A battery safety testing method and device

A safety testing, battery technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, measuring electricity, etc., can solve the problems of non-repeatability, inaccurate reflection, and large differences between batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

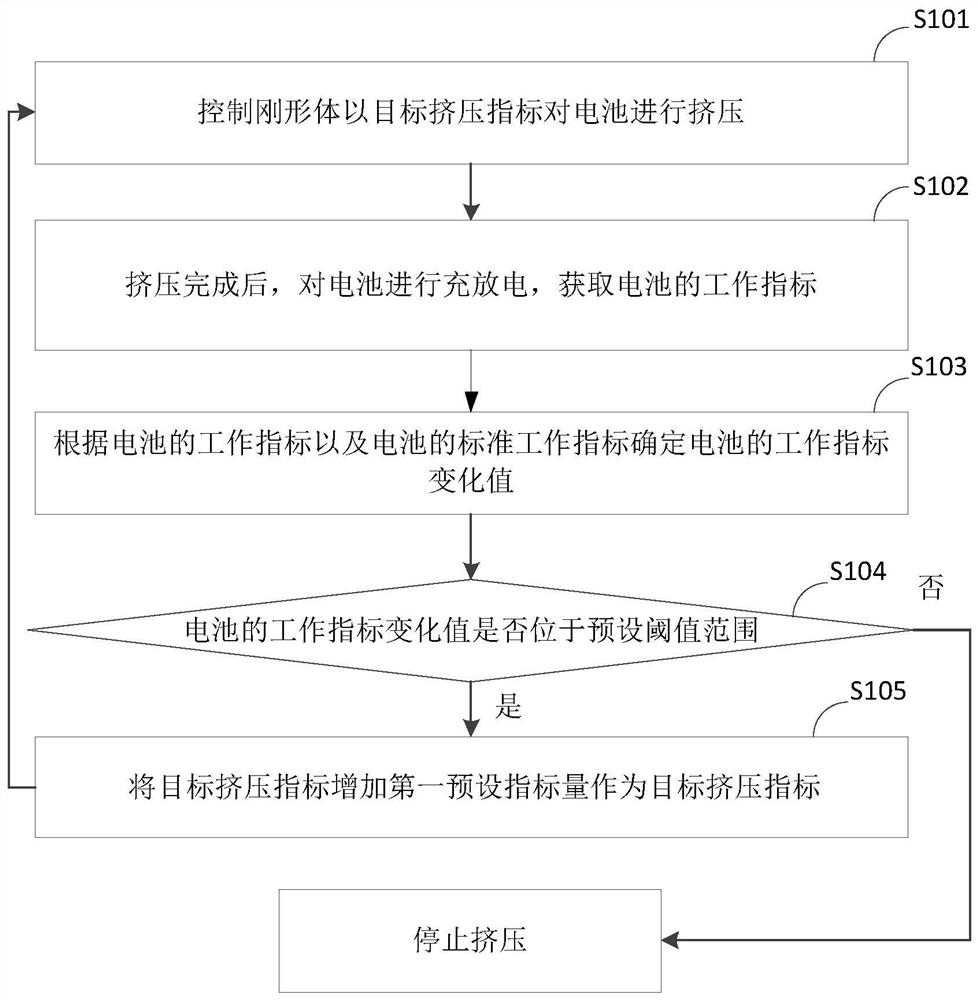

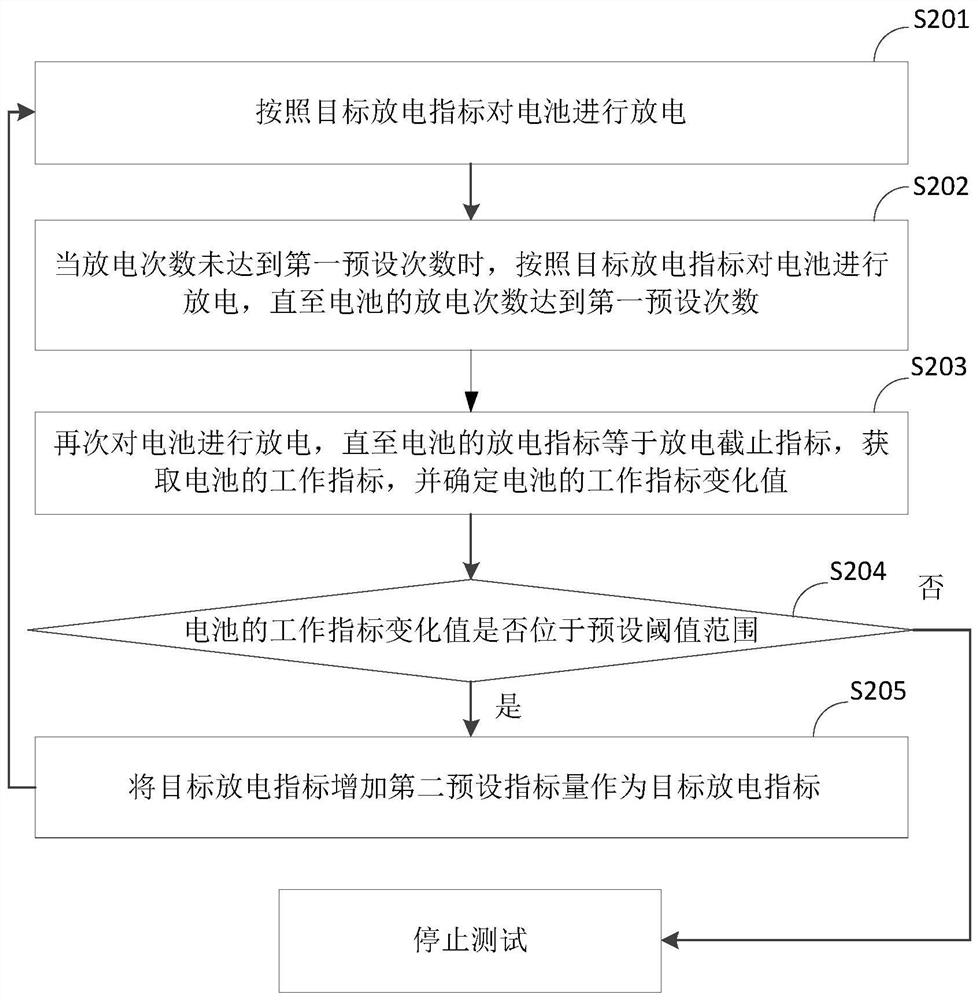

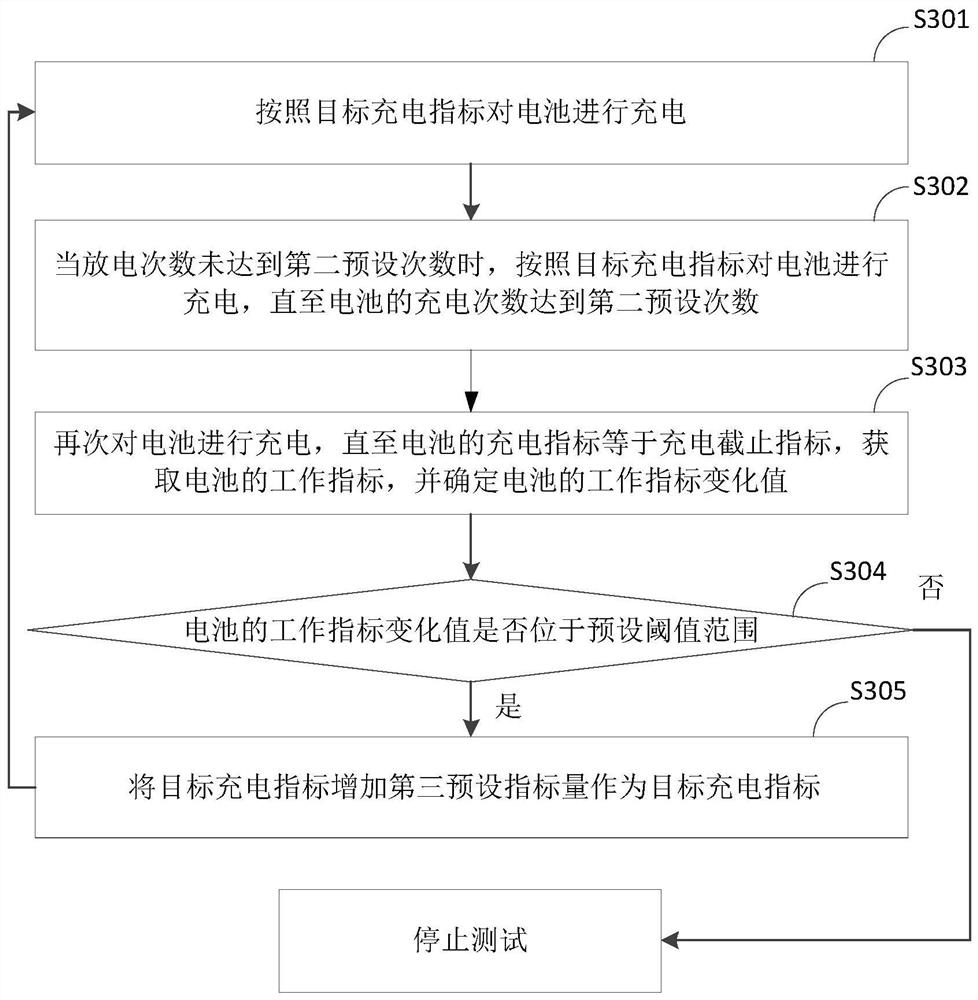

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above objects, features and advantages of the present application more obvious and understandable, the embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0050] In order to facilitate the understanding of the technical solution provided by this application, the background technology involved in this application will first be described below.

[0051] The inventor found through the research on the traditional battery safety test that the traditional battery safety test is often a destructive test, which cannot be repeated, and is quite different from the actual state of the battery, which cannot provide reliable data for battery safety warnings in accordance with. However, dangerous conditions such as fire and explosion of batteries in actual work are often a gradual accumulation process, not a one-time direct damage.

[0052] Based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com