Pressing and disassembling device for engine gudgeon pins

A piston pin and engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, difficult to guarantee assembly accuracy, low assembly efficiency, etc., achieve high degree of mechanical automation, save internal space, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with embodiment and accompanying drawing.

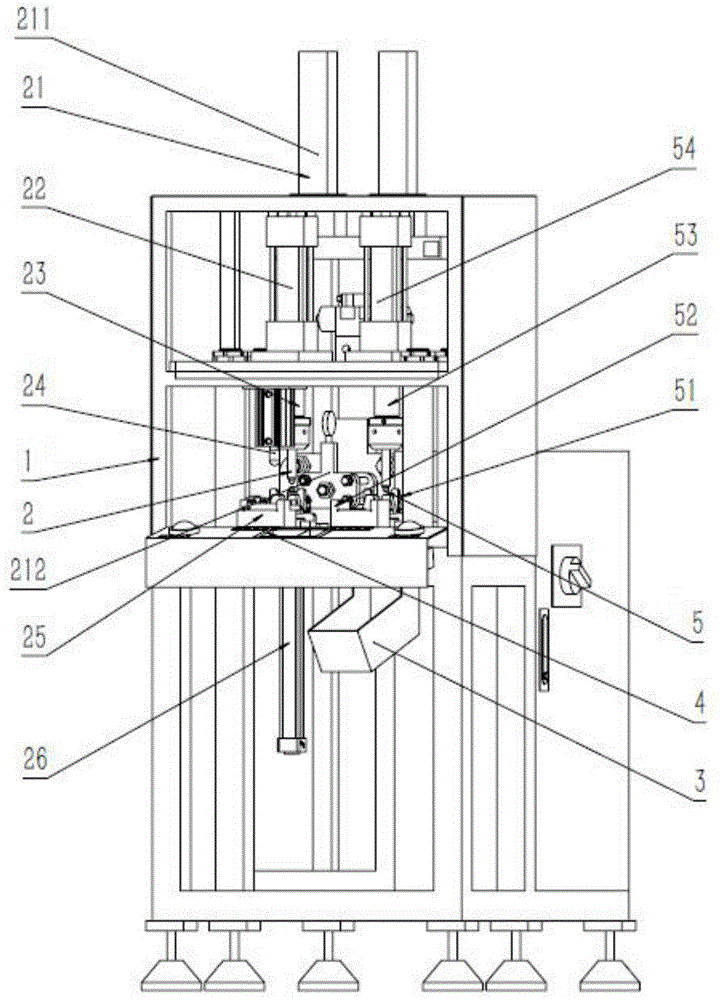

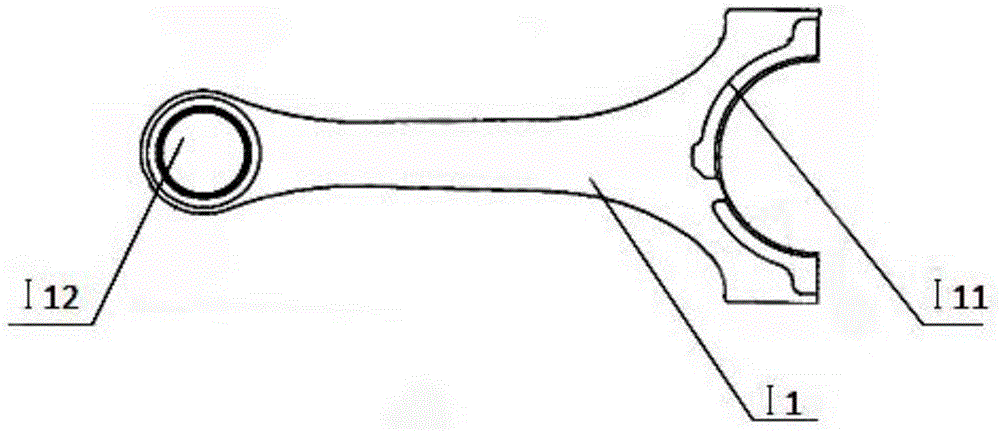

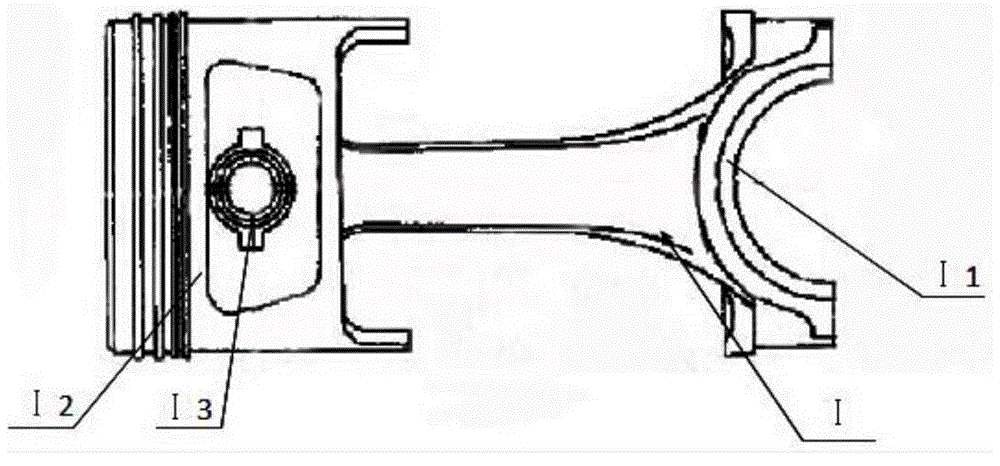

[0033] What the present invention designs is a kind of press dismantling device of engine piston pin (abbreviation device, refer to figure 1 , 4 -6, 8-17), including the pin drop groove 3 and the connecting pin oil immersion groove assembly 4, characterized in that the device also includes a support frame assembly 1, a pin pressing mechanism 2 and a pin removal mechanism 5.

[0034] The support frame assembly 1 (see figure 1 , 16 , 17) consists of skeleton structure 11, control cabinet 12, rear lower fixed plate 13, rear upper fixed plate 14, front upper fixed plate 15, support column 16, button bracket 17, two-hand operation button 18, front lower fixed plate 19 and can adjustable feet 110; the lower part of the frame structure 11 is screwed to fix the adjustable feet 110; the control cabinet 12 is fixed to the rear of the frame structure 11 by bolts; both end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com