Liquid jetting head, liquid jetting recording apparatus, and method for filling liquid jetting head with liquid

A technology of liquid jet head and jet body, which is applied in printing and other directions, can solve problems such as printing failure, and achieve the effects of preventing pollution, stabilizing liquid jetting, and improving the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0089] (Liquid jet recording device)

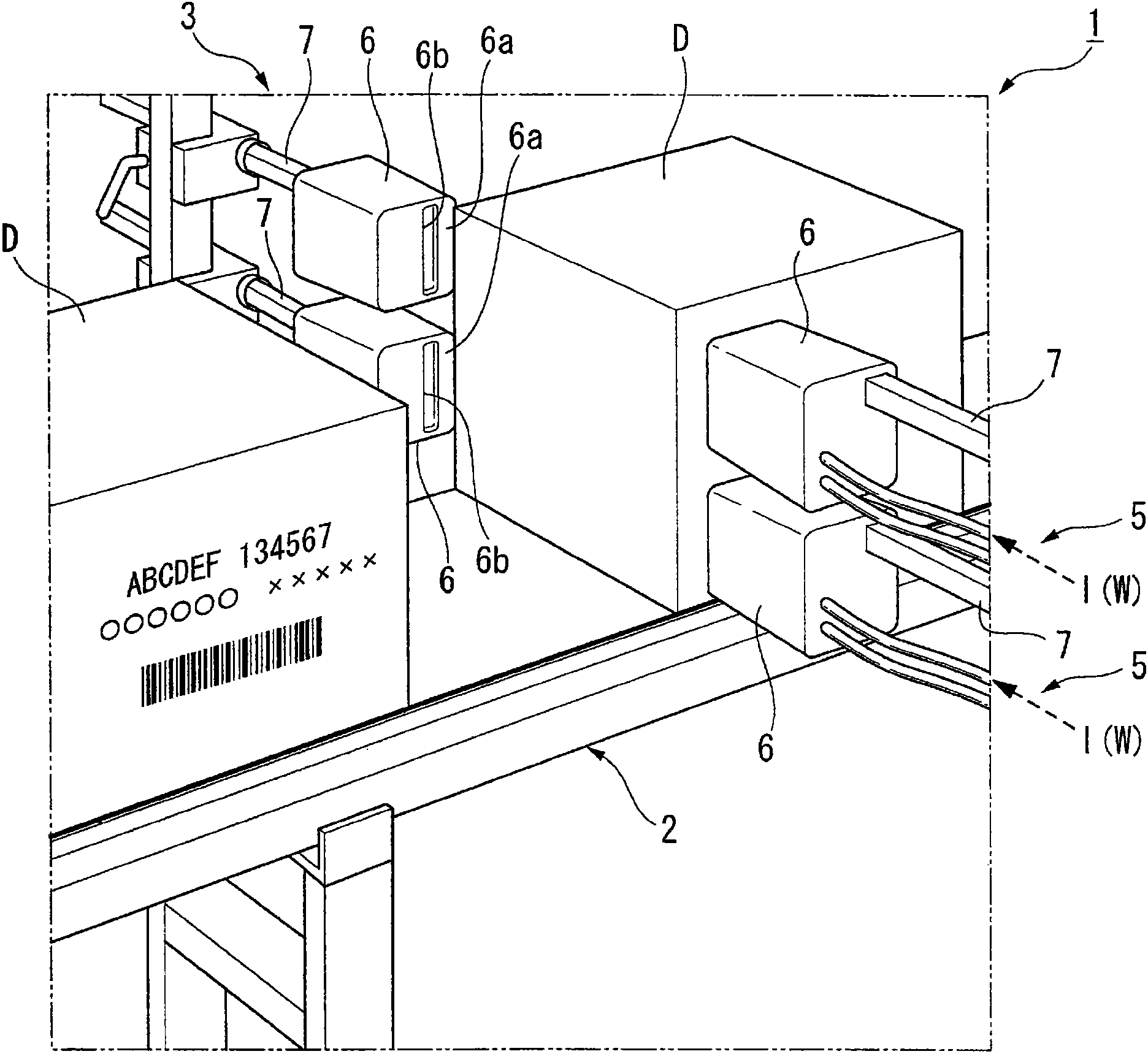

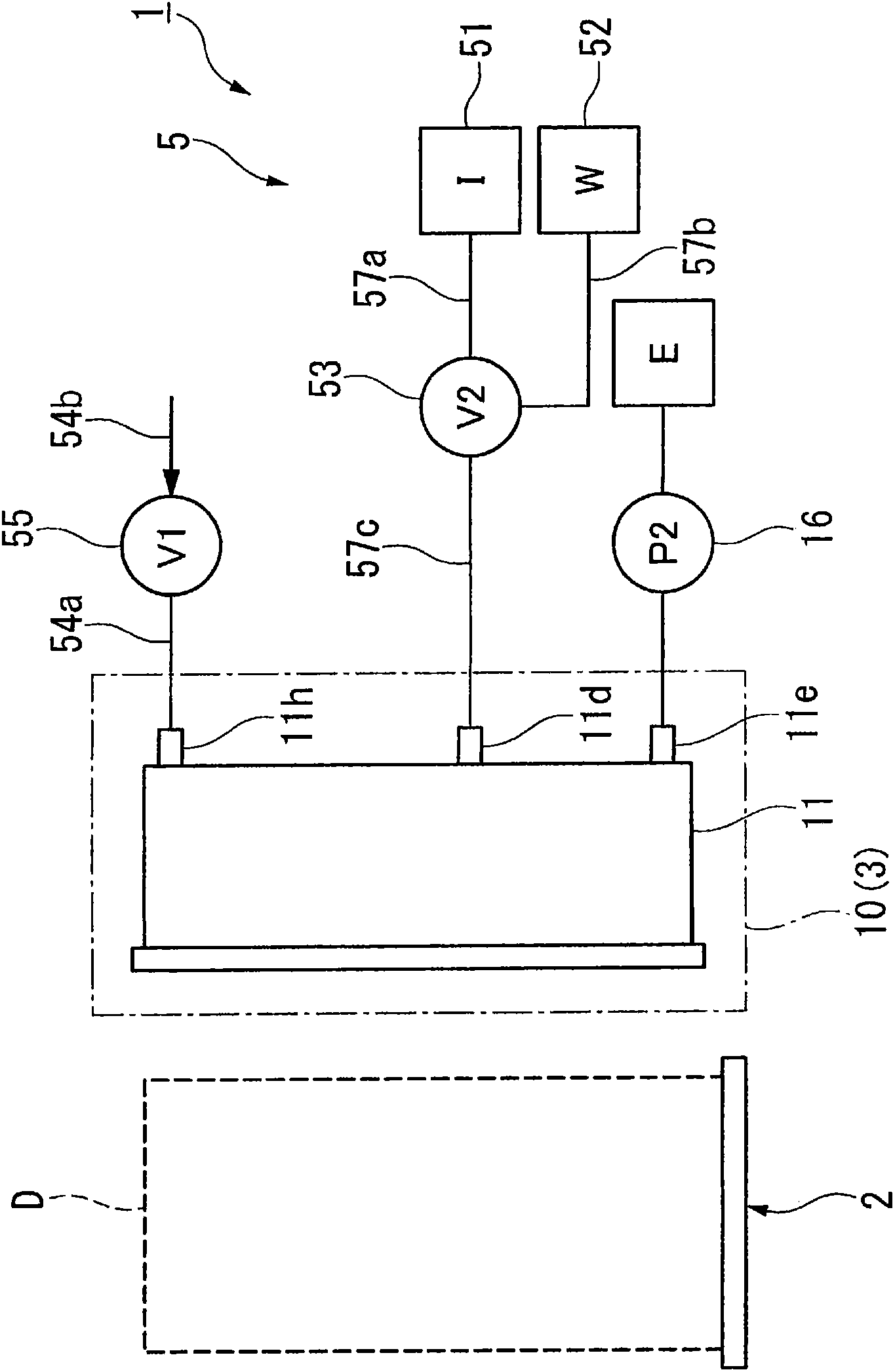

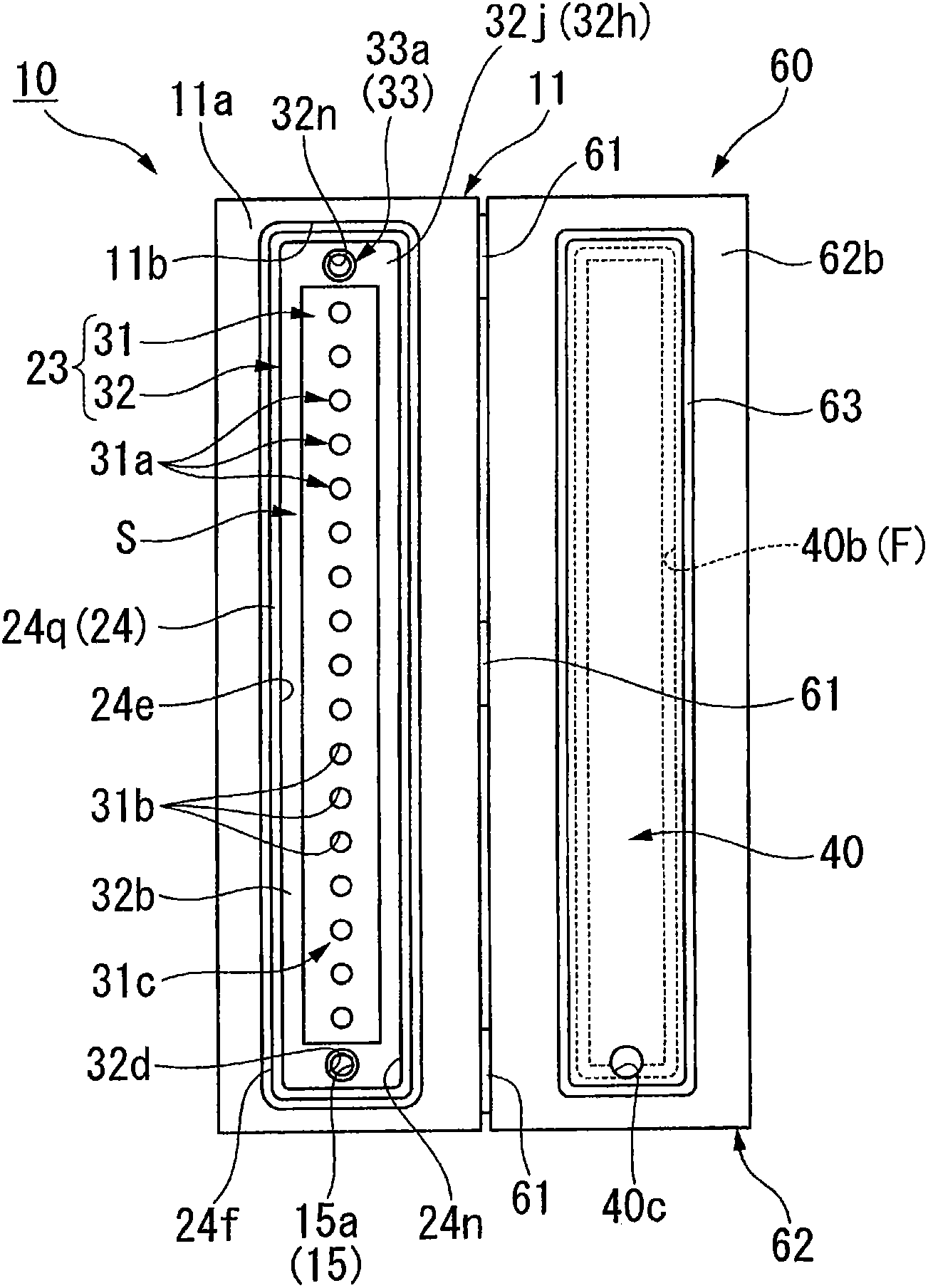

[0090] figure 1 is a perspective view showing an ink jet recording device (liquid jet recording device) 1 according to a first embodiment of the present invention, figure 2 It is a schematic configuration diagram of the inkjet recording device 1 . This inkjet recording device 1 is connected to a designated personal computer, and discharges (ejects) ink (first liquid) I to perform printing on a tank D based on print data transmitted from the personal computer. The inkjet recording apparatus 1 includes a belt conveyor 2, an ink discharge unit 3, an ink supply unit 5, and a suction pump (suction device) 16, wherein the belt conveyor 2 conveys the box D in one direction, and the ink discharge unit 3 includes A plurality of inkjet heads 10, such as figure 2 As shown, the ink supply unit 5 supplies the ink I and the cleaning liquid (second liquid) W to the inkjet head 10 , and the suction pump 16 is connected to the inkjet head 10 .

[00...

no. 2 approach

[0204] Next, a second embodiment of the present invention will be described. Figure 15 is a schematic configuration diagram of the inkjet head 100 of the second embodiment viewed from the right side, Figure 16 Yes Figure 15 Sectional view of line IV-IV.

[0205] Compared with the inkjet head in which the opening and closing mechanism of the above-mentioned first embodiment is configured as a door type, the difference of the inkjet head 100 is that the opening and closing mechanism is configured as a shutter type, and the opening and closing mechanism 110 and the opening and closing mechanism 110 are provided. The absorber 140 of the closing mechanism 110.

[0206] In addition, the same code|symbol is attached|subjected to the member of the same structure as 1st Embodiment mentioned above, and description is abbreviate|omitted.

[0207] like Figure 15 , 16 As shown, the opening and closing mechanism 110 of the inkjet head 100 of this embodiment includes a pair of guide...

no. 3 approach

[0218] Next, a third embodiment of the present invention will be described. In addition, the same code|symbol is attached|subjected to the member of the same structure as 1st Embodiment mentioned above, and description is abbreviate|omitted.

[0219] Figure 17 It is an enlarged cross-sectional view of a main part of the inkjet head 200 of the third embodiment.

[0220] The inkjet head 200 differs from the above-described opening and closing mechanisms 60 and 110 in that the opening and closing mechanism is a sliding door type, and includes an opening and closing mechanism 210 and an absorber 240 .

[0221] like Figure 17 As shown, the opening and closing mechanism 210 of the inkjet head 200 of this embodiment is constituted by the shutter 205 and the sealing member 63 which are supported by the guide part which is not shown in the figure.

[0222] The shutter 205 is a thin plate formed to have a larger opening area than the wall opening 24n, and is guided by guides (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com