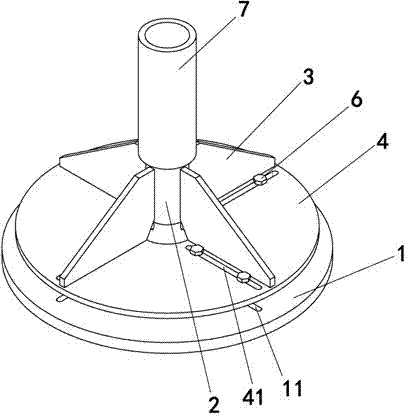

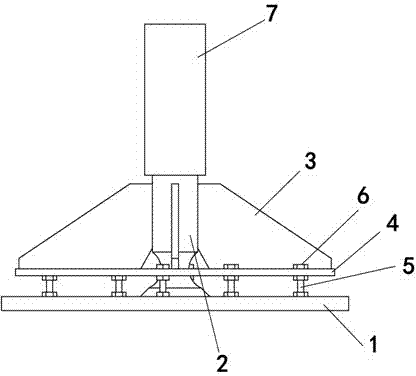

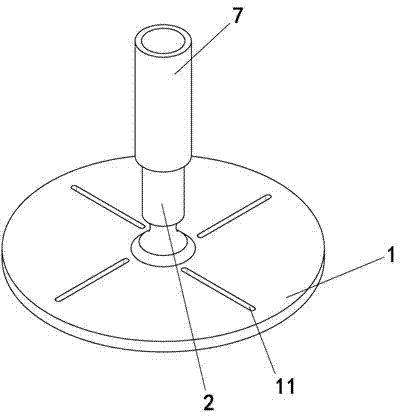

Rack experimental device with adjustable rigidity and rigidity adjusting method thereof

A technology of bench experiment and adjustment method, which is applied in the direction of measuring device, vehicle test, mechanical component test, etc., can solve the problems such as poor fatigue test effect of the whole vehicle or other parts, and the rigidity of the fixture cannot be adjusted conveniently. , to achieve the effect of improving accuracy and effect, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] The gist of the present invention is, by carrying out fatigue test to automobile whole vehicle or other spare parts to existing bench test device, especially for the analysis of the fatigue test demand of assembly part and single piece, find that existing bench test device is in rigidity Insufficiency in adjustment, especially the different direction adjustment of stiffness, makes it difficult for the stiffness of the fixture on the bench test device to approach the stiffness of the installation point during the fatigue test, resulting in the poor effect of the fatigue test. A simple structure is provided, which not only The stiffness of the bench test device can be adjusted conveniently, especially the bench test device which can conveniently adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com