Thermal endurance testing apparatus and methods for photovoltaic modules

A photovoltaic module, heat resistance technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, strength characteristics, etc., can solve problems such as slow crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Reference will now be made in more detail to the embodiments of the present invention, one or more of which are shown in the accompanying drawings. Each example is provided by way of explaining the present invention, rather than limiting the present invention. In fact, it is clear to those skilled in the art that various modifications and variations can be made in the present invention without departing from the scope or spirit of the present invention. For example, features shown or described as part of one embodiment can be used in conjunction with another embodiment to yield a still further embodiment. Therefore, it is expected that the present invention includes these modifications and variations falling within the scope of the appended claims and their equivalents.

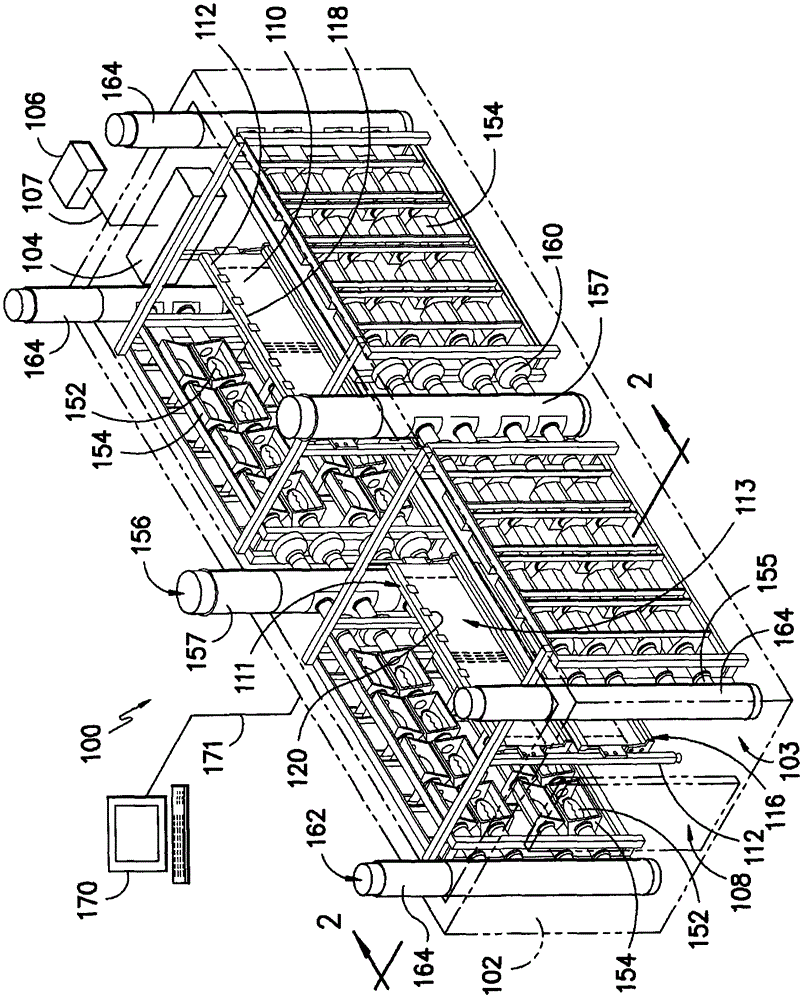

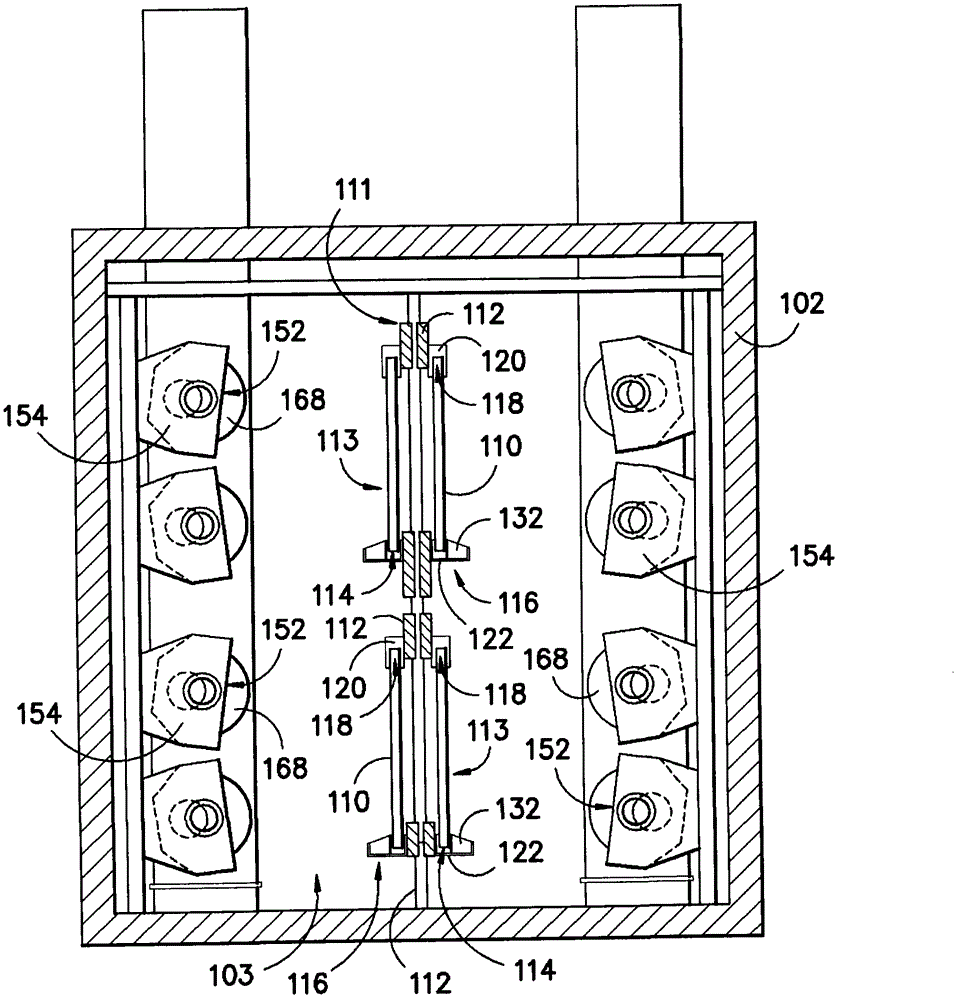

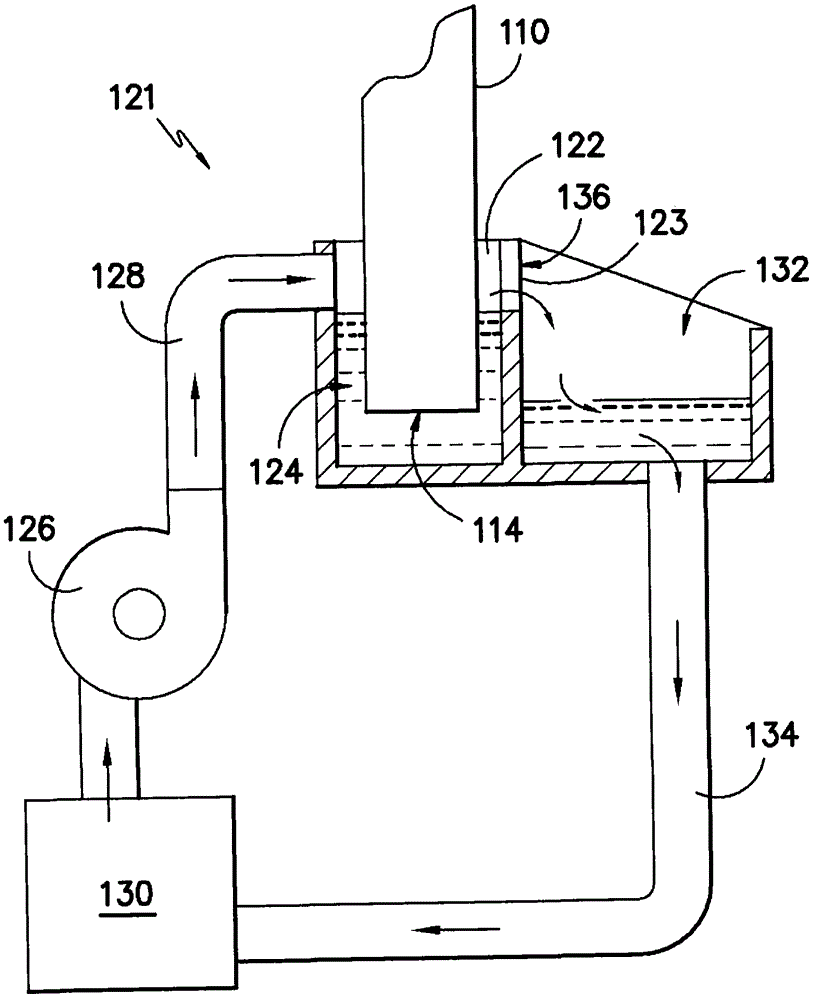

[0060] Some equipment and methods are provided for testing the heat resistance of the glass substrate of the PV module (ie, solar panel) and / or measuring its resistance to thermal fatigue under various e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com