Inkjet printhead employing piezoelectric actuator and method of manufacturing the inkjet printhead

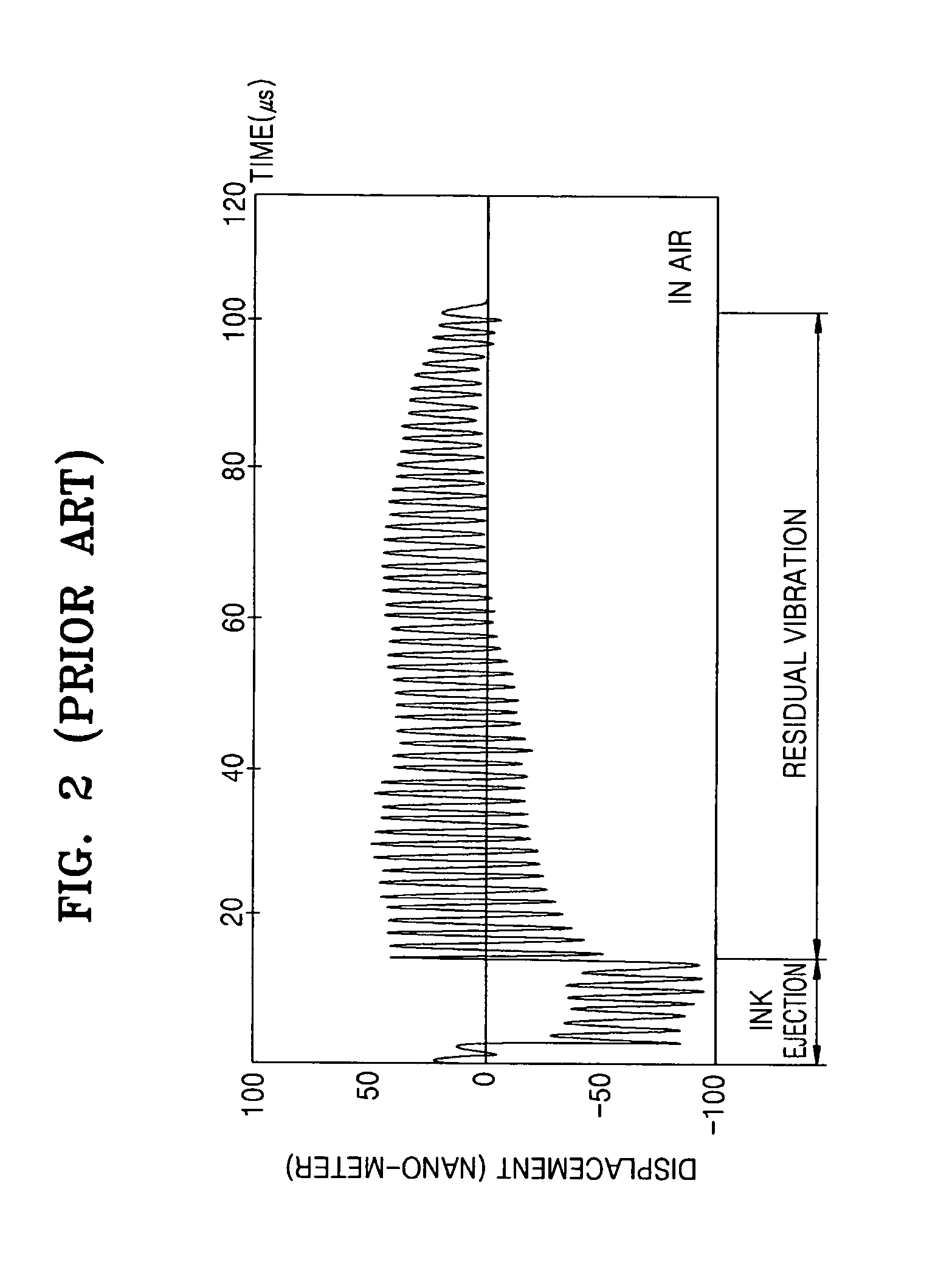

a piezoelectric actuator and inkjet printing technology, applied in printing and other directions, can solve the problems of difficulty in constant speed ejecting of ink droplets, irregular volume of ejecting ink droplets, etc., and achieve the effect of quick dampening a residual vibration of a piezoelectric layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Reference will now be made in detail to the embodiments of the present general inventive concept, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The embodiments are described below in order to explain the present general inventive concept by referring to the figures. A size of each constituent element in the drawings may be exaggerated for a convenience of explanation. Also, where a layer is described to exist on another layer, the layer can exist while directly contacting the other layer or a third layer can exist therebetween.

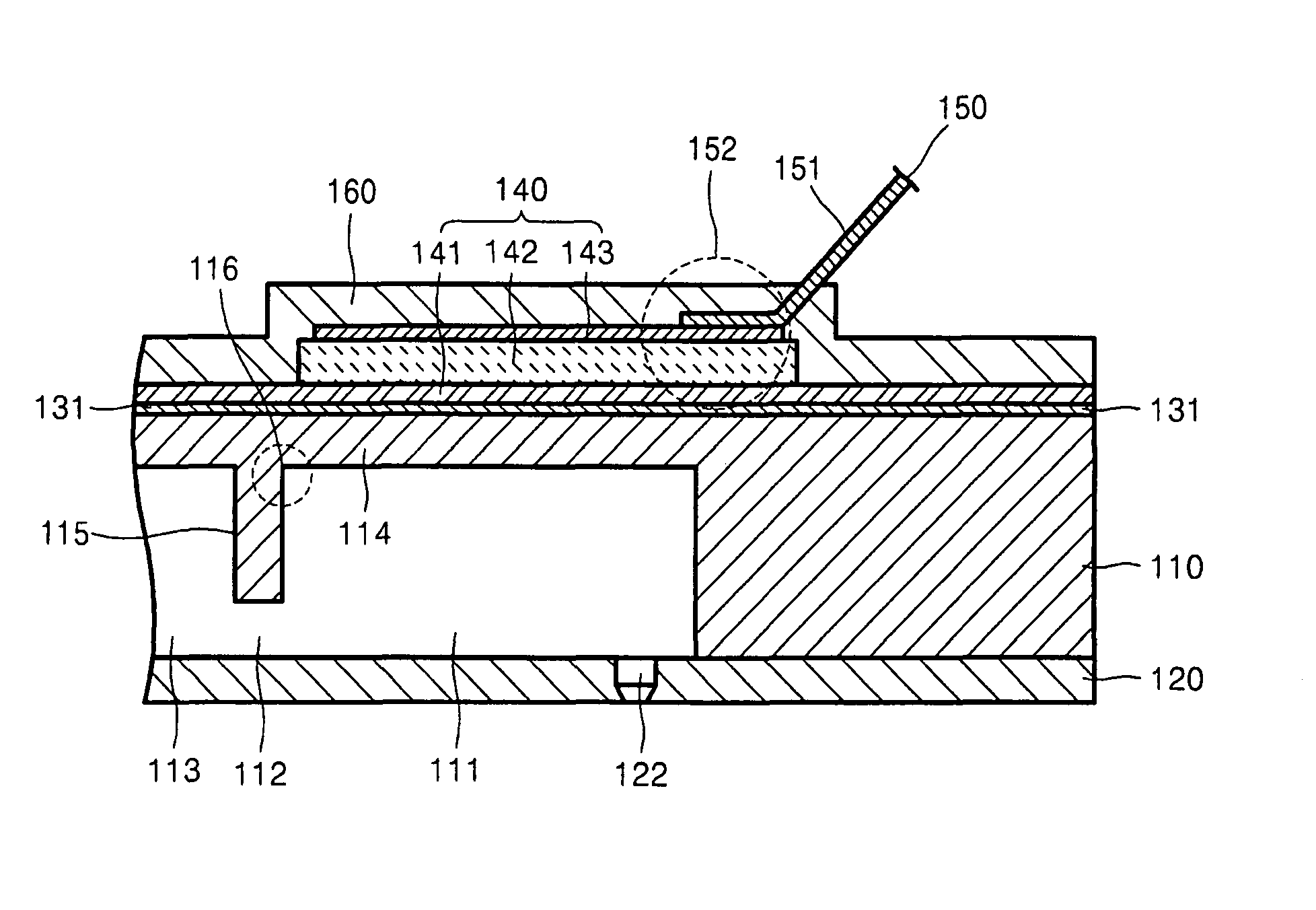

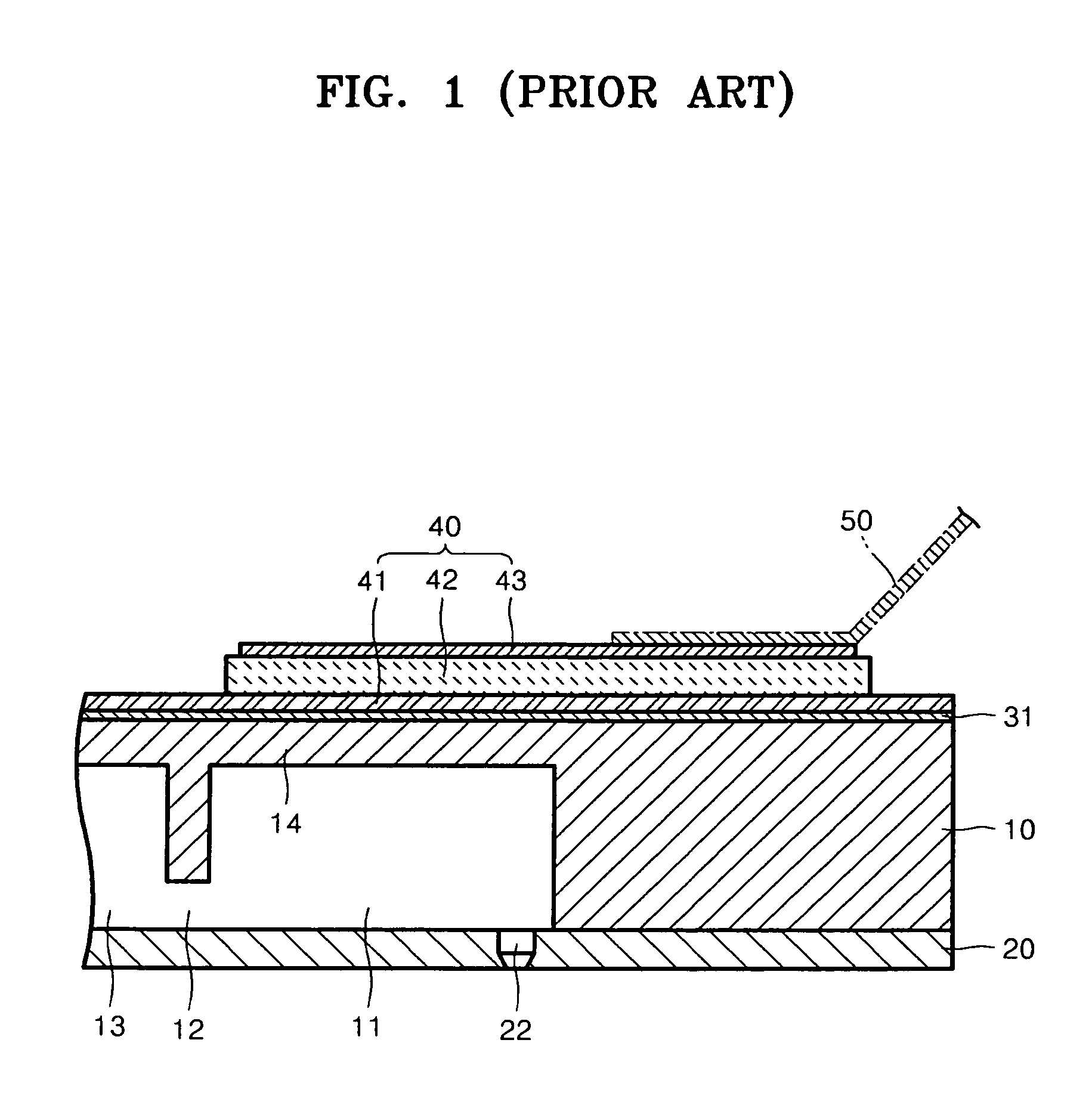

[0034]FIG. 3 is a cross-sectional view illustrating a configuration of an inkjet printhead, according to an embodiment of the present general inventive concept. FIG. 4 is a plan view illustrating the inkjet printhead of FIG. 3. Referring to FIGS. 3 and 4, an inkjet printhead according to an embodiment of the present general inventive concept includes a fluid path for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com