A kind of 89srcl2 solution production device

A technology for a production device and a dissolving device is applied in the field of radioisotope preparation to achieve the effects of reducing radiation dose, improving filtration efficiency, and reducing radiation hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

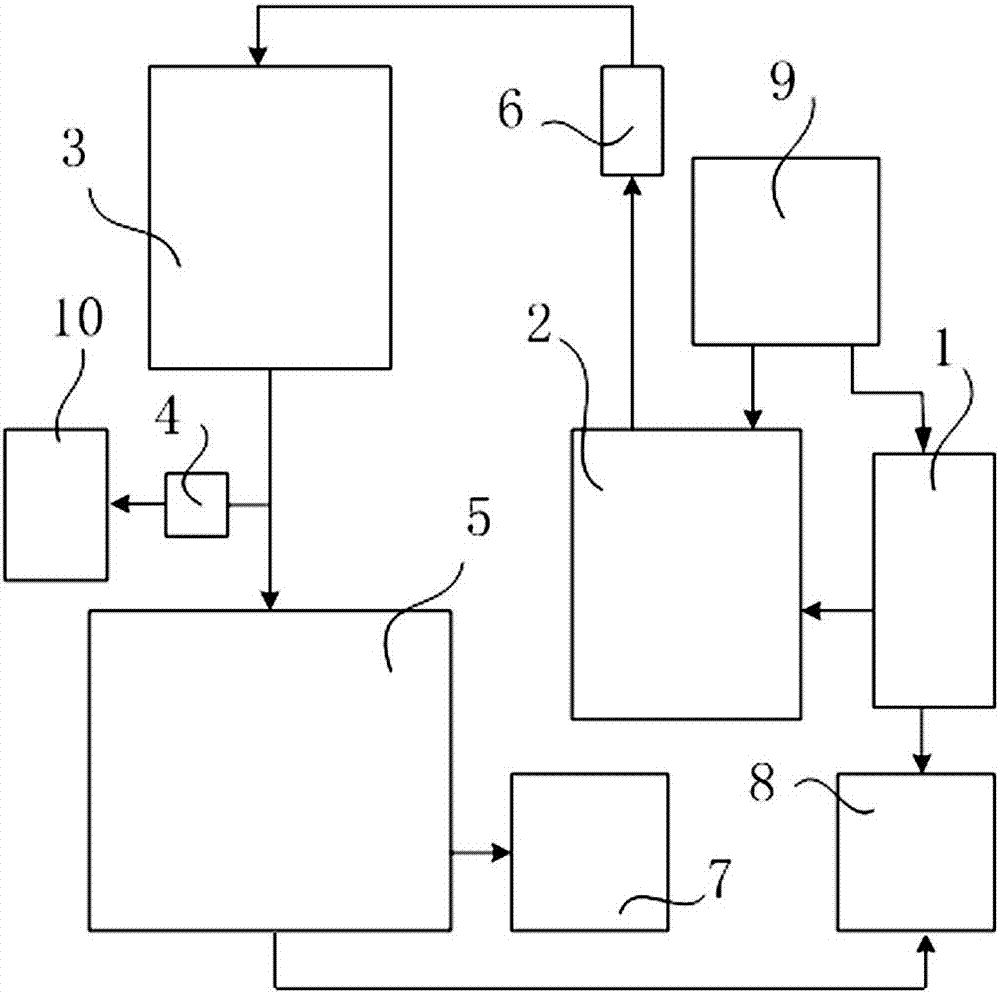

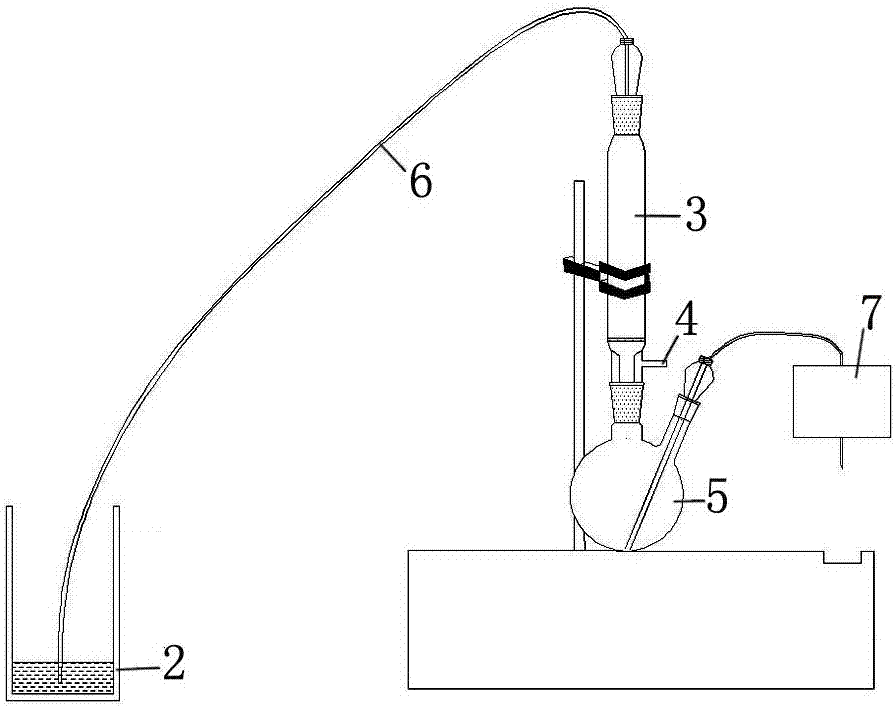

[0036] A sort of 89 SrCl 2 Solution production devices, such as figure 1 and figure 2 As shown, it includes a target tube crushing and dissolving device 2 , a filter device 3 , an air extraction joint 4 , a filling bottle 5 , a delivery pipeline 6 , a packing device 7 and a water pump 10 .

[0037] Wherein, the target tube crushing and dissolving device 2 includes a base 13, a crushing groove 14 arranged on the base 13, and a breaking hammer 15 placed in the crushing groove 14, such as Figure 4 shown. One end of the delivery pipe 6 communicates with the liquid inlet of the filter device 3 , and the other end extends to the inner bottom of the tank 14 .

[0038]The filter device 3 is preferably composed of a sand core filter column and a 0.1 μm-10 μm microporous filter membrane arranged in the sand core filter column. The sub-bottling 5 can be a two-necked bottle or a three-necked bottle, preferably a two-necked bottle in the present embodiment. A solution outlet and a s...

Embodiment 2

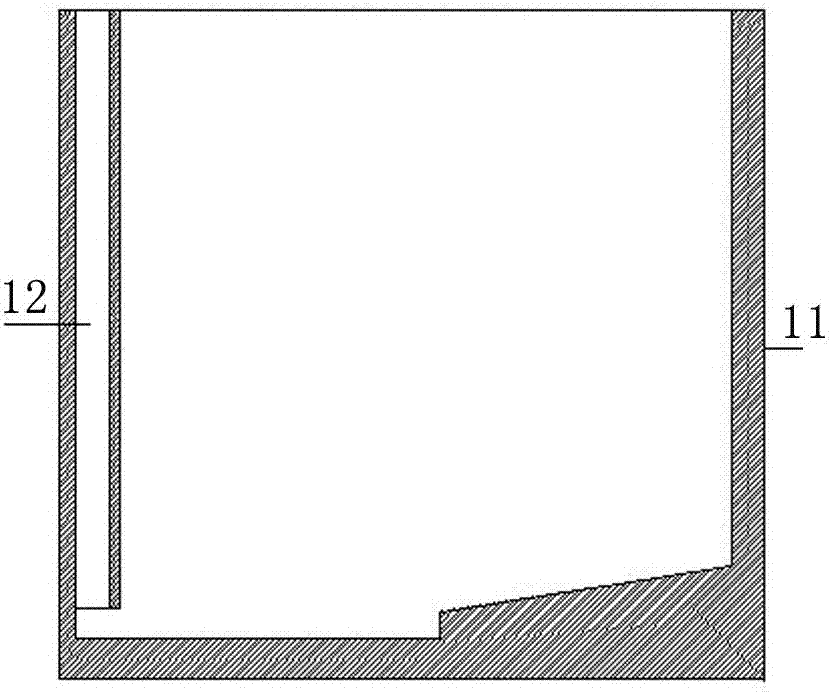

[0044] The difference between this embodiment and Embodiment 1 is that this embodiment adds a target tube cleaning device 1 for target cleaning, such as image 3 As shown, the specific settings are as follows:

[0045] The target tube cleaning device 1 includes a washing tank 11 and a drain pipe 12, the bottom of the washing tank 11 is provided with a collecting tank for collecting the liquid after washing, and an inclined guide surface for the liquid to flow to the collecting tank after washing, and the draining The lower end of the pipe 12 extends into the collection tank. The upper end of the drain pipe 12 is connected with a waste liquid collecting device 8 .

[0046] Before the target is transferred to the target tube crushing and dissolving device 2, the target is first transferred to the target tube cleaning device 1, cleaned with nitric acid, deionized water, etc., and then the washing waste liquid is discharged into the waste liquid collection device 8. .

[0047] ...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 or 2 is that this embodiment further optimizes the structure of the target tube crushing and dissolving device 2, such as Figure 4 As shown, the specific settings are as follows:

[0050] A funnel 16 is also arranged on the top of the crushing tank 14, and a baffle 17 is arranged in the funnel 16 to prevent debris and samples from splashing out during crushing. The target tube crushing and dissolving device 2 is also connected with a peristaltic pump 9 for inputting the solution for dissolving the powder in the target. Through the arrangement of the peristaltic pump 9, not only can effectively realize the continuous production of products, but also can effectively add cleaning solution to realize cleaning of the whole device of the present invention, and the operation is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com