Scaffold with automatic installation characteristic

A technology of building and moving columns, applied in the field of building sheds, can solve the problems of no automated structure, spending a lot of time installing and dismantling building sheds, production process and cost impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

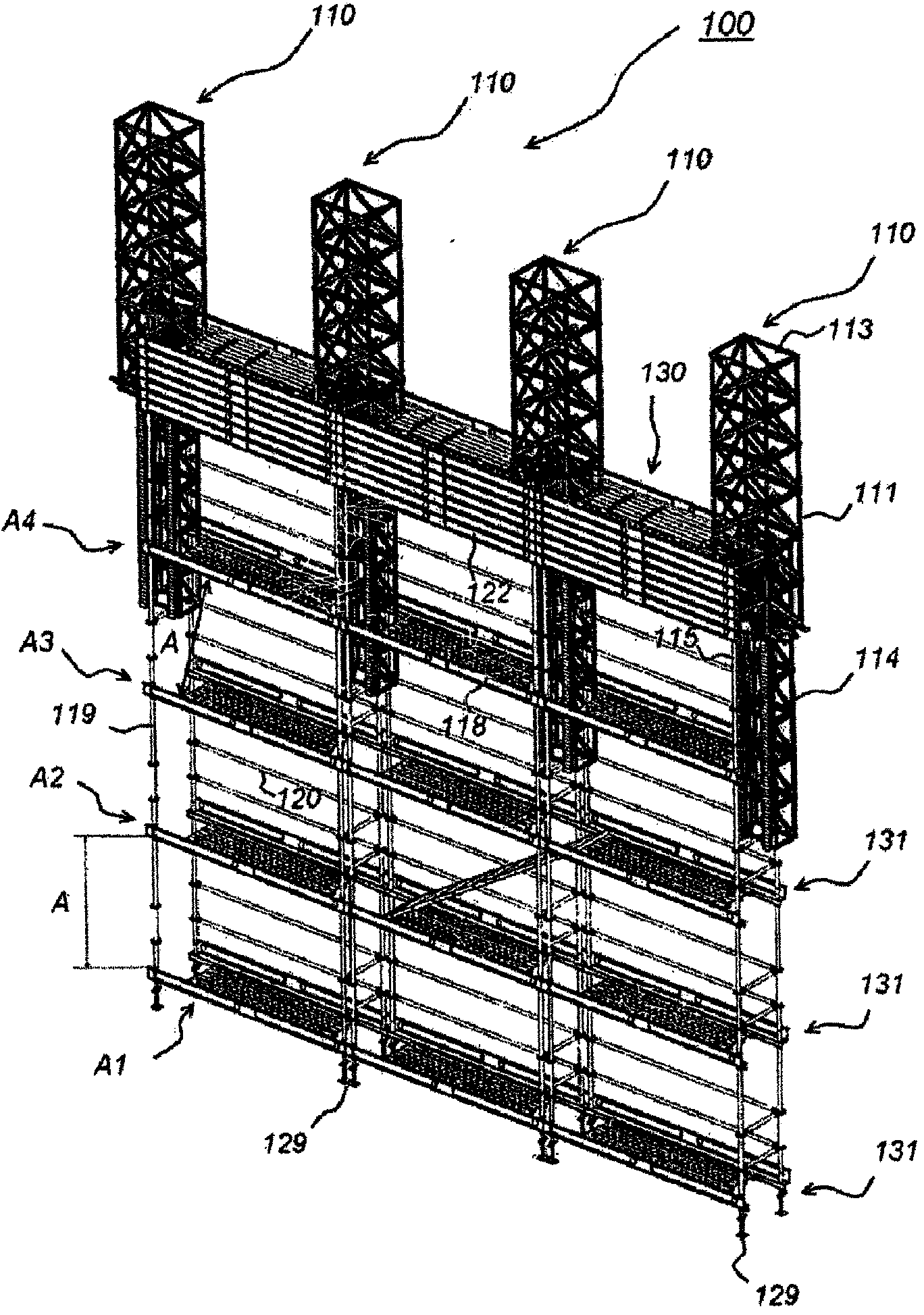

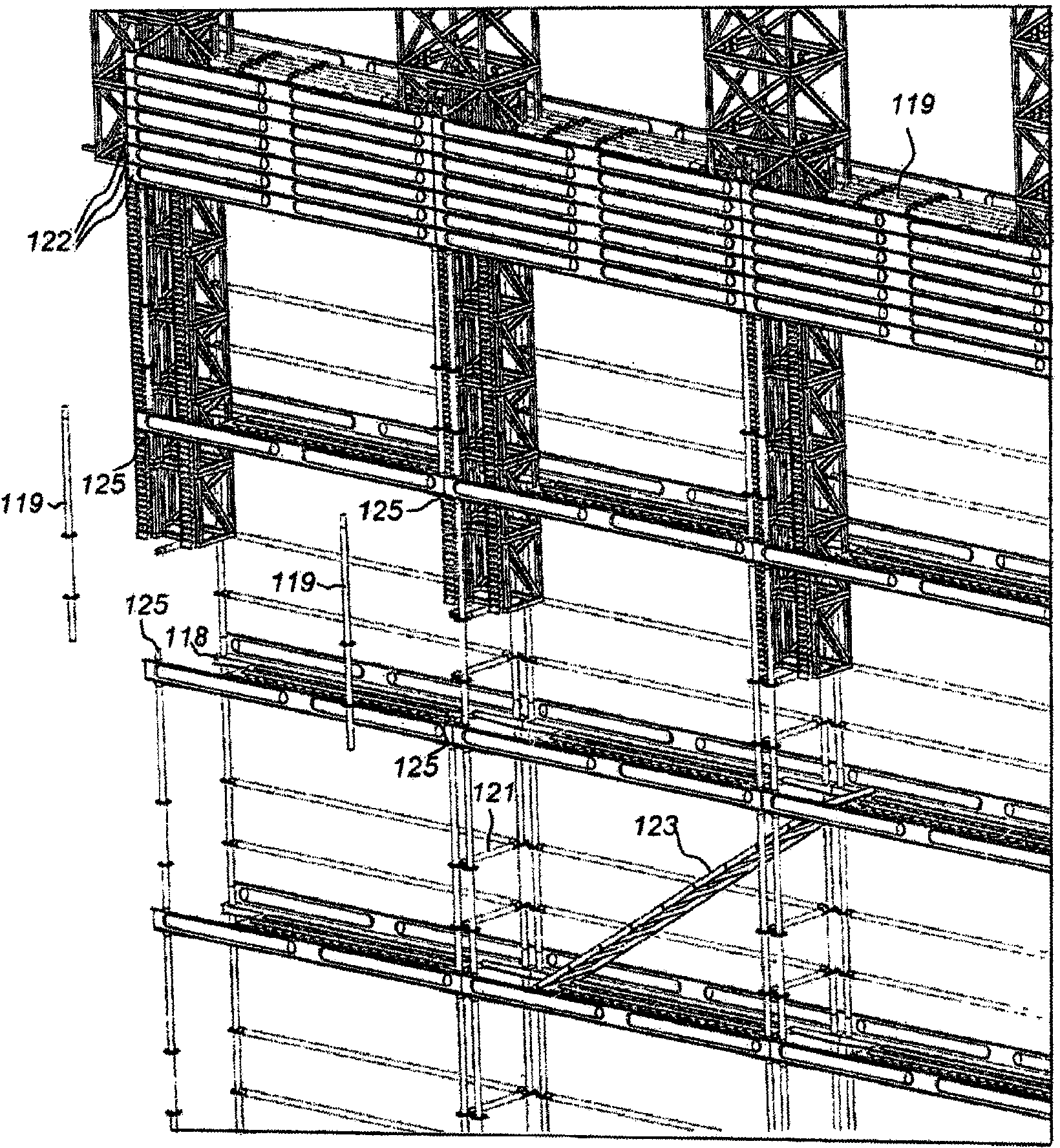

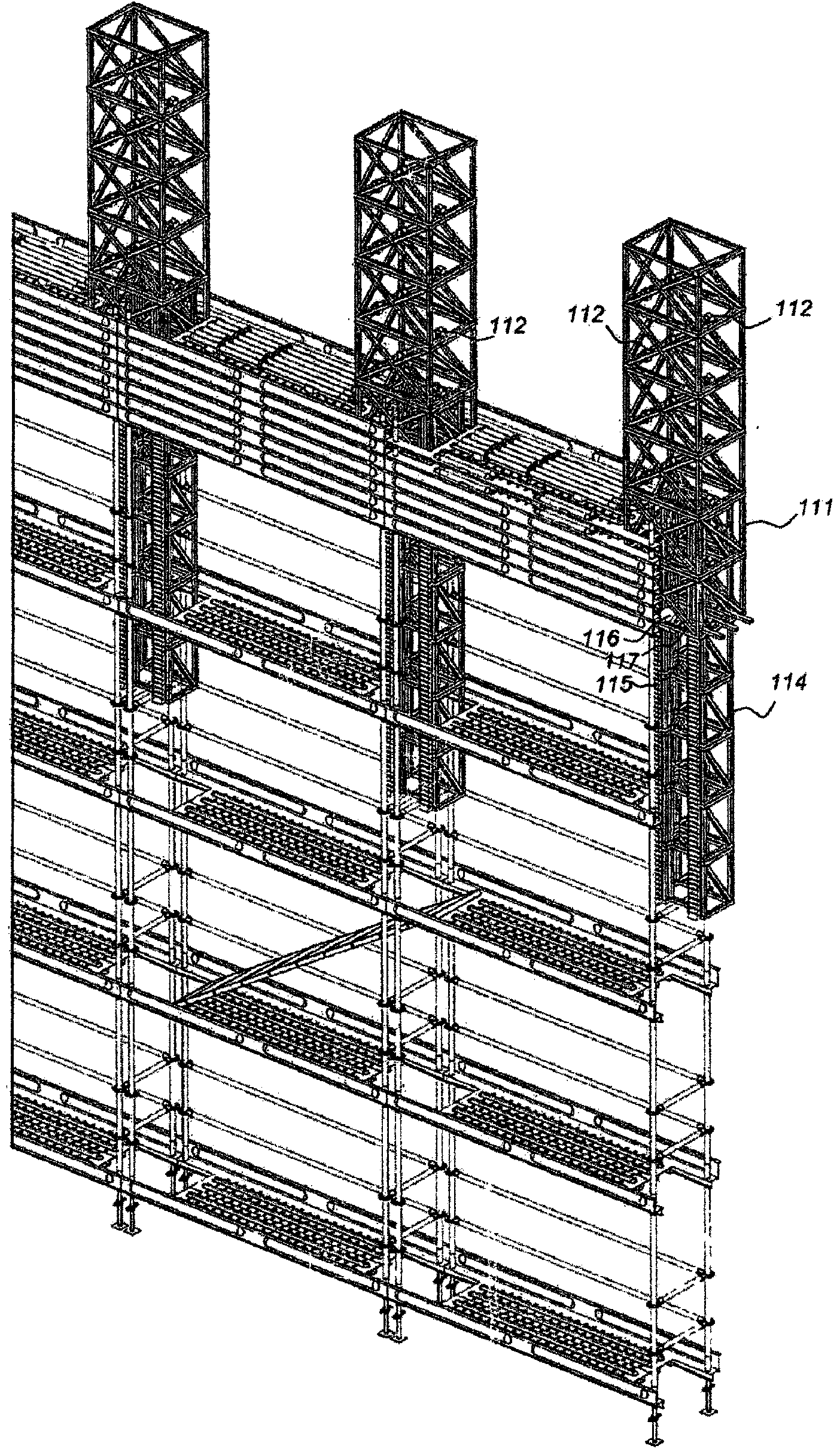

[0037] The present invention relates to an automated building shed (100), which can be used on high-rise buildings during, for example, construction, repair, painting, painting and maintenance; said automated building shed (100) is characterized in that it includes a building shed module (130), a plurality of moving columns (110), a plurality of vertical and transverse molding strips (119, 120) and a plurality of guide elements (125); ; The plurality of moving columns (110) open the building shed through a drive unit (116), thereby forming a working distance (A) between each pair of superimposed layers (131); the plurality of vertical and lateral forming strips (119, 120) are located within each working distance (A) between each pair of stacked layers (131); said plurality of guide elements (125) are located on a plurality of carrier plates (118) for securing Vertical molding strips (119).

[0038] When the building shed is driven by the driving unit (116), a plurality of ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com