Device and method for controlling switched reluctance motors for electric vehicles on basis of CPLD

A switched reluctance motor and control device technology, applied in the direction of electronic commutator, etc., can solve the problems of difficulty in adapting to the working environment, reduced flexibility and reliability of switched reluctance motor control, slow running speed, etc., and achieve good real-time control Effect and anti-interference ability, no software operation delay, the effect of improving the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

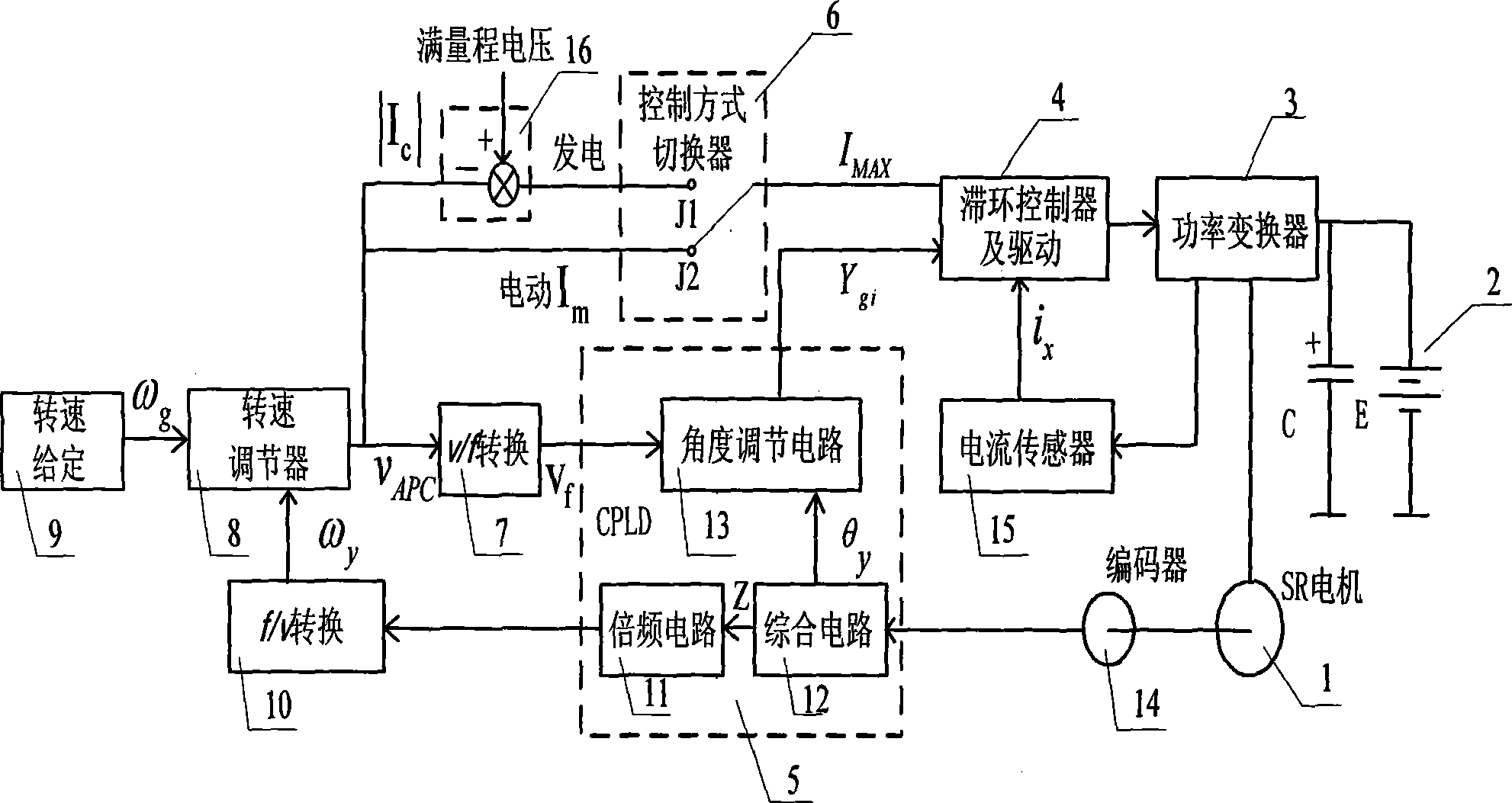

[0027] Such as image 3 As shown, the device is composed of two main components connected by a programmable logic device (CPLD) and a peripheral hardware circuit.

[0028] The inside of the main control unit realized by CPLD device 5 includes:

[0029] An integrated circuit 12 for integrating the three rotor position signals output by the encoder into a square wave signal whose frequency is proportional to the rotating speed;

[0030] A frequency multiplication circuit 11 is used to accept the square wave signal output by the integrated circuit 12, and multiply the frequency of the square wave signal into a high frequency square wave signal corresponding to the frequency and the rotational speed;

[0031] An angle adjustment circuit 13 is used to give the on-time and off-time of each phase according to the duty ratio control signal Vf and the period control signal Z, which includes a frequency and duty ratio conversion circuit for outputting period and composite signals Cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com