Bidirectional spiral electrostatic spinning device

An electrospinning, bidirectional helical technology, used in textiles and papermaking, filament/thread forming, feeding solution to spinnerets, etc. Fiber film quality and other issues, to reduce electrostatic interference and electric field concentration, easy automatic control, and improve the efficiency of electrospinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

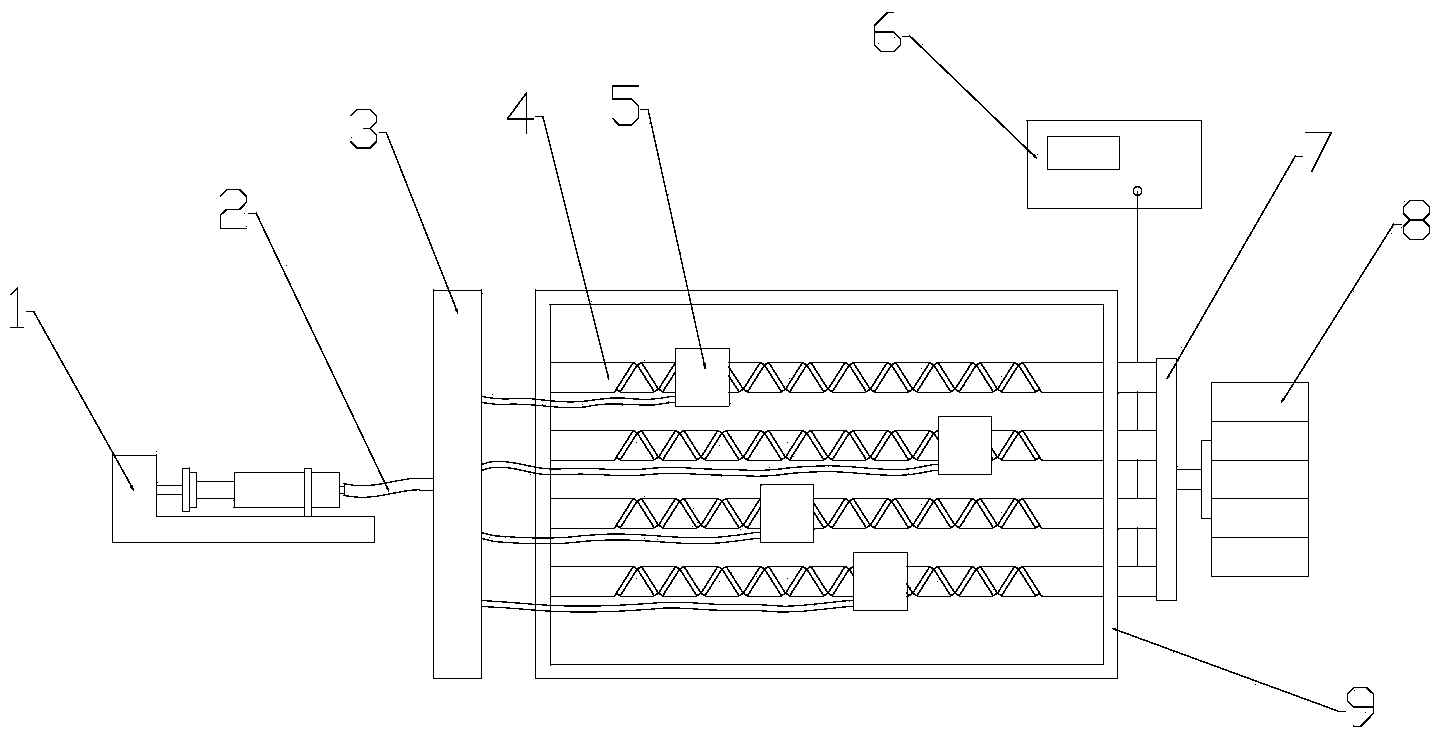

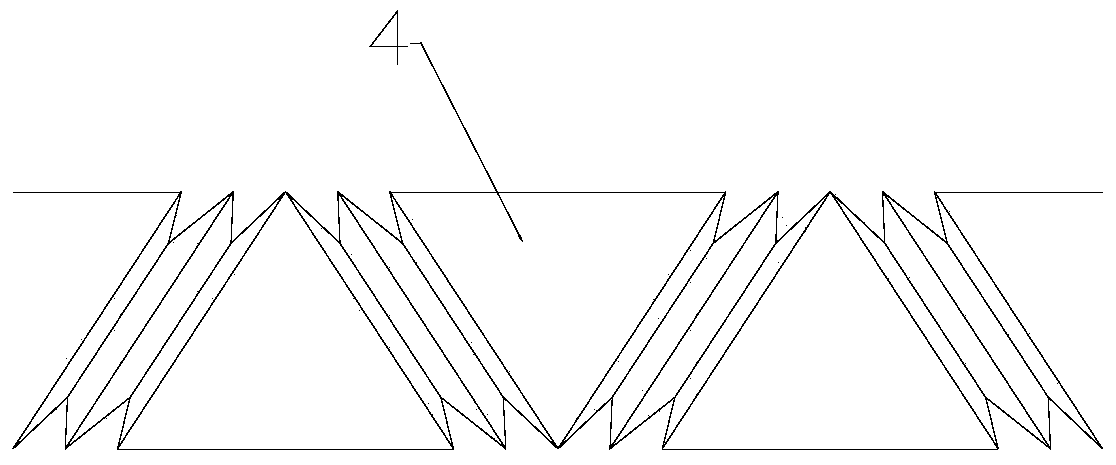

[0031] see Figure 1~6 , the embodiment of the present invention is provided with two-way threaded guide rod 4, liquid storage slider 5, vertical slide rod 14, guide rail 15, frame 9, controllable injection device 1, liquid conduit 2, liquid dispensing device 3, high voltage power supply 6 , air pump 10, pressure regulating valve 11, gas conduit 12, partition 16, motor 8, driven pulley 17, driving pulley 18, V-shaped belt 7, air hole array 19 and collection device 13.

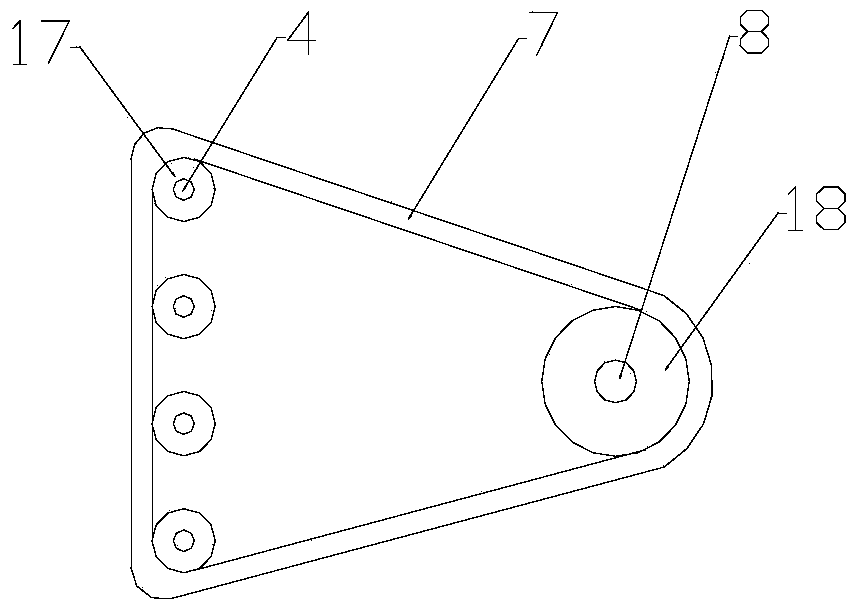

[0032]The two-way threaded guide rod 4 is clamped and fixed on the frame 9, and the end of each two-way threaded guide rod 4 is equipped with a driven pulley 17, and the driven pulley 17 is connected to the motor 8 through the V-shaped belt 7. The driving pulley 18 of the main shaft is connected to realize the rotation of multiple bidirectional threaded guide rods 4 driven by the motor 8 at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com