A kind of motorcycle engine connecting rod and its manufacturing process

A technology for engine connecting rods and motorcycles, which is applied to connecting rods, mechanical equipment, shafts and bearings, etc., can solve the problems of accelerating crack formation and expansion, easily generating cracks, and reducing the fatigue strength of connecting rods, so as to reduce the risk of cracks Opportunity, delay the oxidation process, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

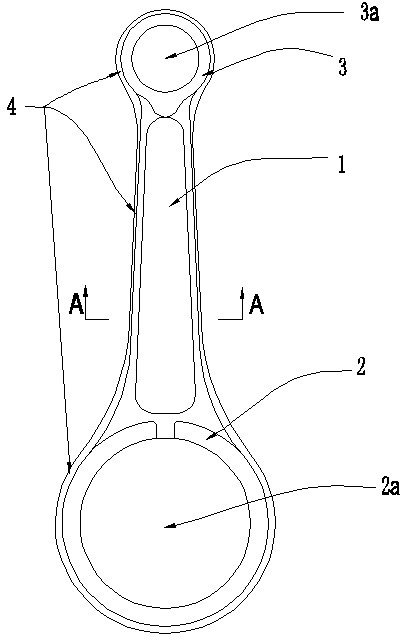

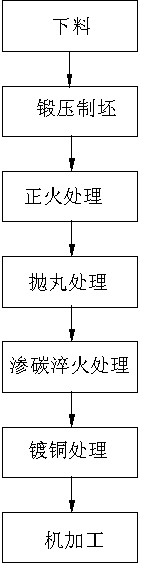

[0014] See figure 1 with figure 2 : a motorcycle engine connecting rod, with a rod body 1, a big head 2 and a small head 3 are respectively arranged at the two ends of the rod body 1, a crank pin mounting hole 2a is provided on the big head 2, and a crank pin mounting hole 2a is arranged on the small head 3 is provided with a piston pin installation hole 3a, and the surface of the shaft 1, the big head 2 and the small head 3 is plated with a copper layer 4, and the thickness L of the copper layer 4 is 0.05mm-0.09mm.

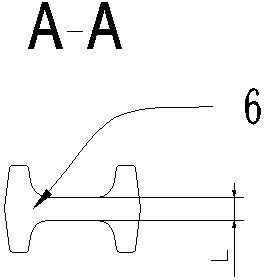

[0015] See figure 2 : grooves 1a are formed on the upper and lower surfaces of the shaft 1 along the length direction, the cross section of the shaft 1 is in the shape of an "I" shape, and the two grooves 1a on the upper and lower surfaces of the shaft 1 The thickness between the bases is 2.5mm.

[0016] combine figure 1 with figure 2 with imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com