Molten steel refining slag composition design method

A technology of composition design and refining slag, which is applied in the field of composition design of molten steel refining slag, can solve the problem that the target composition of inclusions cannot be taken into account at the same time, and achieve the effect of reducing the number of inclusions, ensuring quality and performance, and realizing precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

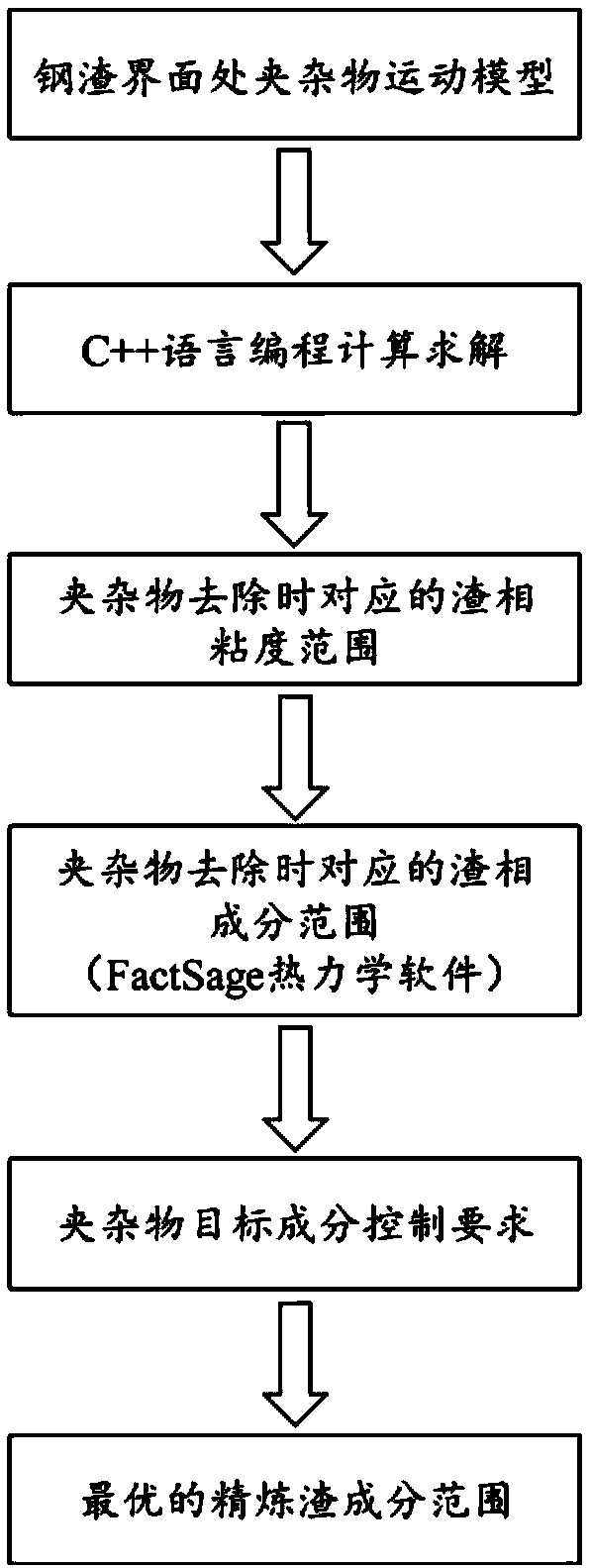

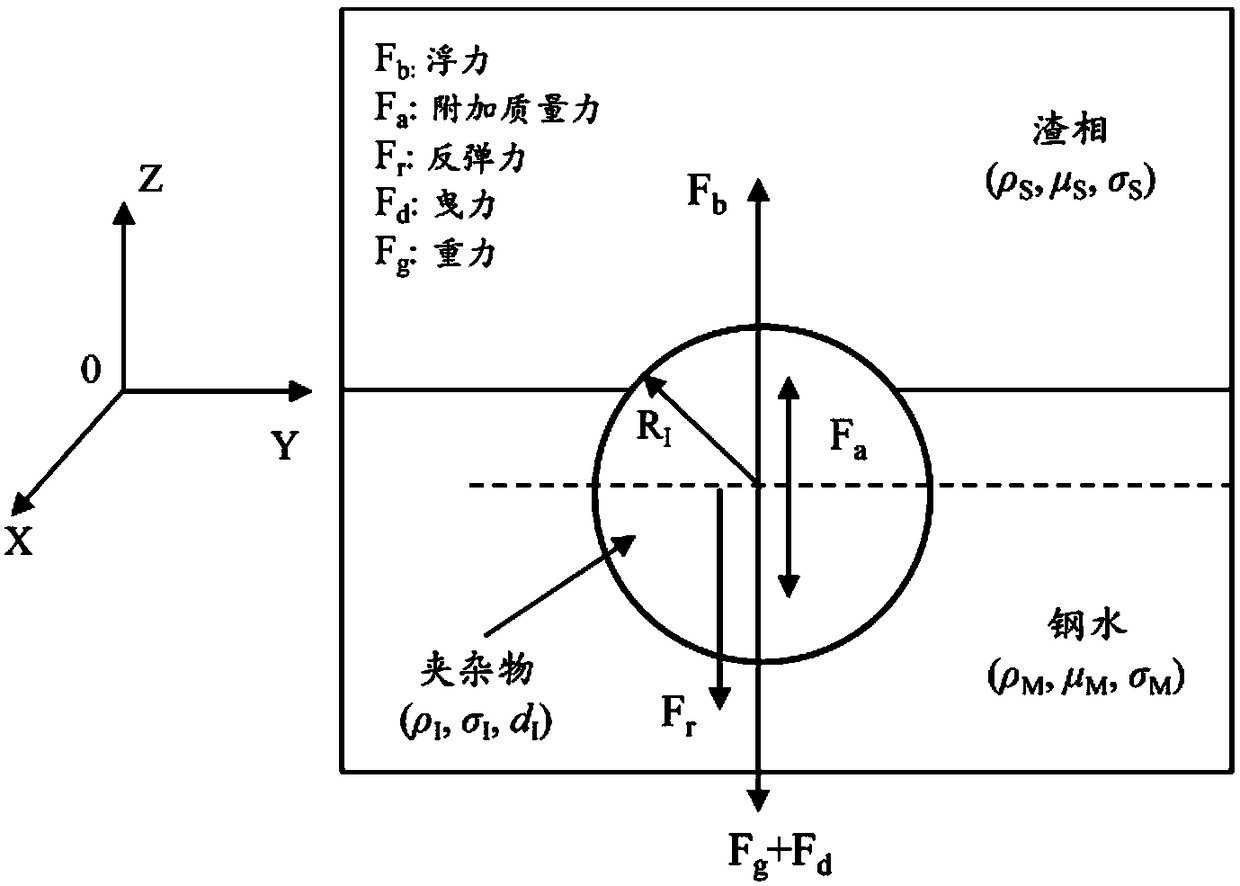

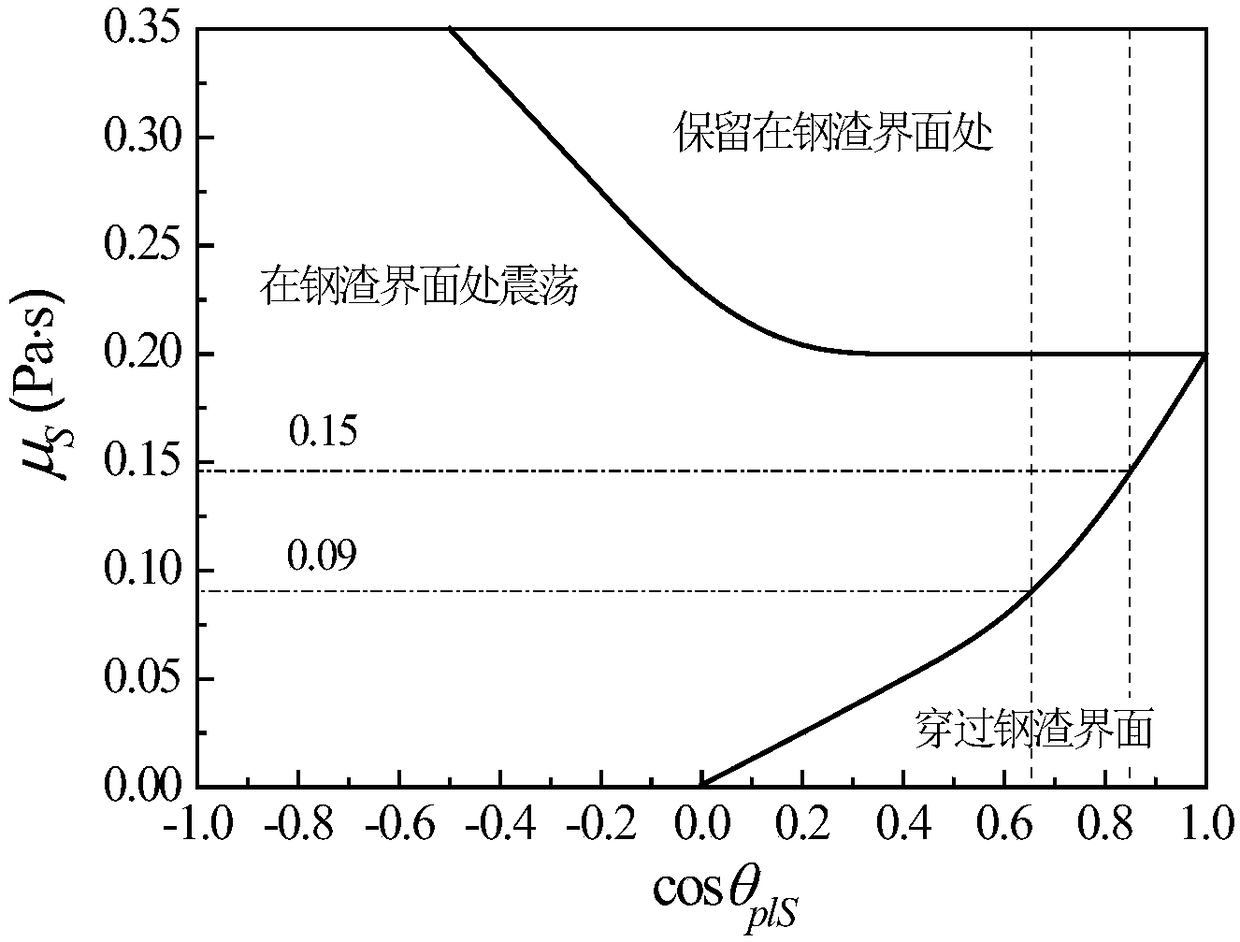

[0095] This embodiment is mainly aimed at the production of bearing steel. Al deoxidation is mainly used in the production process of bearing steel. The Al element added to molten steel reacts with [O] in the steel: 2[Al]+3[O]=Al 2 o 3 , the corresponding inclusions are mainly Al 2 o 3 . Due to the need to ensure that the steel has a low oxygen content in the production process of bearing steel, and the level of oxygen content is related to the oxide inclusion Al 2 o 3 is closely related to the amount of Al 2 o 3 The removal of inclusions at the steel slag interface is beneficial to reduce the oxygen content in the steel. For this purpose, for CaO-SiO 2 -Al 2 o 3 Slag system, according to Al 2 o 3 The inclusions are subjected to buoyancy, drag, rebound and additional mass force at the steel slag interface, and the Al 2 o 3 The motion model of inclusions at the steel slag interface is calculated and solved by using C++ language and the fourth-order Runge-Kutta meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wettability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com