A system and method for preparing a zirconium coating

A coating layer and powder technology, which is applied in the system field of preparing zirconium coating coatings, can solve the problems of low utilization rate of zirconium sources, high corrosion of containers, and difficulty in popularization, etc., and achieve production cost reduction and coating temperature Low, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

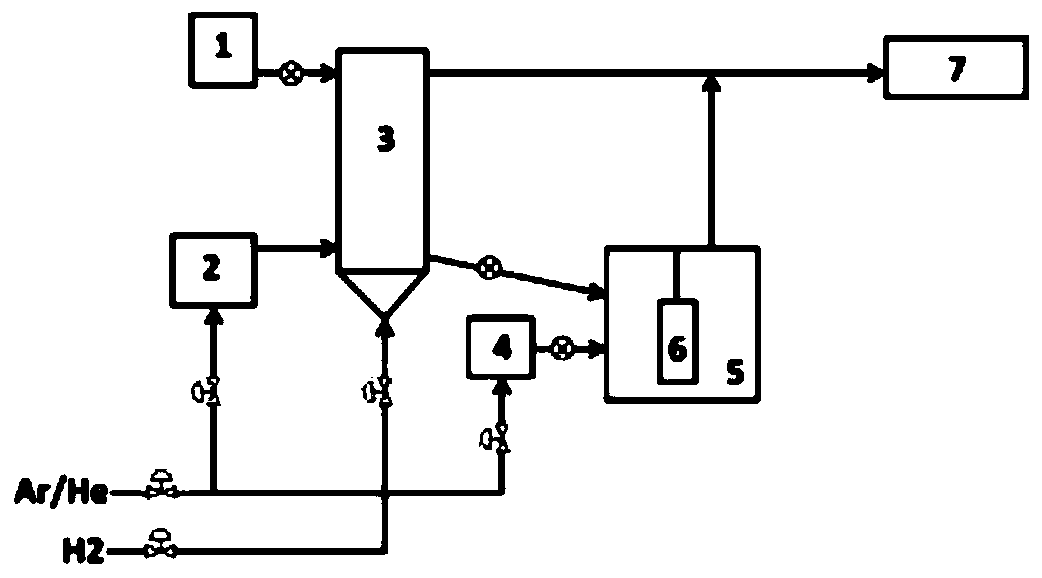

[0030] combine figure 1 , the system for preparing the Zr cladding layer in this embodiment includes: a first powder silo 1, a gasification device 2, a fluidized bed 3, a second powder silo 4, a coating chamber 5, a substrate 6, and an exhaust gas treatment device 7;

[0031] The discharge port of the first powder silo 1 is connected to the feed port of the fluidized bed 3 through a pipeline and a material valve; the gas inlet of the gasification device 2 is connected with an inert gas through a pipeline and a gas valve Connect; the gas outlet of the gasification device 2 is connected with the gas inlet of the fluidized bed 3 through a pipeline and a gas valve; the gas inlet of the fluidized bed 3 is connected with an inert gas or H 2 Connected by a pipeline with a gas valve; the gas outlet of the fluidized bed 3 is connected with the tail gas treatment device 7 by a pipeline; the outlet of the fluidized bed 3 is connected with the inlet of the coating chamber 5 through The ...

Embodiment 2

[0033]In this embodiment, the method for preparing the Zr cladding layer using the system in the above-mentioned embodiment 1 specifically includes the following steps: the material in the first powder silo 1 enters the fluidized bed 3 through a pipeline and a material valve; Enter the gasification device 2, carry gaseous materials into the fluidized bed 3 at a certain temperature; inert gas or H 2 Enter the fluidized bed 3 and react at a certain temperature for a period of time; the gas in the fluidized bed 3 enters the tail gas treatment device 7 through a pipeline to realize the treatment and reuse of the tail gas; the base 6 is located in the package In the coating chamber 5; the reacted material in the fluidized bed 3 enters the coating chamber 5 through the material valve and the pipeline; the material in the second powder silo 4 enters the said coating chamber through the material valve and the pipeline In the cladding chamber 5, react at a certain temperature for a per...

Embodiment 3

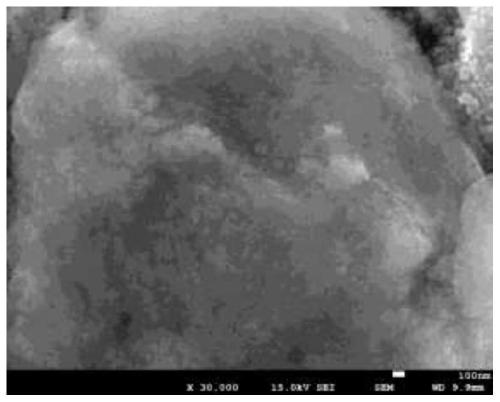

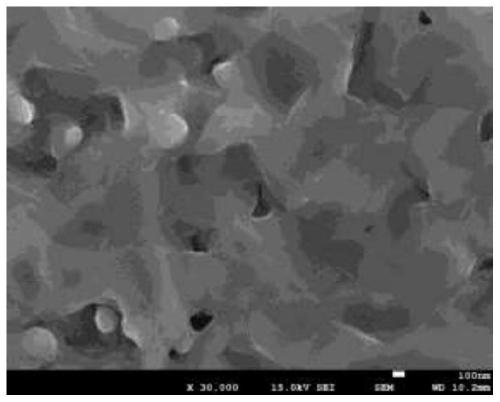

[0035] In this embodiment, on the basis of the above-mentioned embodiment 2, the powder in the first powder silo 1 is sponge zirconium; the material in the gasification device 2 is zirconium tetrachloride, the temperature is 80°C, and the carrier gas is Ar; the temperature of the fluidized bed 3 is 750°C, and the reaction time is 60min; the fluidizing gas in the fluidized bed 3 is H 2 The material in the second powder silo 4 is a mixture of NaCl and KCl in an equimolar ratio; the substrate 6 in the coating chamber 5 is 316L stainless steel; the temperature of the coating chamber 5 is 350°C , the reaction time is 5min. figure 2 The SEM image of the prepared Zr-coated 316L stainless steel shows that 3-5nm nano-zirconium particles are deposited on the 316L substrate, and the deposition temperature is about 500°C lower than the traditional deposition temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com