A method for the homogeneous preparation of covalent organic framework materials using high pressure

A technology of covalent organic framework and high-pressure homogenization, applied in chemical instruments and methods, and other chemical processes, can solve the problems of large amount of organic solvent usage, long synthesis time, complex process, etc., and achieve short reaction time and low cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

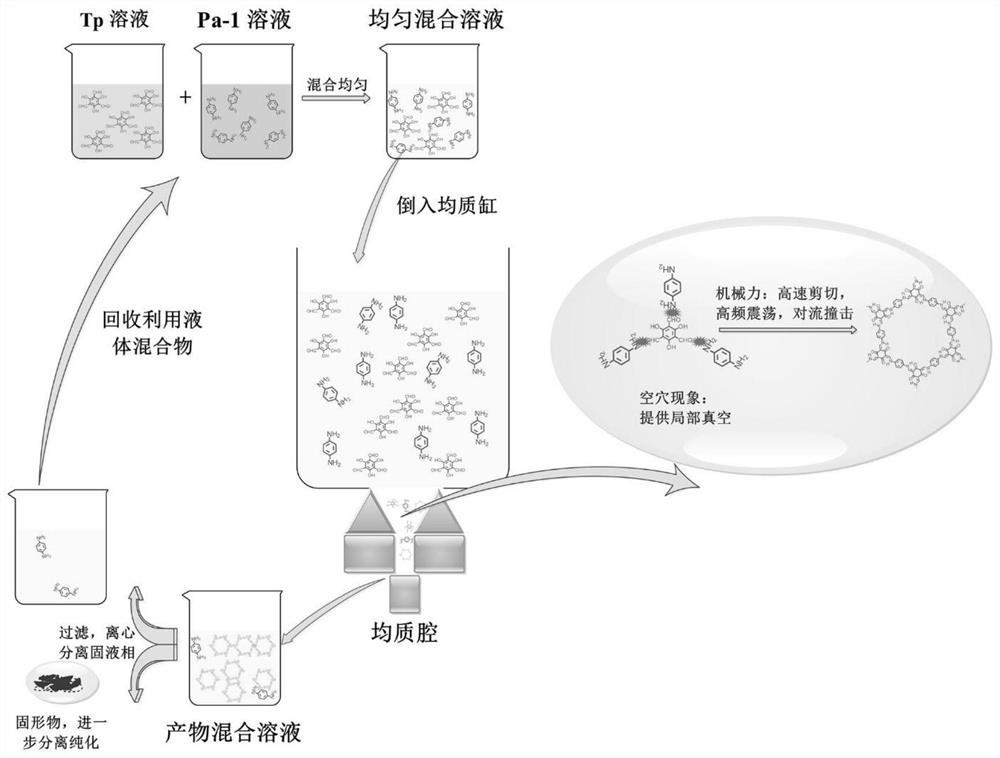

Method used

Image

Examples

Embodiment 1

[0033] S1. At normal temperature and pressure, add 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde (1mmol) and p-phenylenediamine (1.5mmol) into a 500mL beaker at a molar ratio of 1:1.5 , add 300mL water, 150mL glacial acetic acid, and stir for 5min with a mechanical mixer;

[0034] S2. Under normal temperature and pressure, turn on the circulating condensed water of the high-pressure homogenizer, and adjust the temperature to 0°C, add the above-mentioned suspension to the high-pressure homogenizer, and circulate the homogeneous reaction for 30 minutes at a homogenization pressure of 100 MPa;

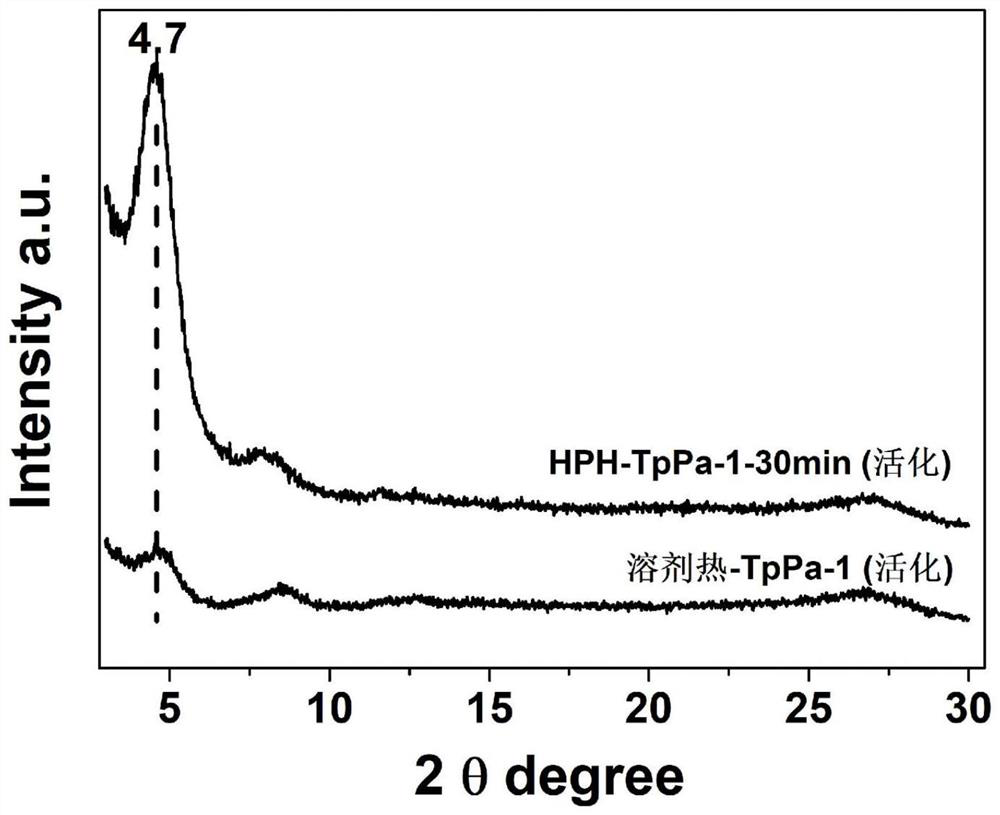

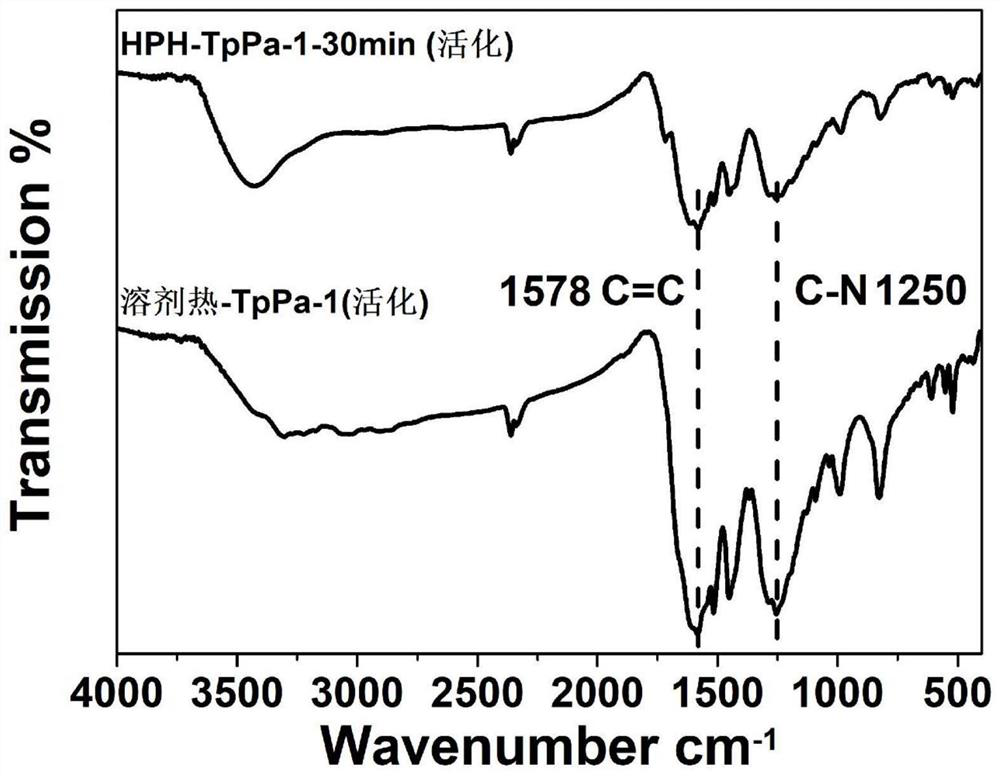

[0035] S3. After the reaction is over, use a 500mL beaker to take the reaction suspension, and vacuum filter to obtain a solid product. The filtrate is recovered and stored. After the product is washed with water, ethanol, and acetone in sequence, it is dried at 150°C for 12 hours to obtain a high-pressure average product. The HPH-TpPa-1 prepared by mass method has an isolated yield of 81...

Embodiment 2

[0041] S1. At normal temperature and pressure, add 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde (1mmol) and p-phenylenediamine (1.5mmol) into a 500mL beaker at a molar ratio of 1:1.5 , add 300mL water, 150mL glacial acetic acid, and stir for 5min with a mechanical mixer;

[0042] S2. Under normal temperature and pressure, turn on the circulating condensed water of the high-pressure homogenizer, and adjust the temperature to 0°C, add the above-mentioned suspension to the high-pressure homogenizer, and circulate the homogeneous reaction at a homogenization pressure of 100 MPa for 120 minutes;

[0043] S3. After the reaction is over, use a 500mL beaker to take the reaction suspension, and vacuum filter to obtain a solid product. The filtrate is recovered and stored. After the product is washed with water, ethanol, and acetone in sequence, it is dried at 150°C for 12 hours to obtain a high-pressure average product. The HPH-TpPa-1 prepared by mass method has an isolated yield of 82%...

Embodiment 3

[0045] S1. At normal temperature and pressure, add 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde (1mmol) and p-phenylenediamine (2mmol) into a 500mL beaker at a molar ratio of 1:2, Add 300mL of water and 150mL of glacial acetic acid, and stir for 5min with a mechanical stirrer;

[0046] S2. Under normal temperature and pressure, turn on the circulating condensed water of the high-pressure homogenizer, and adjust the temperature to 0°C, add the above-mentioned suspension to the high-pressure homogenizer, and circulate the homogeneous reaction at a homogenization pressure of 100 MPa for 120 minutes;

[0047] S3. After the reaction is over, use a 500mL beaker to take the reaction suspension, and vacuum filter to obtain a solid product. The filtrate is recovered and stored. After the product is washed with water, ethanol, and acetone in sequence, it is dried at 150°C for 12 hours to obtain a high-pressure average product. The HPH-TpPa-1 prepared by mass method has an isolated yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com