Method for improving thickness of decarburized layer of small square billet of tire cord steel

A technology for cord steel and billet is applied in the field of improving the thickness of the decarburized layer of the cord steel billet. Layer thickness, avoid sharp corner effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for improving the thickness of the decarburized layer of the cord steel billet. The cord steel is produced by the process of heating, rough rolling, middle rolling, pre-finish rolling, finish rolling and air cooling. The heating process adopts The heating furnace consists of a preheating section, a heating section I, a heating section II and a soaking section in sequence. The method for improving the thickness of the decarburized layer of the cord steel billet includes the following steps:

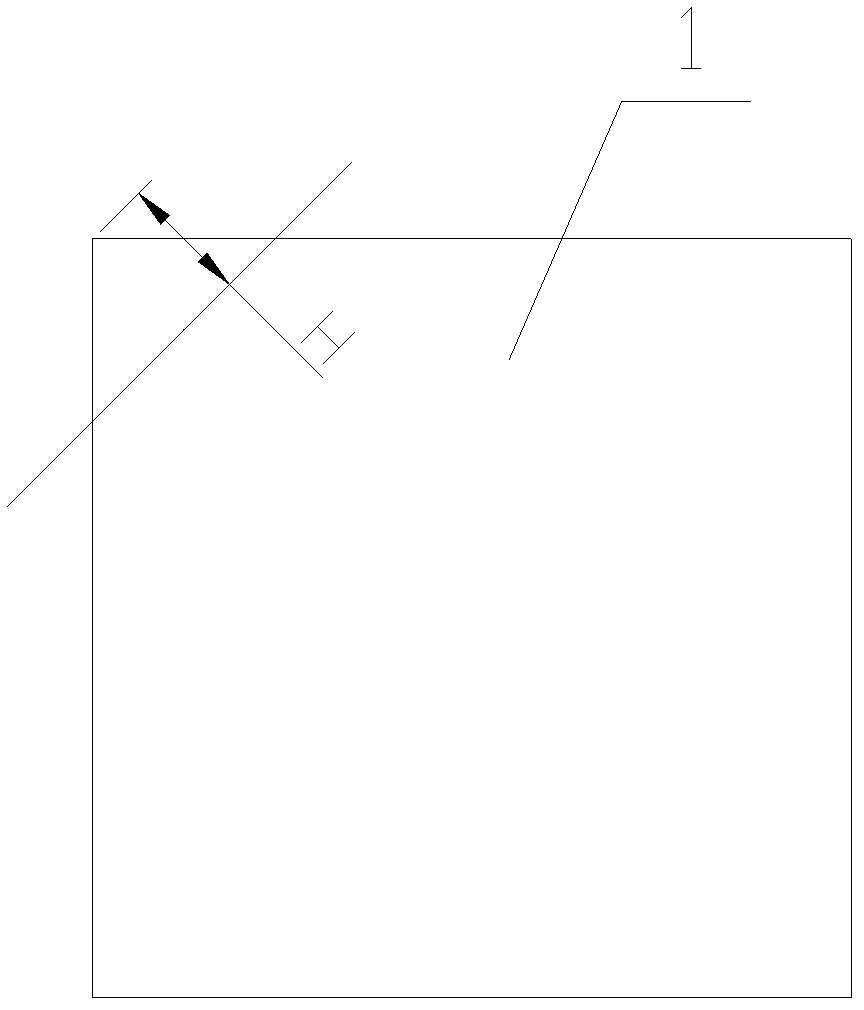

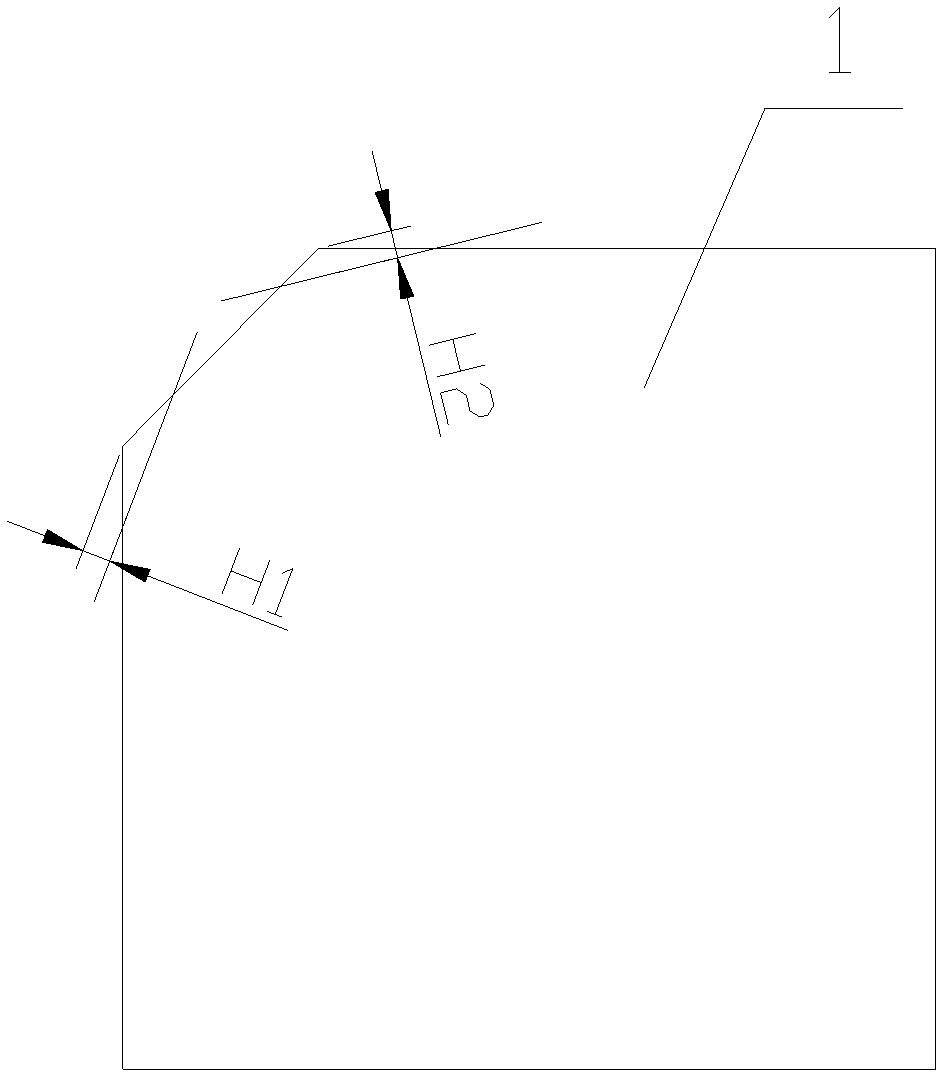

[0029] (1) Before the heating process, the corner of the billet 1 is ground, at first one of the four corners of the billet 1 is ground along the rolling direction of the billet, such as figure 1 As shown, the grinding depth H is 0.3mm, and the grinding depth H is the vertical distance from the apex of the corner to the rolling direction of the billet; then the two generated corners are ground, as shown in figure 2 As shown, the grinding depths H1 ...

Embodiment 2

[0036] This embodiment provides a method for improving the thickness of the decarburized layer of the cord steel billet. The cord steel is produced by the process of heating, rough rolling, middle rolling, pre-finish rolling, finish rolling and air cooling. The heating process adopts The heating furnace consists of a preheating section, a heating section I, a heating section II and a soaking section in sequence. The method for improving the thickness of the decarburized layer of the cord steel billet includes the following steps:

[0037] (1) Before the heating process, the corner of the billet 1 is ground, at first one of the four corners of the billet 1 is ground along the rolling direction of the billet, such as figure 1 As shown, the grinding depth H is 0.2mm, and the grinding depth H is the vertical distance from the corner vertex to the rolling direction of the billet; then the two generated corners are ground, as shown in figure 2 As shown, the grinding depths H1 and H...

Embodiment 3

[0044] This embodiment provides a method for improving the thickness of the decarburized layer of the cord steel billet. The cord steel is produced by the process of heating, rough rolling, middle rolling, pre-finish rolling, finish rolling and air cooling. The heating process adopts The heating furnace consists of a preheating section, a heating section I, a heating section II and a soaking section in sequence. The method for improving the thickness of the decarburized layer of the cord steel billet includes the following steps:

[0045] (1) Before the heating process, the corner of the billet 1 is ground, at first one of the four corners of the billet 1 is ground along the rolling direction of the billet, such as figure 1 As shown, the grinding depth H is 0.5mm, and the grinding depth H is the vertical distance from the corner vertex to the rolling direction of the billet; then the two generated corners are ground, as shown in figure 2As shown, the grinding depths H1 and H2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com