Vacuum chuck manipulator paw

A technology of vacuum suction cups and mechanical grippers, applied in the field of industrial manufacturing and mechanical equipment, can solve the problems that mechanical grippers cannot play an effective role, the opening angle of the grippers is limited, and the size of the grippers has a great influence, so as to achieve ingenious design and easy operation , good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

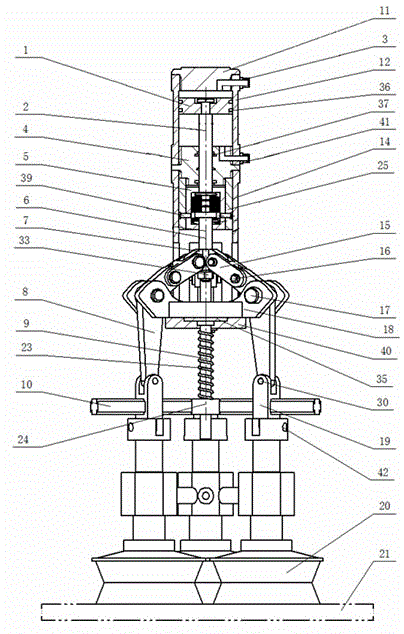

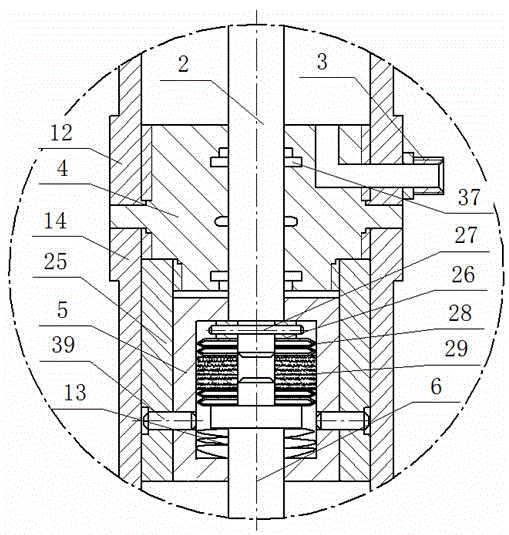

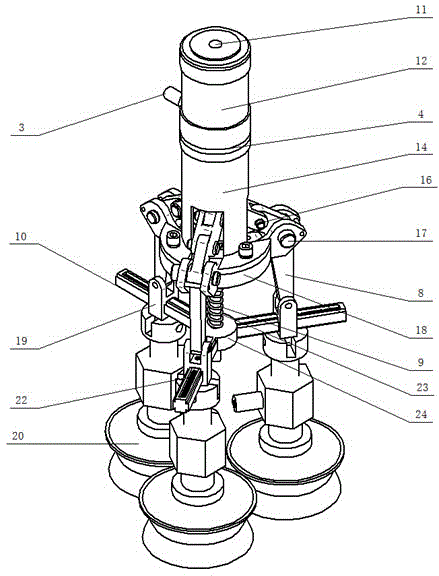

[0035] Example 1: Such as Figure 1-11As shown, the vacuum suction cup manipulator includes piston 1, piston rod 2, pipe joint I3, front cylinder cover 4, sleeve 5, push-pull rod 6, push-pull head 7, three knuckles 8, connecting rod 9, suction cup chute 10. Rear cylinder cover 11, cylinder barrel 12, slack spring 13, connecting seat 14, hinge 15, hinge shaft 16, knuckle shaft 17, mounting seat 18, movable hand frame 19, vacuum sucker 20, pull-back spring 22, spring 23. Connecting ring 24, sleeve connecting seat 25, piston rod fixing plate 26, piston pin 27, disc spring set, friction plate 29, movable hand frame pin 30, spring stopper 31, stopper screw 32, lock nut 33. Piston nut 34, pressure plate 35, sealing ring 36, sealing ring 37, connecting rod fixing plate 40, pipe joint II 41, hinge pin 42; wherein the cylinder barrel 12 is connected with the external thread on the upper end of the front cylinder cover 4, and the rear cylinder cover 11 is connected with the internal...

Embodiment 2

[0041] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, except that four knuckles 8 are set, which are distributed in the circumference range at an angle of 90°; corresponding to the installation location;

[0042] Described vacuum sucker 20 is installed on the movable arm rest 19 by hinge pin 42, and vacuum sucker can select standard sucker for use according to the object 21 types to be lifted; The frames are fixed together in series, and accordingly the number of vacuum suction cups 20 is consistent with the number of movable hand frames 19 .

[0043] This solution obtains greater and more stable adsorption force by increasing the number of vacuum chucks 20 and changing their layout, and the size and weight of the object to be lifted 21 are doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com