Method for preparing carbon nano tube by taking coke as raw material and prepared carbon nano tube

A carbon nanotube, coke technology, applied in the direction of carbon nanotube, nanocarbon, nanotechnology, etc., to achieve the effect of economy and quality assurance, easy operation, and ensure uniform gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of carbon nanotubes of the present invention may comprise the following steps:

[0071] (1) Pulverize the coke, sieve it to a particle size of less than 150 μm, and then dry it to obtain pretreated coke; mix the pretreated coke with coker wax oil at a mass ratio of 2:1-3:1 Stir and mix evenly to obtain a mixture of coke and coked wax oil; the mixture of coke and coked wax oil is molded using a mold and a hydraulic press, wherein the molding pressure of the hydraulic press is 10 atmospheres, and the molding speed is 0.5cm / s. Obtaining a hollow coke rod with an outer diameter of 11-13mm and an inner diameter of 7-9mm;

[0072] (2) cutting the hollow coke rod with an outer diameter of 11-13 mm and an inner diameter of 7-9 mm into a uniform length of 10 cm;

[0073] (3) at 0.15-0.25m 3 Under the protection of nitrogen at a flow rate of / h, the above-mentioned hollow coke rod with an outer diameter of 11-13mm, an inner diameter of 7-9mm, and a length...

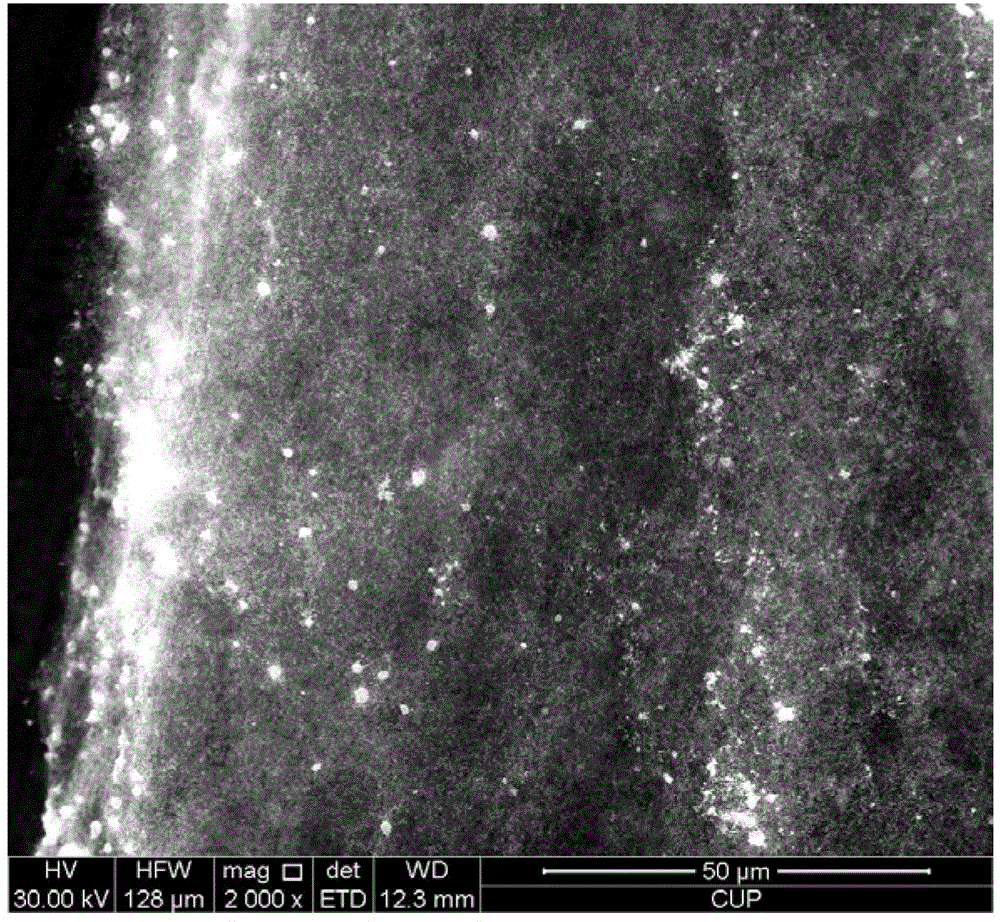

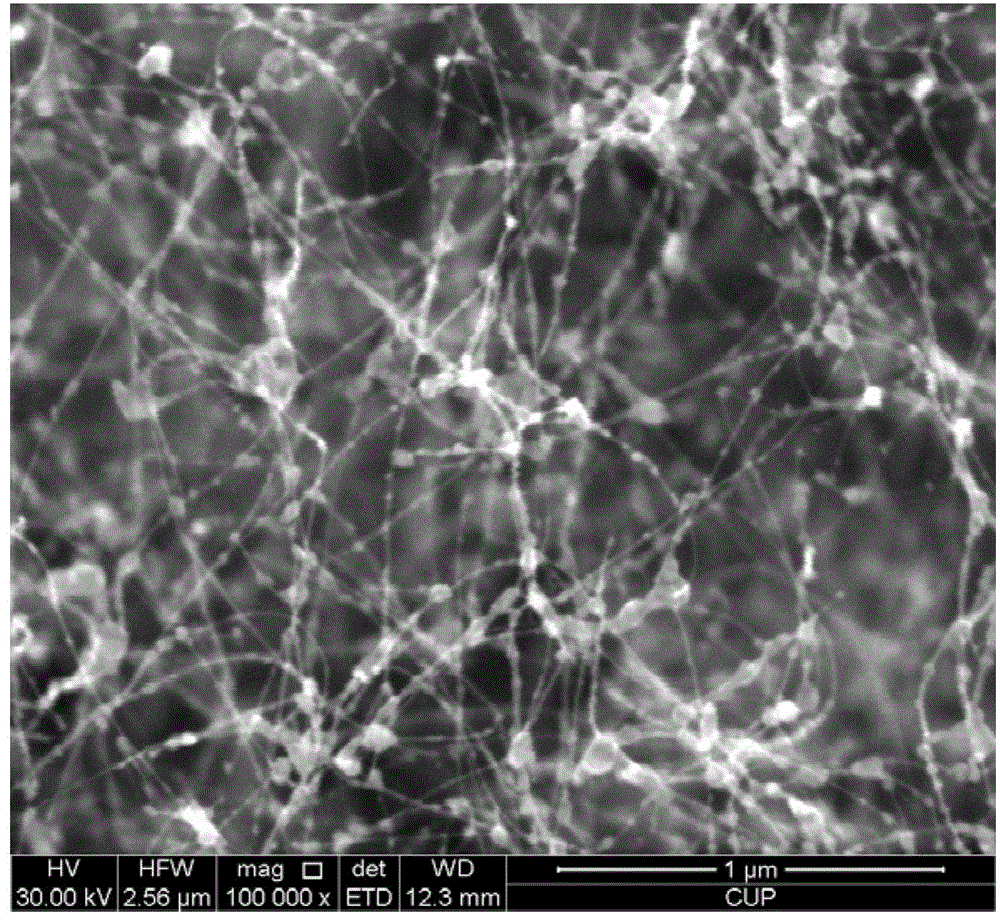

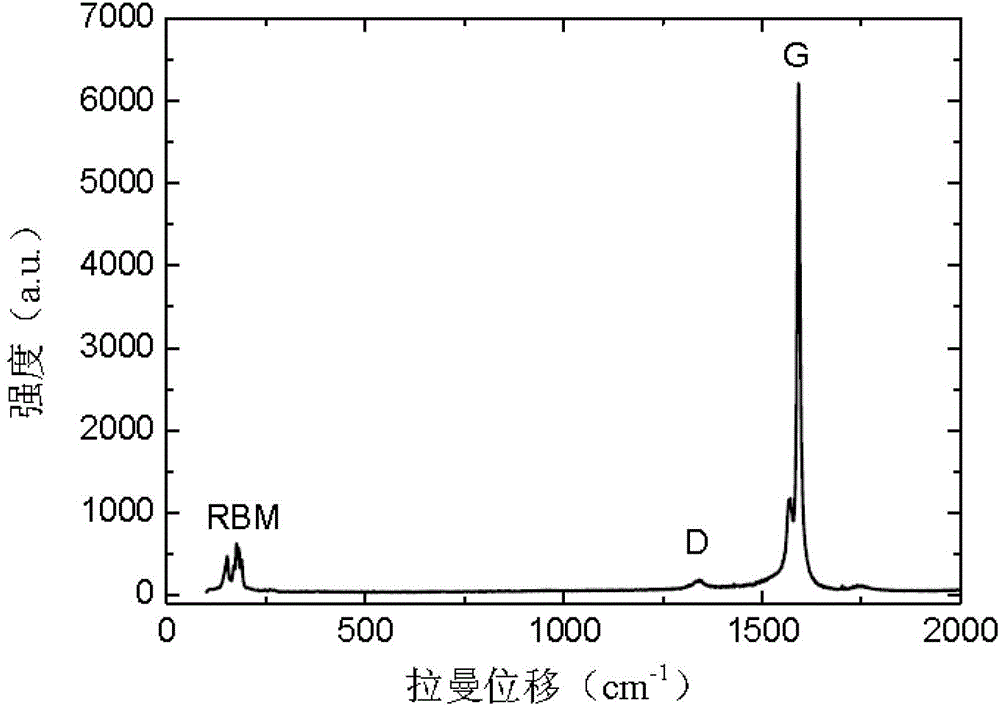

Embodiment 1

[0080] The present embodiment provides a kind of single-walled carbon nanotube, and its preparation method comprises the following steps:

[0081] (1) 500g of coke (the composition analysis results of the coke are shown in Table 1) was pulverized in a pulverizer, and sieved to a particle size of less than 150μm, and then dried to obtain pretreated coke; 200g of the pretreated The treated coke and 100g of coking wax oil are stirred and mixed evenly in a stirrer to obtain a mixture of coke and coking wax oil; the mixture of coke and coking wax oil is put into a mold, and a hydraulic press is used for compression molding, wherein, The molding pressure of the hydraulic press is 10 atmospheres, and the molding speed is 0.5cm / s to obtain a hollow coke rod with an outer diameter of 12mm and an inner diameter of 8mm;

[0082] (2) Cut the hollow coke rod with an outer diameter of 12 mm and an inner diameter of 8 mm into a uniform length of 10 cm;

[0083] (3) Put the above-mentioned h...

Embodiment 2

[0092] This embodiment provides a double-walled carbon nanotube, the preparation method of which is basically the same as that of Example 1, the difference being that in the step of performing the arc discharge gasification reaction, nitrogen is used instead of helium as the reaction gas, The single-walled carbon nanotubes formed on the collecting frame and the double-walled carbon nanotubes formed on the surface of the anode are obtained.

[0093] Collect the prepared single-walled carbon nanotubes and double-walled carbon nanotubes, weigh and calculate the yield respectively, and obtain the yield of the single-walled carbon nanotubes of this embodiment as 0.64g / h, and the yield of the double-walled carbon nanotubes is 0.64g / h. The productivity was 0.3 g / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com