Acrylic acid cathode electrophoretic paint for producing composite coating and application thereof

A cathodic electrophoresis and composite coating technology, applied in coating, electrophoretic plating, electrophoretic coating and other directions, can solve the problems of lack of strong metallic texture of electroplating, low utilization rate of bottoming materials, poor working environment of workers, etc., to achieve metallic texture. Strong, low cost, excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

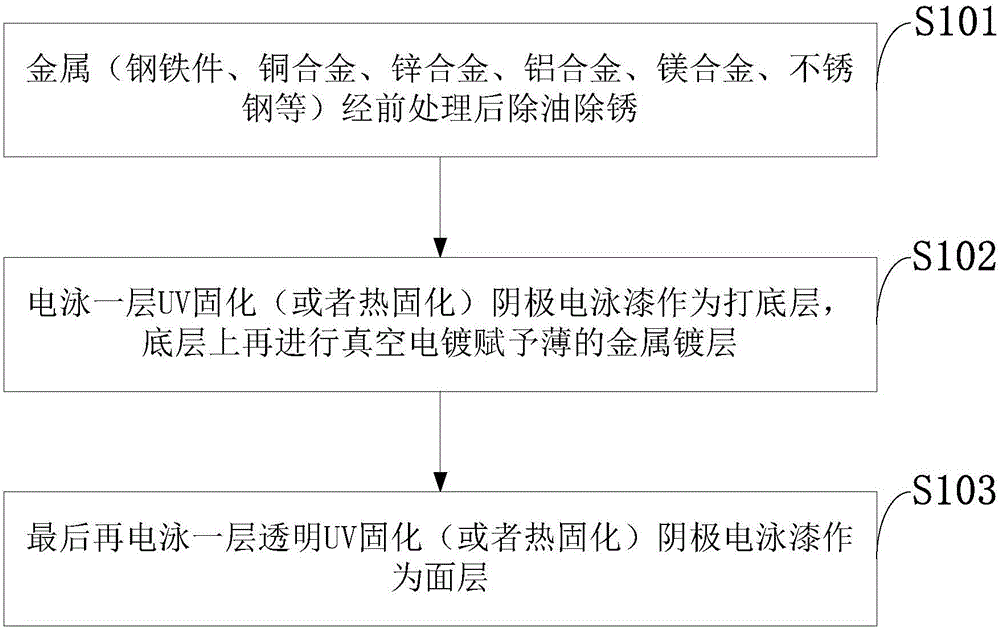

[0048] 1. Main process flow

[0049] Metal parts → pretreatment → pure water washing → cathodic electrophoresis → pure water washing → curing → vacuum plating → pure water washing → cathodic electrophoresis → pure water washing → curing → finished product.

[0050] 2. Detailed implementation steps

[0051] (1) Pretreatment

[0052] Different pretreatments are carried out according to different substrates and surface conditions of materials, mainly including simple mechanical cleaning, degreasing, derusting, etching, water washing, etc.

[0053] (2) Pure water washing, pure water cleaning, the conductivity of pure water is required to be less than 5us / cm, and the time: 10-20s.

[0054] (3) Cathodic electrophoresis (primer)

[0055] According to different substrates, cathodic electrophoresis adopts thermosetting acrylic cathodic electrophoresis process or UV curing acrylic cathodic electrophoresis process.

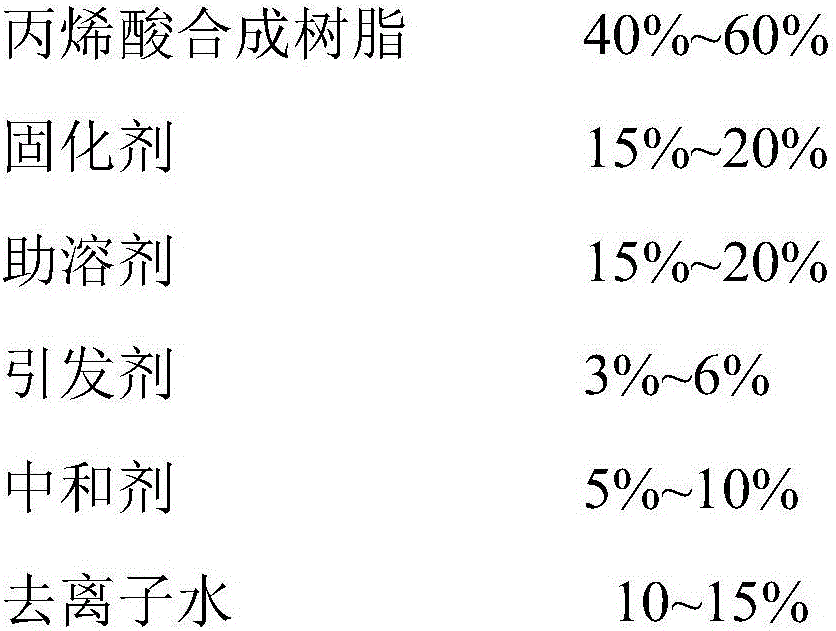

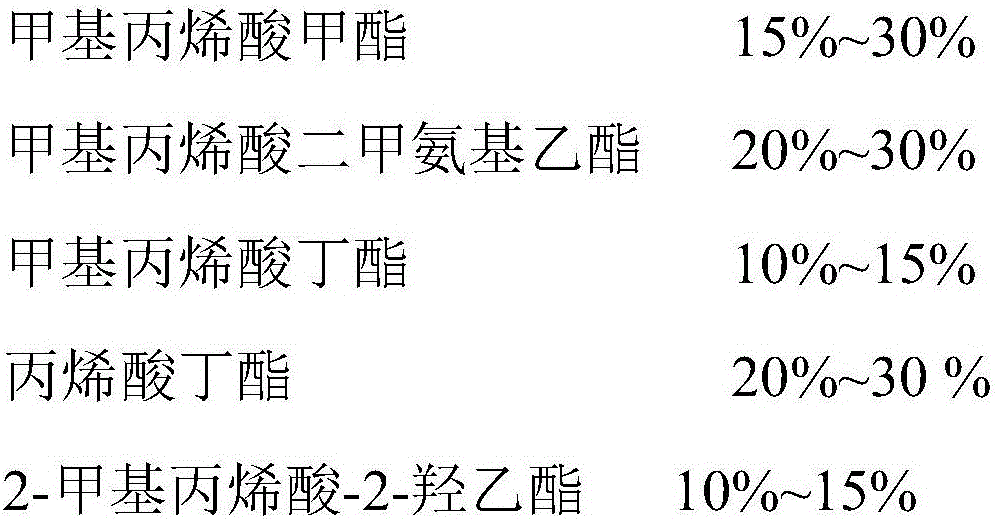

[0056] ① Composition of electrophoretic paint for thermosetting acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com