Method for preparing sealing pad of solid oxide fuel cell and waste material recovery process

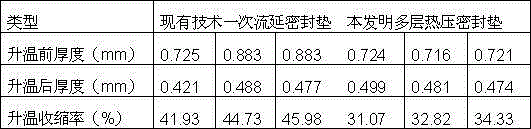

A solid oxide and fuel cell technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve the problems of restricted production efficiency of gaskets, excessive shrinkage of gaskets, and low sealing success rate, etc., to achieve Improve the success rate of sealing, avoid the difficult control of thickness uniformity, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Fabrication of Gasket Blank by Tape Casting

[0043] Weigh 120g of sealing material powder, add it to 25g of xylene and butyl acetate (according to 1:1 mass ratio) mixed solvent, add 6g of dispersant, and use a roller ball mill at 125rpm for 8 hours to mix.

[0044] Then add 4g of binder and 4g of plasticizer, and use a roller ball mill at a speed of 80rpm for 8 hours to mix evenly to obtain a stable slurry with a moderate viscosity.

[0045] After the slurry is sieved through a 190-mesh sieve and vacuum degassed, it is poured on the PET bottom film, driven forward by the bottom film, and a green body with a uniform thickness is obtained after passing through a scraper with a knife height of 0.3mm. The casting table is heated to 50°C, and when the biscuit reaches the end of the casting table, it is rolled up together with the PET base film.

[0046] Preparation of gasket

[0047] Peel off the green body from the PET base film, align the 6 layers of green body, and...

Embodiment 2

[0052] Recycling of Gasket Blank Waste

[0053] The green body waste remaining after trimming in Example 1 was recovered.

[0054] Weigh 80g of the blank blank of the sealing gasket, add 30g of xylene and butyl acetate (according to 1:1 mass ratio) mixed solvent, and use a roller ball mill to mix evenly at 80rpm for 8 hours; repeat the method described in Example 1 Subsequent steps in preparing the green gasket.

[0055] After testing, the heat resistance, deformation resistance and other properties of the sealing gasket prepared by using the recycled waste materials are not different from those of the sealing gasket prepared in Example 1.

Embodiment 3

[0057] Fabrication of Gasket Blank by Tape Casting

[0058] Weigh 120g of sealing material powder, add it to 40g of xylene and butyl acetate (according to 1:2 mass ratio) mixed solvent, add 10g of dispersant, and use a roller ball mill at a speed of 125rpm for 8 hours to mix.

[0059] Then add 6g of binder and 10g of plasticizer, and use a roller ball mill at a speed of 80rpm for 8 hours to mix evenly to obtain a stable slurry with a moderate viscosity.

[0060] After the slurry is sieved through a 190-mesh sieve and vacuum degassed, it is poured on the PET bottom film, driven forward by the bottom film, and a green body with a uniform thickness is obtained after passing through a scraper with a knife height of 0.3mm. The casting table is heated to 50°C, and when the biscuit reaches the end of the casting table, it is rolled up together with the PET base film.

[0061] Preparation of gasket

[0062] Peel off the green body from the PET base film, align the 6 layers of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com