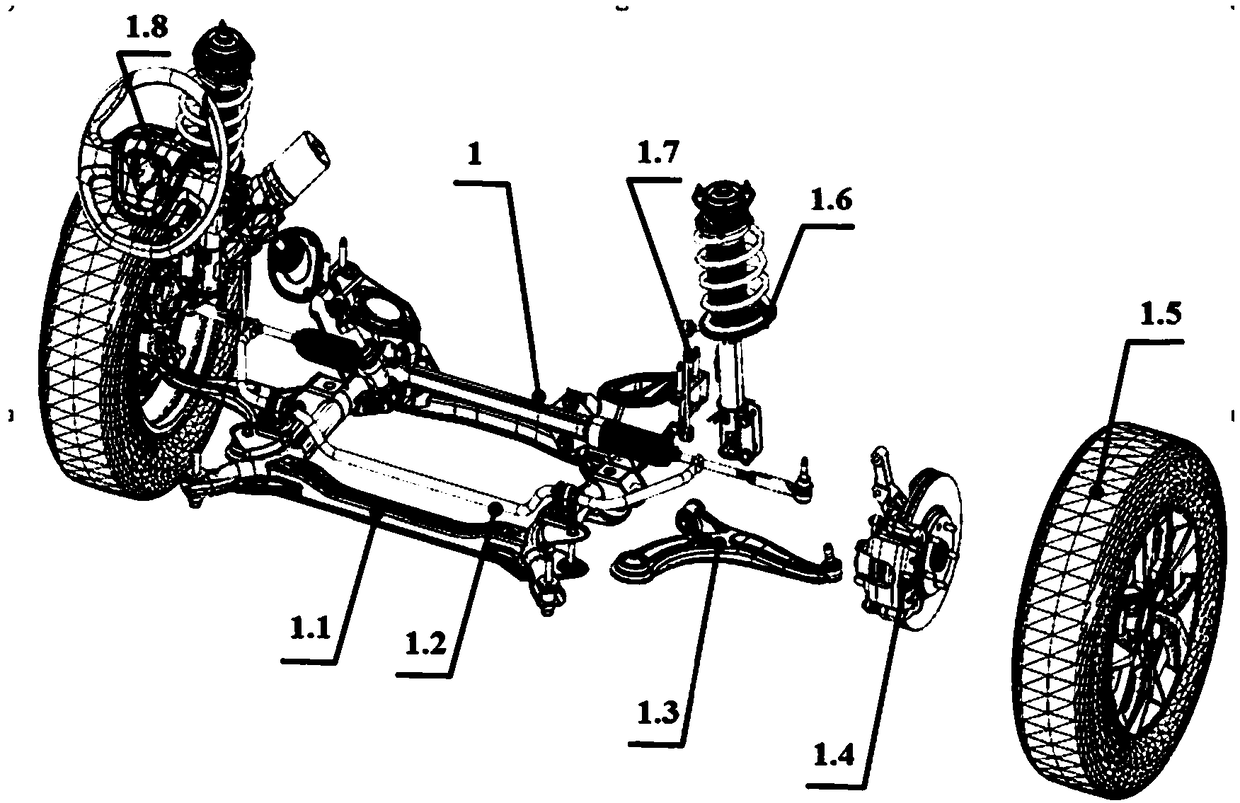

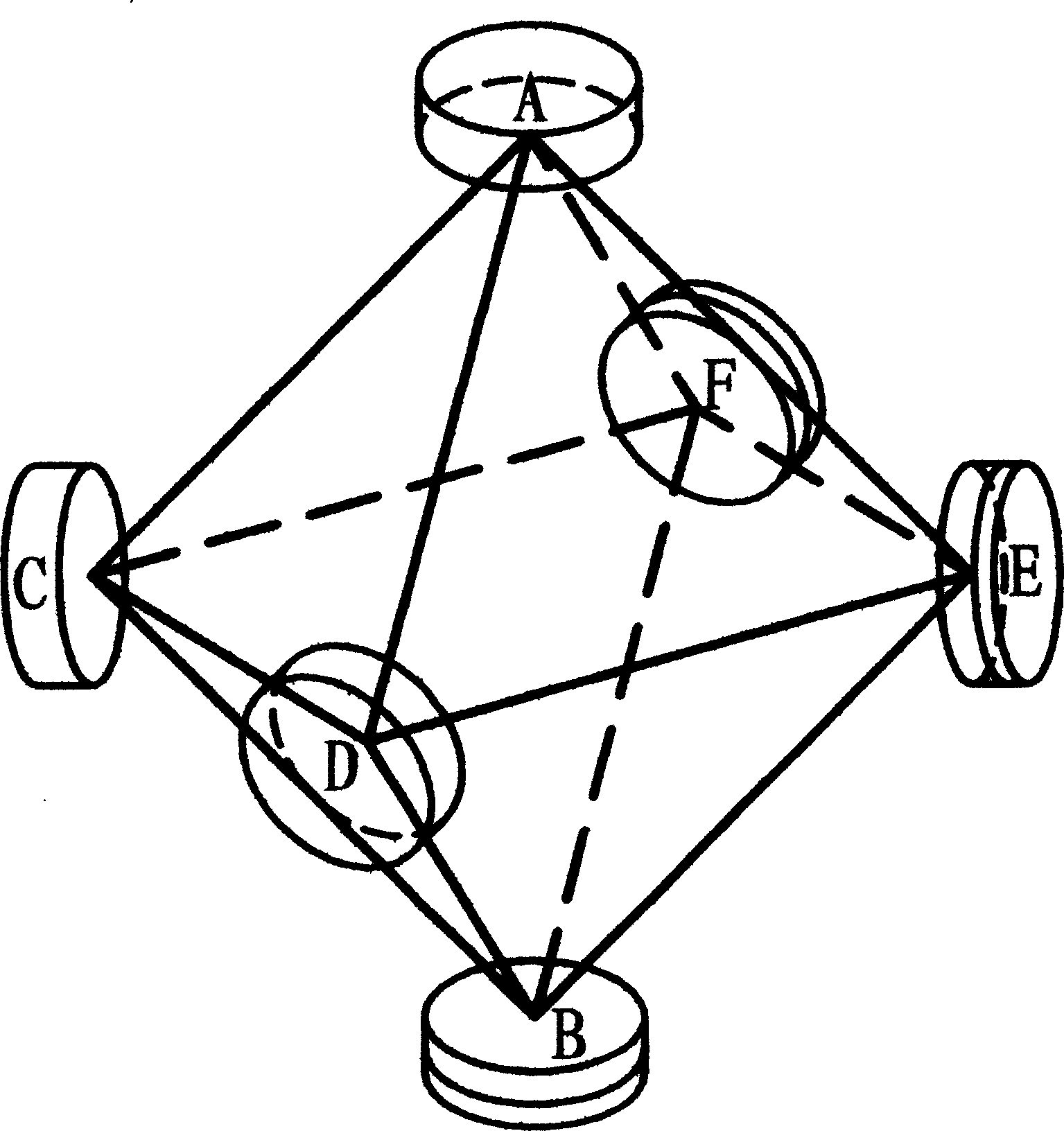

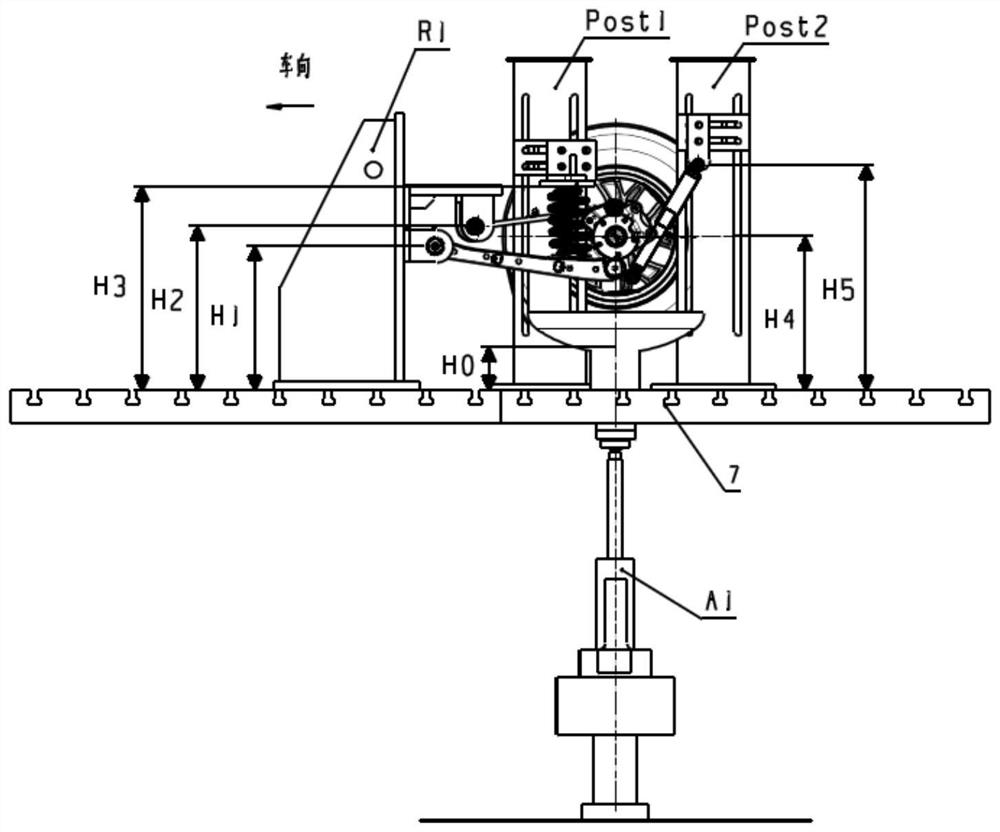

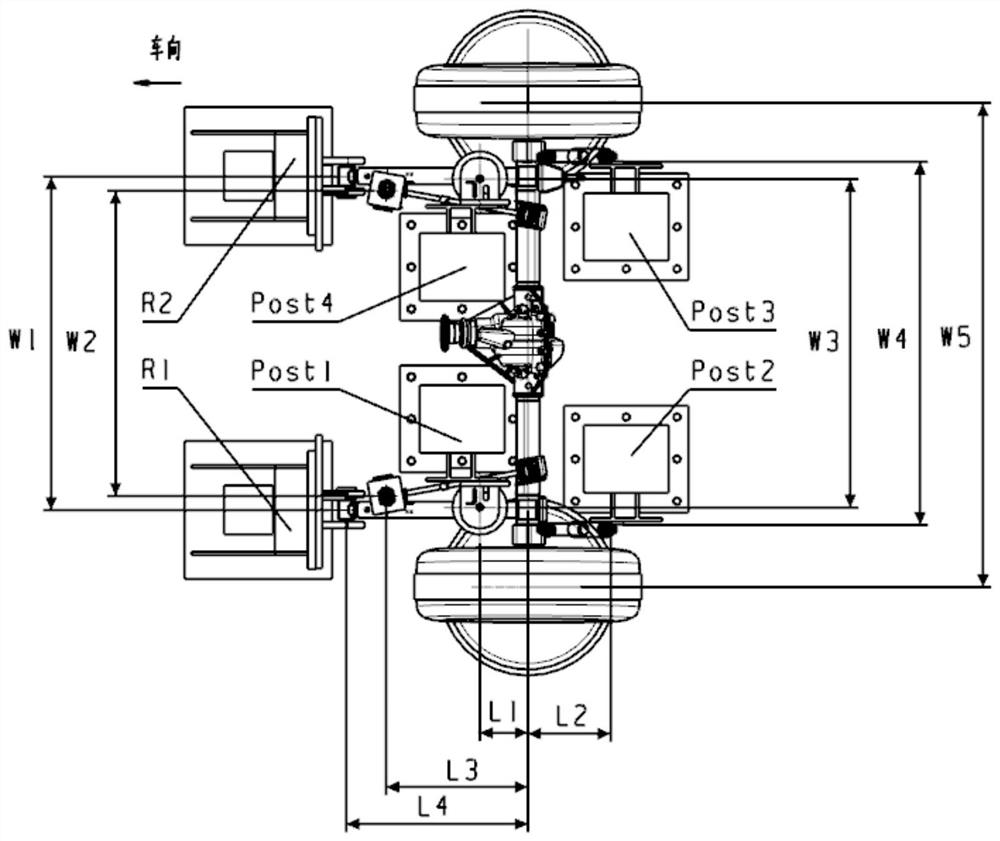

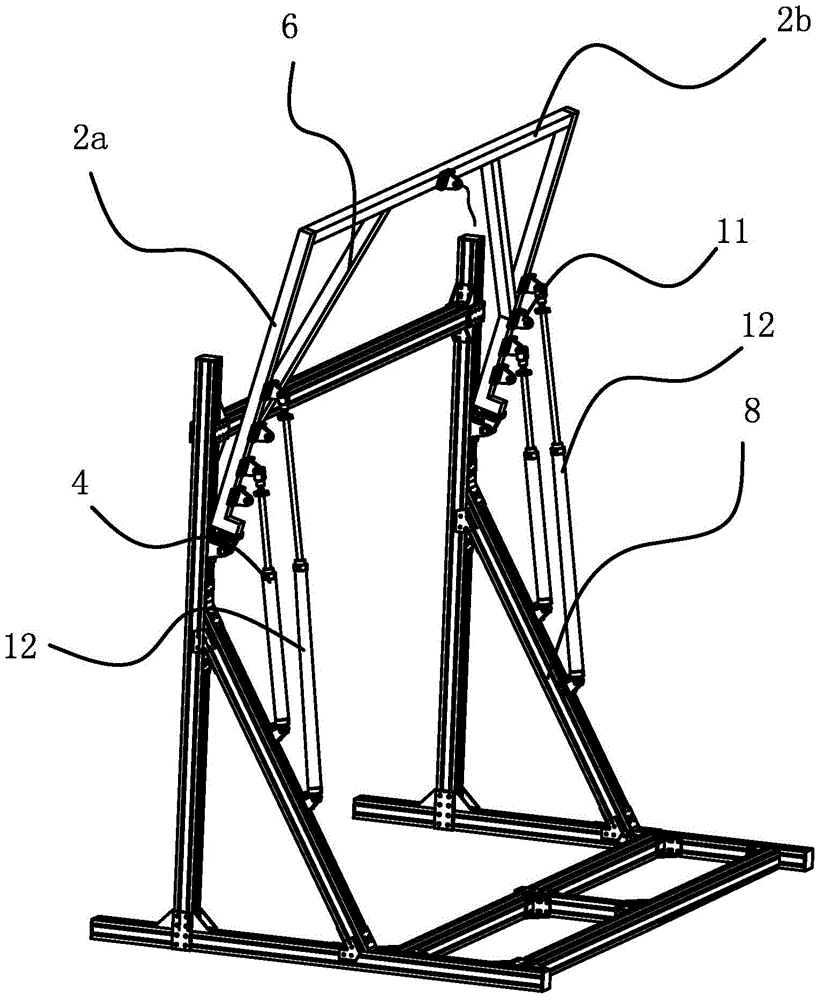

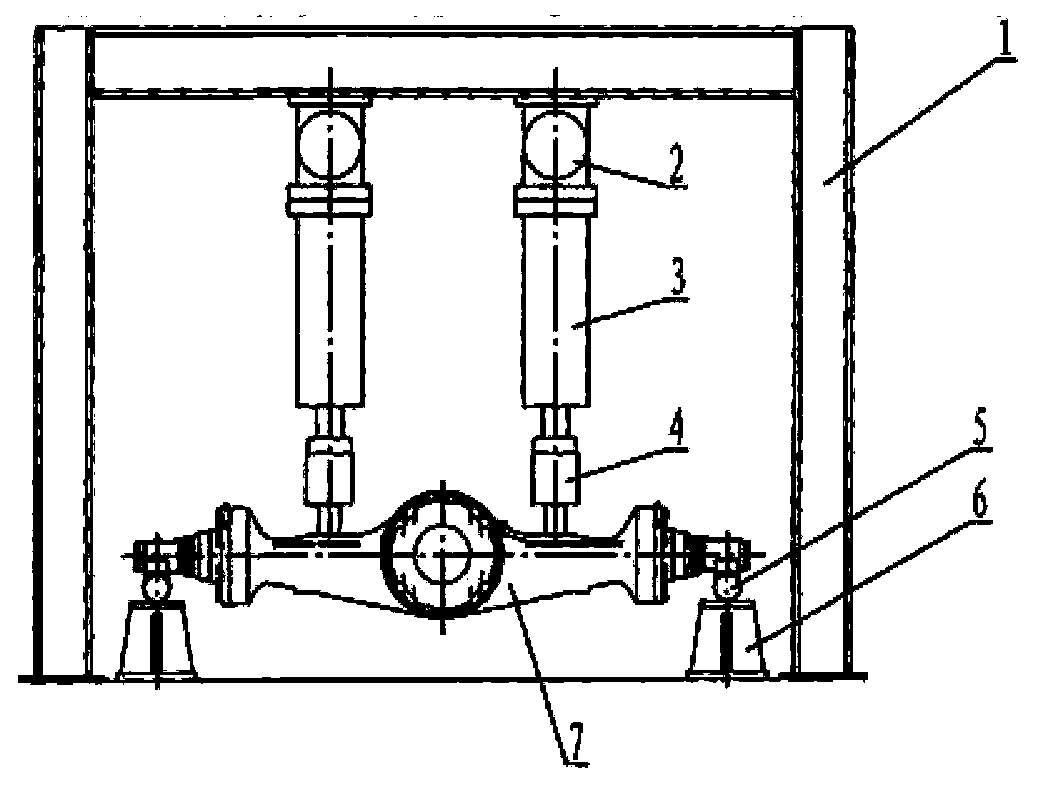

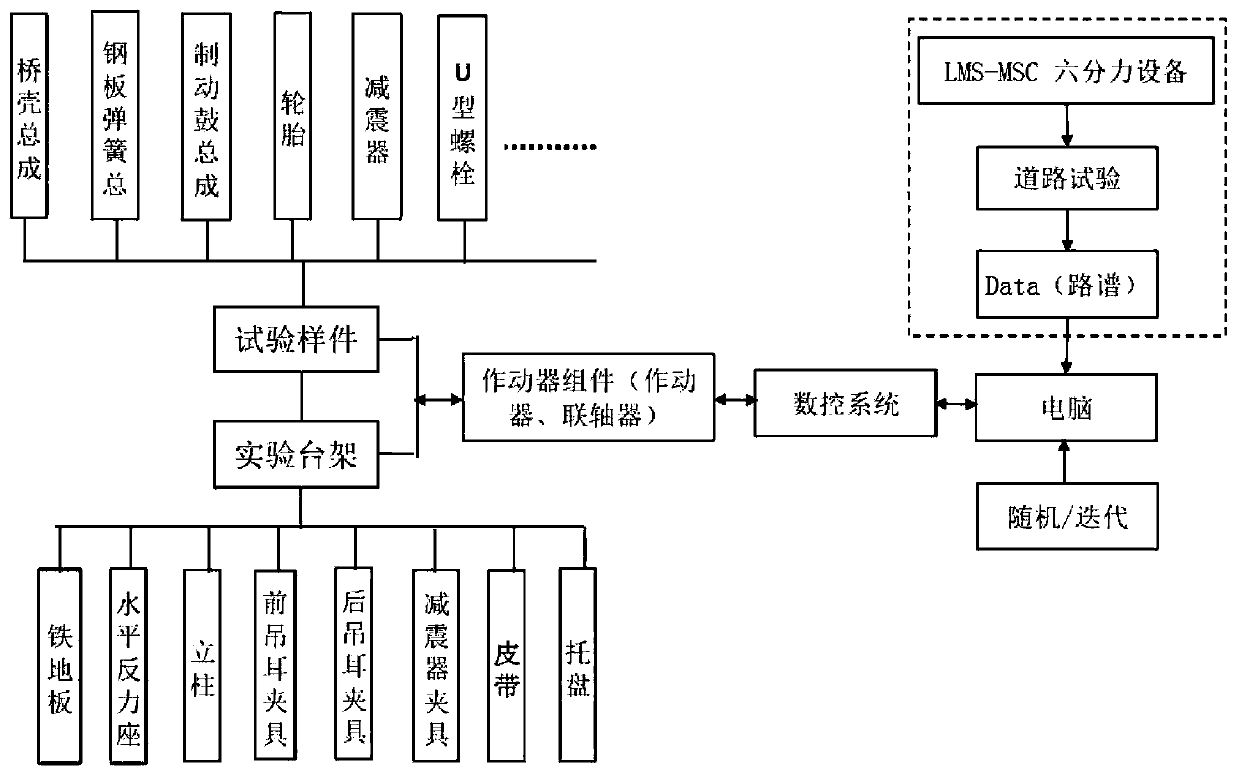

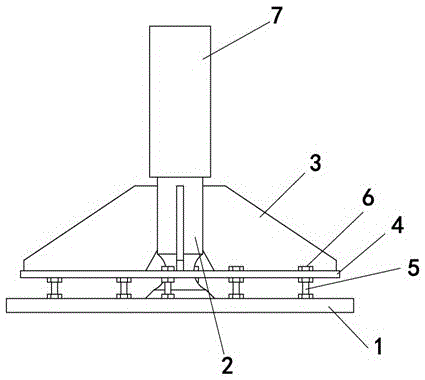

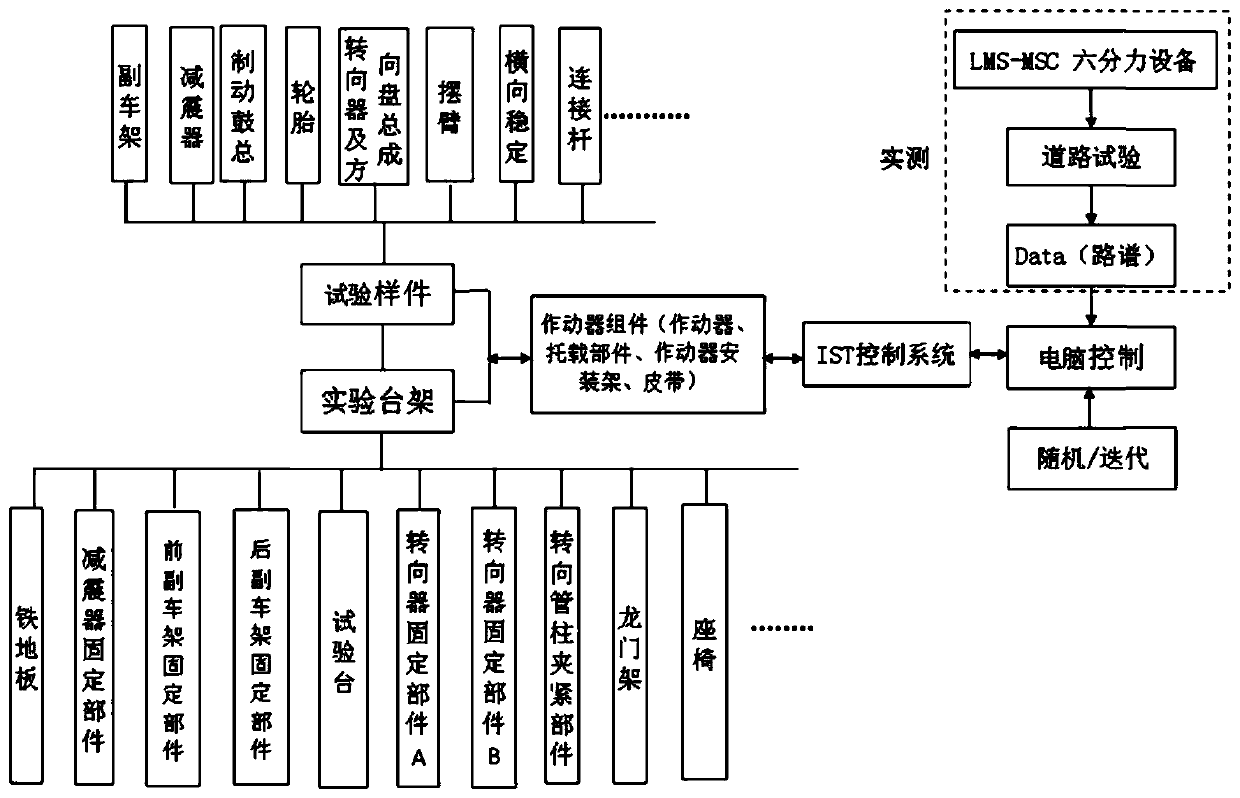

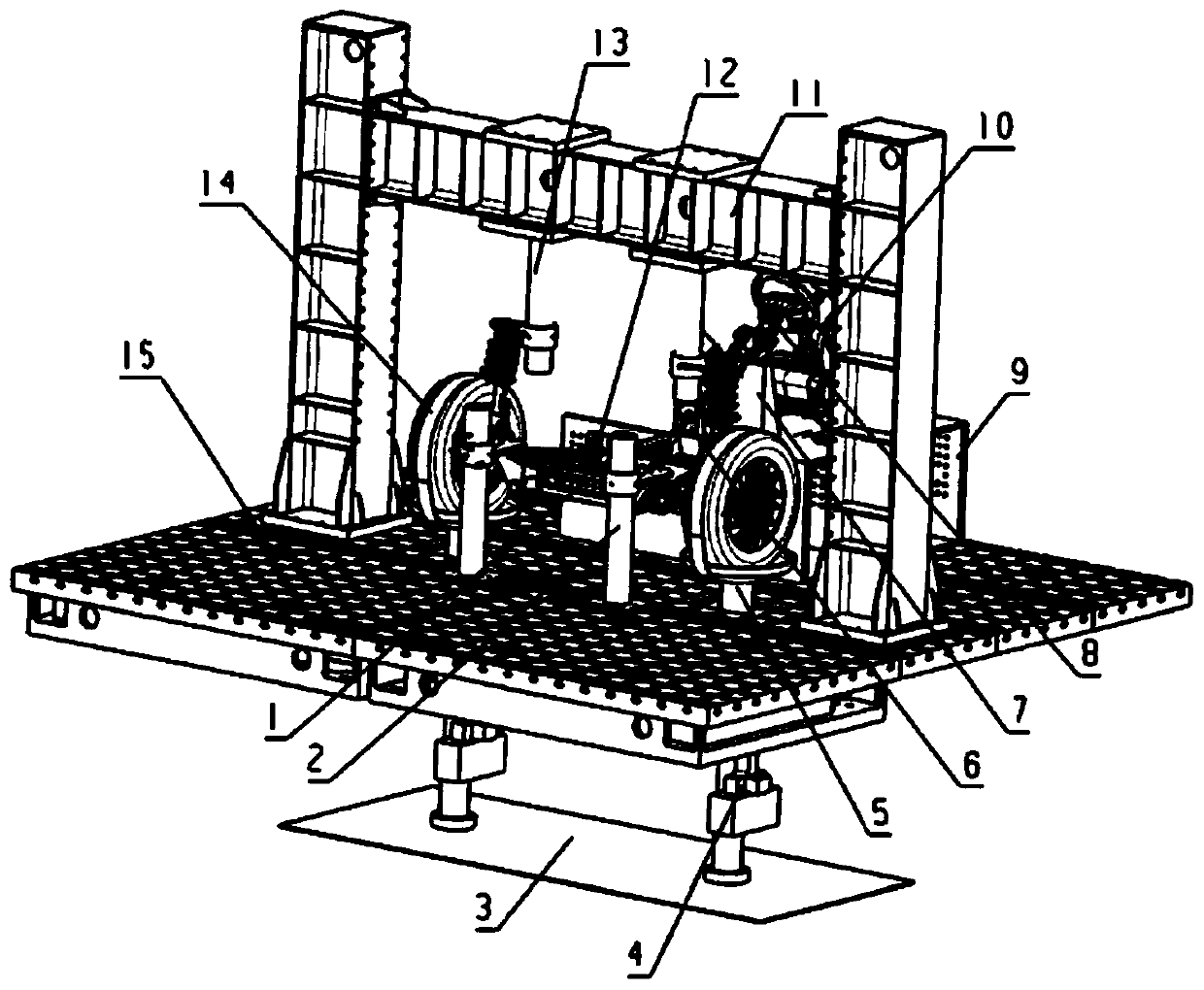

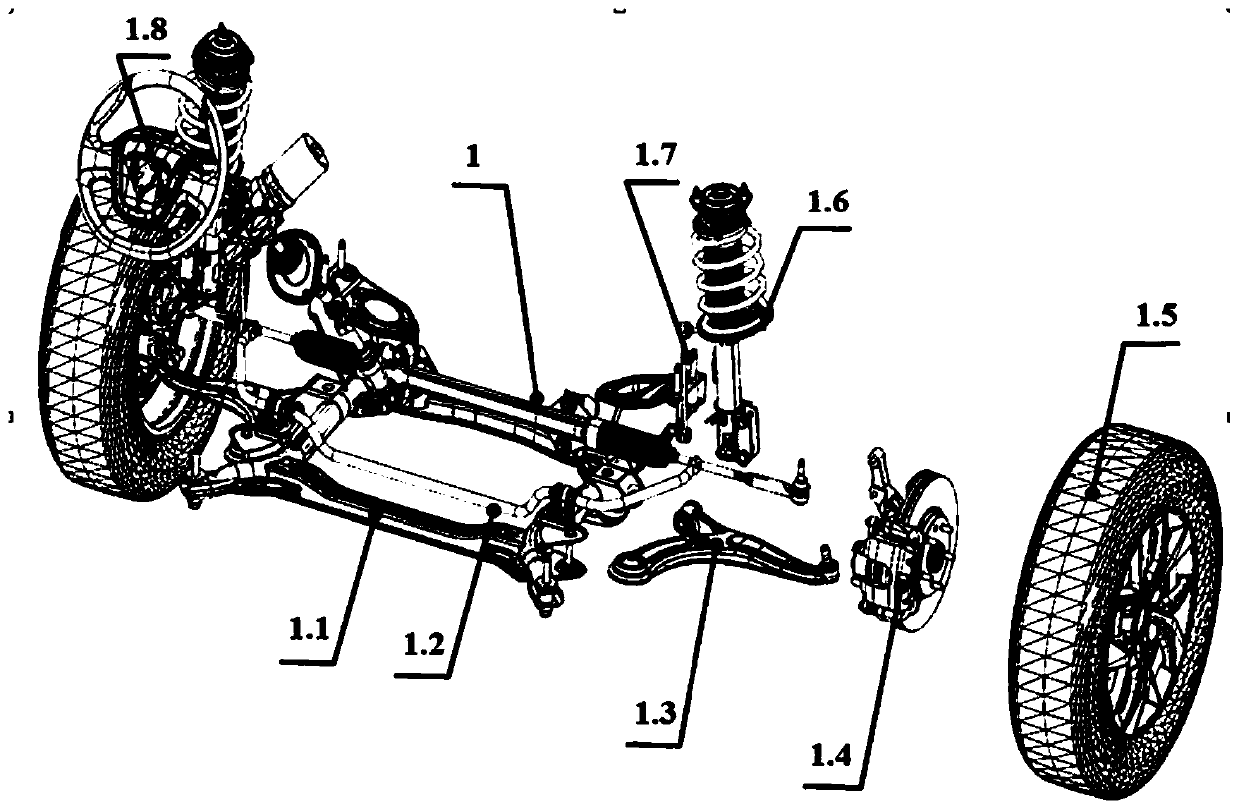

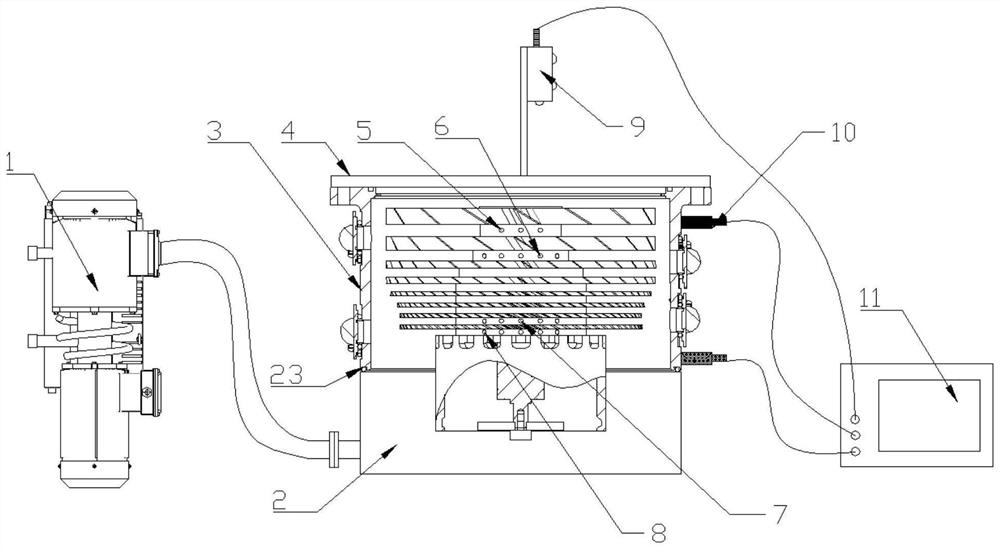

Non-driving front suspension assembly comprehensive fatigue durability testing device and method

ActiveCN109060386AShorten the development cycleWith test functionVehicle suspension/damping testingSteering angleVehicle frame

The invention relates to a non-driving front suspension assembly comprehensive fatigue durability testing device and method. The testing device comprises an experiment table frame, an actuator assembly and a numerical control system; the experiment table frame comprises a front auxiliary frame fixing component, a steering gear fixing component, a portal frame, a rear auxiliary frame fixing component and a shock absorber fixing component; the experiment table frame is used for simulating the fixing effect of a suspension assembly on a vehicle body so as to fix the suspension assembly; the actuator assembly is controlled by the numerical control system to load a left tire and a right tire up and down separately; and the numerical control system is used for detecting the fatigue durability test data of various working conditions of the suspension assembly in different steering states. The influence of different steering angles on the fatigue durability test conclusion of the non-driving front suspension assembly is comprehensively considered, so that real and reliable experimental benchmarking data are provided for design of the non-driving front suspension assembly and fatigue life analysis and the like, thereby shortening the development period of each part of the non-driving front suspension assembly and lowering the cost and the like.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

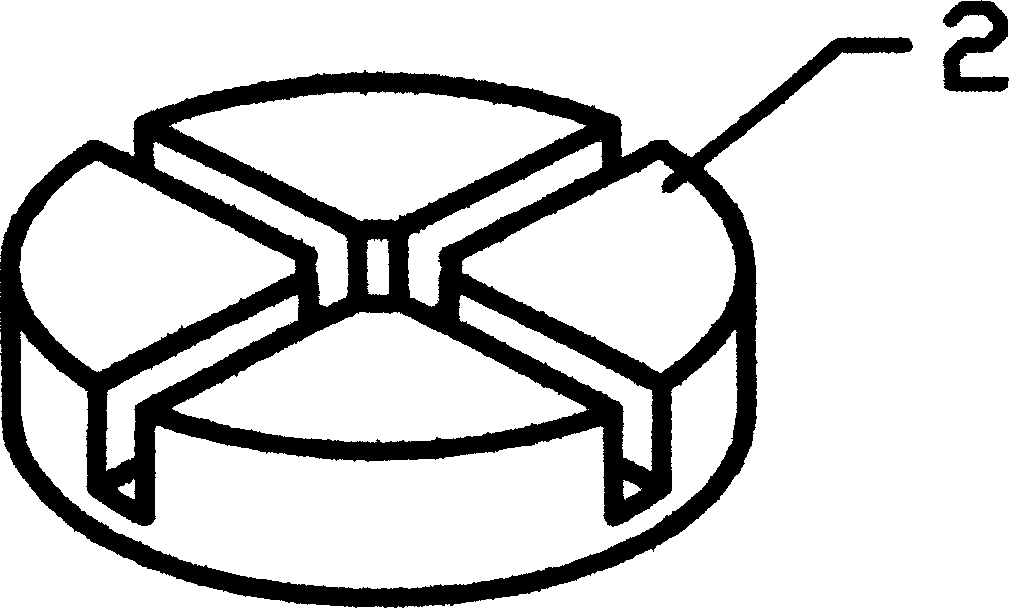

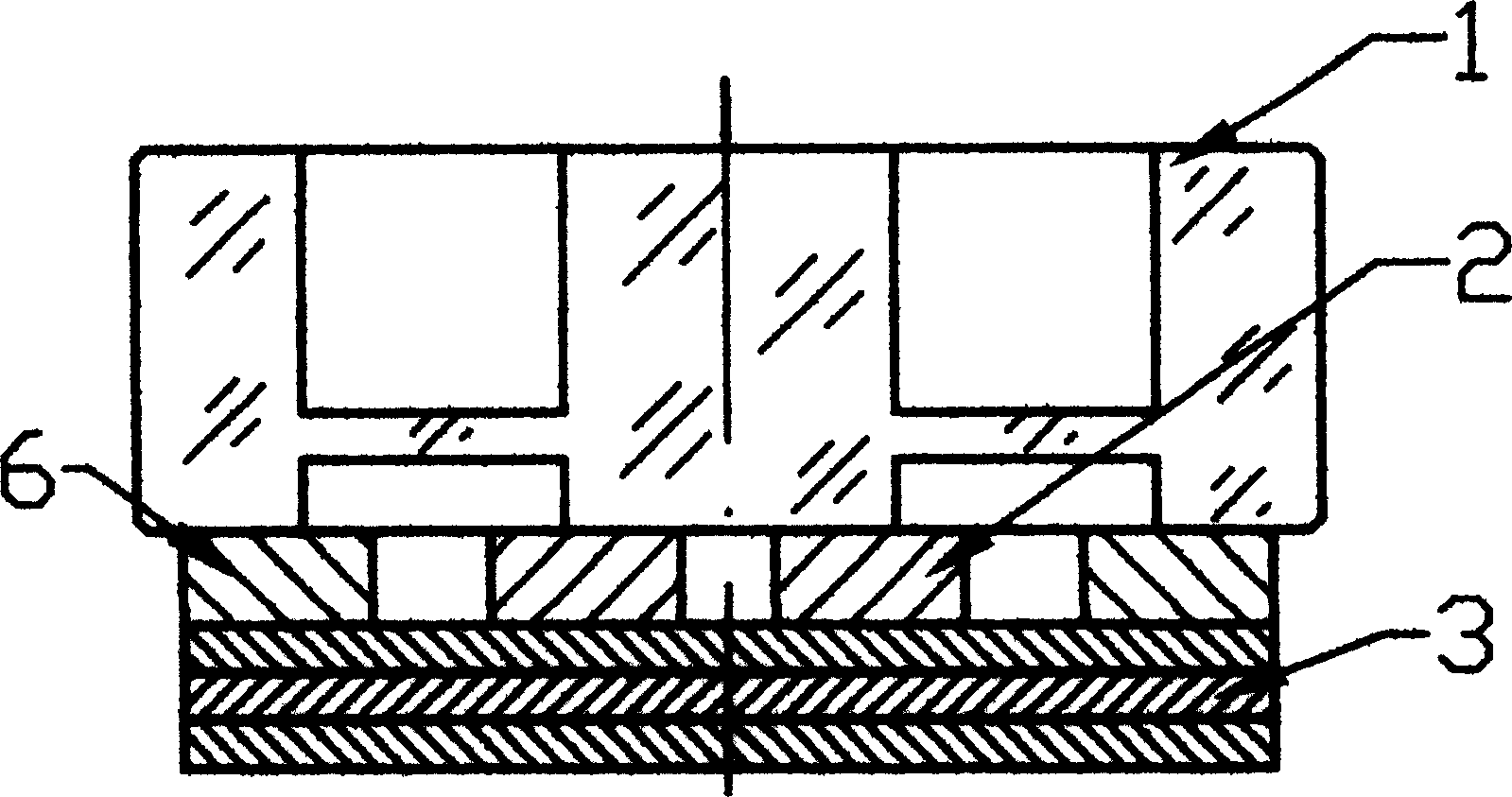

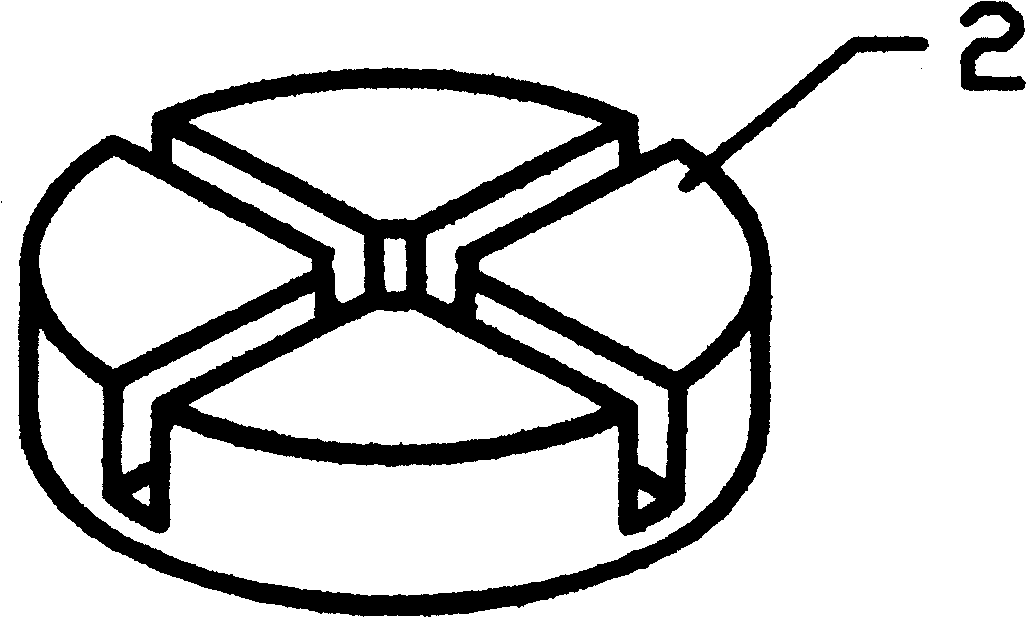

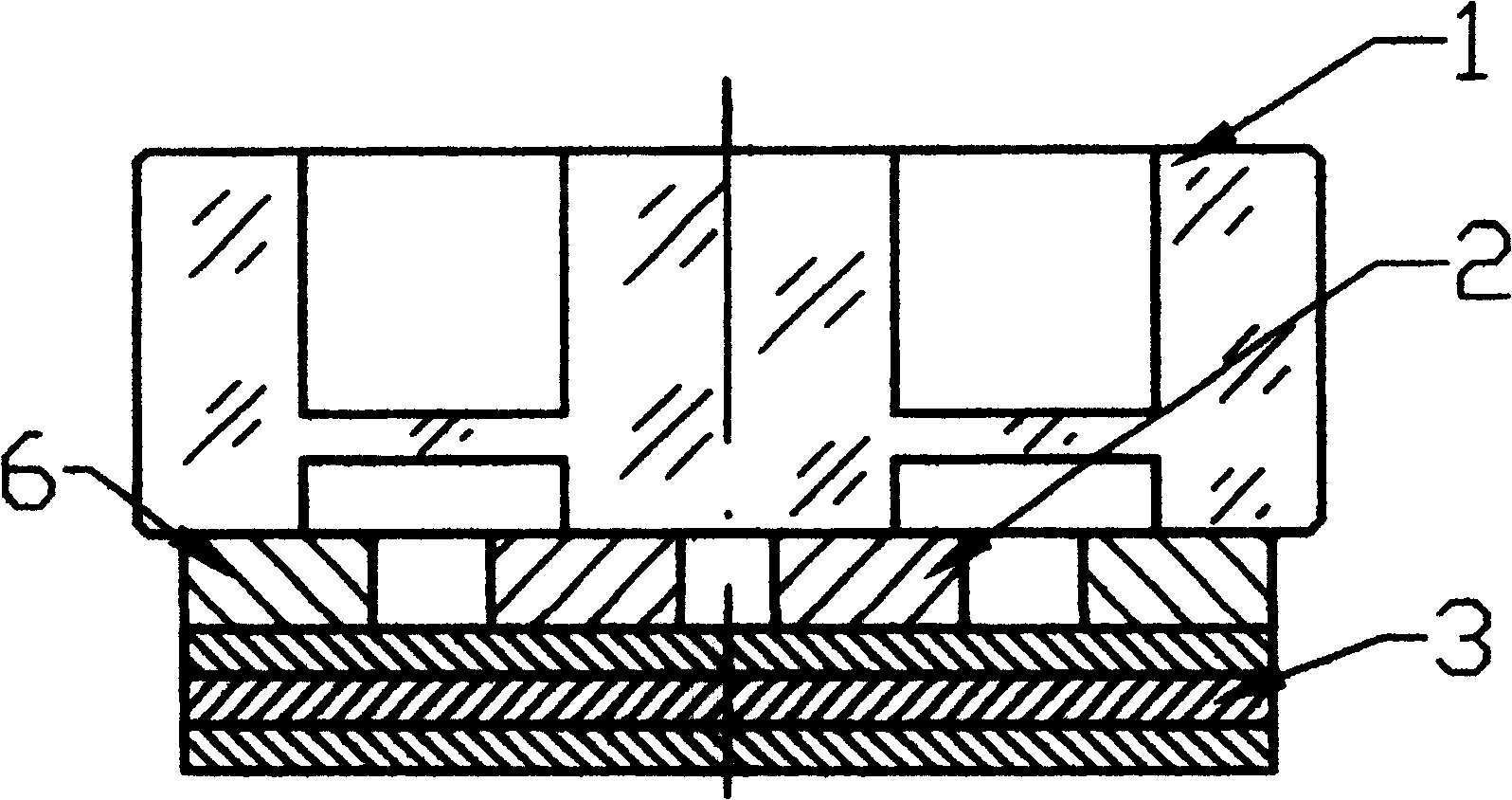

Cavity adjusting method for laser gyro and used light path and path length control mirror

ActiveCN1603752AIn line with the actual working statusRealize full scan tuningSagnac effect gyrometersGyroscopePath length

This invention discloses a laser gyroscope chamber adjusting method and its light path distance control lens. The method is the following: to exert toothed wave voltage on four control units of the angle control elements; to whole scan loop light path in two-dimensional space, wherein, two control units in one group are of same frequency and reverse voltage; the maximum scanning voltage of the output light intensity is the chamber voltage of the best loop resonance light path. The light path distance control lens comprises slotted vane , angle control element , matching loop and distance control element.

Owner:NAT UNIV OF DEFENSE TECH

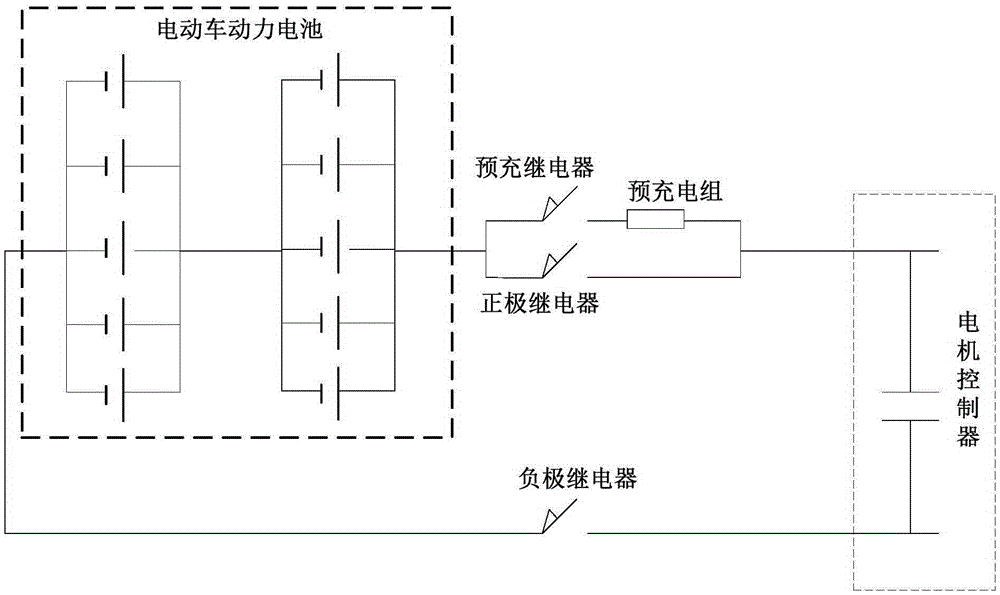

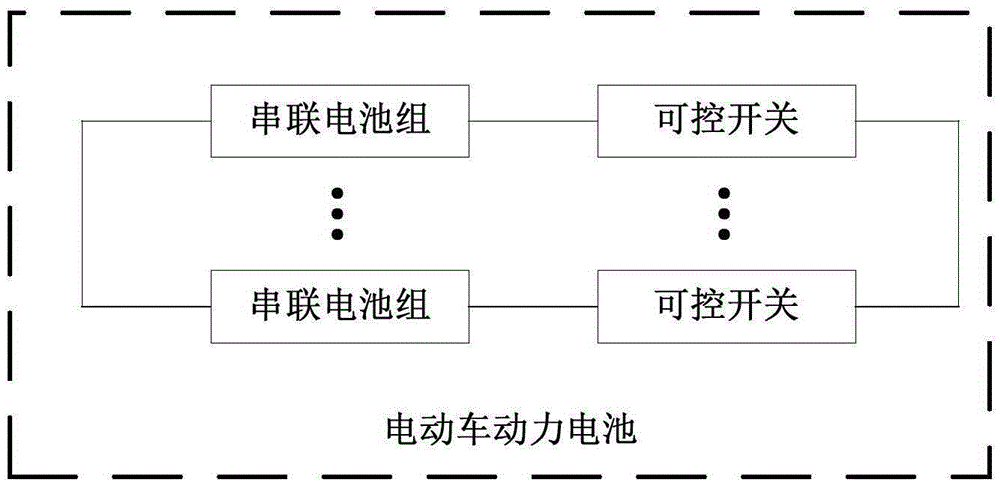

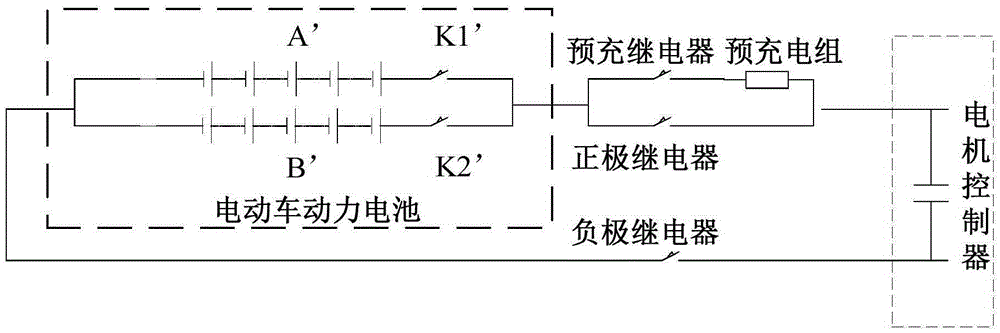

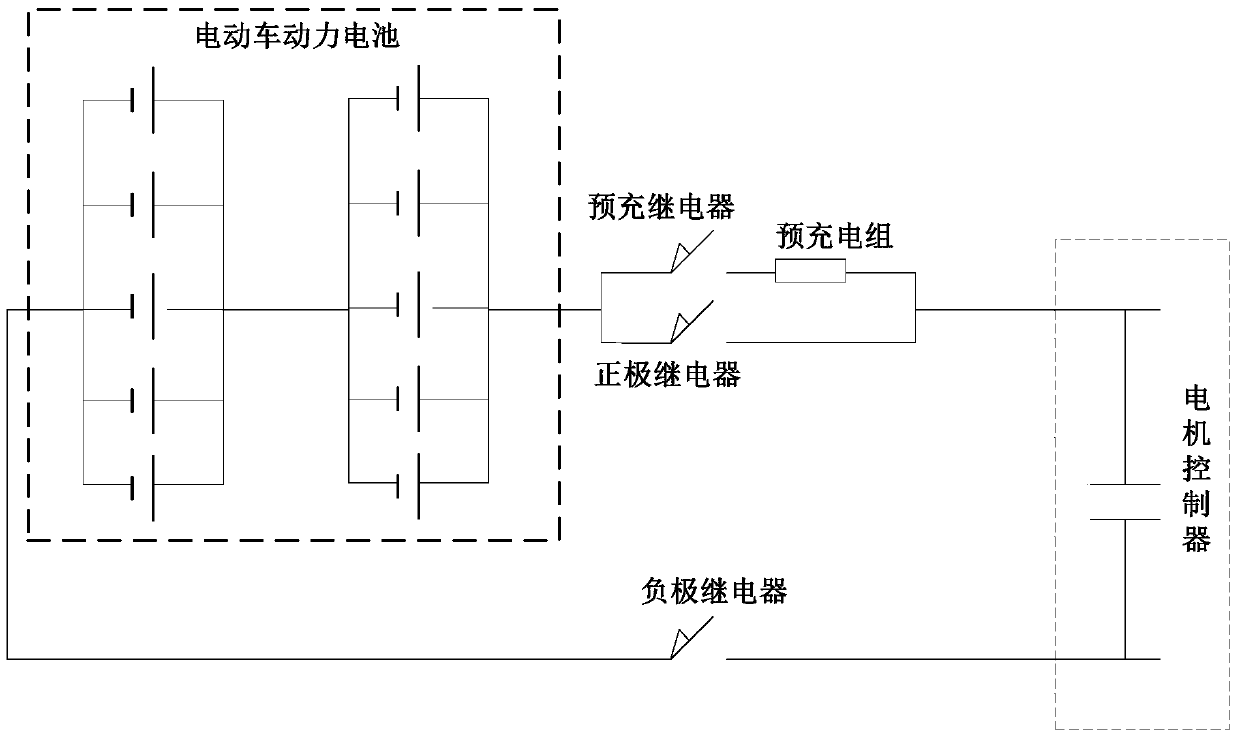

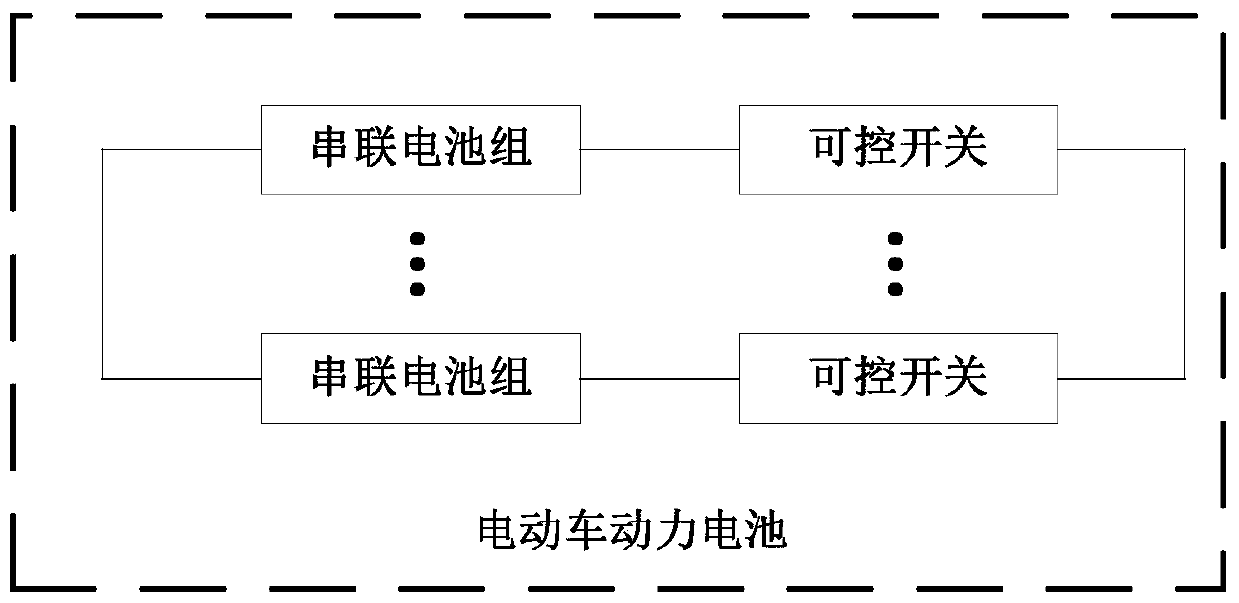

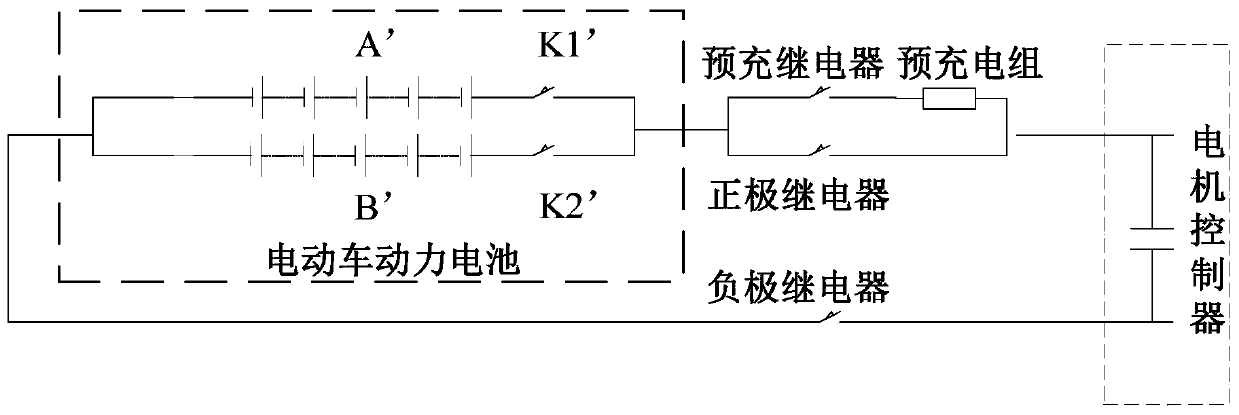

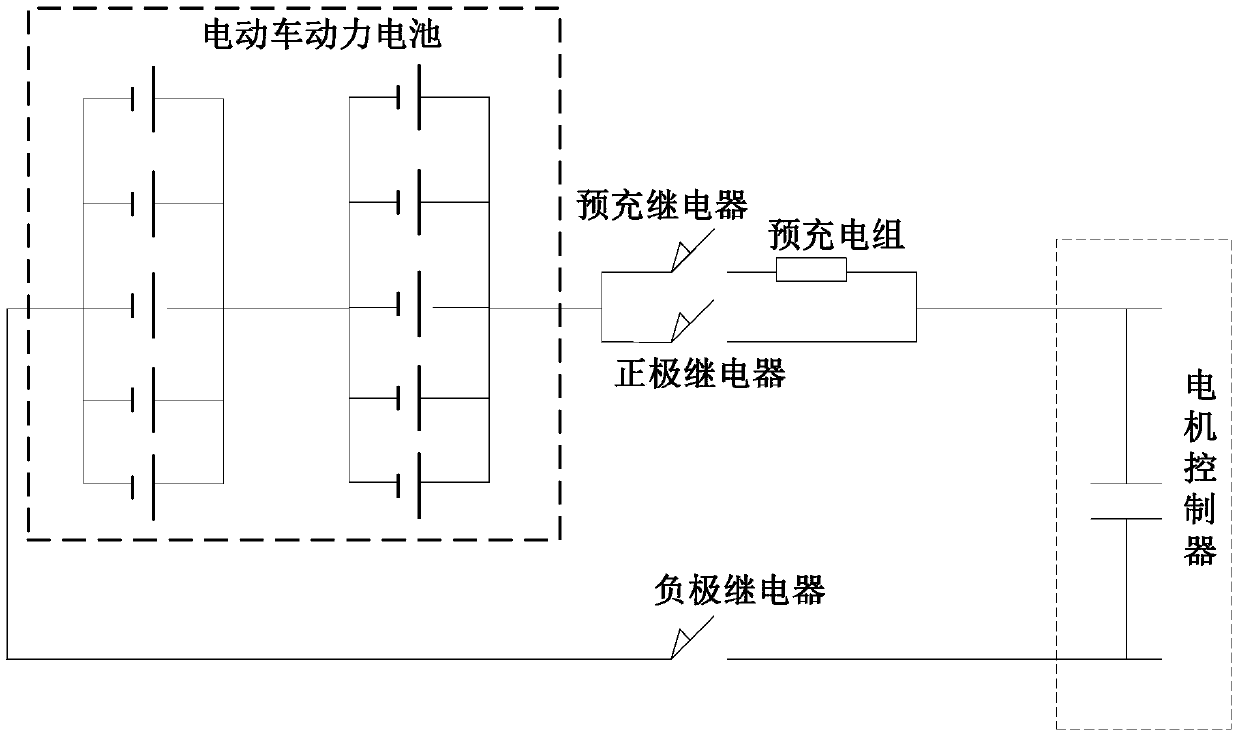

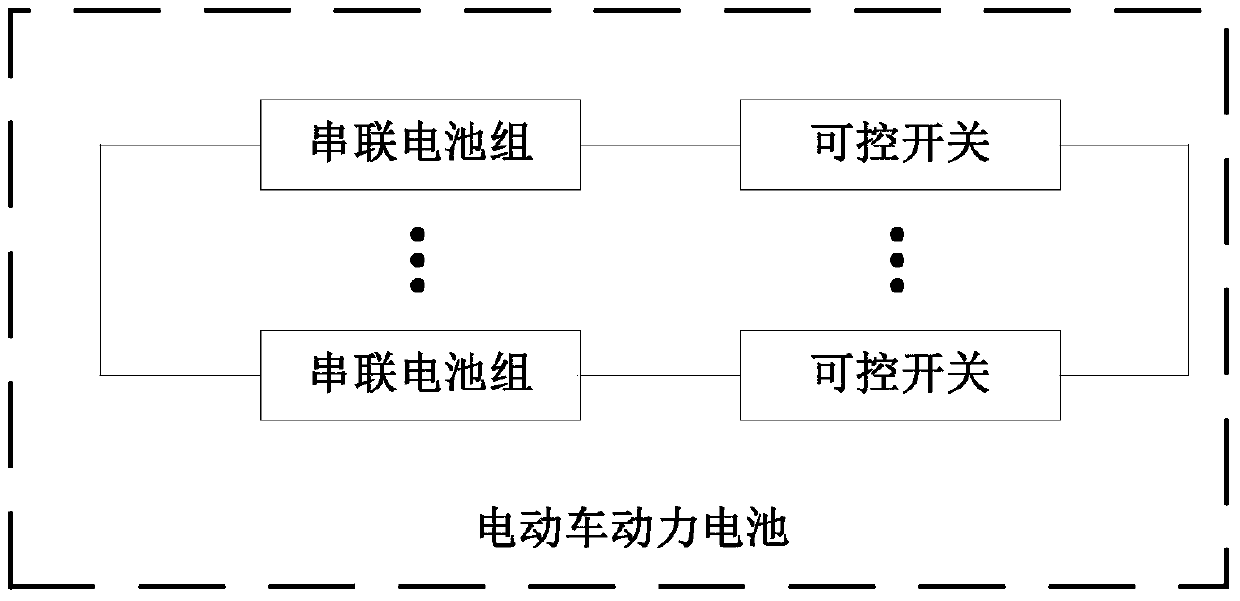

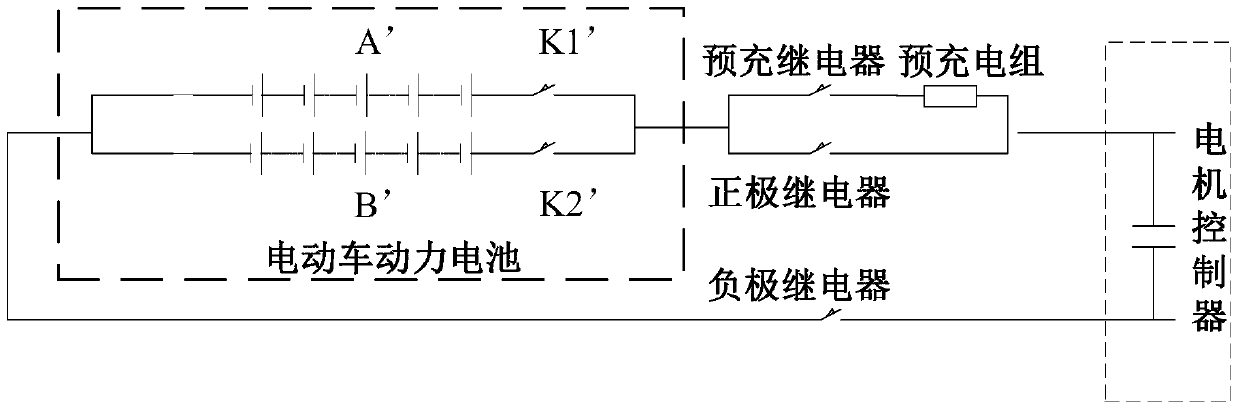

Power distribution method and device of electric vehicle power battery and electric vehicle

InactiveCN106712152AImprove fault detection efficiencyImprove accuracyBatteries circuit arrangementsElectric powerElectrical batteryElectric vehicle

The invention provides a power distribution method and device of an electric vehicle power battery and an electric vehicle. The electric vehicle power battery comprises at least two series-connected battery groups in parallel. The power distribution method comprises a step of judging the number of the series-connected battery groups in a working state at present, a step of determining the maximum total discharging current of the electric vehicle power battery according to the maximum discharging current of a series-connected battery group in a working state at present if the number of the series-connected battery groups in a working state at present is one, a step of determining the maximum total discharging current of the electric vehicle power battery according to a condition whether the discharging between the series-connected battery groups in a working state at present is balanced and the maximum discharging current of the series-connected battery group whose actual discharging current exceeds a limit most easily in all series-connected battery groups in a working state at present if the number of the series-connected battery groups in a working state at present is larger than two, and a step of determining the total output power of the electric vehicle power battery according to the maximum total discharging current. The power distribution is reasonable.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

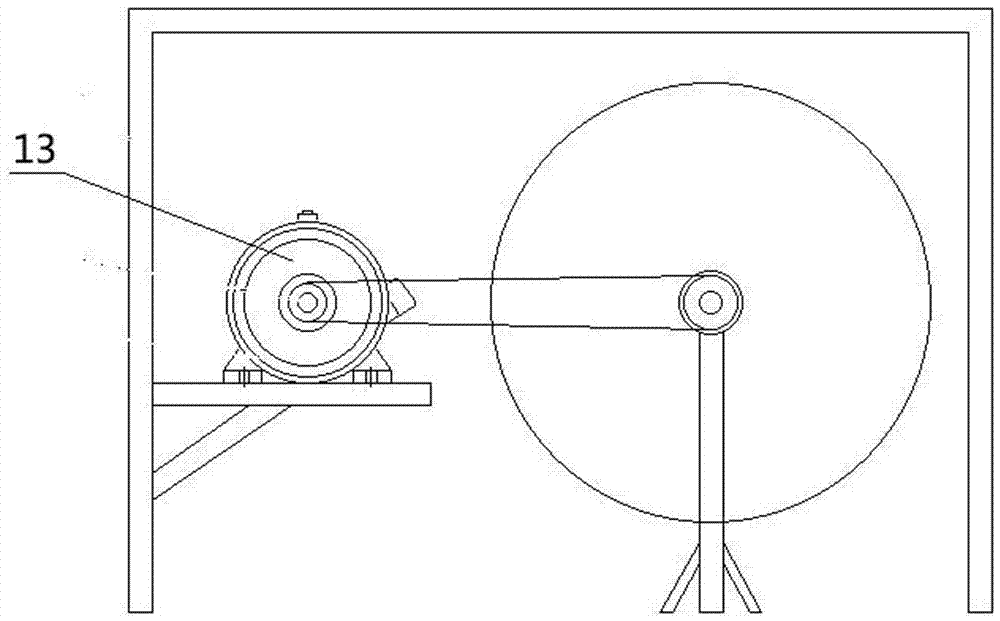

Tank type erosion abrasion testing device and method

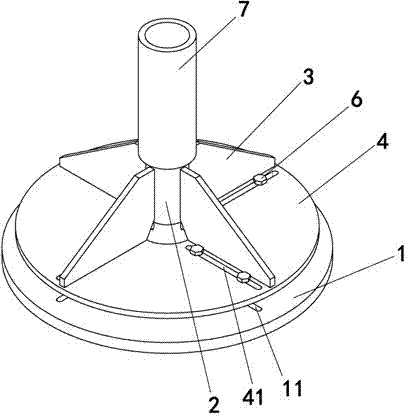

ActiveCN106885749AImprove uniformityAvoid uneven slurry consistencyInvestigating abrasion/wear resistanceTest sampleEngineering

The invention belongs to the technical field of wear test devices, and in particular relates to a tank type erosion wear test device and method. The tank type erosion wear test device comprises a bracket and a test sample clip, wherein the bracket is provided with a rotatable hollow roller; the hollow roller is provided with a sealing cover; a through hole is formed in the hollow roller or the sealing cover; the test sample clip is arranged in the hollow roller and is connected with the bracket; when the hollow roller rotates, the test sample clip is static and immobile; a blade is arranged on an inner wall of the hollow roller. According to the tank type erosion abrasion testing device and method, types of slurry milling materials, pH (Potential of Hydrogen) values of slurry, an erosion linear speed of a test sample and an erosion angle all can be adjusted, and the tank type erosion wear test device is applicable to researches on performance of wear-resisting materials; the position of the test sample in the hollow roller can be adjusted through a displacement device, and demands on the size of the test sample are not strict; tests for erosion wear performance of the test sample at different positions are realized; the adjustment of the erosion angle in a range of 0 to 90 degrees can be realized by adjusting the test sample clip.

Owner:中钢不锈钢管业科技山西有限公司

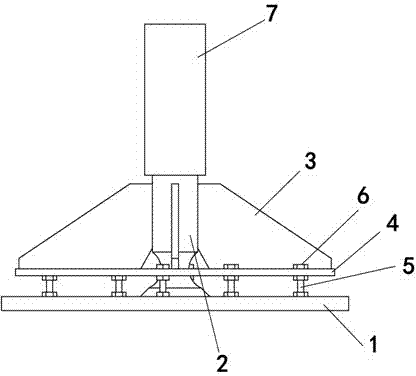

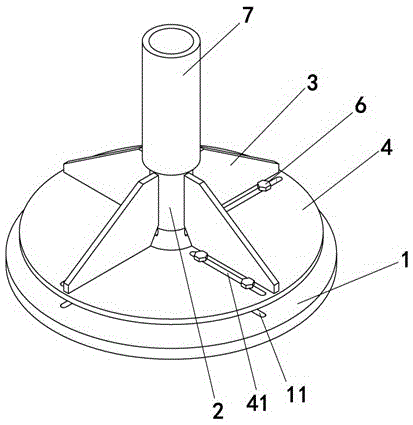

Rack experimental device with adjustable rigidity and rigidity adjusting method thereof

ActiveCN102879205AStiffness adjustmentIn line with the actual working statusVehicle testingMachine part testingExperimental validationFatigue testing

The invention provides a rack experimental device with adjustable rigidity and a rigidity adjusting method thereof in order to solve the problem that the conventional rack experimental device has a bad fatigue test effect on the whole automobile or other parts of the automobile. According to arrangement of bolts and fastening nuts corresponding to bottom support through grooves and base through grooves and the setting of height of a supporting cylinder, the rigidity of the rack experimental device can be conveniently adjusted, particularly the rigidity can be adjusted in different directions, so that a fatigue test state accords with an actual operating state of the automobile body and the other parts of the automobile, the precision and effect of the fatigue test of the automobile body and the other parts of the automobile are greatly improved, and an accurate experimental validation guidance is provided for the design of the automobile and the parts.

Owner:NINGBO HUIZHONG AUTOMOTIVE CHASSIS MFG

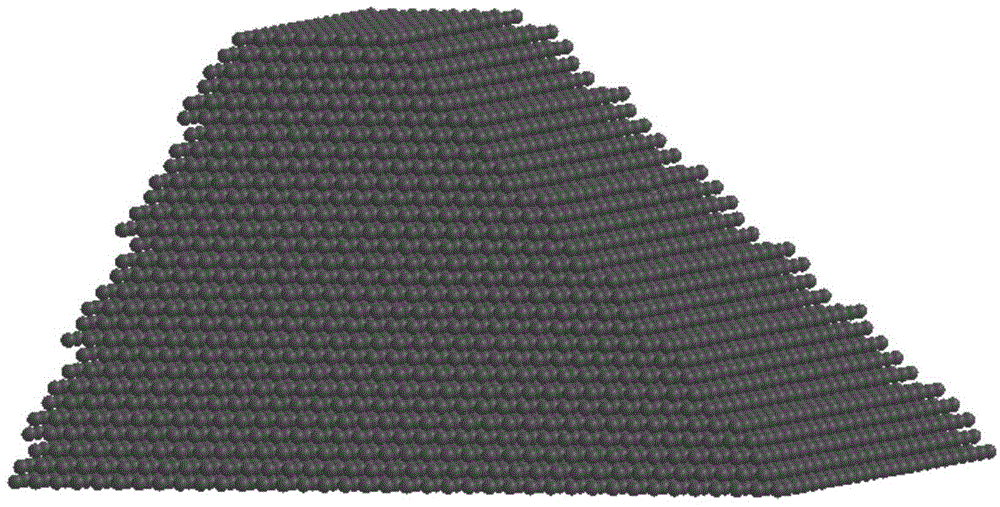

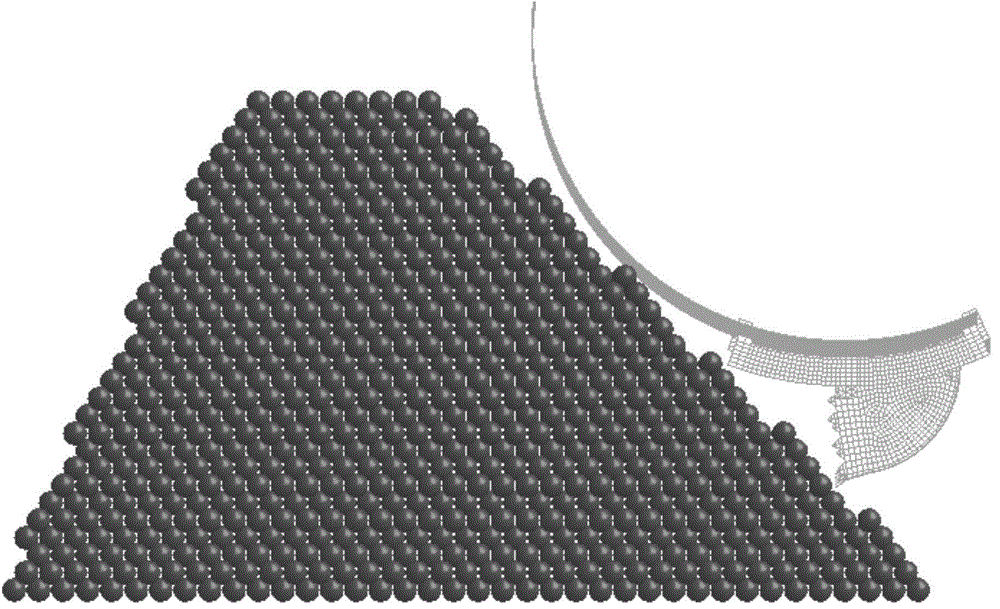

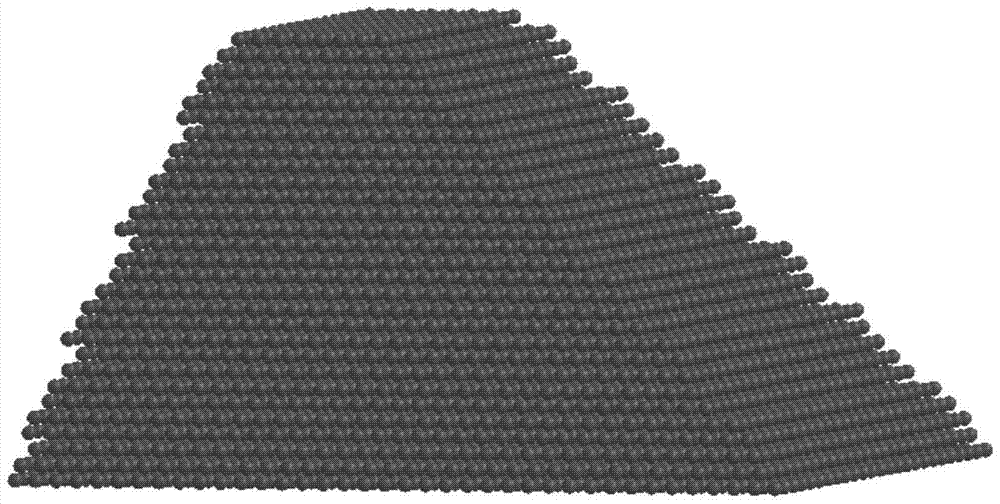

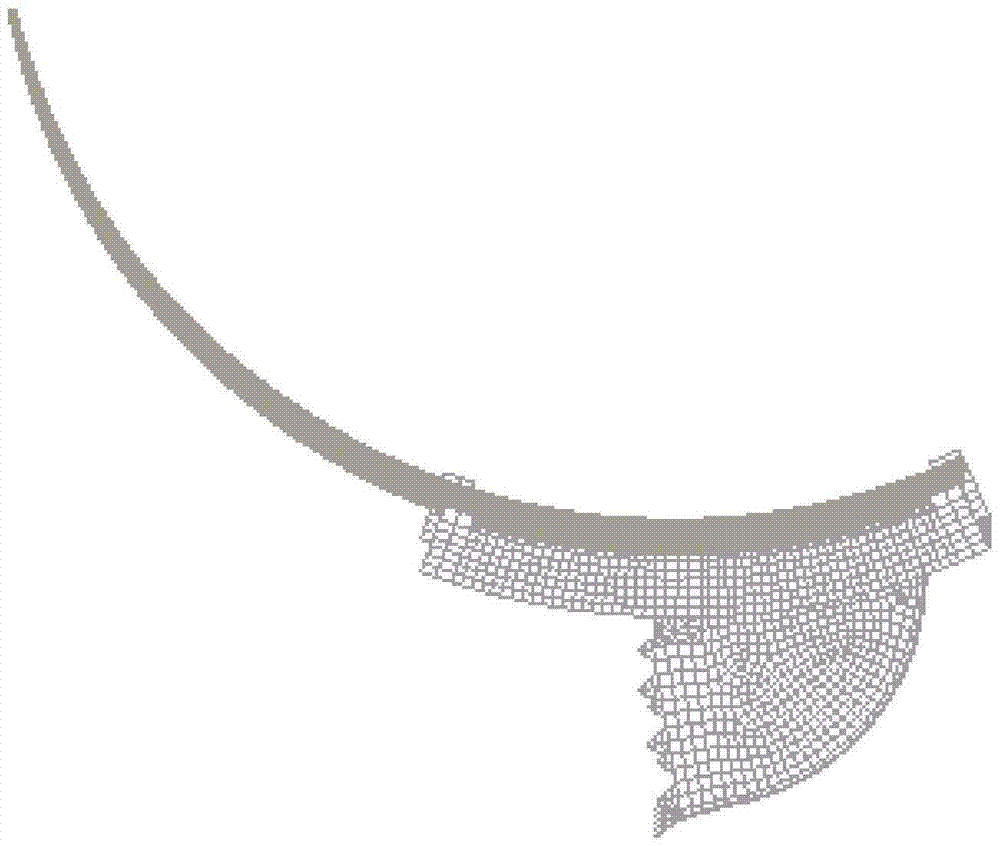

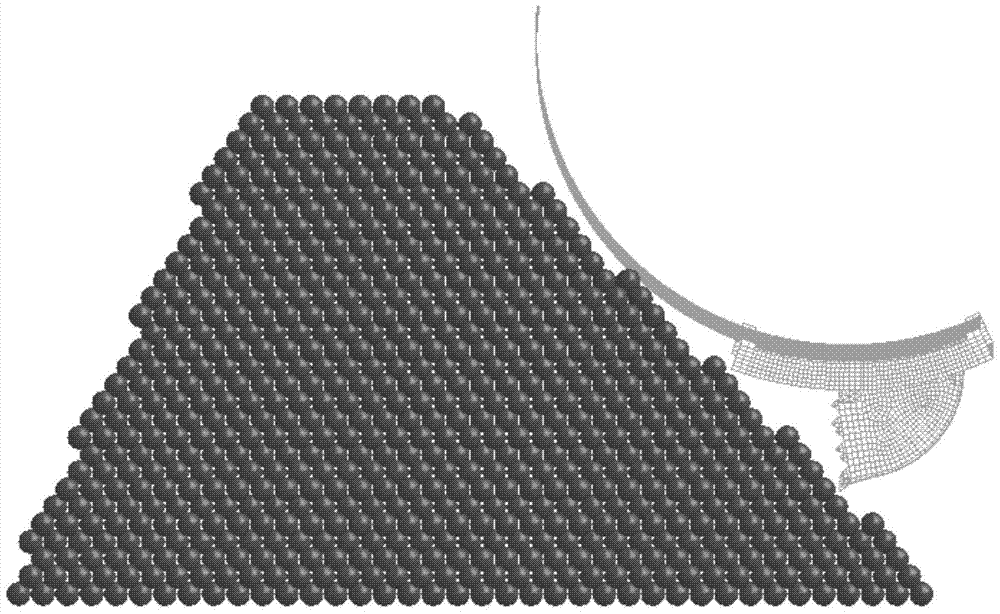

Method for establishing excavating, material-taking and cutting resistance time history simulation model of bucket wheel machine

ActiveCN104615833AReduce porosityThe turning track is correctSpecial data processing applicationsEngineeringUnit model

The invention provides a method for establishing an excavating, material-taking and cutting resistance time history simulation model of a bucket wheel machine. The method comprises the following steps of establishing a material pile model; establishing a bucket finite unit model; and combining the material pile model and the bucket finite unit model. A sphere particle unit is coupled with the finite unit to establish the simulation model creatively, and model data required for simulation of a cutting resistance time history are provided.

Owner:HUNAN CHANGZHONG MACHINERY

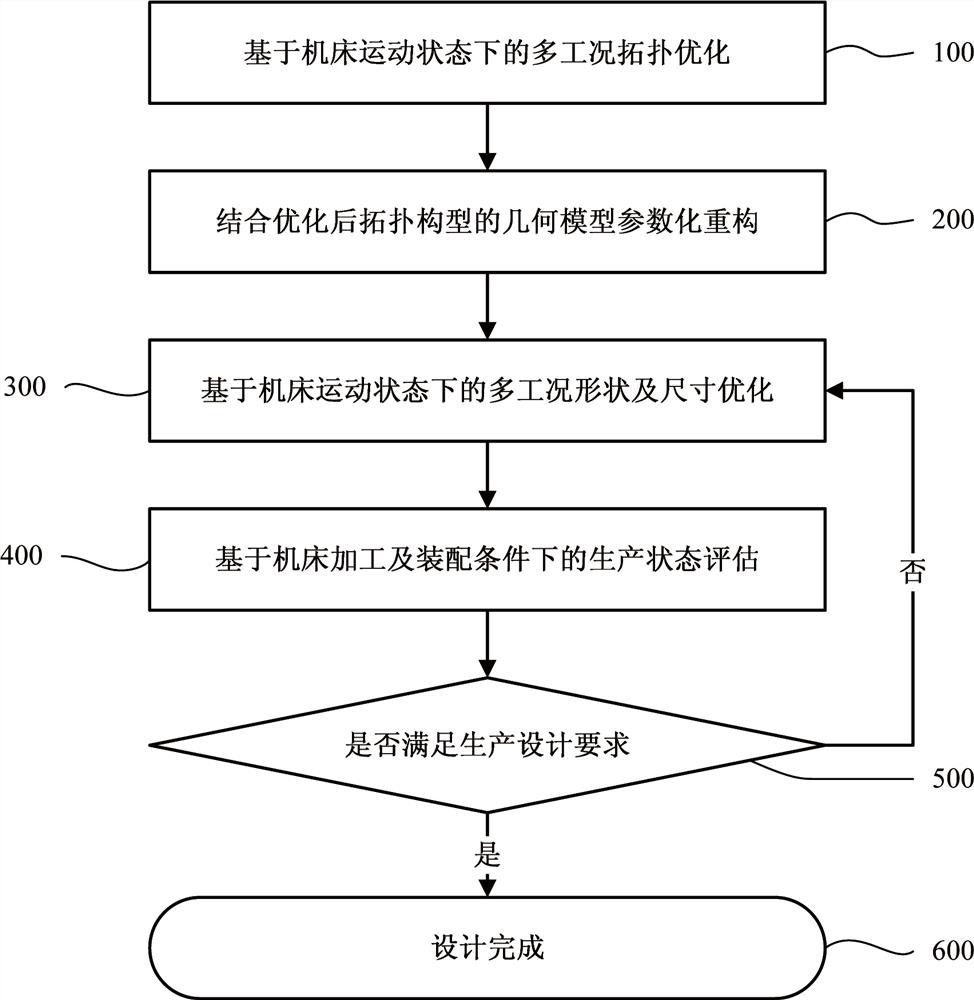

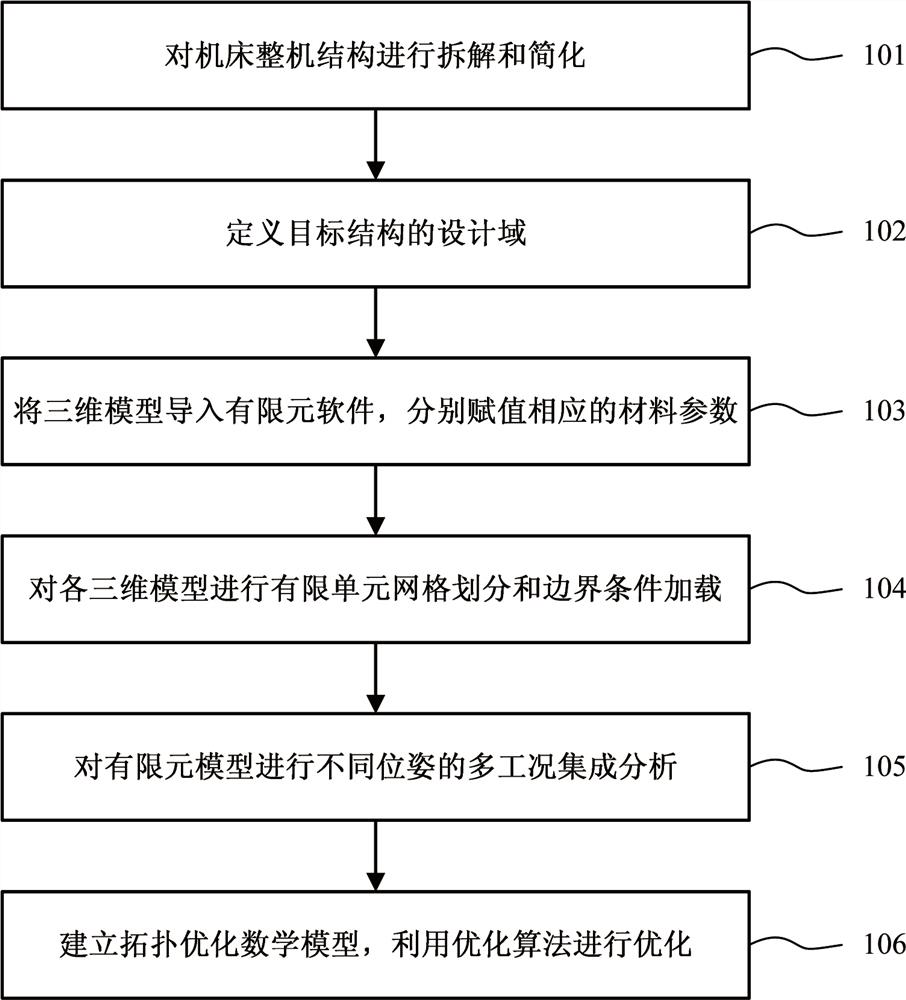

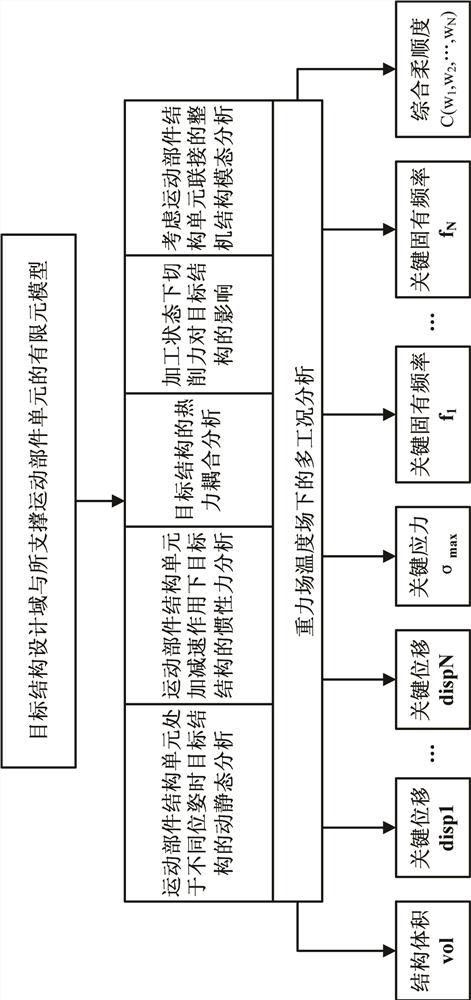

Key host assembly structure optimization design method based on machine tool working state

PendingCN112487673AIn line with the actual working statusMeet rigid requirementsGeometric CADDesign optimisation/simulationGeometric modelingProcess engineering

The invention relates to a structure optimization design method of a machine tool component, in particular to a key host component structure optimization design method based on a machine tool workingstate. The method comprises the following steps: A, performing multi-working-condition topological optimization based on a machine tool motion state; B, parameterization reconstruction is carried outon the geometric model combined with the optimized topological structure; C, optimizing the shape and the size based on multiple working conditions of the machine tool in the motion state; D, performing production state evaluation based on machine tool machining and assembling conditions. The method is not limited to an assembly structure needing to be optimized, but comprehensively considers complete machine mounting structures such as the motion connecting piece and the supported piece, and fully considers various motion states and various working conditions of the machine tool, so that theoptimized design index is closer to the actual working state of the machine tool, and the optimized structure is higher in reliability.

Owner:BEIJING JINGDIAO GRP CO LTD

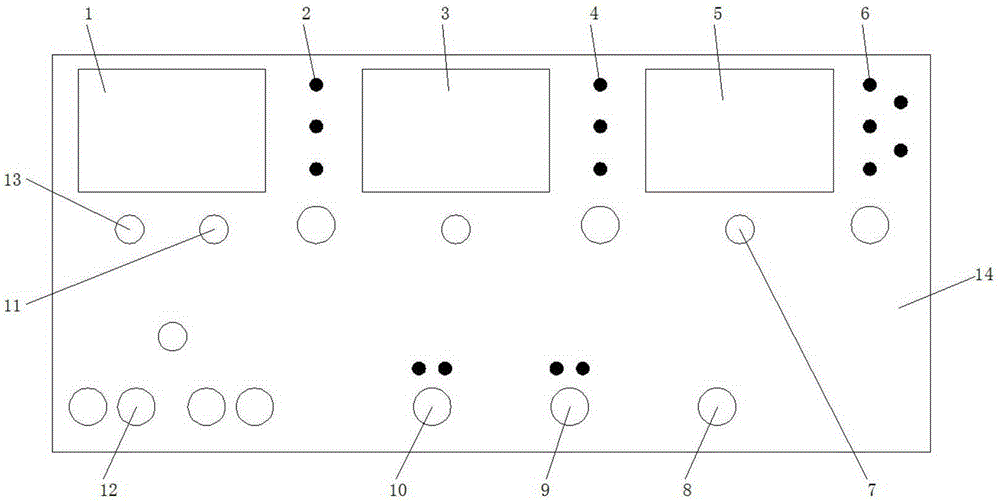

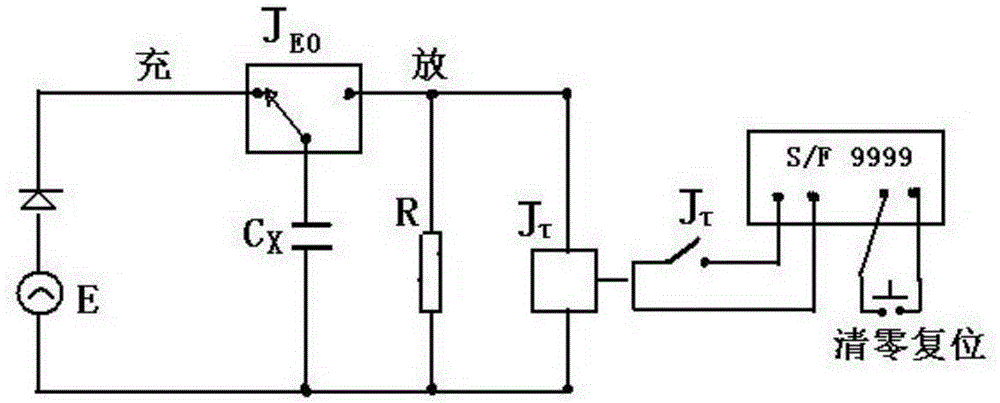

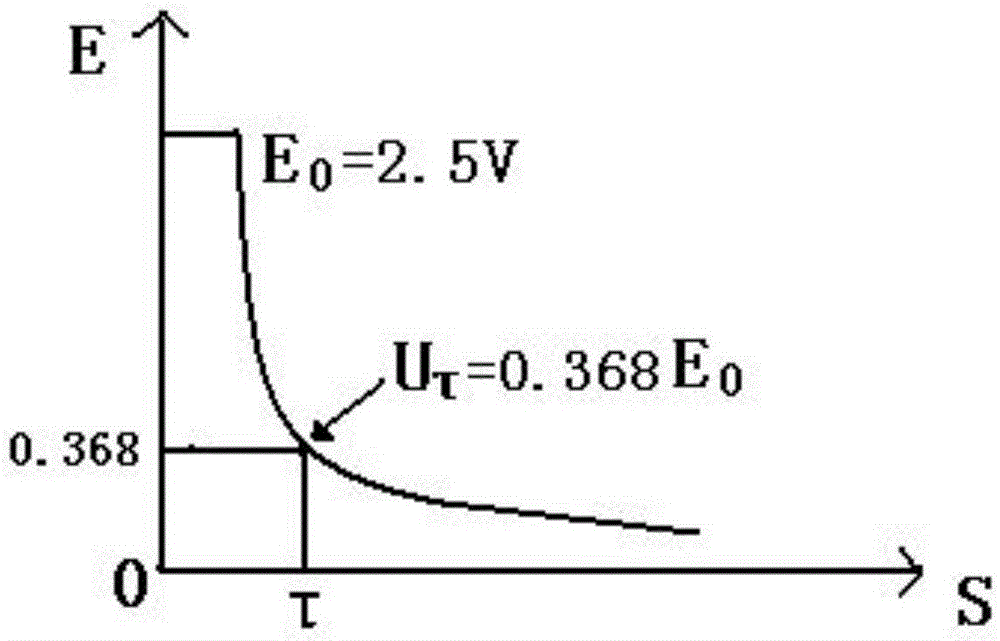

Farad meter for ultrahigh capacitance detection

InactiveCN105425050AIn line with the actual working statusSimple structureCapacitance measurementsCapacitanceInternal resistance

The invention discloses a Farad meter for ultrahigh capacitance detection, which comprises a Farad meter panel, wherein a Farad capacitance value display is disposed on the Farad meter panel, one side of the Farad capacitance value display is successively equipped with a Farad capacitance range selection switch, a display of a testing voltage and a leak current, a testing voltage selection switch, an inner resistance value display and an inner resistance range selection switch, a capacitance testing button and a capacitance meter reading reset button are respectively disposed under the Farad capacitance value display, a binding post of a tested capacitance is disposed under the capacitance testing button and the capacitance meter reading reset button, one side of the binding post of the tested capacitance is successively equipped with a charging control switch, a constant-current selection switch and a power source switch, and an inner resistance testing button is disposed under the inner resistance value display. The Farad meter for the ultrahigh capacitance detection disclosed by the invention can better satisfy an actual working state of the ultrahigh capacitance, wherein measuring and control data needs not to be treated by intelligent computer processing, the capacitance can be displayed clearly and objectively, the structure is simple, and utilization is convenient.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

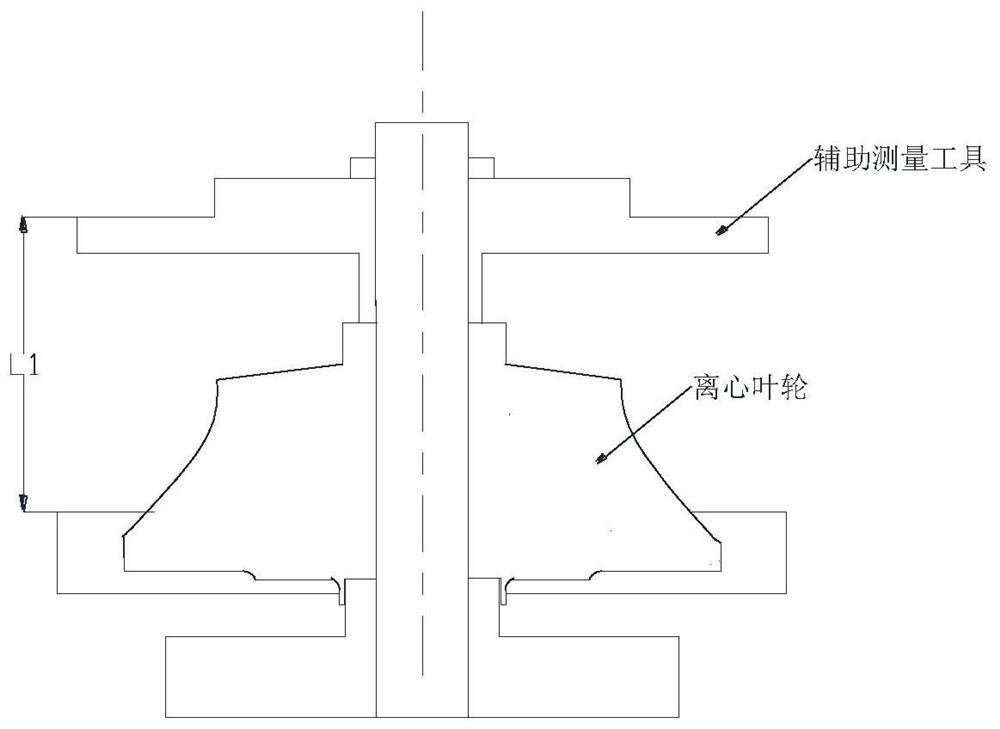

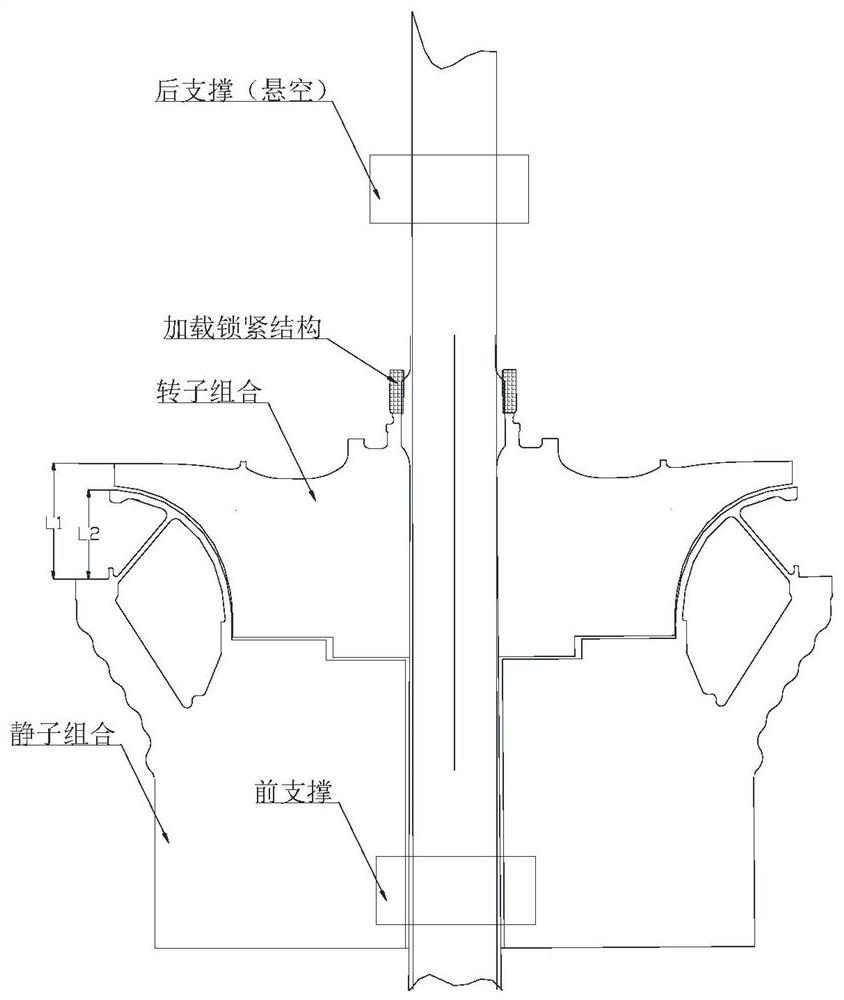

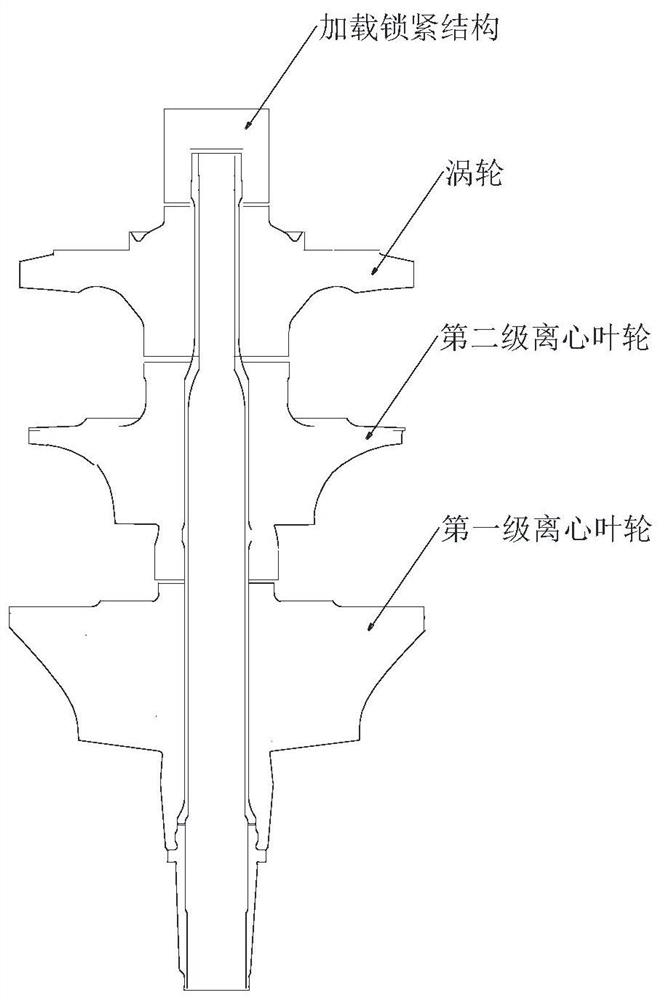

Device and method for measuring axial dimension of aero-engine rotor

PendingCN114001689AIn line with the actual working statusAvoids the need to repeatedly confirm measurement pointsMechanical measuring arrangementsClassical mechanicsControl theory

The invention discloses a device and a method for measuring an axial dimension of an aero-engine rotor. The device can achieve the assembly of all parts of a rotor combination, can apply axial loading, better accords with the actual working state of the rotor, and is higher in measurement result accuracy. The rotor coaxial device is used for supporting front and rear fulcrums of the assembled rotor combination so that the fact that all stages of rotors of the rotor combination are coaxial is ensured, and the problem of axial deviation of the rotors caused by single-point support is avoided. The blade limiting device is used for circumferentially limiting the blade of the rotor so that the problem that a measurer needs to repeatedly confirm a measuring point due to the fact that the blade is not on a measuring head movement track of the three-coordinate measuring device or the measuring head is not in contact with the blade is solved, and the measuring efficiency is improved. The three-coordinate measuring device can complete the measurement of all axial dimensions in the same rotor state, does not need excessive measurement auxiliary tools, simplifies the dimension chain calculation, and is better in universality.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for creating simulation model of cutting resistance time history for excavation and reclaiming of bucket wheel machine

ActiveCN104615833BReduce porosityThe turning track is correctSpecial data processing applicationsTime courseElement model

The invention provides a method for creating a time history simulation model of bucket wheel excavation and reclaiming cutting resistance, including the steps of building a stockpile model, building a bucket finite element model, and combining the stockpile model with the bucket finite element model. For the first time, the coupling of spherical particle elements and finite elements is used to create a simulation model, which provides the model data required for simulating the time history of cutting resistance.

Owner:HUNAN CHANGZHONG MACHINERY

A tank type erosion wear test device and method

ActiveCN106885749BImprove uniformityAvoid concentration unevennessInvestigating abrasion/wear resistanceWear testingSlurry

The invention belongs to the technical field of wear test devices, in particular to a tank-type erosion wear test device and method, a tank-type erosion wear test device, including a bracket and a sample holder, and the bracket is provided with a rotatable hollow drum, the hollow drum is provided with a sealing cover, the hollow drum or the sealing cover is provided with a through hole, the sample holder is arranged inside the hollow drum and connected with the support, when the hollow drum rotates, the sample The clamp is stationary, and blades are arranged on the inner wall of the hollow cylinder; the type of slurry abrasive, the pH value of the slurry, the erosion linear velocity and the erosion angle of the sample of the present invention can be adjusted, and are suitable for wear-resistant materials. Performance research; through the displacement device, the position of the sample clamp in the hollow cylinder can be adjusted, and there is no strict requirement on the size of the sample, so that the test of the erosion and wear performance of the sample at different positions can be realized; by adjusting the sample clamp, it can be realized The erosion angle can be adjusted within the range of 0 to 90 degrees.

Owner:中纲不锈钢管业科技山西有限公司

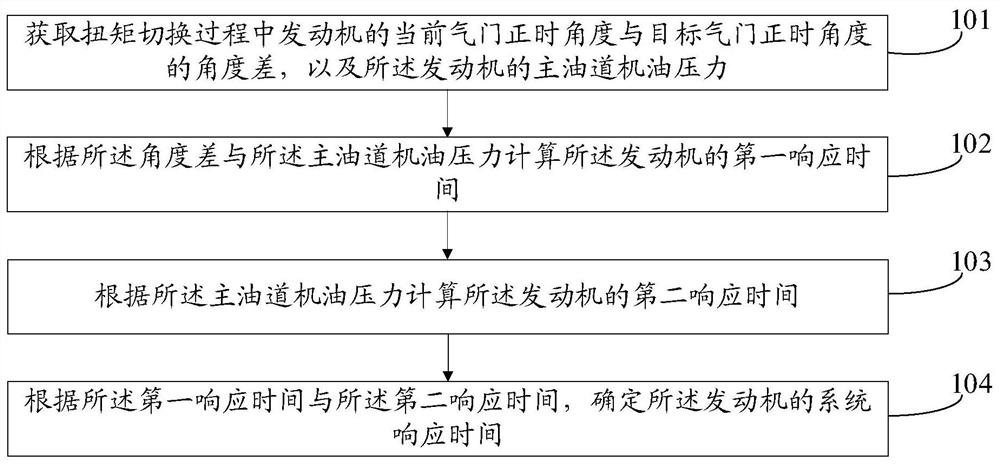

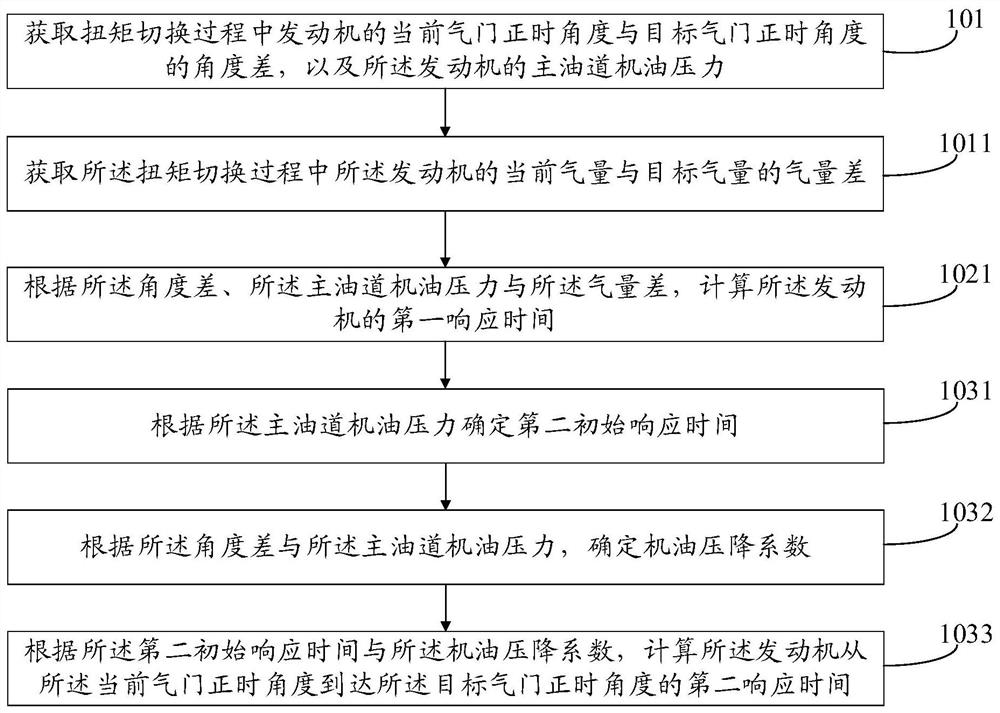

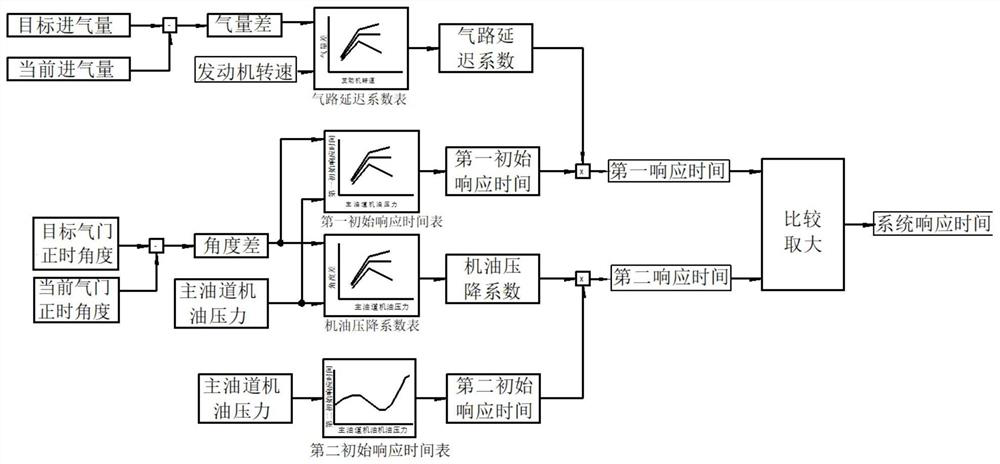

Method and device for calculating engine response time

ActiveCN112696276BIn line with the actual working statusGuaranteed normal outputInternal combustion piston enginesOutput powerEngineeringMechanical engineering

The present invention provides a method and device for calculating engine response time, which are applied in the field of engine cylinder deactivation control. The method may include obtaining the angle difference between the current valve timing angle of the engine and the target valve timing angle during the torque switching process, and The oil pressure of the main oil gallery of the engine; the first response time of the engine is calculated according to the angle difference and the oil pressure of the main oil gallery; the second response time of the engine is calculated according to the oil pressure of the main oil gallery ; Determine the system response time of the engine according to the first response time and the second response time. Through the solutions provided by the embodiments of the present invention, it is possible to accurately calculate the system response time actually required by the random cylinder deactivation engine during the torque switching process.

Owner:GREAT WALL MOTOR CO LTD

Cavity adjusting method for laser gyro and used light path and path length control mirror

ActiveCN100424470CIn line with the actual working statusRealize full scan tuningSagnac effect gyrometersAxial displacementGyroscope

This invention discloses a laser gyroscope chamber adjusting method and its light path distance control lens. The method is the following: to exert toothed wave voltage on four control units of the angle control elements; to whole scan loop light path in two-dimensional space, wherein, two control units in one group are of same frequency and reverse voltage; the maximum scanning voltage of the output light intensity is the chamber voltage of the best loop resonance light path. The light path distance control lens comprises slotted vane , angle control element , matching loop and distance control element.

Owner:NAT UNIV OF DEFENSE TECH

Power distribution method and device for power battery of electric vehicle, and electric vehicle

InactiveCN106712152BImprove fault detection efficiencyImprove accuracyBatteries circuit arrangementsElectric powerPower batteryPower flow

The invention provides a power distribution method and device of an electric vehicle power battery and an electric vehicle. The electric vehicle power battery comprises at least two series-connected battery groups in parallel. The power distribution method comprises a step of judging the number of the series-connected battery groups in a working state at present, a step of determining the maximum total discharging current of the electric vehicle power battery according to the maximum discharging current of a series-connected battery group in a working state at present if the number of the series-connected battery groups in a working state at present is one, a step of determining the maximum total discharging current of the electric vehicle power battery according to a condition whether the discharging between the series-connected battery groups in a working state at present is balanced and the maximum discharging current of the series-connected battery group whose actual discharging current exceeds a limit most easily in all series-connected battery groups in a working state at present if the number of the series-connected battery groups in a working state at present is larger than two, and a step of determining the total output power of the electric vehicle power battery according to the maximum total discharging current. The power distribution is reasonable.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

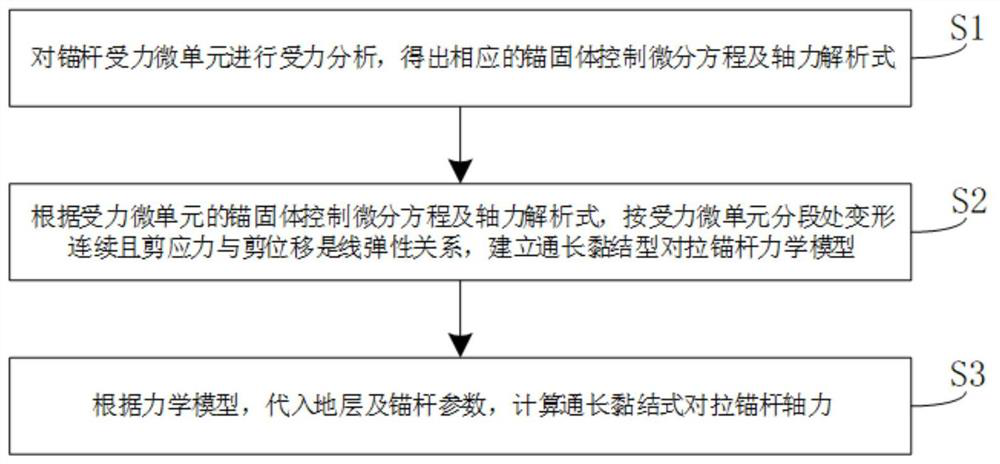

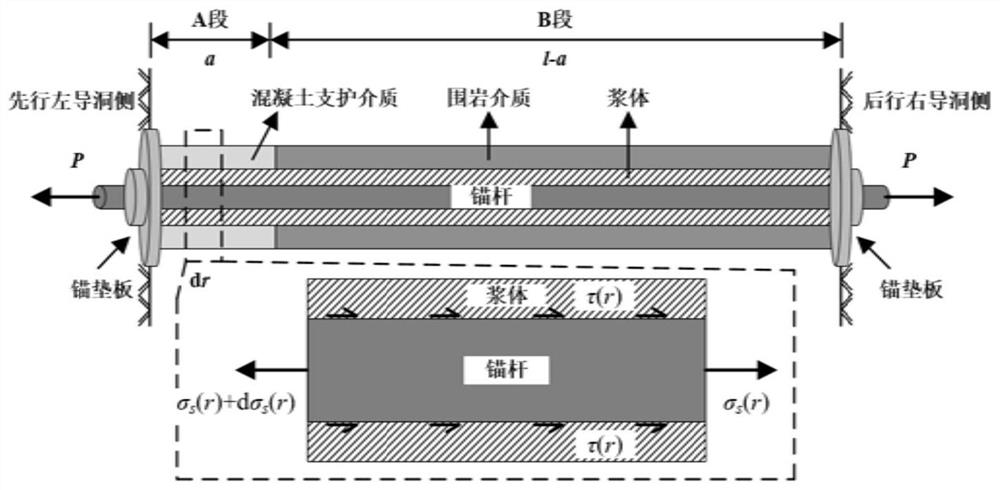

Method for calculating axial force distribution of core soil full-length bonding type counter-pulling anchor rod

PendingCN113935155AIn line with the actual working statusSimply survey the parametersDesign optimisation/simulationComplex mathematical operationsMechanical modelsClassical mechanics

The invention provides a method for calculating axial force distribution of a core soil full-length bonding type counter-pulling anchor rod, which comprises the following steps of: carrying out stress analysis on an anchor rod stress micro-unit to obtain a corresponding anchoring body control differential equation and an axial force analytic expression; according to the anchoring body control differential equation and the axial force analytic expression of the stress micro-unit, establishing a full-length bonding type opposite-pulling anchor rod mechanical model according to the situation that deformation at the segmented position of the stress micro-unit is continuous and shear stress and shear displacement are in a linear elastic relation; and according to a mechanical model, substituting the stratum and anchor rod parameters, and calculating the axial force of the full-length bonding type opposite-pulling anchor rod. The core soil full-length bonding type opposite-pulling anchor rod mechanical model is provided which satisfies the actual working state of the opposite-pulling anchor rod, considers the influence of the double-sidewall method side pilot tunnel excavation sequence, is used for predicting the axial force of the opposite-pulling anchor rod at a certain position, provides a reference for design and construction of the opposite-pulling anchor rod, can further obtain distribution curve of the axial force of the full-length bonding type opposite-pulling anchor rod along the full length of the rod body, and can obtain the axial force distribution curve only by inputting simple geological exploration parameters.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

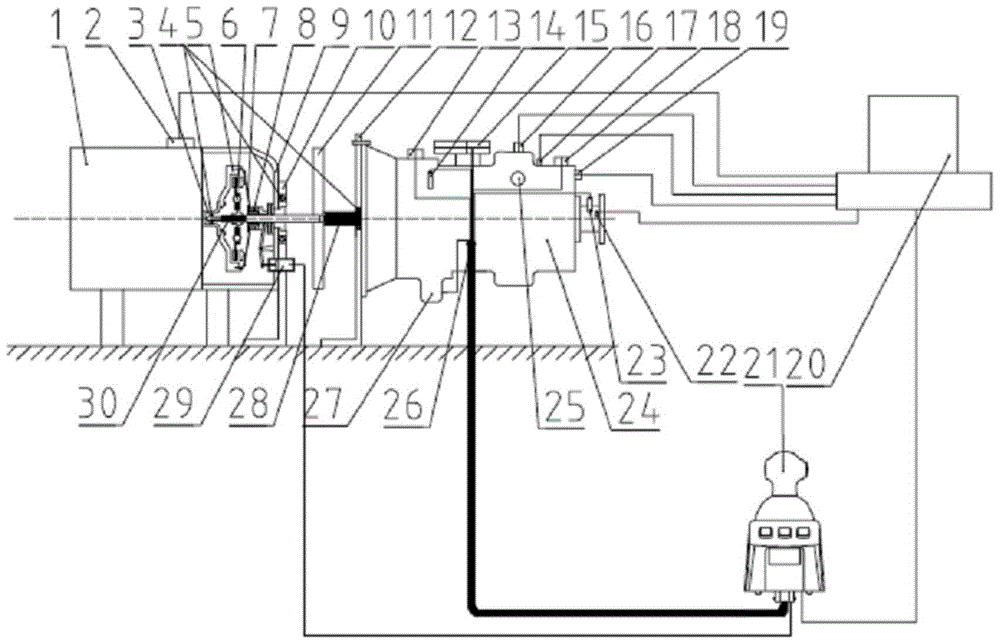

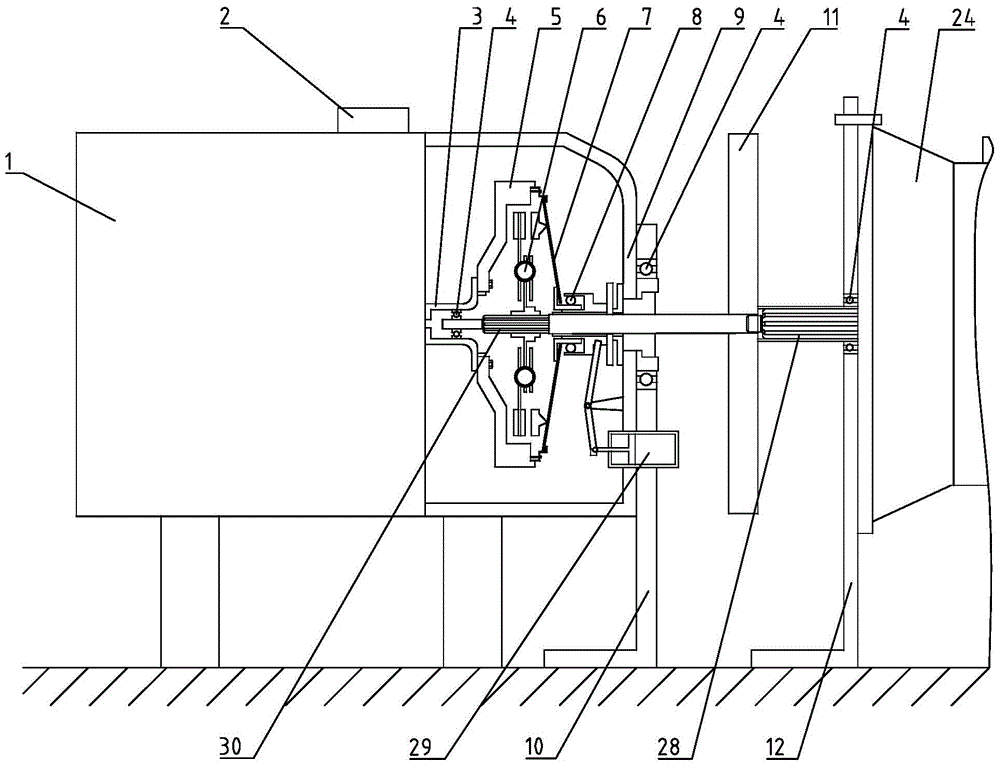

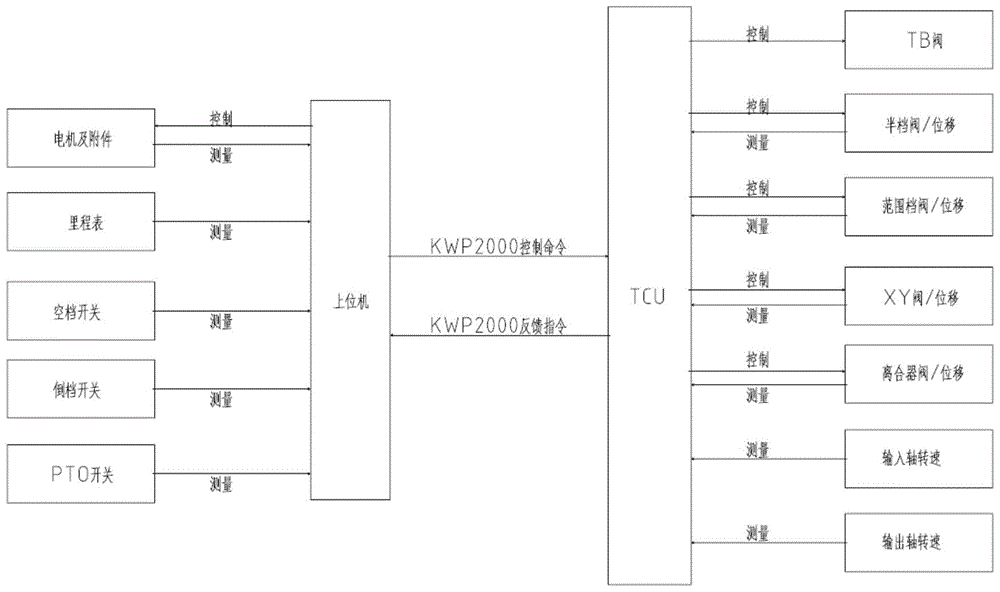

A kind of amt offline detection method

ActiveCN104034527BAvoid the repetitive process of testing individuallyReduce testing costsMachine gearing/transmission testingSolenoid valveTransformer

An AMT offline detection test bench of the invention includes a power device, a clutch and a host computer; the output end of the power device is provided with a first flywheel; the pressure plate of the clutch is fixed on the first flywheel, and the friction plate is provided with an output end and a transformer to be tested The transmission shaft is connected to the transmission input shaft of the transmission, and the release bearing of the clutch is fitted on the transmission shaft; the IO port of the host computer and the clutch valve of the clutch are respectively connected with the IO port of the control unit of the transmission under test; the IO port of the host computer is also separately The control end of the power unit is connected with the control part of the clutch, and the input port of the upper computer is connected with the feedback part of the clutch. The detection method of the present invention includes the following steps: 1) testing the air tightness of the transmission under test, and connecting the air source interface of the wiring harness interface; 2) turning on the power for initialization; 3) entering the self-learning mode; 4) each solenoid valve state and sensor signal test; 5) power take-off switch test; 6) end detection by generating test report.

Owner:SHAANXI FAST GEAR CO

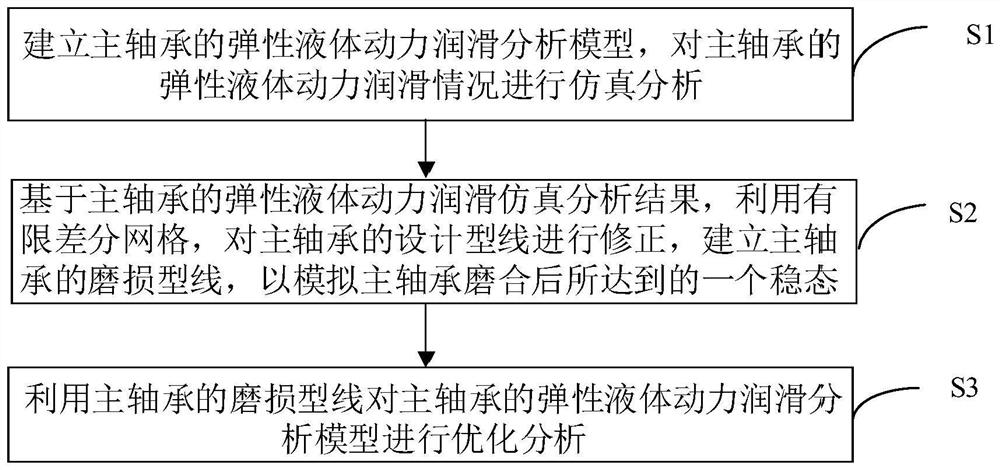

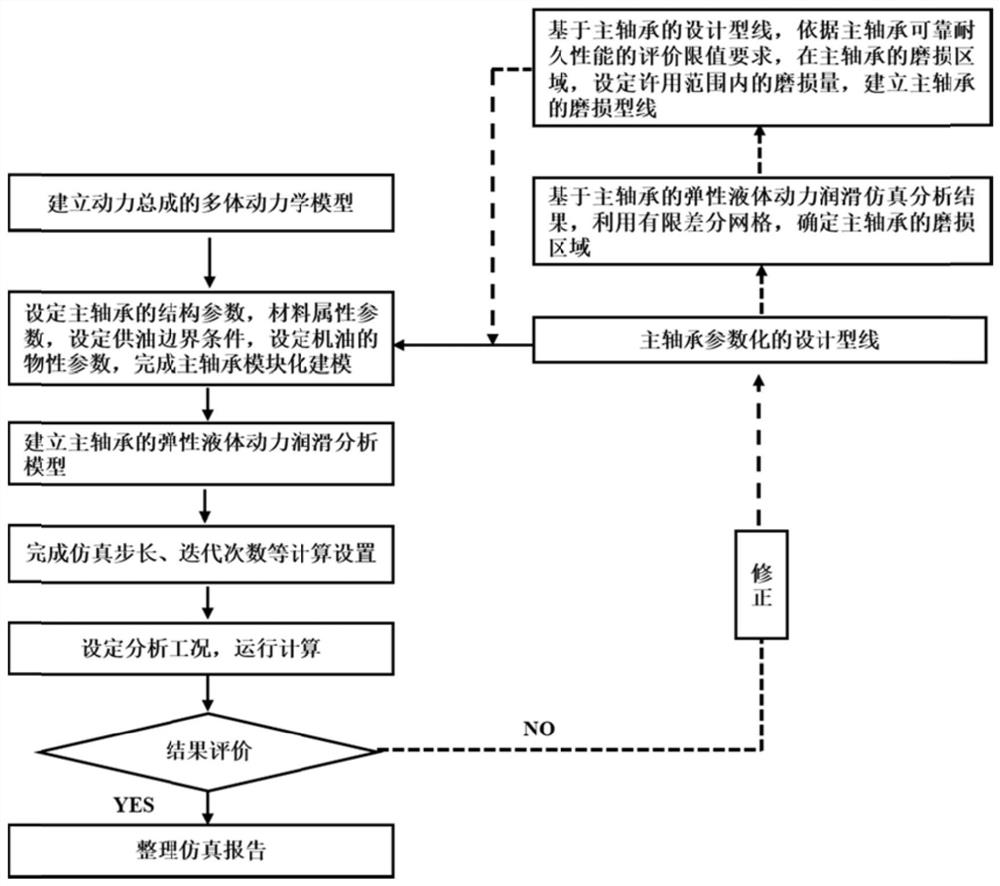

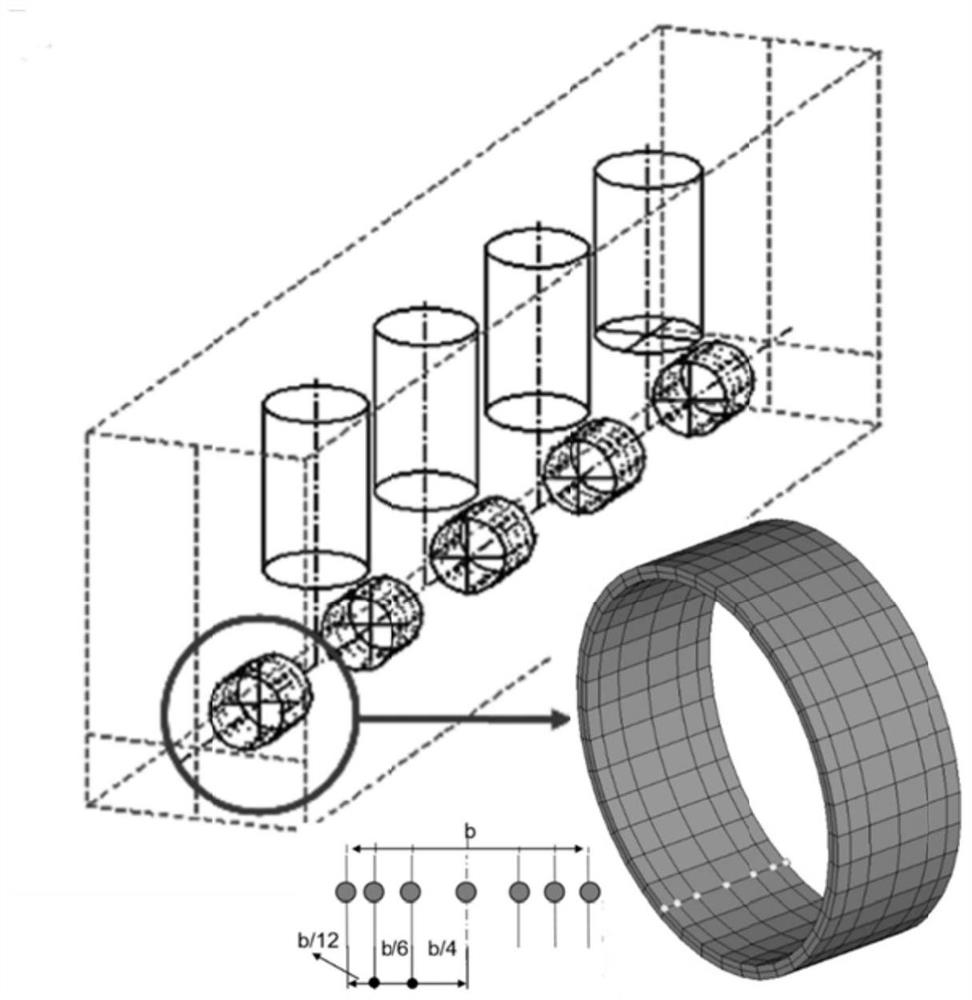

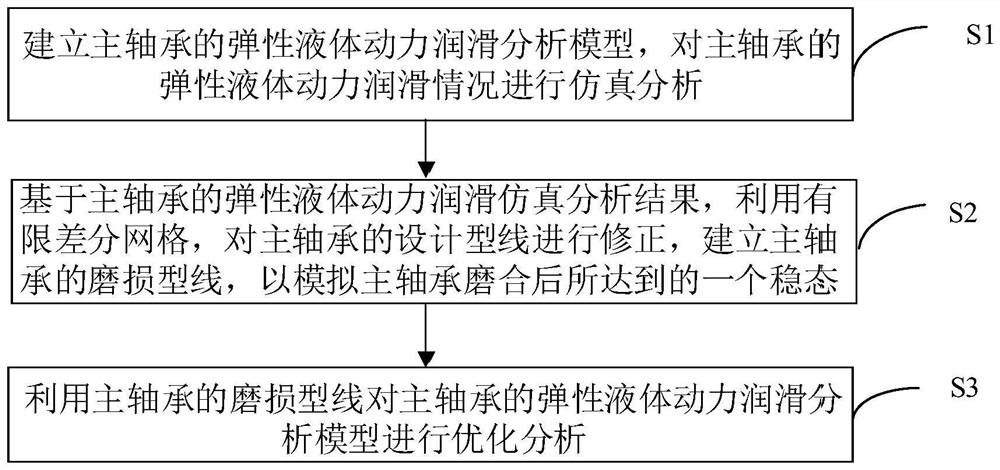

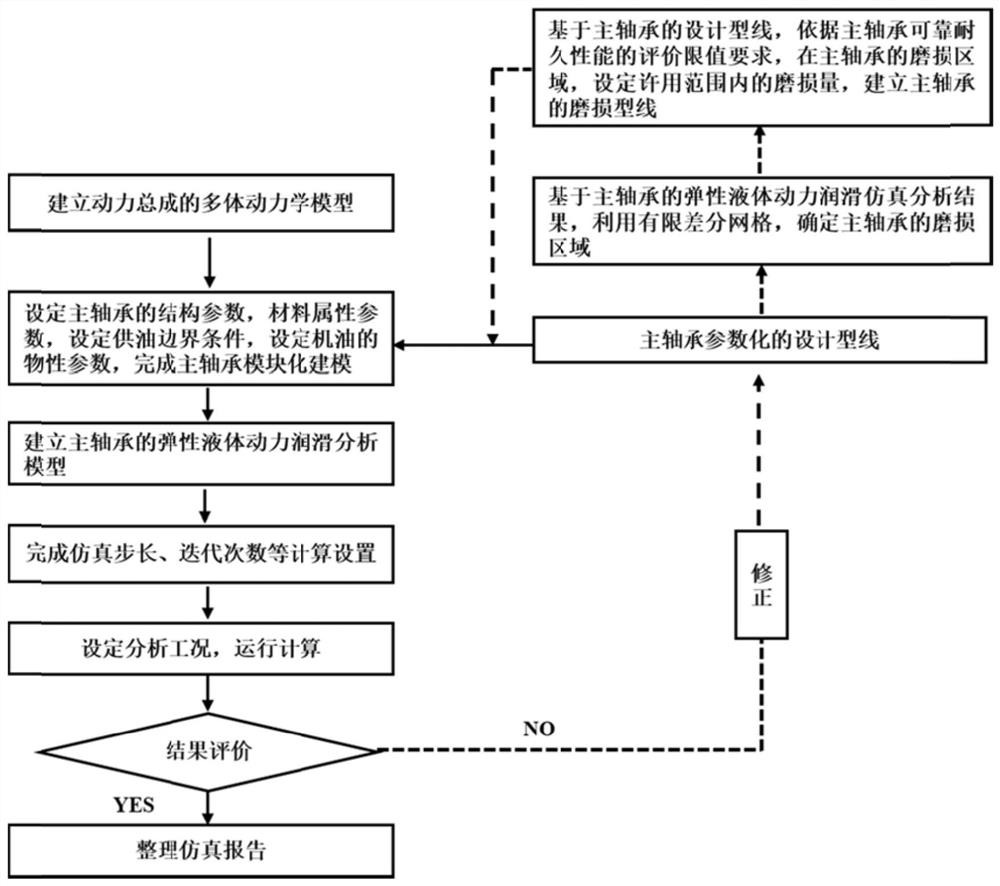

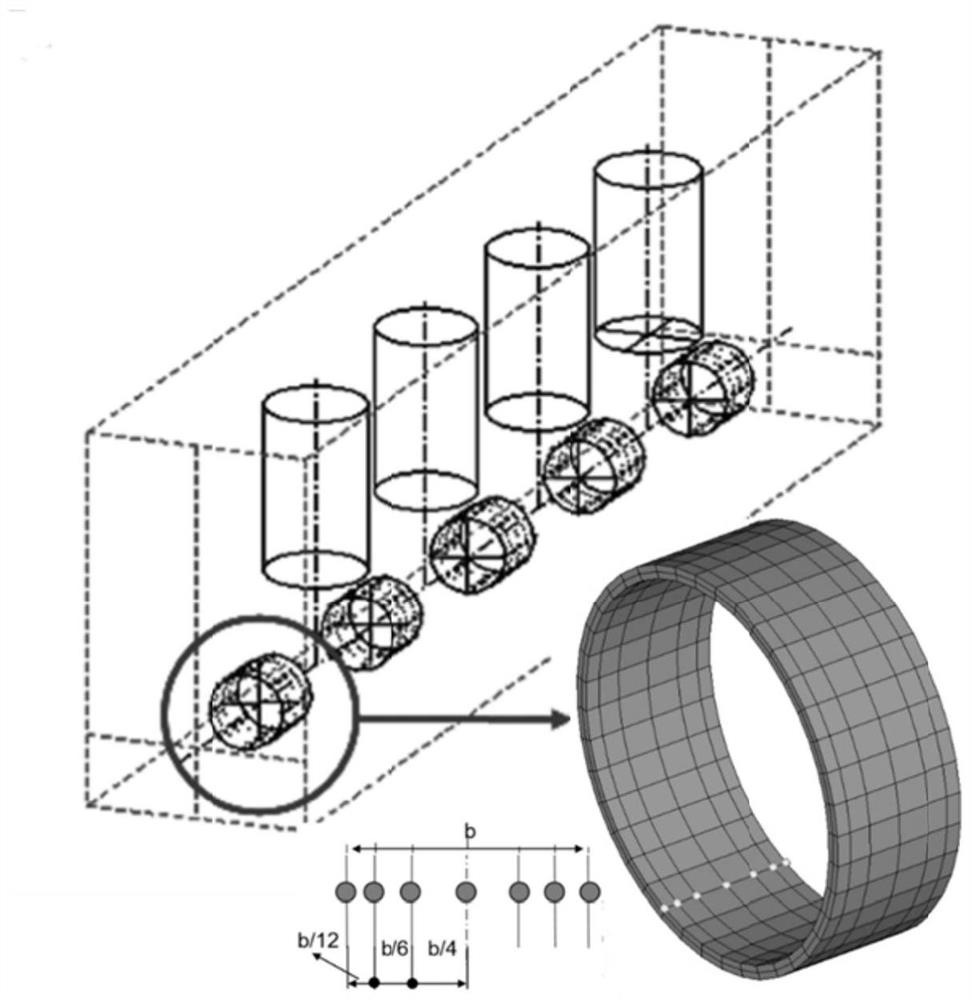

Method and device for correcting wear profile of main bearing of engine

ActiveCN112580242BReduce false positive rateImprove development efficiencyGeometric CADDesign optimisation/simulationClassical mechanicsLubrication

The invention discloses a method and device for correcting the wear profile of an engine main bearing, belonging to the technical field of engine bearing power, wherein the realization of the method includes: establishing an elastic hydrodynamic lubrication analysis model of the main bearing, Carry out simulation analysis of lubrication conditions; based on the simulation analysis results of elastohydrodynamic lubrication of the main bearing, use the finite difference grid to correct the design profile of the main bearing, and establish the wear profile of the main bearing to simulate the main bearing after running-in A steady state of the main bearing; use the main bearing's wear profile to optimize the analysis model of the elastohydrodynamic lubrication of the main bearing. The invention simulates a steady state of the main bearing after running-in through the wear profile of the main bearing, which is more in line with the actual working state of the main bearing, thereby improving the simulation accuracy of the elastic dynamic lubrication analysis of the main bearing and reducing the reliability and durability of the main bearing. false positive rate.

Owner:DONGFENG MOTOR CORP HUBEI

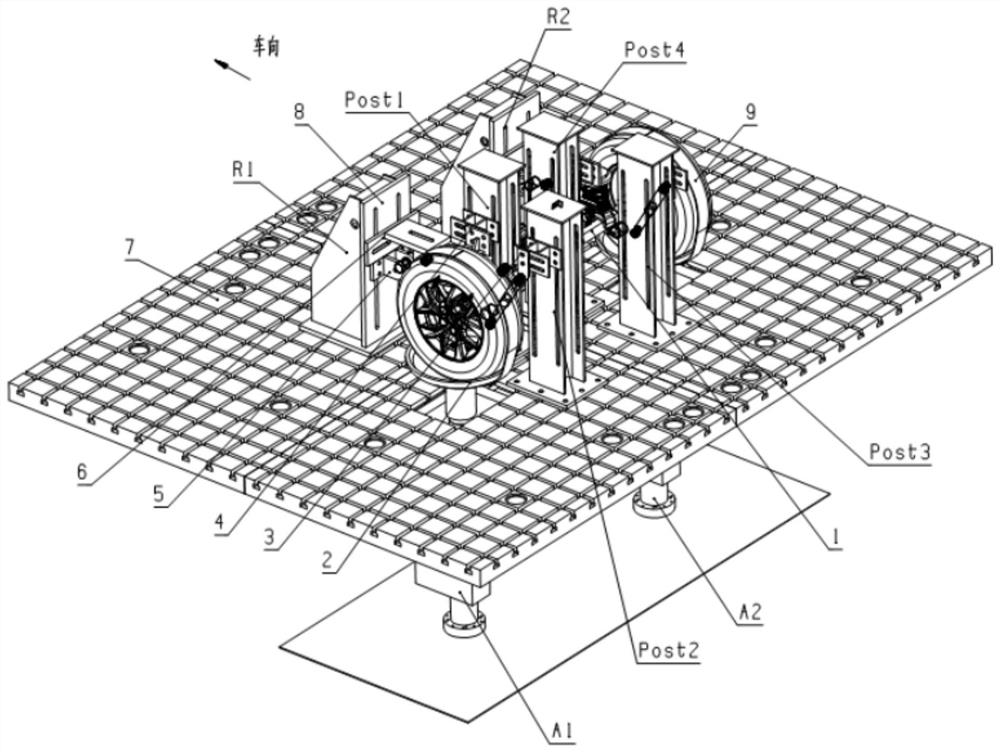

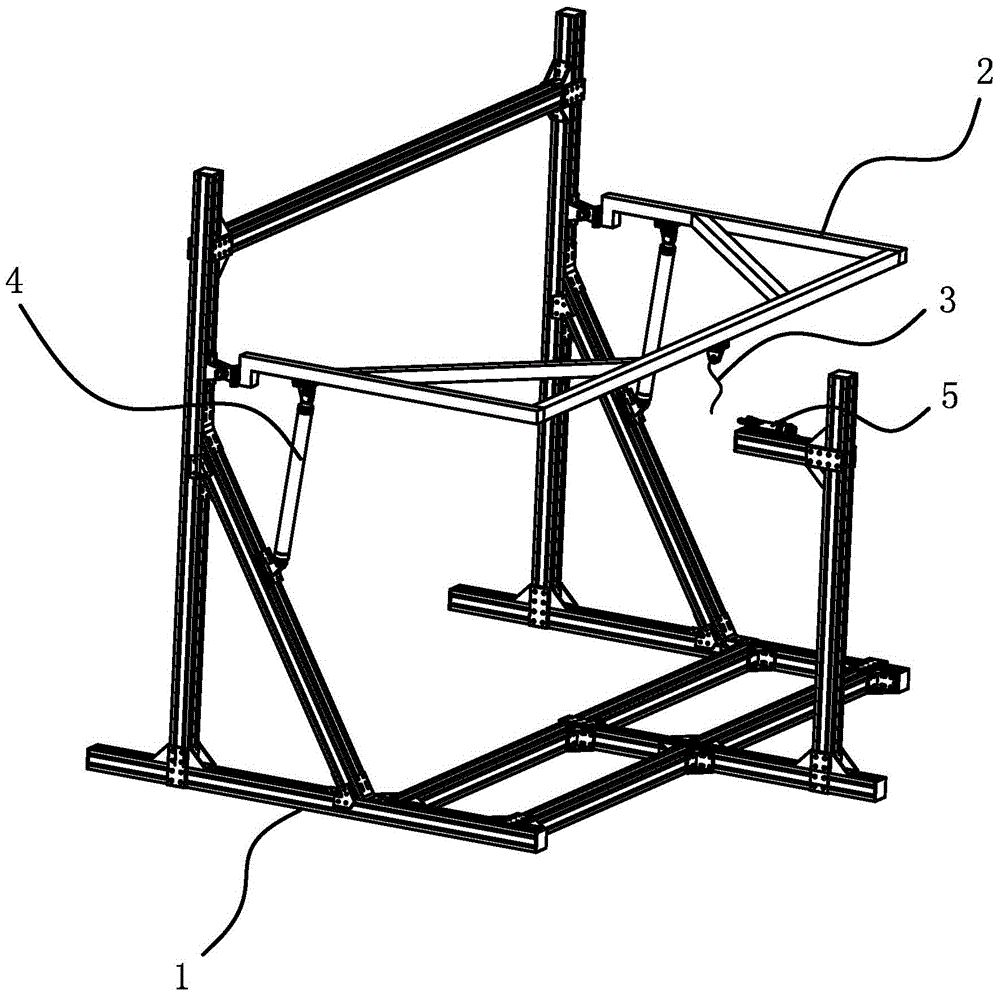

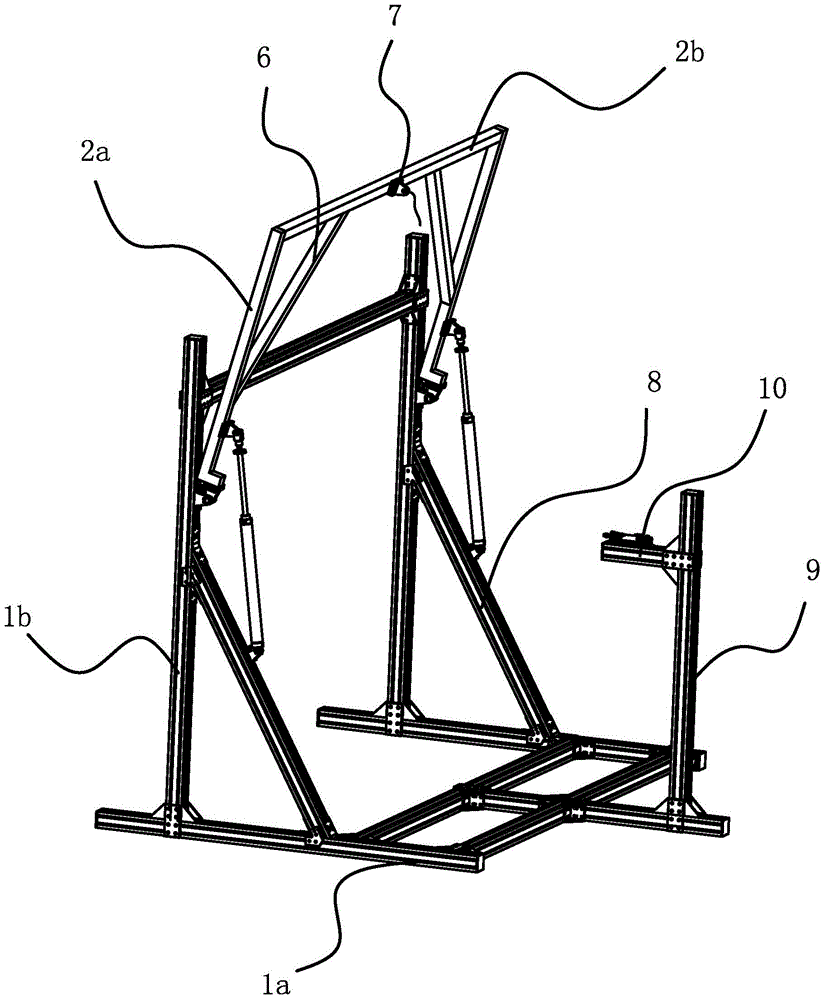

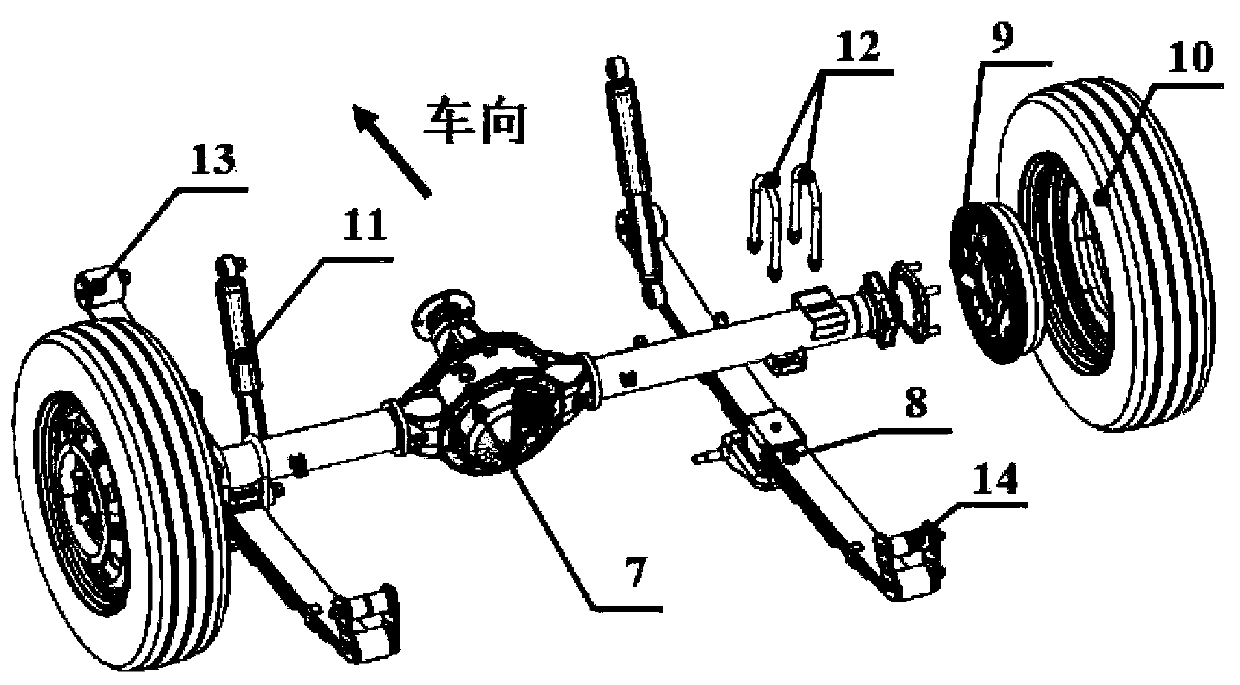

Fatigue durability test device and method for multi-link rear suspension axle housing assembly

ActiveCN108931382BShorten the development cycleLow costVehicle testingMachine part testingControl armControl theory

The invention relates to a fatigue endurance testing device and method for a multi-link rear suspension axle housing assembly. A tire of a multi-link rear suspension assembly is arranged and fixed ona tray on the top of an actuating support member. A left horizontal reaction force seat and a right horizontal reaction force seat are fixed on an iron floor, and upper and lower control arm members are fixed on the horizontal reaction force seats to fix an upper control arm and a lower control arm respectively. Four columns are fixed on the iron floor, wherein spring fixing parts are fixed on twoof the columns, and springs are fixed on the spring fixing parts and are adjusted in height through sliding grooves. Shock absorber fixing parts are fixed on another two columns, and shock absorbersare fixed on the shock absorber fixing parts and are adjusted in height through sliding grooves. The fatigue endurance testing device and method realize durability testing of the shock absorbers, thesprings, the upper and lower control arms and other components and can provide real and reliable experimental data for design and fatigue service life analysis of a multi-link axle housing assembly, thereby reducing the development cycle of the multi-link axle housing assembly, saving cost, etc.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

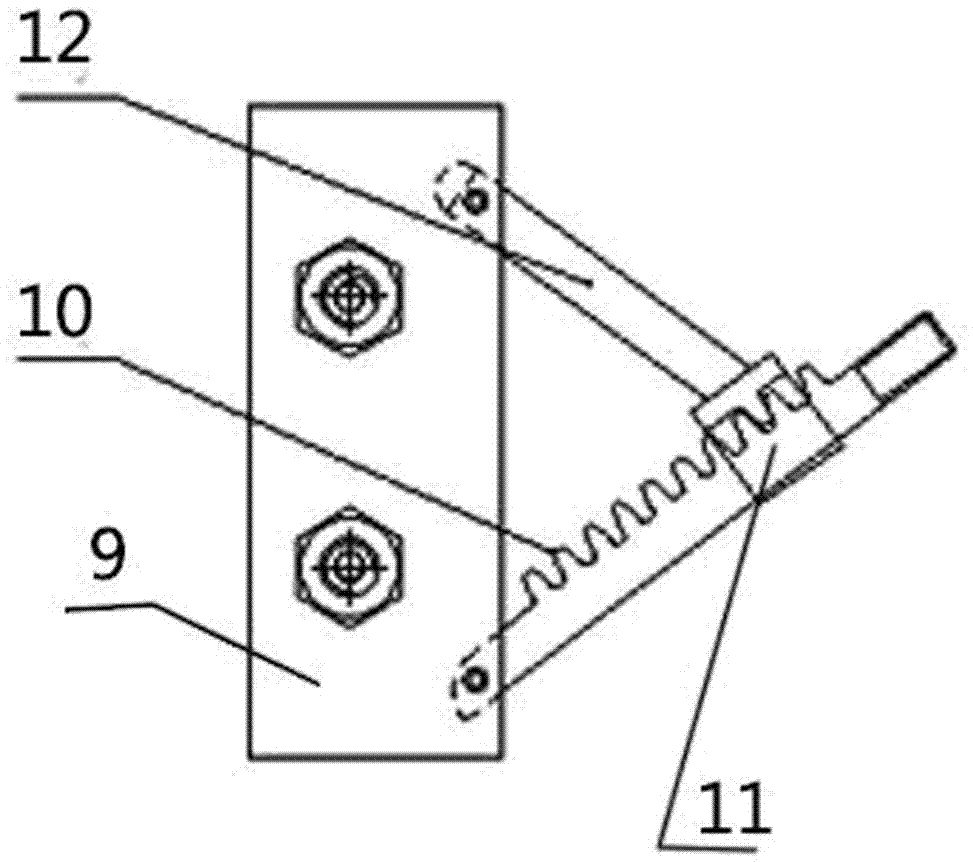

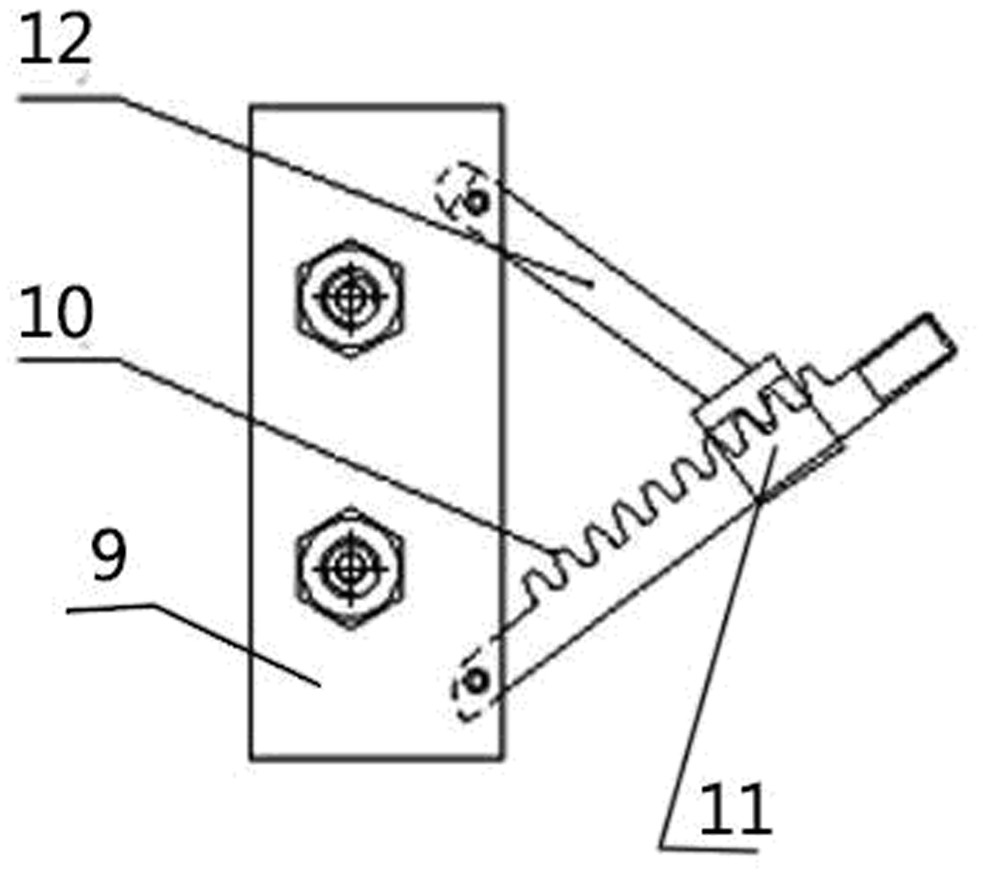

An Endurance Test Device for Engine Compartment Hinges

ActiveCN103575526BIn line with the actual working statusAchieve strength and durability testMachine part testingInsertion stentAutomotive engineering

The invention provides an endurance test device for an engine compartment cover hinge, which belongs to the technical field of automobiles. It solves the problem that the existing durability test device cannot automatically close the engine cover, and cannot simulate the action of closing the engine cover in a real environment. The durability test device of the engine compartment cover hinge includes a support stand and a support hinged on the support stand. The support is connected with a rope chain that can be connected with the engine compartment cover. The cylinder one that engine compartment cover is opened, is also provided with the auxiliary structure that stops and falls again when engine compartment cover falls to a certain height on the support stand. The auxiliary structure can make the engine compartment cover stop when it falls to a certain height and fall again, help the engine compartment cover to close correctly, simulate the closing process of the engine compartment cover more realistically, and make the test data more accurate.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

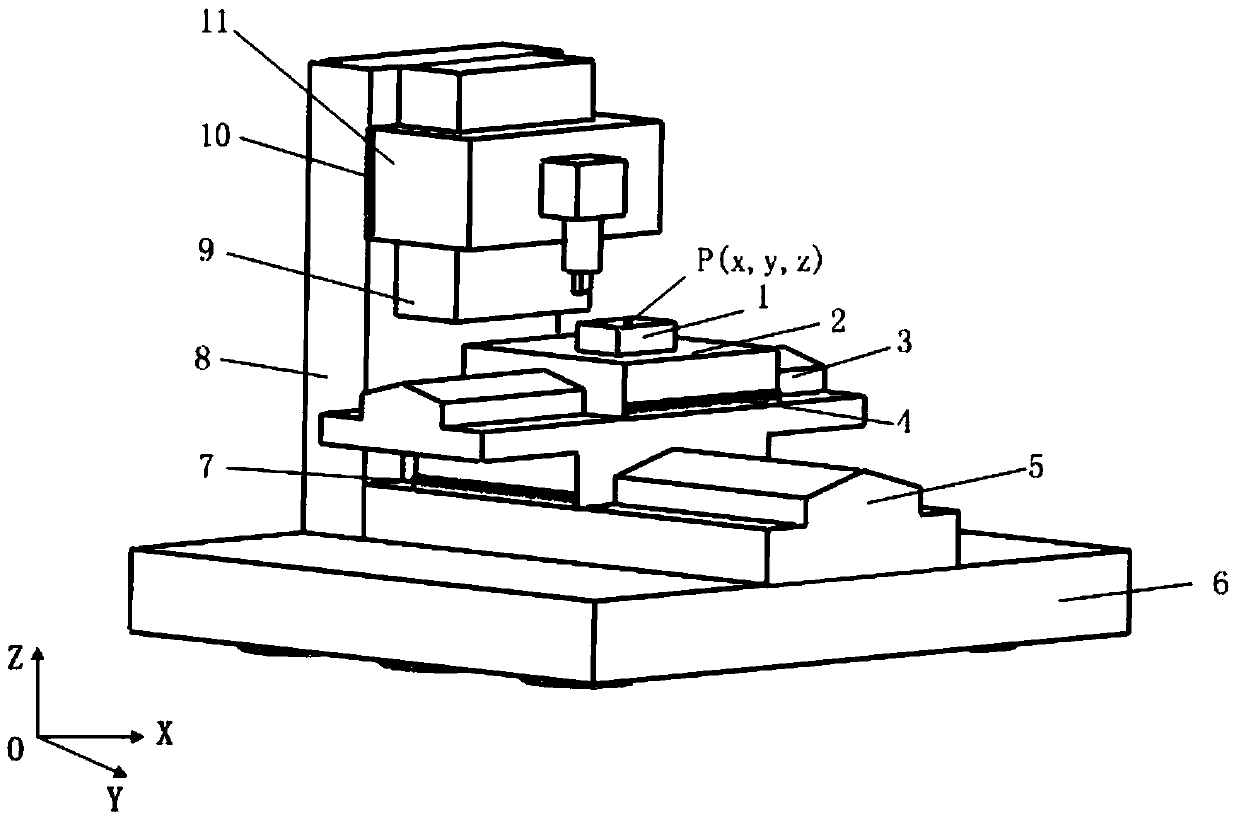

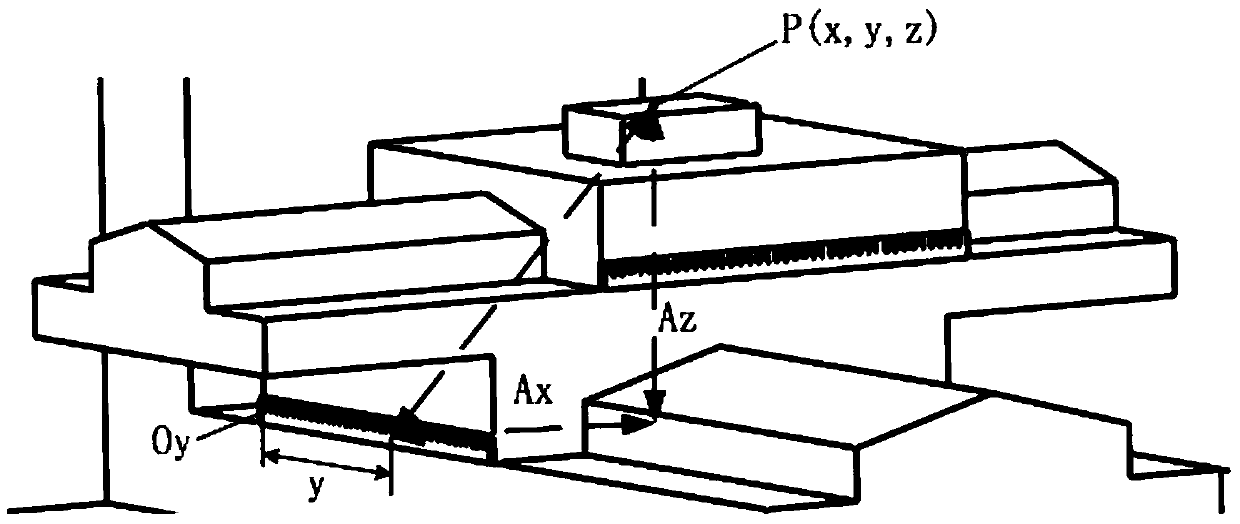

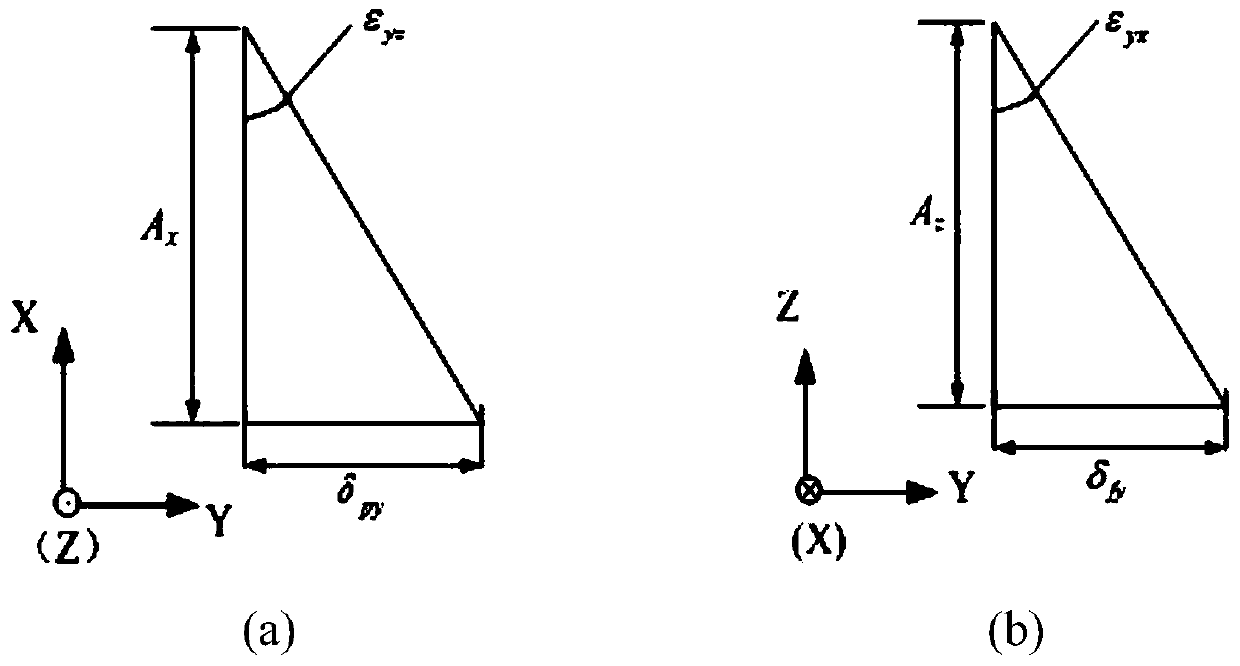

An Error Compensation Control Method for a Stacked Workbench

ActiveCN104965958BIn line with the actual working statusImprove machining accuracySpecial data processing applicationsAngular degreesControl theory

The present invention discloses an error compensation control method for a stack worktable. The method is applied to the technical field of error compensation of machine tools and comprises: analyzing an Abbe error in the Y direction of a machining point caused by a swing angle and a pitch angle of a Y-axis guide rail of a stackable worktable, and building an Abbe error model; analyzing correlation and compensatory impacts of an angular error of the Y-axis guide rail of the stackable worktable on an angular error of an X-axis guide rail; building an Abbe error model in the X direction of the machining point under the combined effects of the angular error of the X-axis guide rail and the angular error of the Y-axis guide rail; and applying the model to perform compensation control on a two-dimensional Abbe error of unidirectional motion of the stackable worktable. The model is higher in accuracy, conforms better to the actual operating state of the worktable, and provides the basis for further error measurement and error compensation, thereby effectively improving machining accuracy of machine tools.

Owner:ANHUI UNIV OF SCI & TECH

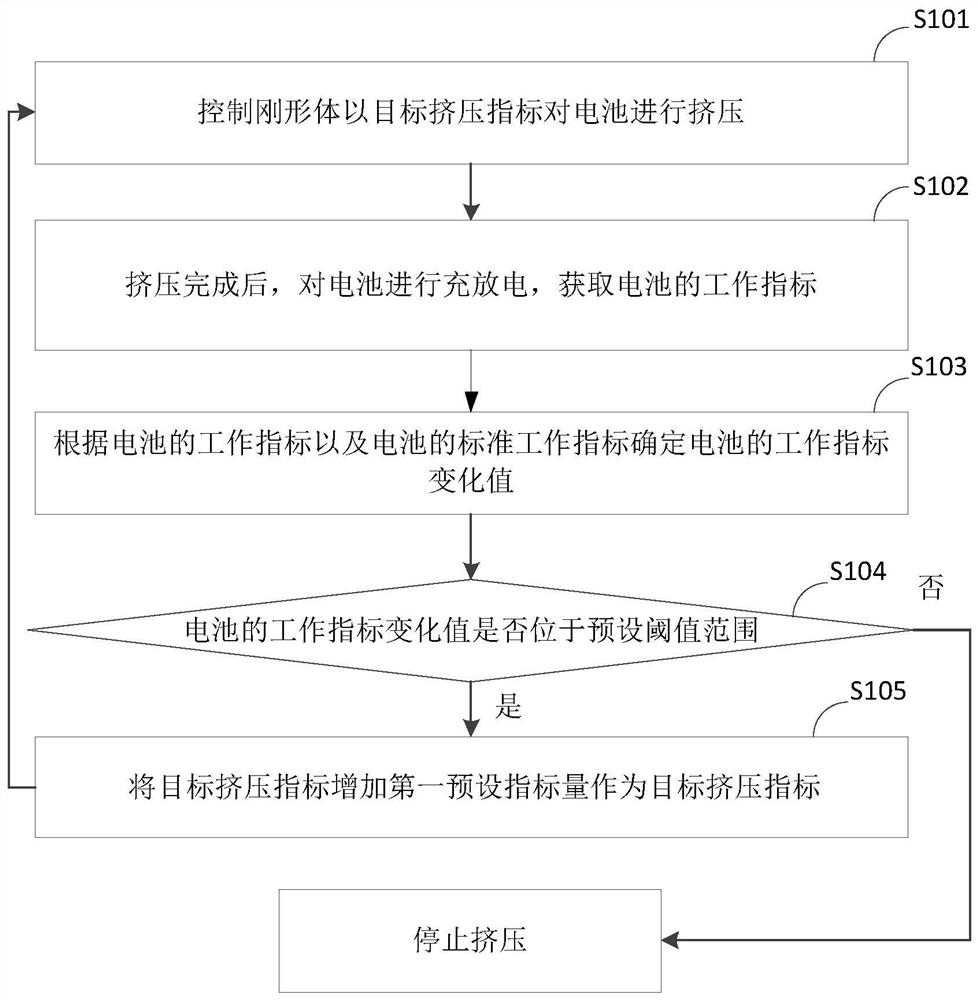

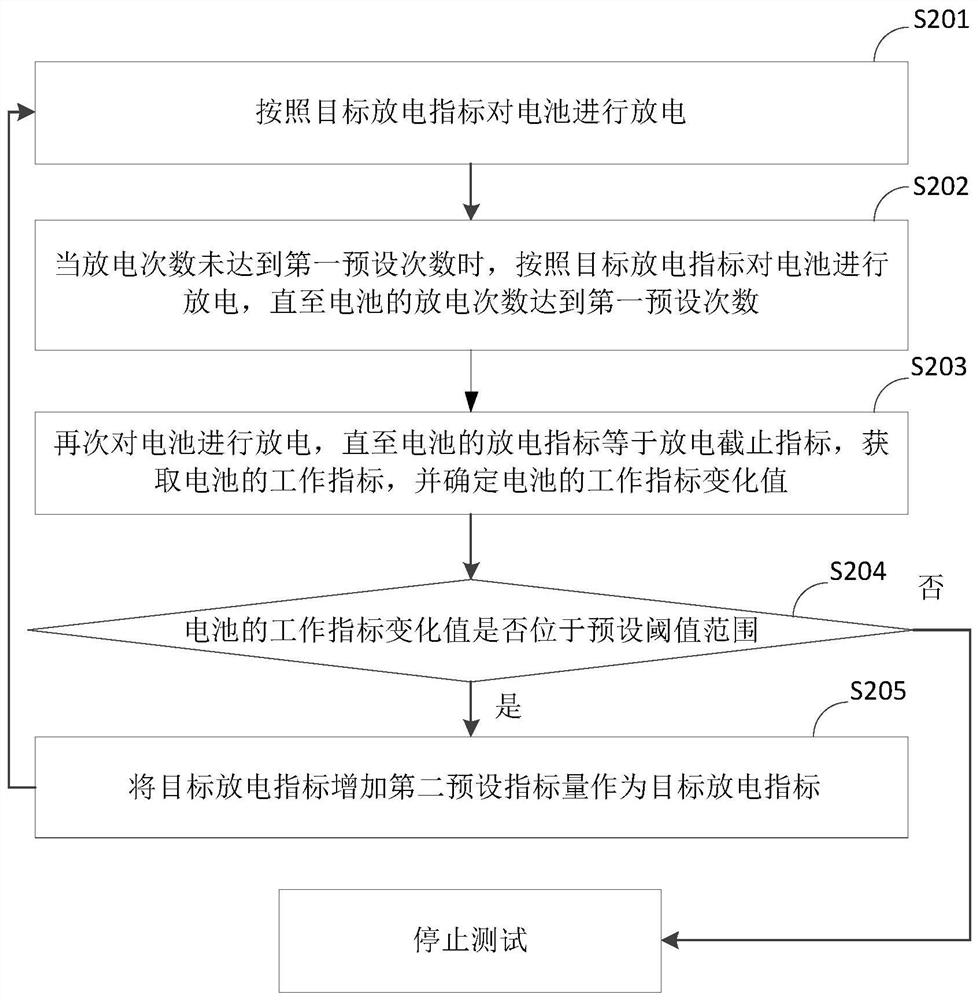

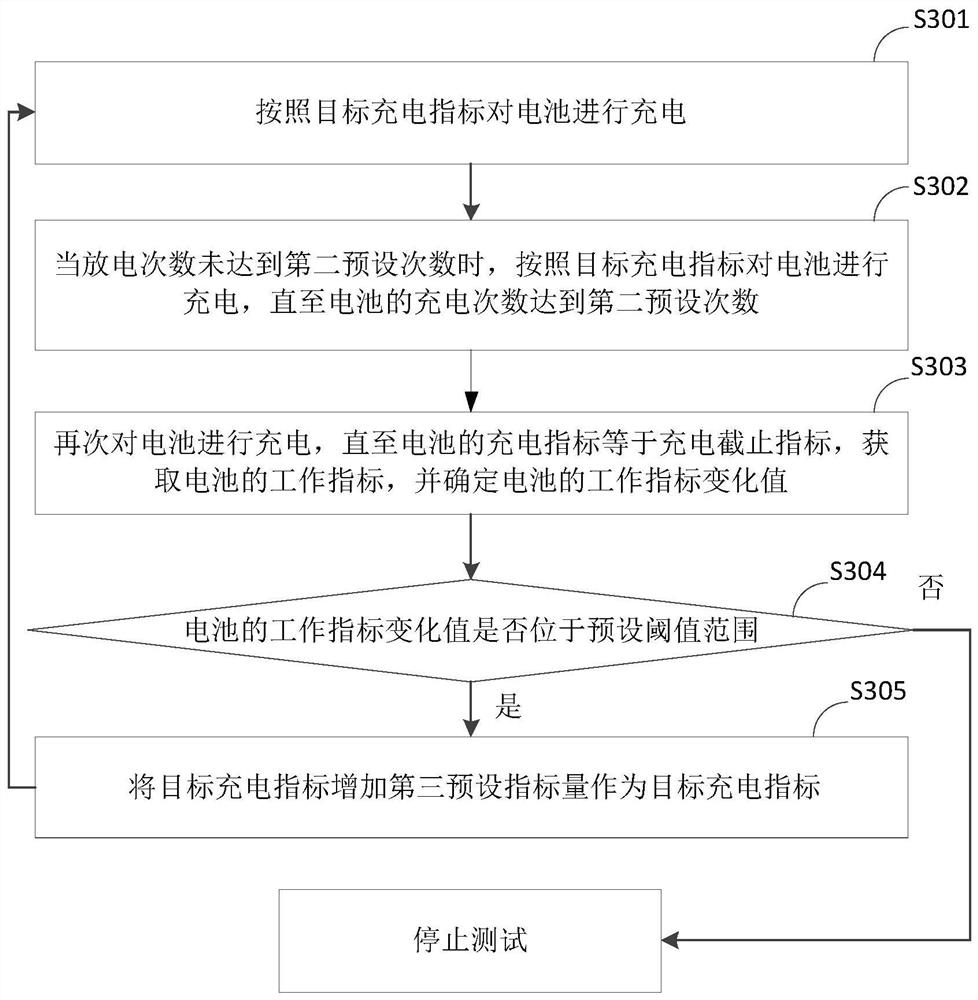

A battery safety testing method and device

ActiveCN110850310BAvoid destructionIn line with the actual working statusElectrical testingMaterial strength using tensile/compressive forcesControl engineeringSafety testing

The embodiment of the present application discloses a battery safety testing method and device. By gradually increasing the extrusion index and performing normal work for a period of time, various indicators of the battery are detected to determine that the battery is in danger through changes in various indicators. state, to avoid damage to the battery caused by a one-time extrusion test, and to observe the various indicators of the battery after each extrusion in real time, which is more in line with the actual working state of the battery and improves the accuracy of the test.

Owner:NEUSOFT REACH AUTOMOBILE TECH (SHENYANG) CO LTD

Method and device for fatigue durability test of axle housing assembly simulating road

ActiveCN108871796BShorten the development cycleGuaranteed accuracyVehicle testingMachine part testingTest sampleReciprocating motion

The invention relate to a fatigue endurance testing method and device for an axle housing assembly of a simulated road, and the device comprises an experiment frame, an actuator assembly, and a digital control system. The experiment frame is fixedly provided with a test sample piece with the axle housing assembly, and simulates the fixing of the test sample piece on a vehicle body. The actuator assembly is disposed below the experiment frame, and the digital control system controls the actuator assembly to make reciprocating motion from the bottom to the top according to experiment parameters,excites the axle housing assembly, and performs the fatigue endurance testing of the simulated road for the axle housing assembly. The devices integrates the impact on the axle housing assembly froman unspring part and a damping device, achieves the reappearing of the working state of the axle housing assembly under various working conditions, and completes the fatigue endurance testing of the simulated road. The device is real and reliable in testing, improves the platformization and universality of an experiment bench, and saves the testing cost.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

Power distribution method and device for power battery of electric vehicle, and electric vehicle

InactiveCN106696725BImprove fault detection efficiencyImprove accuracyElectric devicesVehicular energy storagePower batteryPower flow

The invention provides a power distribution method and device of an electric vehicle power battery and an electric vehicle. The electric vehicle power battery comprises at least two serially connected battery packs mutually connected in parallel. The power distribution method comprises the steps that the number of the serially connected battery packs in a working state currently is judged; if the number of the serially connected battery packs in the working state currently is one, the total maximum discharging current of the electric vehicle power battery is determined according to the maximum discharging current of the serially connected battery pack in the working state currently; if the number of the serially connected battery packs in the working state currently is at least two, the total maximum discharging current of the electric vehicle power battery is determined according to the discharging balance situation of the serially connected battery packs in the working state currently and total maximum discharging currents of the serially connected battery packs; the total output power of the electric vehicle power battery is determined according to the total maximum discharging current. The output power of the electric vehicle power battery can be reasonably allocated and effectively utilized.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Method and device for correcting wear profile of engine main bearing

ActiveCN112580242AReduce false positive rateImprove development efficiencyGeometric CADDesign optimisation/simulationLubricationMain bearing

The invention discloses a method and a device for correcting a wear profile of a main bearing of an engine, which belong to the technical field of engine bearing power, and are implemented by the following steps of: establishing an elastic hydrodynamic lubrication analysis model of the main bearing, and carrying out simulation analysis on the elastic hydrodynamic lubrication condition of the mainbearing; on the basis of an elastic hydrodynamic lubrication simulation analysis result of the main bearing, correcting a design molded line of the main bearing by utilizing a finite difference grid,and establishing a wear molded line of the main bearing so as to simulate a steady state achieved after the main bearing is in running-in; and carrying out optimization analysis on the elastic hydrodynamic lubrication analysis model of the main bearing by utilizing the wear profile of the main bearing. According to the method, a steady state achieved after running-in of the main bearing is simulated through the wear molded line of the main bearing, and the actual working state of the main bearing is better met, so that the simulation precision of elastic dynamic lubrication analysis of the main bearing is improved, and the misjudgment rate of the reliable durability of the main bearing is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

Bench experimental device with adjustable stiffness and its stiffness adjustment method

ActiveCN102879205BStiffness adjustmentIn line with the actual working statusVehicle testingMachine part testingExperimental validationAdjustable stiffness

The invention provides a rack experimental device with adjustable rigidity and a rigidity adjusting method thereof in order to solve the problem that the conventional rack experimental device has a bad fatigue test effect on the whole automobile or other parts of the automobile. According to arrangement of bolts and fastening nuts corresponding to bottom support through grooves and base through grooves and the setting of height of a supporting cylinder, the rigidity of the rack experimental device can be conveniently adjusted, particularly the rigidity can be adjusted in different directions, so that a fatigue test state accords with an actual operating state of the automobile body and the other parts of the automobile, the precision and effect of the fatigue test of the automobile body and the other parts of the automobile are greatly improved, and an accurate experimental validation guidance is provided for the design of the automobile and the parts.

Owner:NINGBO HUIZHONG AUTOMOTIVE CHASSIS MFG

A comprehensive fatigue durability test device and method for a non-driven front suspension assembly

ActiveCN109060386BShorten the development cycleWith test functionVehicle suspension/damping testingVehicle frameSteering angle

The invention relates to a non-driving front suspension assembly comprehensive fatigue durability testing device and method. The testing device comprises an experiment table frame, an actuator assembly and a numerical control system; the experiment table frame comprises a front auxiliary frame fixing component, a steering gear fixing component, a portal frame, a rear auxiliary frame fixing component and a shock absorber fixing component; the experiment table frame is used for simulating the fixing effect of a suspension assembly on a vehicle body so as to fix the suspension assembly; the actuator assembly is controlled by the numerical control system to load a left tire and a right tire up and down separately; and the numerical control system is used for detecting the fatigue durability test data of various working conditions of the suspension assembly in different steering states. The influence of different steering angles on the fatigue durability test conclusion of the non-driving front suspension assembly is comprehensively considered, so that real and reliable experimental benchmarking data are provided for design of the non-driving front suspension assembly and fatigue life analysis and the like, thereby shortening the development period of each part of the non-driving front suspension assembly and lowering the cost and the like.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

Method for overlaying wear-resistant layer of blade shroud of turbine working blade

InactiveCN102107314BMeet the design size requirementsExcellent fusion stateArc welding apparatusPower flowWear resistant

The invention discloses a method for overlaying a wear-resistant layer of a blade shroud of a turbine working blade. In the method, manual tungsten electrode argon arc welding is used, and the specific process parameters meet the requirements that: welding wires are selected from a T800 cobalt-based wear-resistant alloy welding wire which is researched according to a B50TF193 standard of AmericanGeneral Electric Company and an S-6 cobalt-based wear-resistant alloy welding wire which is researched according to an American metal society standard AMS5788; the diameters are phi 1.6mm and phi 1.2mm respectively; a mark and the diameter of a tungsten electrode are WCe20 and phi 2.0mm; the diameter of a nozzle is phi 12mm; welding current is between 20 and 25A; and the flow rate of protective gas is between 10L / min and 12L / min. By the method, the condition of incomplete penetration or over-melting of a Z-shaped gear switching part R is avoided, the problem of overheating of welding is also solved, and the occurrence probability of welding cracks is greatly reduced or avoided. The method completely meets the requirements of the wear-resistant layer in a high-temperature working state after welding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

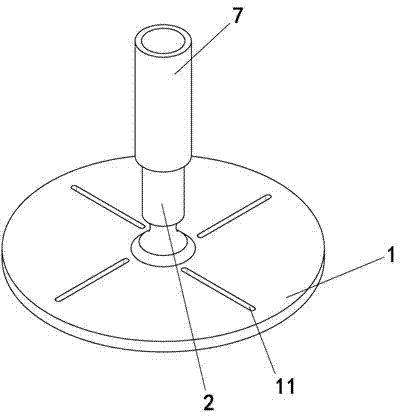

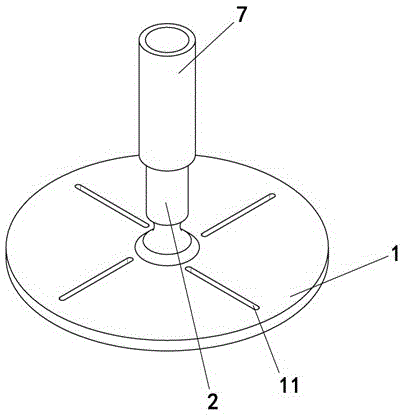

Dynamic balance debugging pump shell and debugging device and method with same

ActiveCN114526864AEasy to installImprove test efficiencyPump componentsStatic/dynamic balance measurementDynamic balanceEngineering

The invention relates to the technical field of vacuum obtaining equipment, in particular to a dynamic balance debugging pump shell and a debugging device and method with the same. A dynamic balance debugging pump shell is provided with a side wall, one end of the side wall is provided with an opening end used for being connected with a pump body of a molecular pump to be tested in a sealed mode, and the other end of the side wall is provided with an end cover. A debugging hole which can be opened is formed in a position, opposite to a balance nail hole in a turbine of the molecular pump to be tested, on the side wall; a detachable gland is arranged on the debugging hole, and a first sealing ring is arranged between the gland and the periphery of the debugging hole. According to the dynamic balance debugging pump shell provided by the invention, in the whole dynamic balance test of the molecular pump, a tester does not need to repeatedly disassemble and assemble the pump shell of the molecular pump, and the dynamic balance debugging of the molecular pump can be carried out only by adding or reducing the balance nails at the balance nail holes at the corresponding positions through the debugging holes; the disassembly and assembly time of the pump shell of the molecular pump in the test is effectively shortened, so that the test efficiency is improved, and the labor intensity of testers can be relieved.

Owner:苏州中科科仪技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com