Enameled wire

A technology of enameled wire and paint layer, which is applied in the direction of transformer/inductor coil/winding/connection, conductor, insulated cable, etc., and can solve problems such as copper pitting, brittleness, and damage to the paint film

Inactive Publication Date: 2004-06-16

SHANGHAI LAITE MODEL

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the commonly used enameled wire, when the temperature is 200 ℃ or more than 200 ℃, copper will accelerate oxidation, at this time copper will produce pitting and brittleness, this oxidation will eventually damage the paint film, and lead to winding failure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

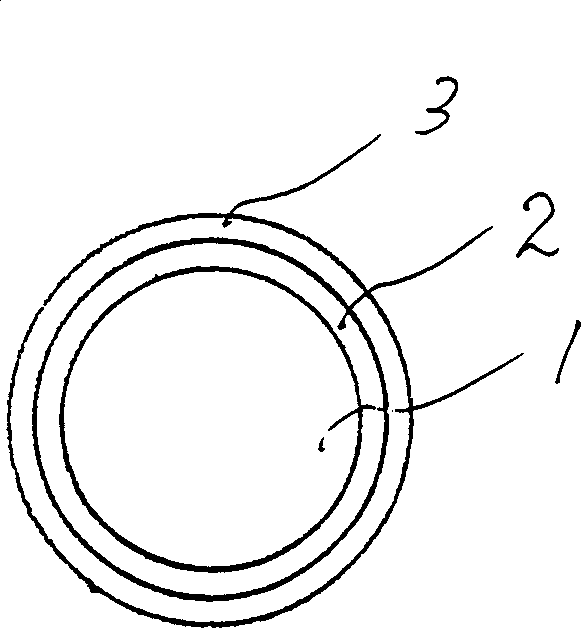

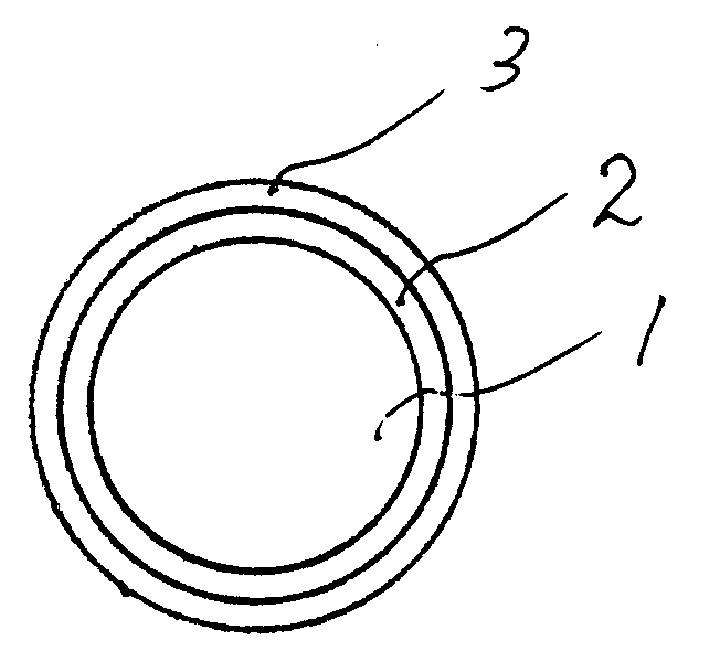

[0006] In the figure, an enameled wire is mainly composed of a copper wire 1 and a paint layer 3, and a protective layer 2 is coated on the copper wire 1. Wherein, the protective layer 2 is coated on the copper wire 1 by means of plating or coating with silver or nickel. Paint layer 3 is a modified polyurethane type enameled wire paint layer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an insulated wire, mainly composed of copper wire and paint layer, its character: it coats a protective layer on the copper wire. Its construction is reasonable. The protective layer slows down the oxidization of the copper wire under 200 deg.C and above, which prolongs the useful life of products and ensures the working performance of products. It has promotional vale.

Description

Technical field: [0001] The invention relates to a wire, in particular to a direct solderable enameled wire. Background technique: [0002] At present, for enameled wires commonly used, when the temperature is at or above 200°C, the copper will be oxidized at an accelerated rate. At this time, the copper will produce pitting and embrittlement. This oxidation will eventually damage the paint film and cause the winding to fail. Invention content: [0003] The technical problem to be solved by the present invention is to provide an enameled wire that can effectively overcome the above defects and effectively protect copper wires. The technical solution adopted by the present invention to solve the technical problem is that an enameled wire is mainly composed of a copper wire and a paint layer, and its characteristic is that a protective layer is coated on the copper wire. Due to the adoption of the above scheme, it is not difficult to conclude that the present invention has ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B7/17H01F27/28

Inventor 盛培根

Owner SHANGHAI LAITE MODEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com