Soft-packed lithium ion battery hot and cold pressing formation device

A lithium-ion battery and chemical formation equipment technology, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high equipment cost, large floor space, low production efficiency, etc., and reduce labor costs. The effect of the intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

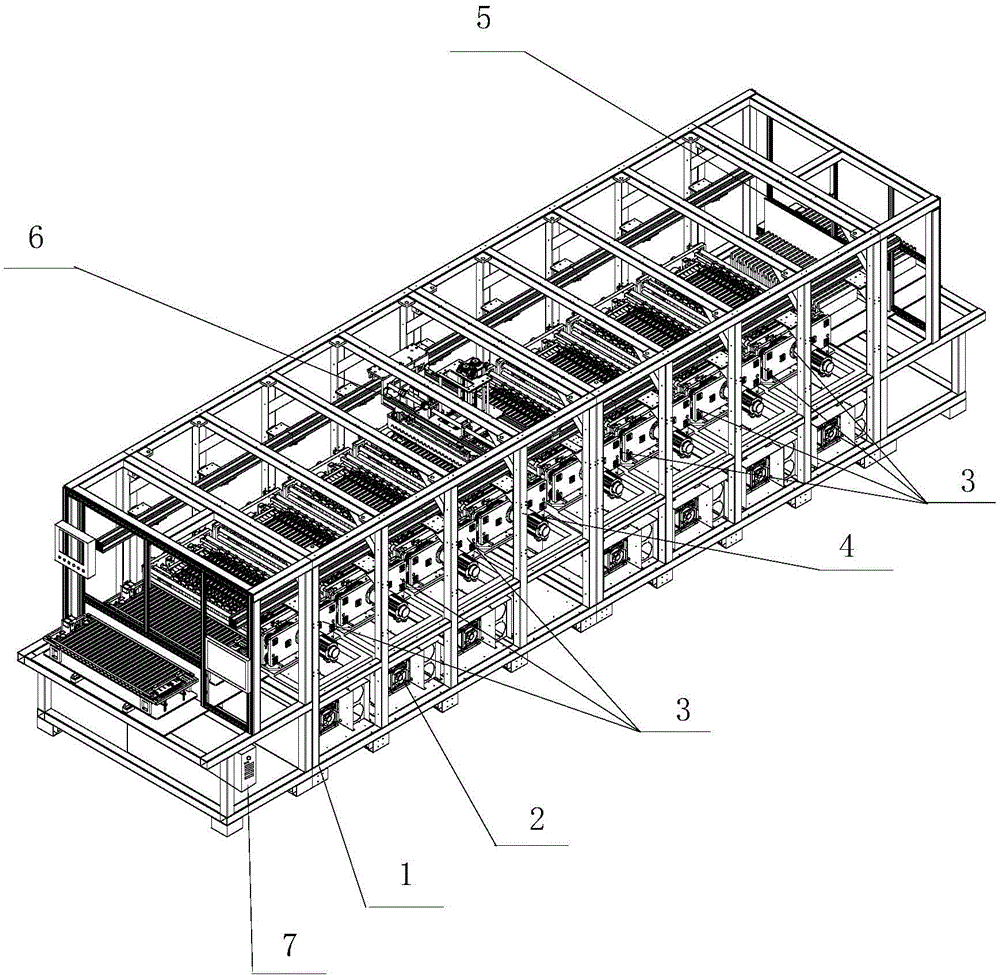

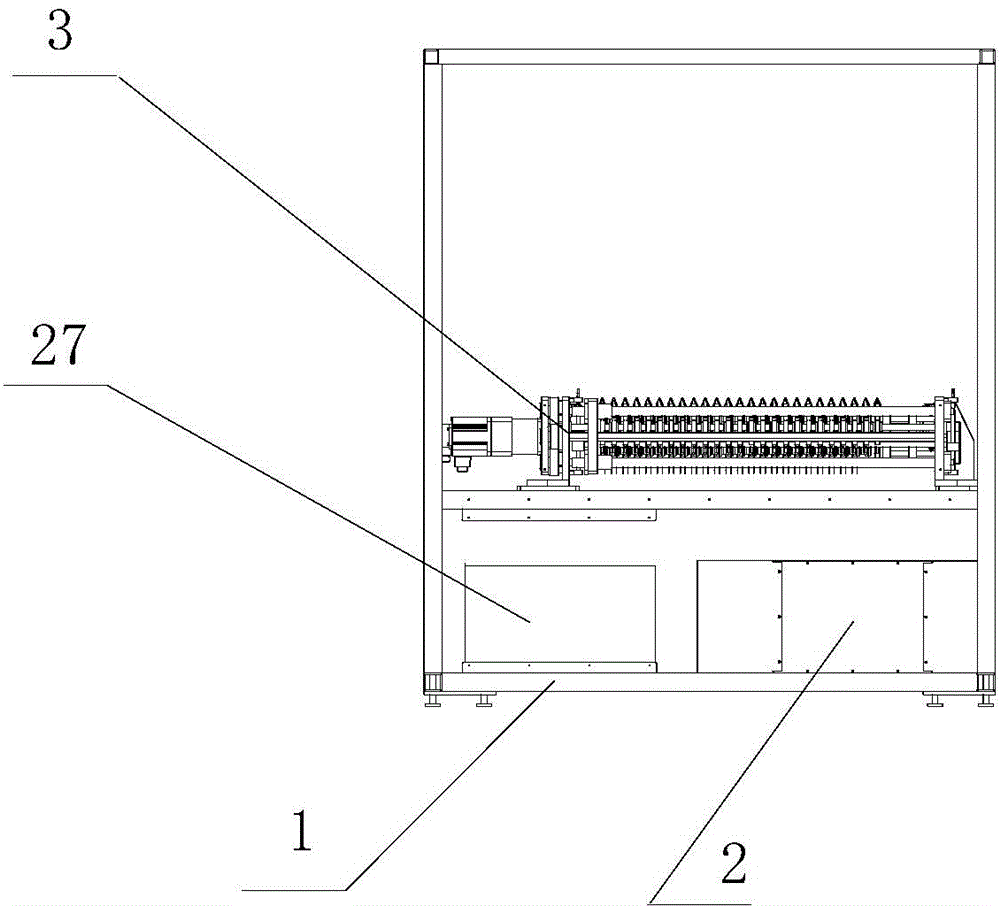

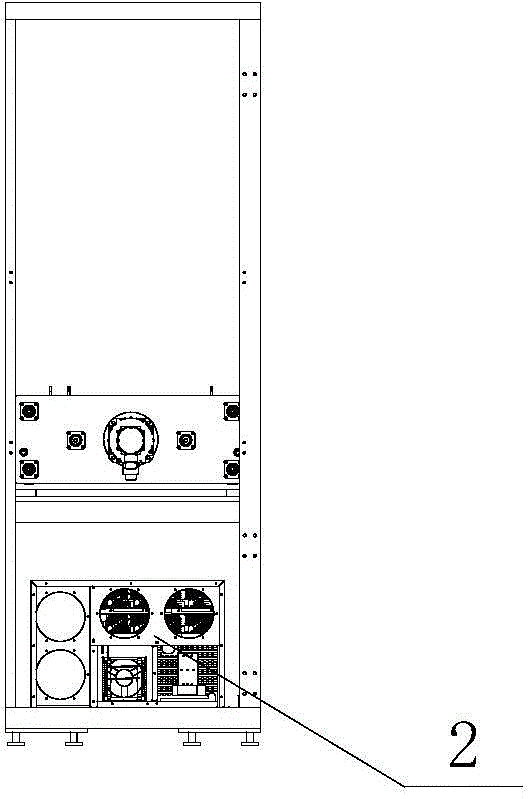

[0073] refer to Figure 1 to Figure 8 , hot and cold pressing forming equipment for soft-pack lithium-ion batteries, including frame 1, variable condition charging and discharging power supply 2, hot pressing forming fixture 3, cold pressing fixture 4, loading and unloading mechanism 5 and battery gripper 6, which can be The variable-condition charging and discharging power supply 2, the hot-pressing fixture 3, the cold-pressing fixture 4, the loading and unloading mechanism 5 and the battery handle 6 are all arranged on the frame 1 and are all controlled by a control mechanism, and the frame Both ends of 1 are provided with the above-mentioned loading and unloading mechanism 5, the above-mentioned cold-pressing jig 4 is arranged between the hot-pressing forming jigs 3, and the described variable-condition charge-discharge power supply 2 and the above-mentioned hot-pressing forming jigs 3 are electrically connected, the hot-pressing fixture 3 and the cold-pressing fixture 2 bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com