Non-round annular wheel crankless engines

A technology of internal gears and engines, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of crankshaft output power shortage, pistons, work loss, dead spots, etc., to reduce fuel consumption, increase conversion rate, and reduce pollution emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

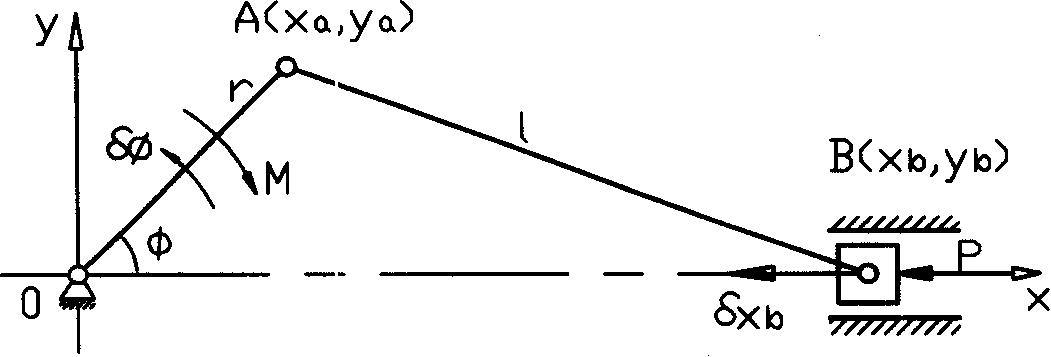

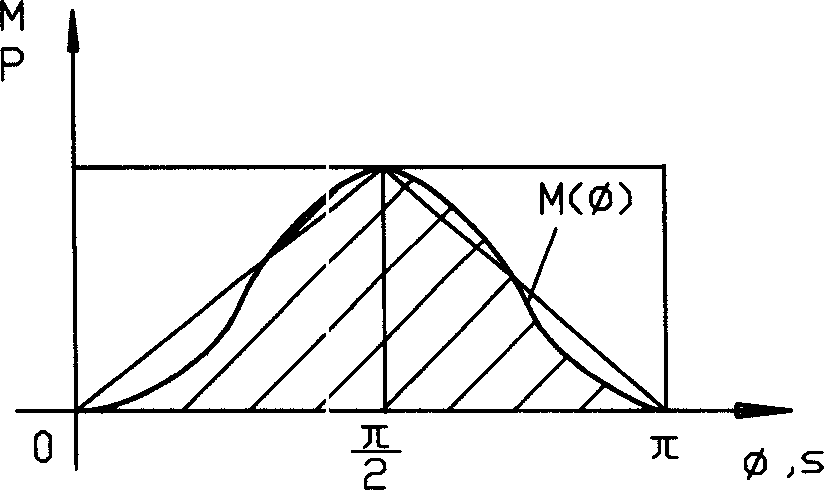

Method used

Image

Examples

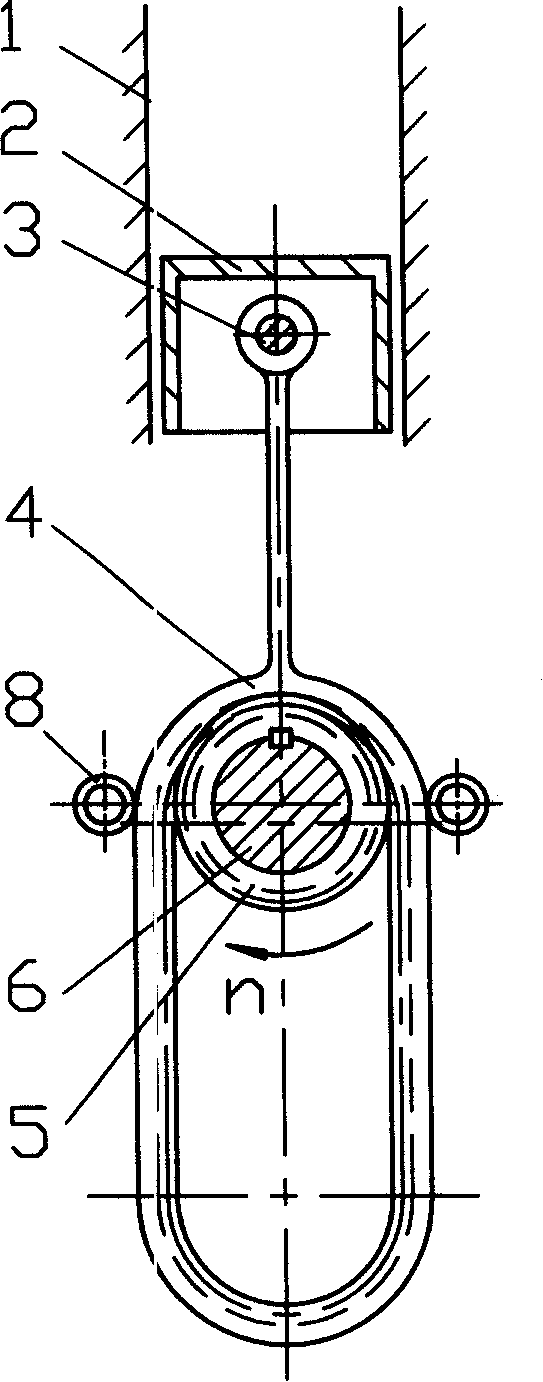

Embodiment Construction

[0015] In order to implement the present invention smoothly, additional devices such as a steam distribution system, an electrical system, an oil supply system, a lubricating system, a cooling system, and a starting system also need to be added, and these devices are no longer involved in the present invention.

[0016] Due to the large inertia of the reciprocating motion of the piston and the non-circular internal gear, the impact and vibration are caused. The pistons of the adjacent two cylinders of the engine and the non-circular internal gear move in opposite directions. Through the connection of the damping spring 9, the spring is used when the piston reaches the upper and lower dead centers. The tension of 9 damps each other, which can effectively reduce the inertial impact.

[0017] For piston air compressors, refrigeration compressors, etc., the main shaft can be changed into a power input shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com