Multilayer piezoelectric element, injection apparatus, and fuel injection system

A piezoelectric element and injection device technology, applied in the direction of charging systems, fuel injection devices, electrical components, etc., can solve the problem of reduced displacement of laminated piezoelectric elements, reduced mechanical strength of piezoelectric ceramics, and slow response speed and other problems, to achieve the effect of increasing the moving speed and moving amount, reducing the grain size and increasing the displacement amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

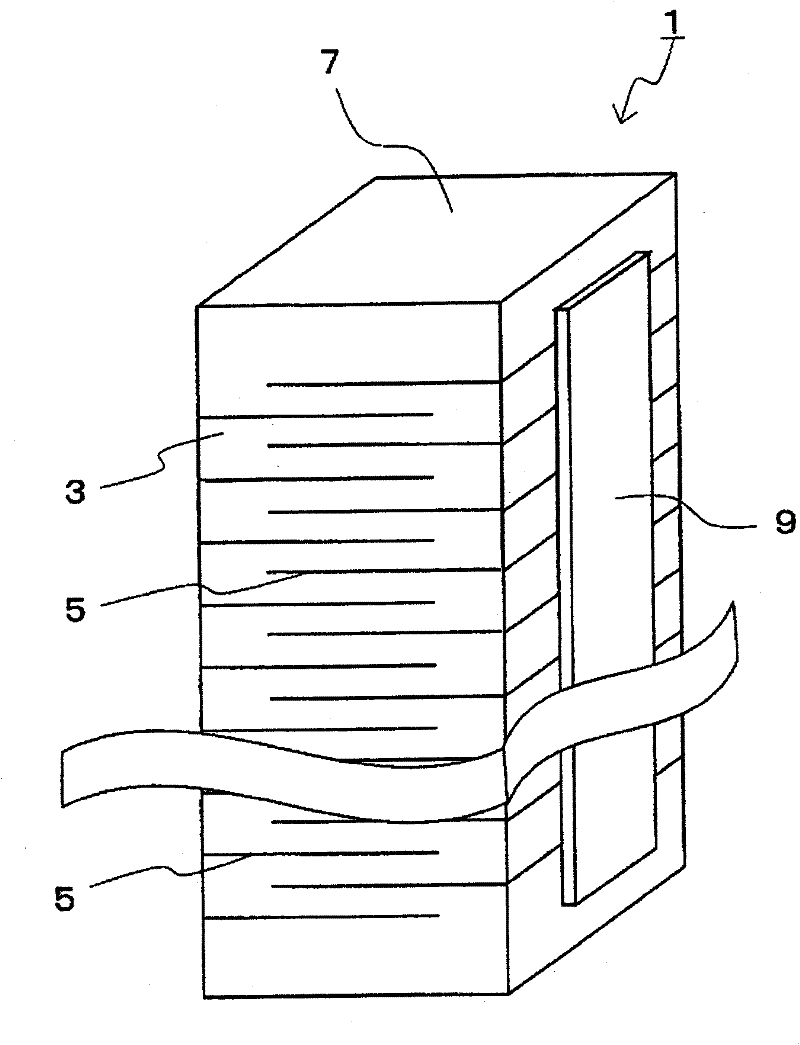

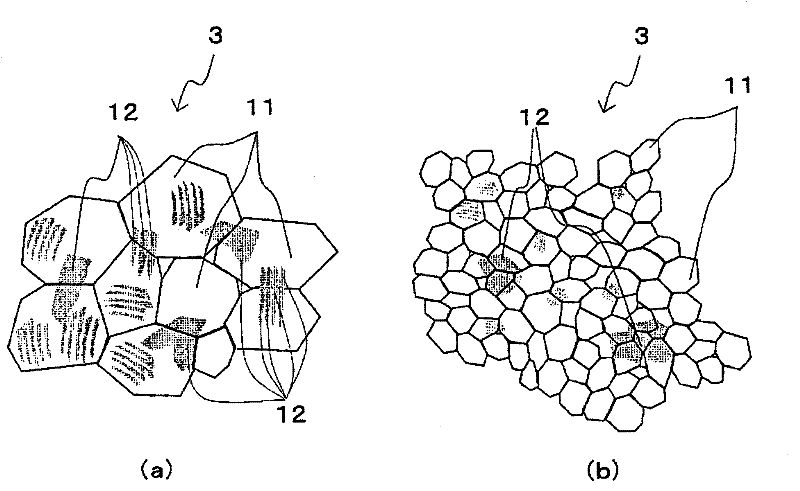

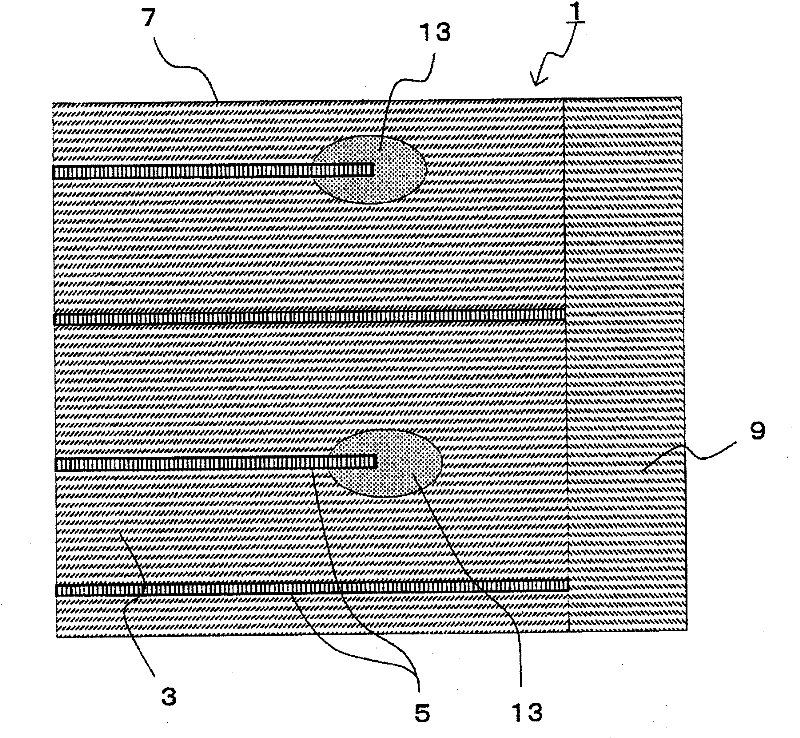

[0069] A piezoelectric actuator including the multi-layer piezoelectric element of the present invention was trial-manufactured as follows.

[0070]

[0071] A slurry was prepared by mixing quasi-fired powder of piezoelectric ceramics with an average particle diameter of 0.4 μm and mainly composed of lead zirconate titanate (PZT), a binder, and a plasticizer. Using this slurry, a ceramic green sheet constituting a fired piezoelectric layer having a thickness of about 150 μm was produced by the doctor blade method. Next, a metal paste for internal electrode layers in which a binder was added to a silver-palladium alloy (70% by mass of silver-30% by mass of palladium) was prepared. This metal paste was screen-printed on one side of the ceramic green sheet, and 300 ceramic green sheets printed with the metal paste were laminated. This laminated molded body was held at a peak temperature of 1100° C. for 200 minutes, and then the temperature was lowered to room temperature over ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com