Preparation method of nickel cobalt lithium manganese oxide cathode material coated with titanium dioxide

A technology of nickel-cobalt lithium manganese oxide and titanium dioxide, which is applied in the direction of positive electrodes, battery electrodes, secondary batteries, etc., can solve the problems of lithium manganate cycle and storage performance, short life, low ion conductivity of coating materials, etc. Achieve excellent electrochemical cycle performance, increase capacity retention rate, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

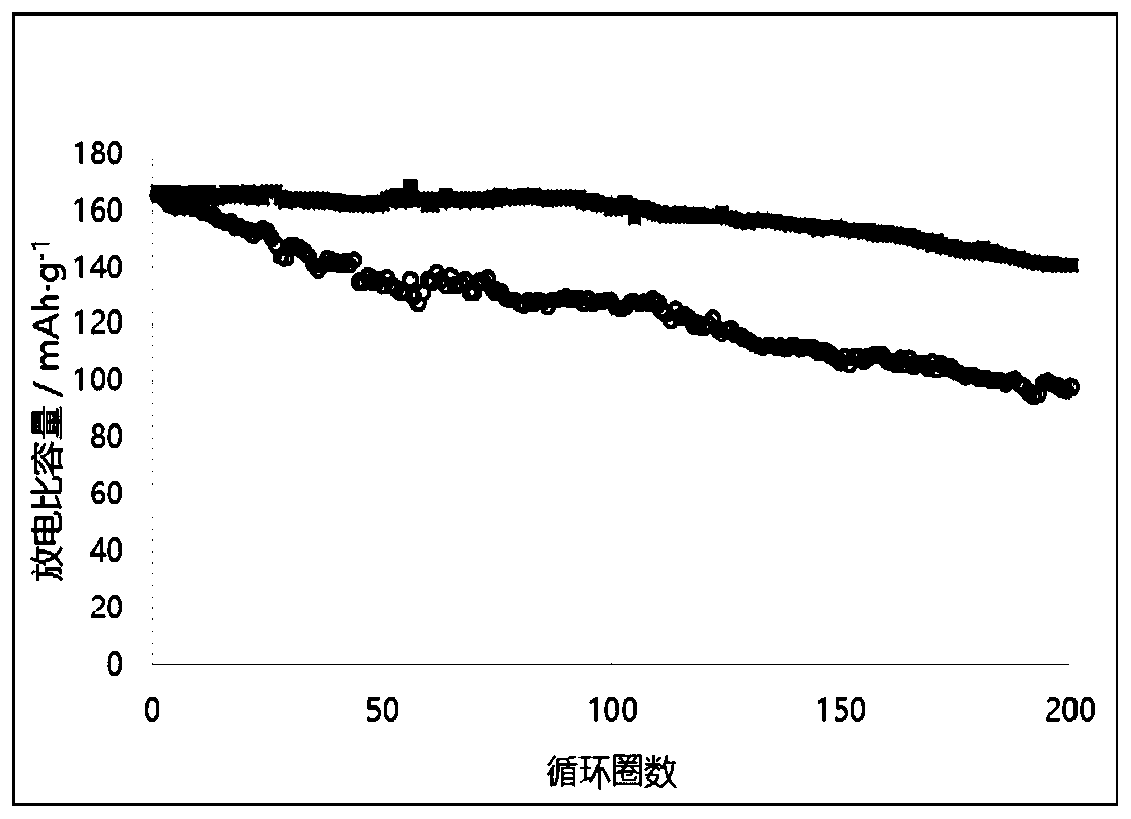

Embodiment 1

[0025] A preparation method of nickel-cobalt lithium manganese oxide positive electrode material coated with titanium dioxide, the steps are as follows: a certain amount of nickel-cobalt lithium manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 The powder is placed in a plasma-enhanced rotary furnace, the vacuum in the furnace cavity is 0.35mbar, and high-purity nitrogen (purity not less than 99.999%) is used as the protective gas, and titanium tetrachloride and high-purity oxygen (purity is not low) are continuously introduced. 99.99%), the intake rate of titanium tetrachloride is 15sccm, the intake rate of high-purity oxygen is 1400sccm, and by pulsed microwave excitation, a layer of titanium dioxide is deposited on the surface of nickel cobalt lithium manganate powder, and the frequency of pulsed microwave is 60MHz, power 6500W, pulse switching time is 0.6ms, 40ms, deposition time is 15min, so as to make the final product nickel cobalt lithium manganate cathode material coated w...

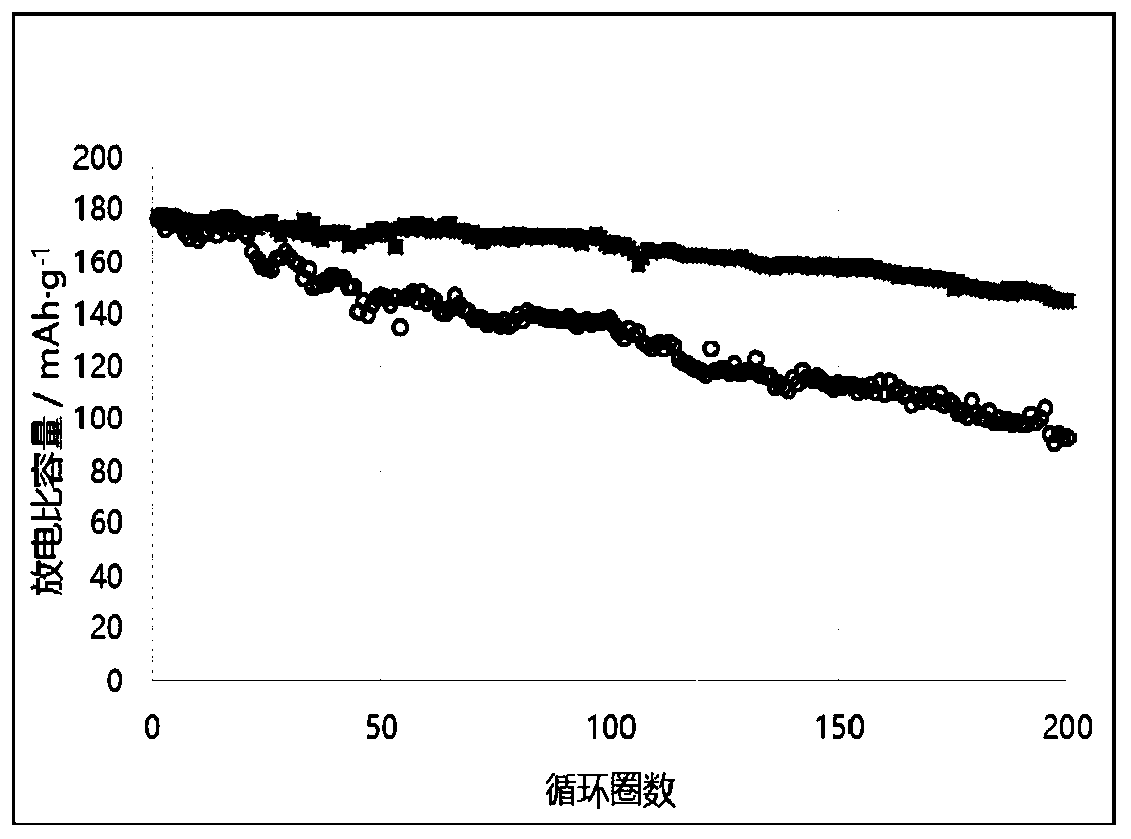

Embodiment 2

[0030] A preparation method of nickel-cobalt lithium manganese oxide positive electrode material coated with titanium dioxide, the steps are as follows: a certain amount of nickel-cobalt lithium manganese oxide LiNi 0.6 co 0.2 mn 0.2 o 2 The powder is placed in a plasma-enhanced rotary furnace, the vacuum in the furnace cavity is 0.35mbar, and high-purity nitrogen (purity not less than 99.999%) is used as the protective gas, and titanium tetrachloride and high-purity oxygen (purity is not low) are continuously introduced. 99.99%), the intake rate of titanium tetrachloride is 20sccm, the intake rate of high-purity oxygen is 1600sccm, and by pulsed microwave excitation, a layer of titanium dioxide is deposited on the surface of nickel cobalt lithium manganate powder, and the frequency of pulsed microwave is 60MHz, power of 6500W, pulse switching time of 0.6ms and 40ms respectively, and deposition time of 10min, so as to obtain the final product nickel-cobalt-lithium-manganese-...

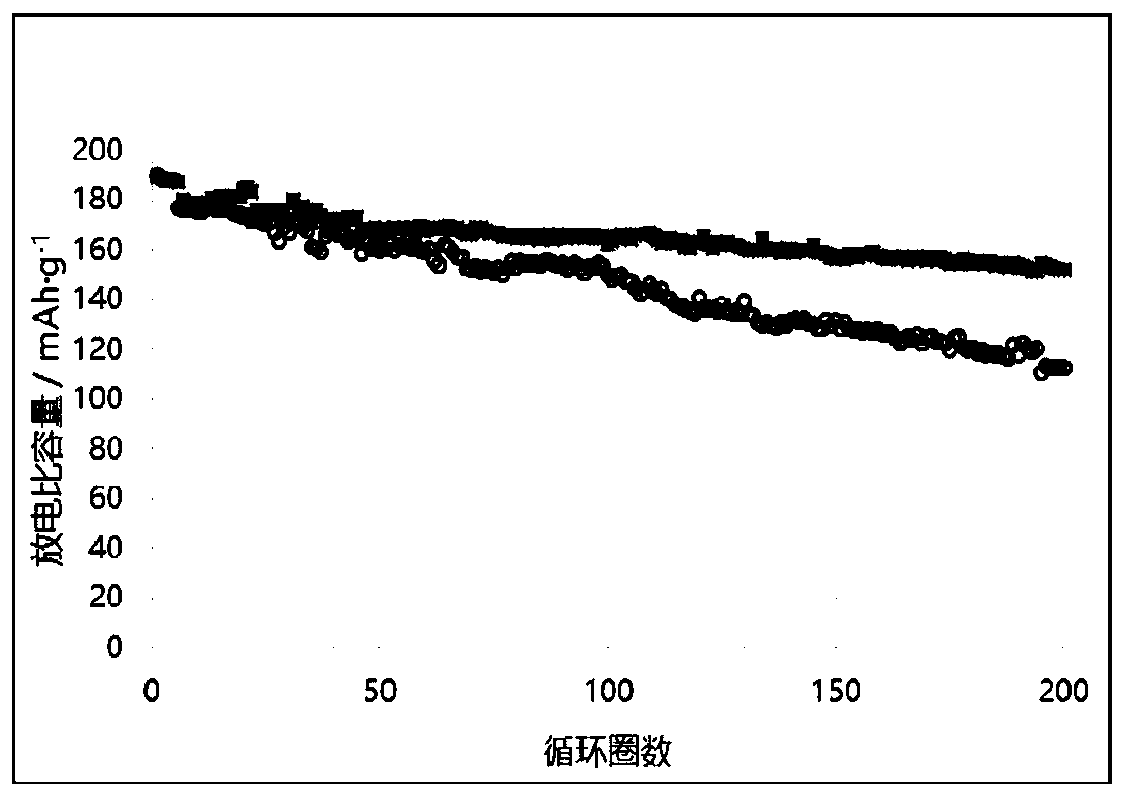

Embodiment 3

[0035] A preparation method of nickel-cobalt lithium manganese oxide positive electrode material coated with titanium dioxide, the steps are as follows: a certain amount of nickel-cobalt lithium manganese oxide LiNi 0.8 co 0.1 mn 0.1 o 2 The powder is placed in a plasma-enhanced rotary furnace, the vacuum in the furnace cavity is 0.35mbar, and high-purity nitrogen (purity not less than 99.999%) is used as the protective gas, and titanium tetrachloride and high-purity oxygen (purity is not low) are continuously introduced. 99.99%), the intake rate of titanium tetrachloride is 20sccm, the intake rate of high-purity oxygen is 1600sccm, and by pulsed microwave excitation, a layer of titanium dioxide is deposited on the surface of nickel cobalt lithium manganate powder, and the frequency of pulsed microwave is 60MHz, power of 6500W, pulse switching time of 0.6ms and 40ms respectively, and deposition time of 10min, so as to obtain the final product nickel-cobalt-lithium-manganese-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com