Pneumatic microdroplet jetting state control system and method based on machine vision

A droplet ejection and machine vision technology, applied in ejection devices and other directions, can solve problems such as reducing experimental efficiency, relying on operator experience and subjective judgment, increasing experimental complexity, etc., to achieve the effect of improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

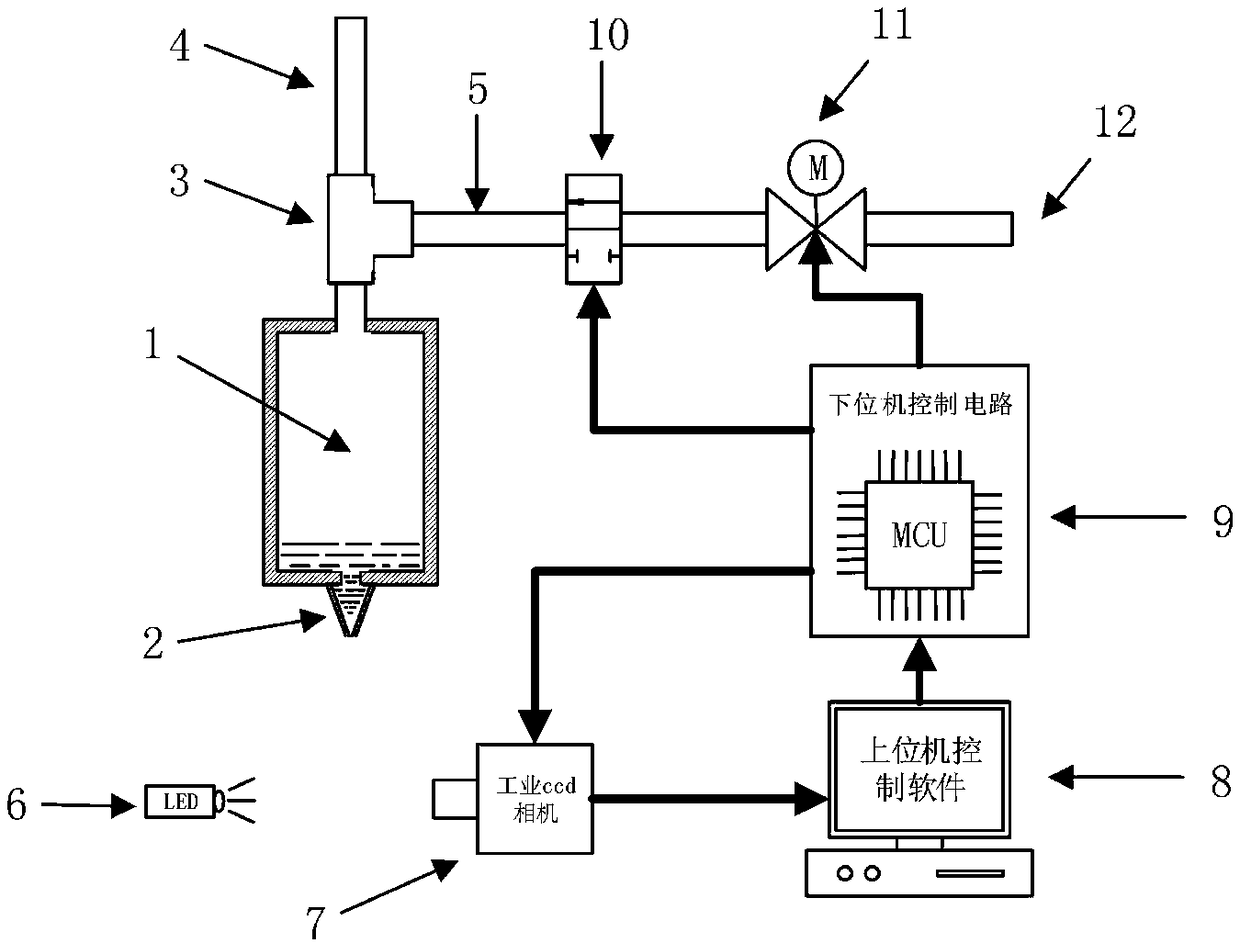

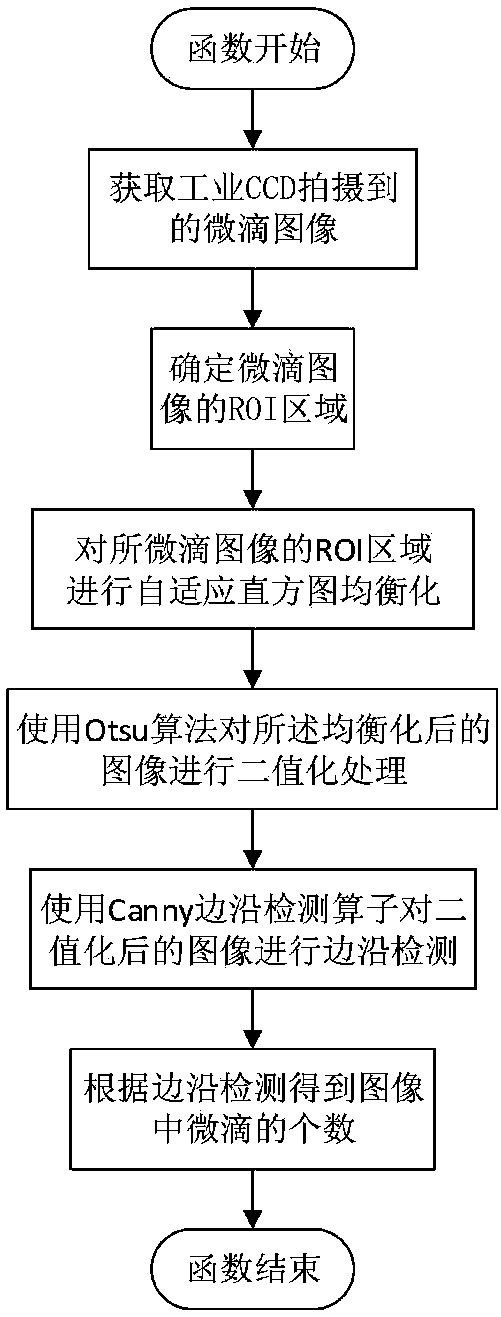

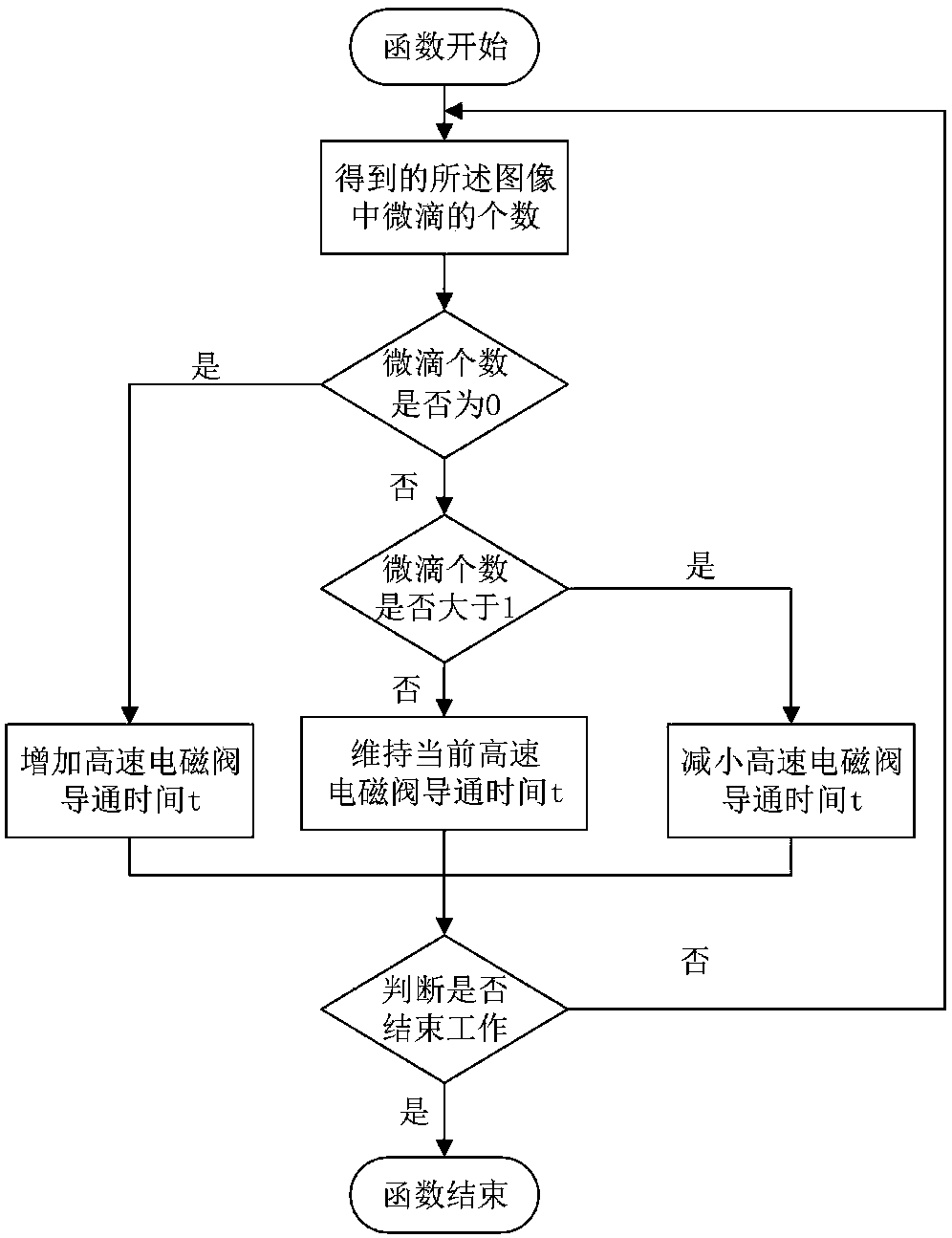

[0040]In this embodiment, the pneumatic droplet ejection device includes a droplet ejection system, a droplet observation system and a droplet control system. The control variable of the droplet control system is the conduction time t of the high-speed solenoid valve, and the air pressure P at the front end of the high-speed solenoid valve is constant.

[0041] Step 1, set the injection parameters of the device and start injection:

[0042] (1) Set the injection frequency of the device on the host computer control software to 80Hz, the conduction time t of the high-speed solenoid valve to 0us, the opening of the electric proportional valve to 25%, and the delay time of the industrial CCD camera to take pictures of 5000us and other parameters;

[0043] (2) Open the industrial CCD camera on the upper computer control software, open the serial communication interface to communicate with the lower computer control circuit, and send the above parameters to the lower computer contro...

Embodiment 2

[0060] In this embodiment, the pneumatic droplet ejection device includes a droplet ejection system, a droplet observation system and a droplet control system. The control variable of the droplet control system is the air pressure P at the front end of the high-speed solenoid valve. P is controlled by the opening of the electric proportional valve, and the conduction time t of the high-speed solenoid valve remains unchanged.

[0061] Step 1, set the injection parameters of the device and start injection:

[0062] (1) On the host computer control software, set parameters such as the injection frequency of the device to 80Hz, the conduction time t of the solenoid valve to 1000us, the opening of the electric proportional valve to 0%, and the delayed photo time of the industrial CCD camera to 5000us;

[0063] (2) Open the industrial CCD camera on the upper computer control software, open the serial communication interface to communicate with the lower computer control circuit, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com