Method for establishing excavating, material-taking and cutting resistance time history simulation model of bucket wheel machine

A technology of cutting resistance and time history, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as computer model simulation, and achieve the effect of reducing void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

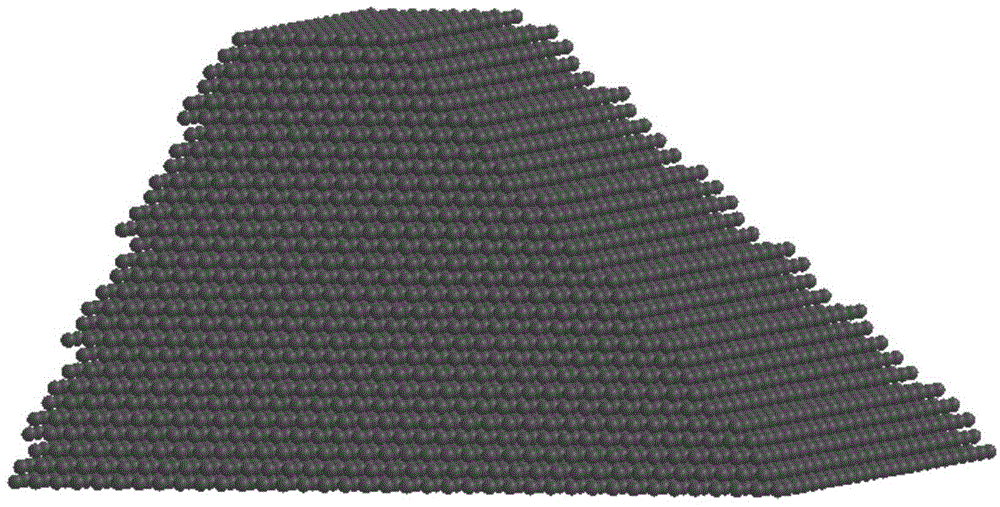

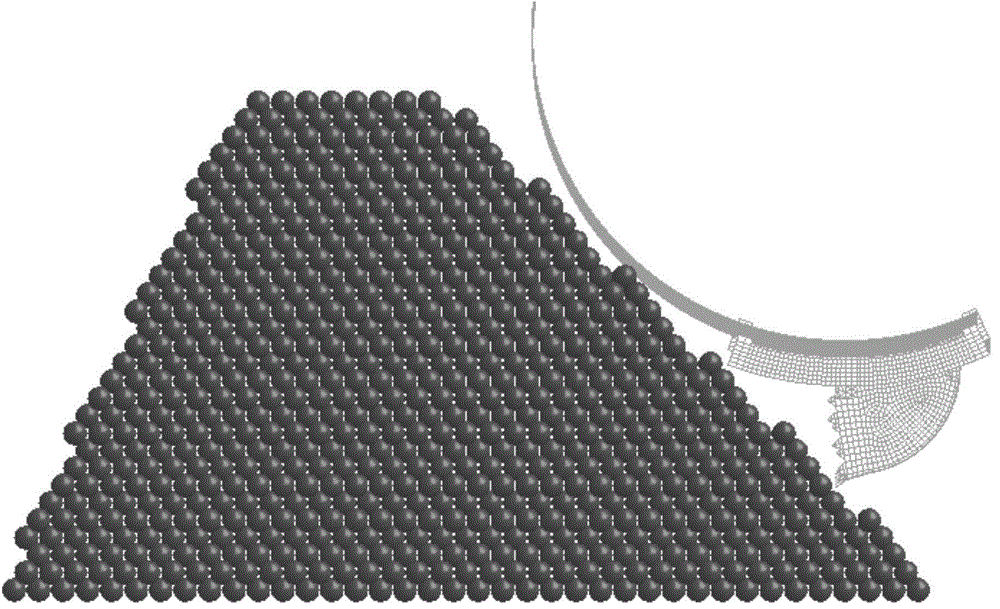

[0073] 1) Determine the actual stockpile geometry and parameters

[0074] The ore stockpile in a stockyard is in the shape of a square pyramid, and its stacking angle is 42 degrees; the length of the lower bottom surface = 5.5m, the width = 3.6m; the corresponding upper top surface length = 1.4m, width = 2.4m; stockpile Height = 2.8m.

[0075] Take the maximum size of the three-dimensional material accumulation body: length = 5.5m, width = 3.6m, height = 2.8m.

[0076] 2) Incorporate the stockpile model into the spatial rectangular coordinate system, and according to the agreement in 2.a, the modeling dimensions of the stockpile model in the X, Y, and Z coordinate directions are:

[0077] Lx=3.6m, Ly=2.8m, Lz=5.5m, the radius of the spherical particle unit is R=0.075m;

[0078] The number of particle units in the X direction is

[0079] The number of particle units in the Y direction is Ny = int ( Ly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com