A substrate conveying device for inkjet printing

A conveying device, inkjet printing technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as affecting the printing efficiency and printing quality of the substrate, overflowing the pixel pits of the substrate, and high rejection rate, etc. Achieve mass continuous production, reduce scrap rate, and ensure the effect of ink stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

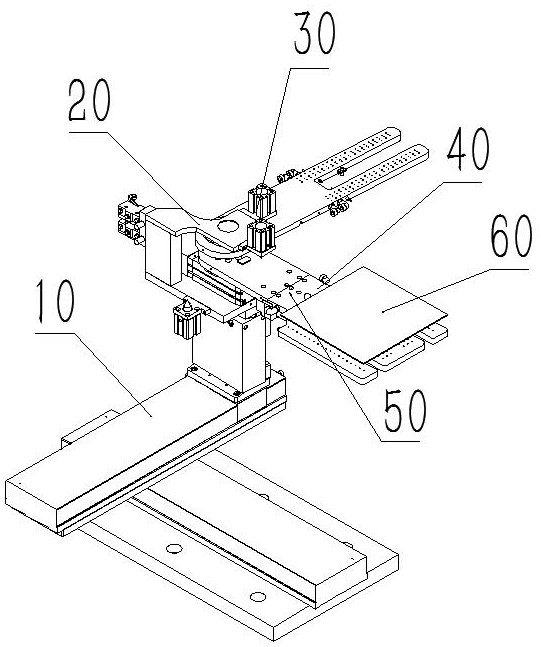

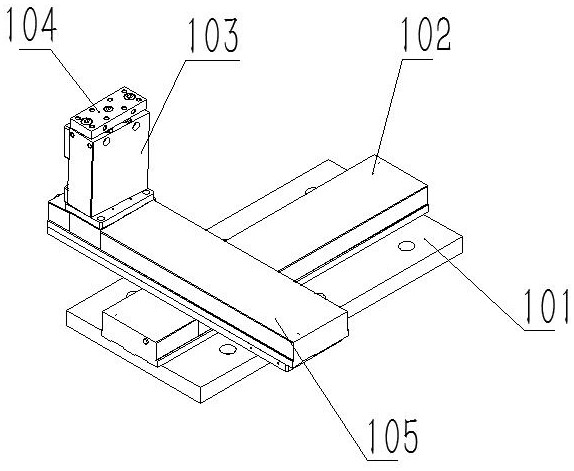

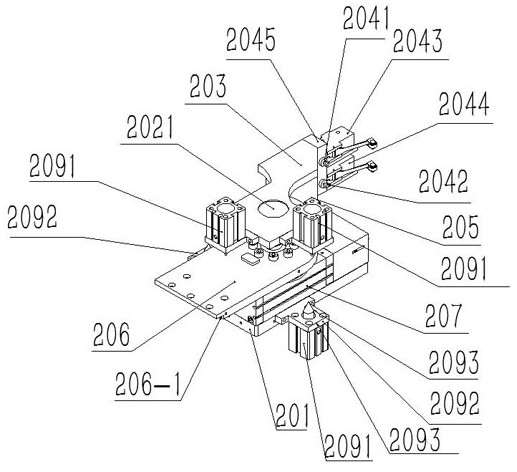

[0032] Please refer to Figure 1 to Figure 10 , a substrate transfer device for inkjet printing of the present invention includes a moving assembly 10 , a rotating assembly 20 , a first transfer assembly 30 and a second transfer assembly 40 . The rotating assembly 20 is installed on the moving assembly 10 and can move along the X direction, Y direction and Z direction of the substrate transfer device driven by the moving assembly 10. The first transfer assembly 30 and the second transfer assembly 40 are connected to the rotation assembly 20 , the rotation assembly 20 can respectively drive the first transfer assembly 30 and the second transfer assembly 40 to make independent rotation movements. It is worth noting that the X direction of the substrate transfer device is the width direction of the substrate transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com