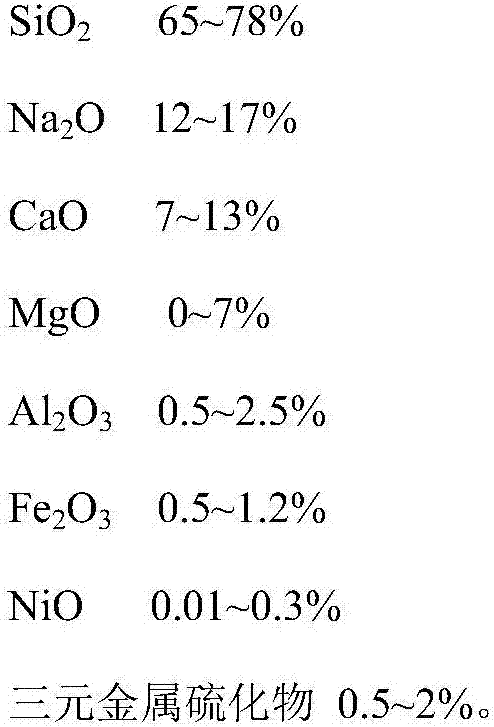

Low-light-transmission privacy energy-saving float glass composition and preparation method thereof

A float glass and composition technology, applied in the field of privacy and energy-saving float glass composition and its preparation, can solve problems such as reducing effect, and achieve the effects of improving uniformity, improving absorption and blocking effect, and promoting clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0027] The preparation of embodiment 1 ternary metal sulfide

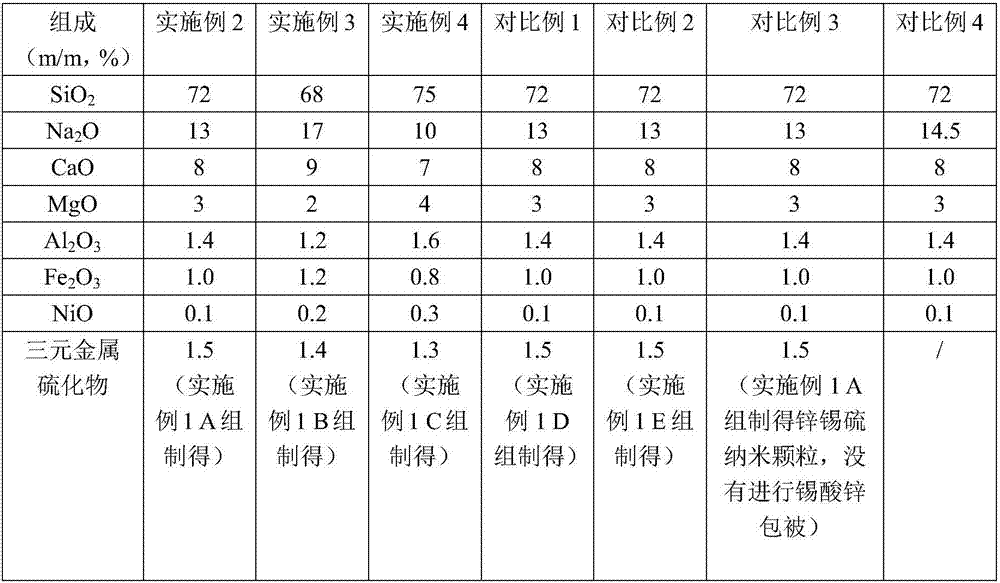

[0028] The composition of zinc-tin-sulfur nanoparticles in group A-E ternary metal sulfides is shown in the table below:

[0029] Raw material (m / m, %) Group A Group B Group C Group D Group E Zinc powder 50 45 40 50 50 tin powder 35 40 40 35 35 Sulfur powder 15 15 20 / 15

[0030] Preparation of group A ternary metal sulfides:

[0031] (1) Mix zinc powder, tin powder and sulfur powder, place them in a polyurethane ball milling tank, use absolute ethanol as the ball milling medium, the ratio of absolute ethanol to powder is 1:2, in an inert gas N 2Under the protection of 400r / min, strengthen the ball mill for 2 hours, put it in a vacuum carbon tube furnace and heat up to 150°C, react for 0.5h, continue to heat up to 400°C, and react for 0.5h. After the reaction is completed, it is cooled to room temperature with the furnace to obtain zinc tin Sulfur nanoparticle...

Embodiment 2

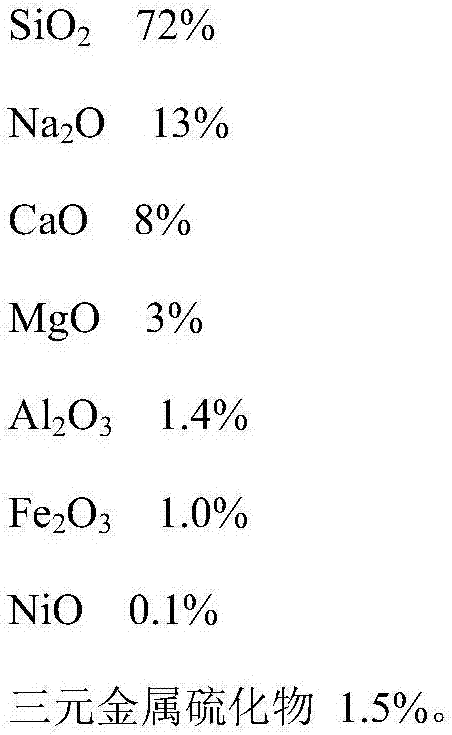

[0038] Embodiment 2 Preparation of privacy and energy-saving float glass composition with low light transmission:

[0039] (1) Weigh SiO according to the formula 2 、Na 2 O, CaO, MgO, Al 2 o 3 , Fe 2 o 3 , NiO and ternary metal sulfide, the mixture is obtained after fully mixing the components;

[0040] (2) Add the mixture obtained in step (1) into the kiln furnace, heat to 1500° C. to melt and clarify to obtain molten glass;

[0041] (3) The molten glass obtained in step (2) is cooled to 1100° C., formed in a tin bath, then annealed in an annealing kiln, and cut to obtain privacy and energy-saving float glass with high ferrous iron and low light transmission.

[0042] Examples 3, 4 and Comparative Examples 1-4 Reference Example 2 for the preparation of the low-transmittance privacy-saving energy-saving float glass composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com