An Endurance Test Device for Engine Compartment Hinges

A technology for engine cover and durability test, which is applied in the automotive field and can solve the problems of inability to automatically close the engine cover, action that cannot be closed, and breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

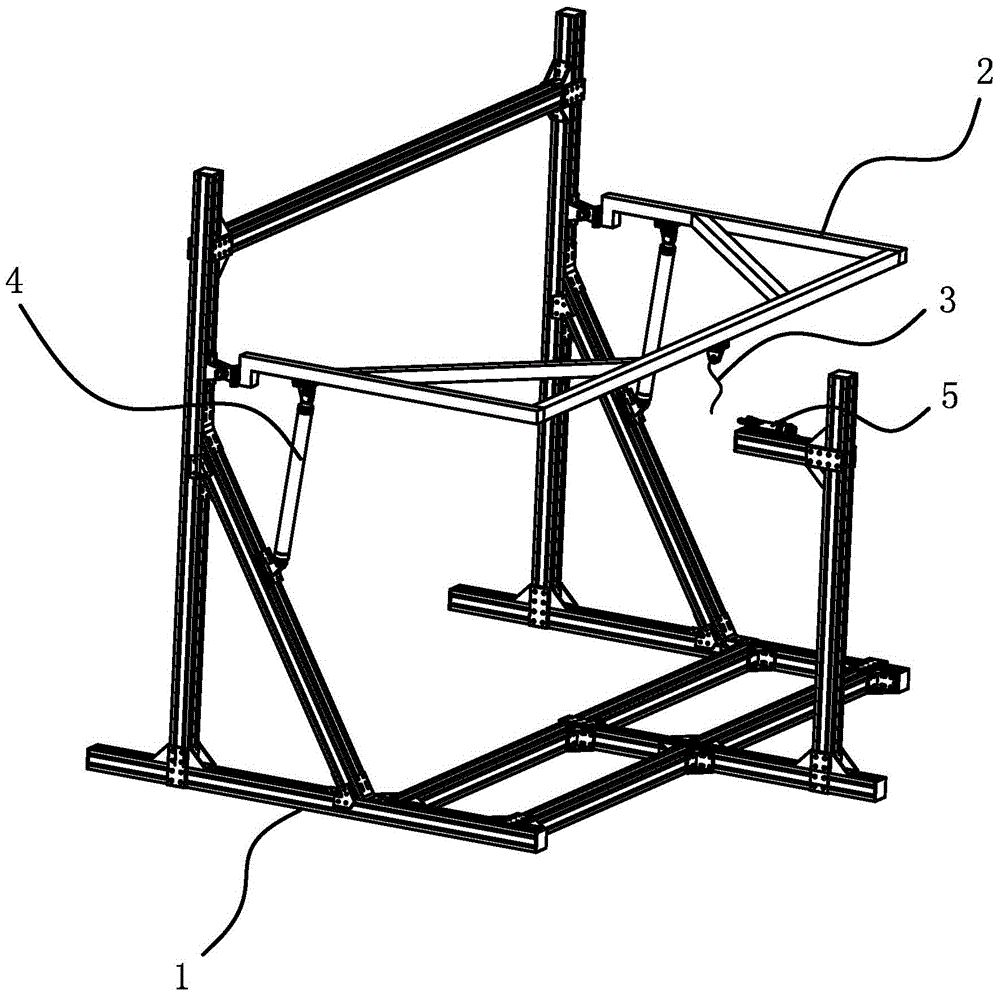

[0024] Such as figure 1 As shown, the endurance test device for the bonnet hinge is mainly used in the automobile laboratory. durable. It includes a support stand 1 and a support 2 hinged on the support stand 1. The support 2 is connected with a rope chain 3 that can be connected with the engine compartment cover. The support stand 1 and the support 2 can be made of aluminum profiles. Between support 2 and support platform 1, be provided with can promote support 2 to drive the cylinder one 4 that engine hatch is opened, and support platform 1 is also provided with the auxiliary structure that can reduce engine compartment cover falling speed.

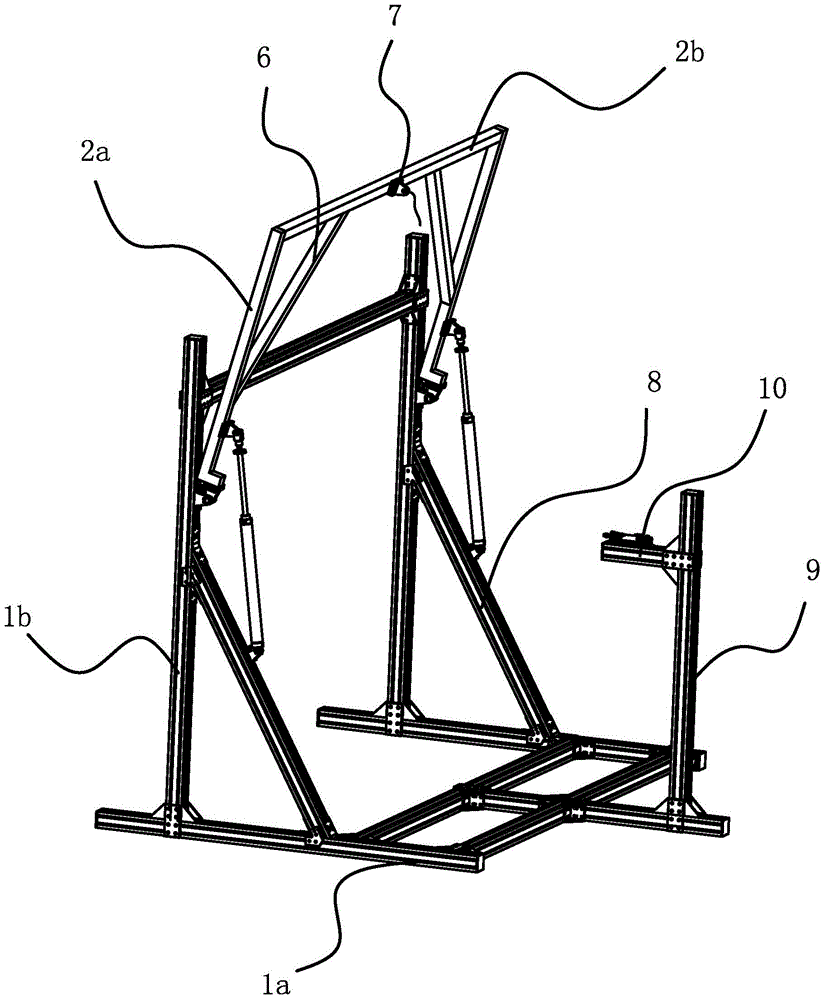

[0025] Specifically, as figure 2 As shown, the auxiliary structure includes a cylinder 2 5 and a column 9 connected to the front end of the support stand 1, the column 9 is fixedly connected with a cylinder seat 10 for fixing the cylinder 2 5, the cylinder 2 5 is horizontally arranged and its height is at a level with the support 2 ...

Embodiment 2

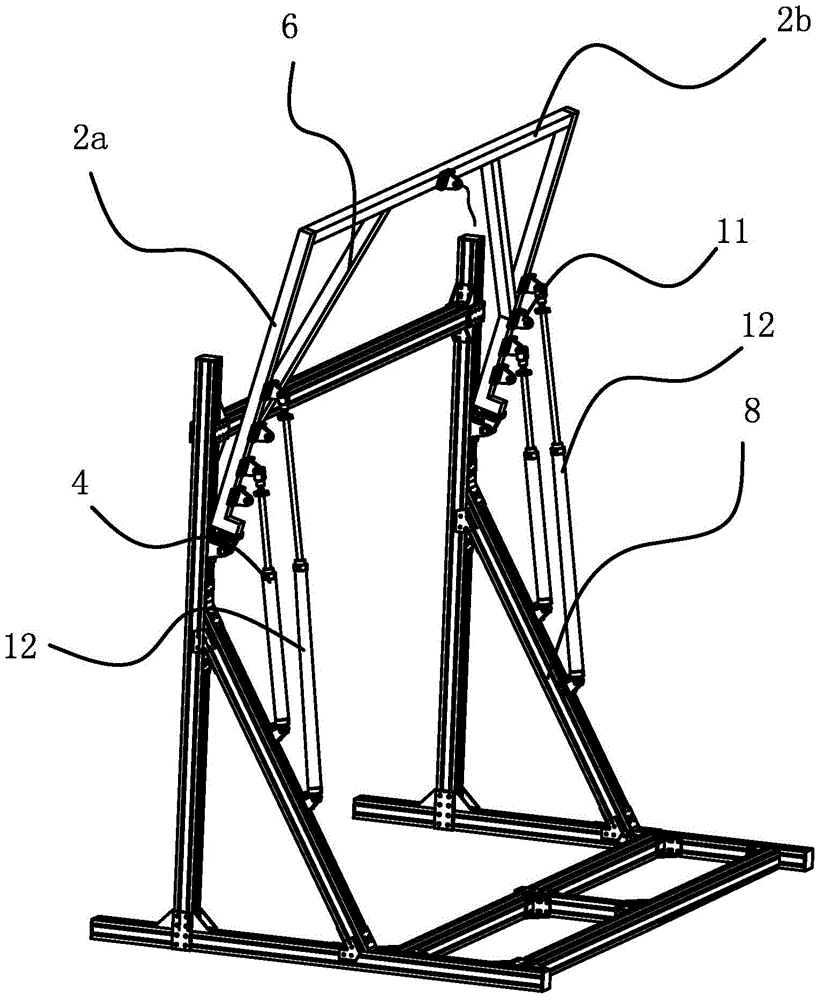

[0029] Such as image 3 As shown, the auxiliary structure includes a gas spring 12 with one end hinged on the support platform 1 and the other end hinged on the bracket 2 . In order to improve the applicability of this endurance test device, an adjustment structure that can adjust the installation position of the cylinder-4 is added.

[0030]A plurality of hinge points 11 for connecting with the cylinder one 4 are arranged in a straight line on the connecting rod 2a at a certain distance. According to the difference in the opening height of the bonnet, the hinged position of the cylinder one 4 and the connecting rod 2a can be adjusted. The lifting height of the whole support 2 is also different in different positions, so that the device is suitable for the bonnet test requirements of various automobiles. The applicability of the device is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com