Preparation method for nitride fluorescent powder and equipment for same

A nitride phosphor and phosphor technology, applied in chemical instruments and methods, chemical industry, luminescent materials, etc., can solve the problem of reducing the luminous intensity and thermal stability of products, affecting the luminous efficiency of nitride phosphors, and unable to achieve large-scale production. Stable preparation of nitride phosphors, etc., to achieve the effect of ensuring safety and service life, good luminous performance, and high nitrogen-containing purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

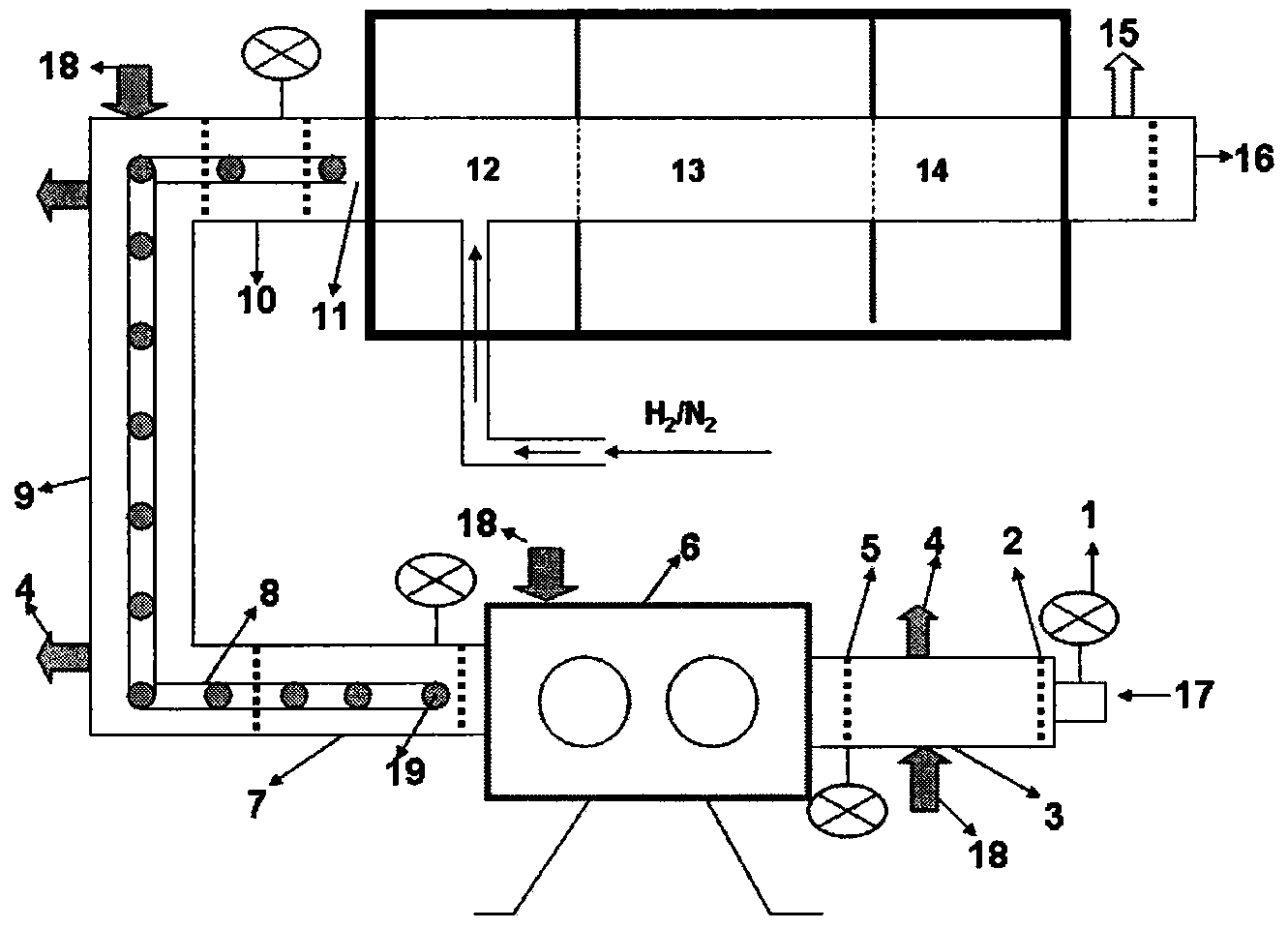

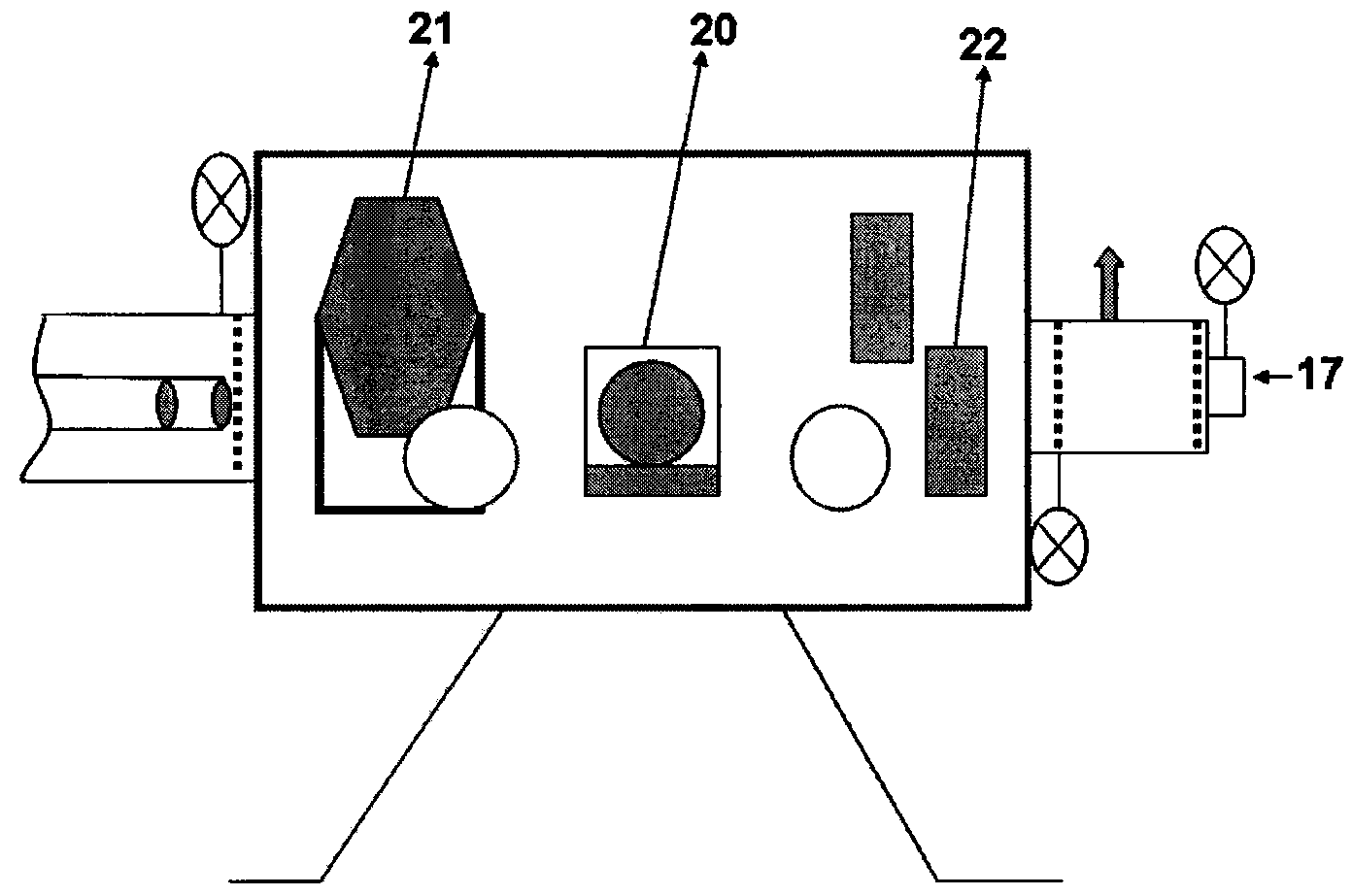

[0033] Use the equipment of the invention to prepare nitride red phosphor Sr 1.98 Si 5 N 8 : 02 Eu. Before the operation starts, such as figure 1 , Various equipment and gates are in the closed state, the specific operations are as follows:

[0034] (1) Pass the raw materials into the glove box through the first transition chamber, open the raw material tank in the glove box, and weigh the corresponding weight of Si according to the stoichiometric ratio 3 N 4 , Sr 2 N 3 And Eu 2 N 3 Raw material, BaF with a mass fraction of 0.01% 2 As a fluxing agent, it is uniformly mixed with the mixing device for 12 hours and then taken out, and filled in a 100mL graphite crucible. The above process is carried out in a glove box, and the glove box is filled with 1.0 atmosphere of nitrogen as a protective atmosphere;

[0035] (2) Place the graphite crucible filled with the sample in the transfer device through the second transition chamber, enter the third transition chamber and the fourth transit...

Embodiment 2

[0039] Use the equipment of the invention to prepare nitride red phosphor Ca 0.3 Sr 1.5 Si 5 N 8 : 0.2 Eu. Before the operation starts, such as figure 1 , Various equipment and gates are in the closed state, the specific operations are as follows:

[0040] (1) Pass the raw materials into the glove box through the first transition compartment, open the raw material tank in the glove box, and weigh the corresponding weight of Ca according to the stoichiometric ratio 2 N 3 , Si 3 N 4 , Sr 2 N 3 And Eu 2 N 3 The raw material, BaF2 with a mass fraction of 5% as a flux, is uniformly mixed in the mixing device for 24 hours and then taken out, and filled in a 100mL graphite crucible. The above process is carried out in a glove box, and the glove box is filled with 1.5 atmospheres of nitrogen as Protective atmosphere

[0041] (2) Place the graphite crucible filled with the sample in the conveying device through the second transition chamber, enter the third transition chamber and the fourth...

Embodiment 3

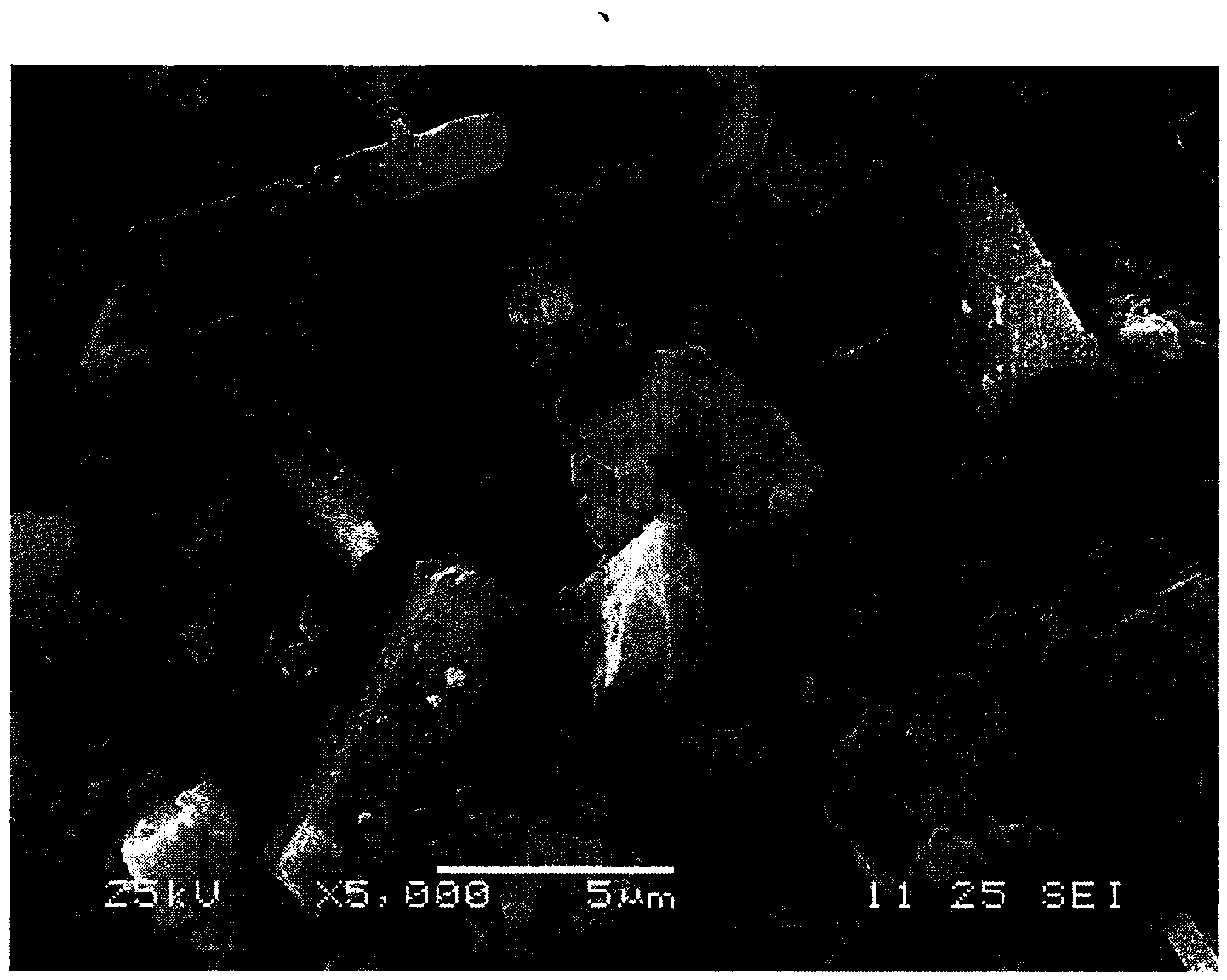

[0045] Adjust red phosphor raw material Ca 2 N 3 And Sr 2 N 3 The ratio of stoichiometry meets Ca 0.6 Sr 1.2 Si 5 N 8 : 0.2 Eu, Ca 0.9 Sr 0.9 Si 5 N 8 : 0.2 Eu, other steps are the same as in Example 2, and the emission spectrum of the sample is shown in the attachment Figure 7-3 And Figure 7-4 , It can be clearly found that with the increase in the proportion of Ca and the decrease of the proportion of Sr, the emission peak of the sample moves in the direction of Zhang long wave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com