Method and device for correcting wear profile of main bearing of engine

A main bearing and engine technology, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., can solve the problems of prolonging the main bearing design and verification cycle, difficult main bearing arrangement, and increasing parts cost, and achieves the optimal arrangement boundary, The effect of improving development efficiency and reducing misjudgment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object of the present invention, the technical solution and advantages more clearly understood, the following in conjunction with the accompanying drawings and embodiments, the present invention will be further elaborated in detail. It should be understood that the specific embodiments described herein are merely used to explain the present invention and are not intended to qualify the present invention. Further, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

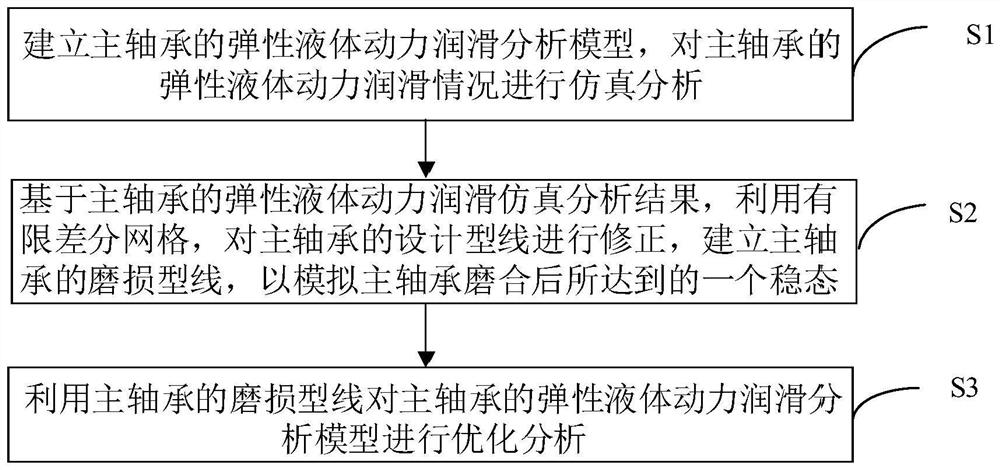

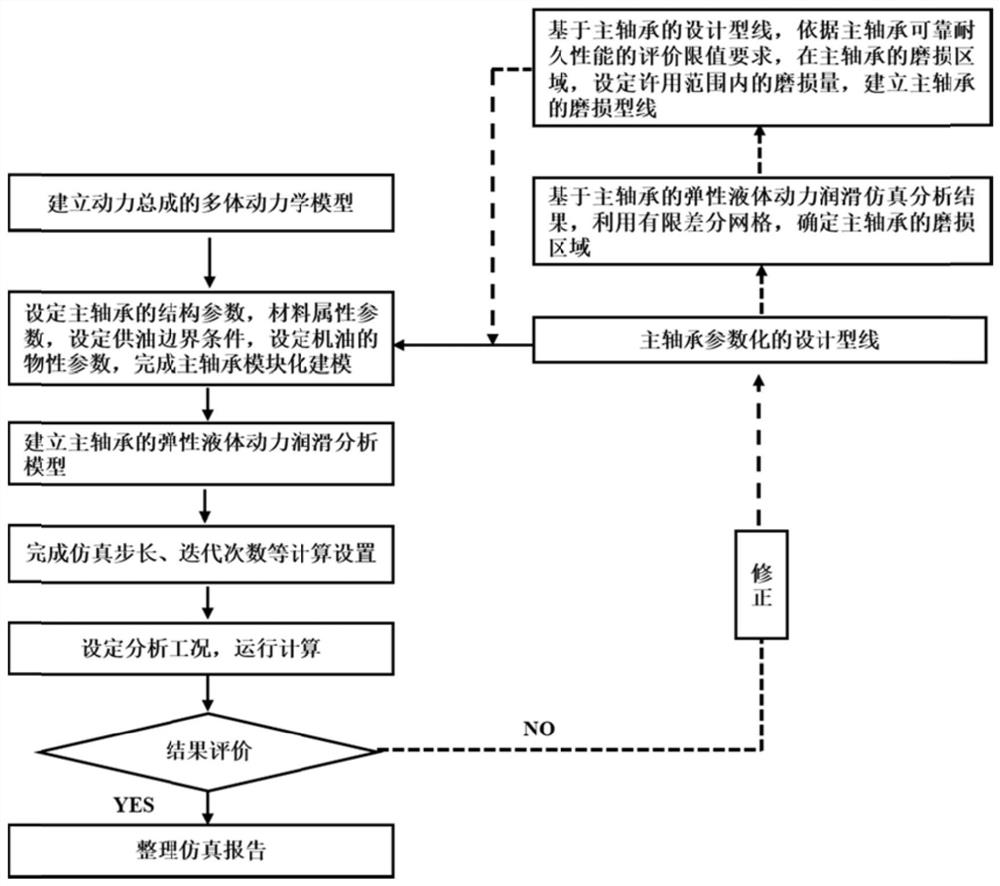

[0049] as Figure 1 Shown is a schematic diagram of a wear pattern correction method for engine main bearings provided in an embodiment of the present invention, comprising the following steps:

[0050] S1: Establish an analysis model of elastic hydrodynamic lubrication of the main bearing, and simulate and analyze the elastic hydrodynamic lubrication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com