Elbow pipe winding guide rail

A guide rail and pipe bending technology, which is applied to conveyors, roller tables, transportation and packaging, etc., can solve the problems of low work efficiency and high labor intensity of manual winding anti-corrosion tapes, and achieve simple structure, low labor intensity and high winding precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

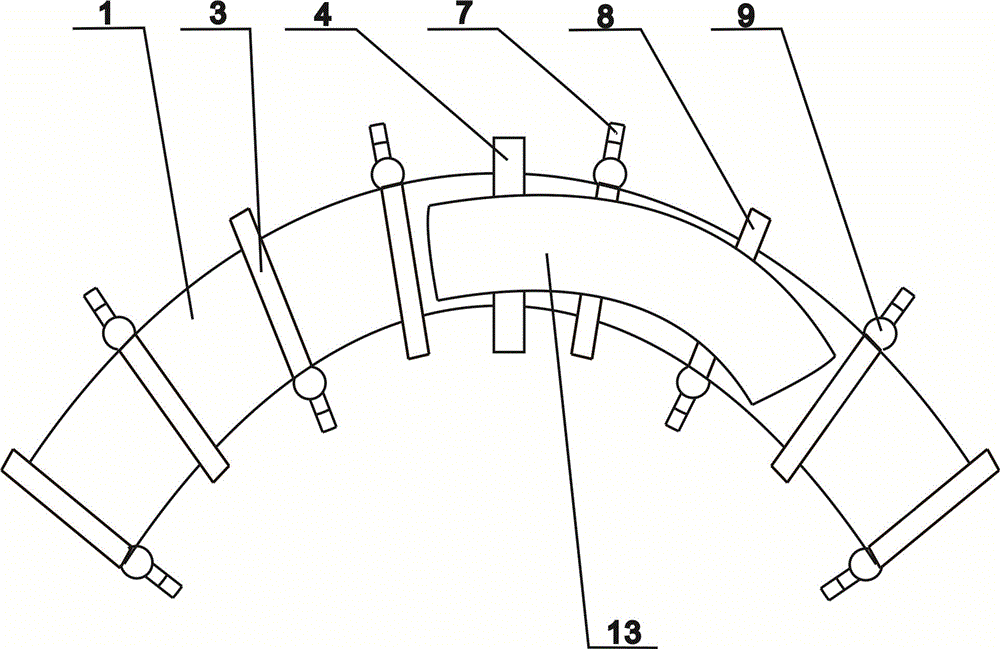

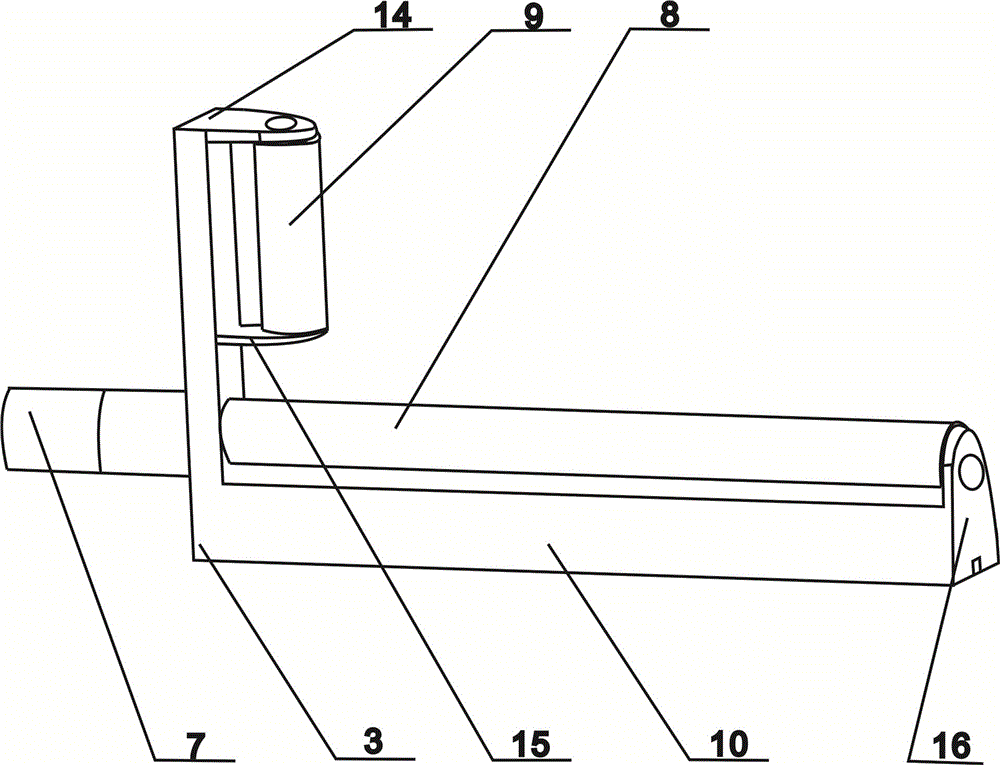

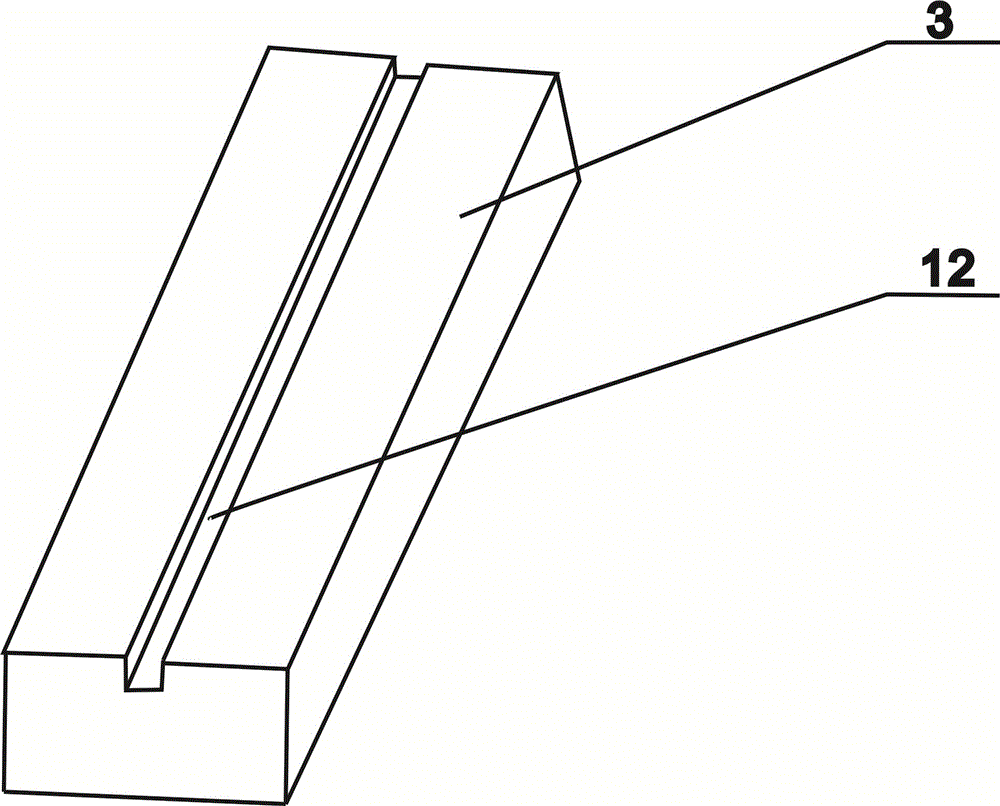

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] As shown in the figure, a curved pipe winding guide rail includes a base plate 1, a base plate sleeper rail 2, and a drive unit 3; 1 is fixedly connected, the base plate 1 is fan-shaped; the base plate sleeper rail 2 is composed of an adjustment base plate 5 and a slider 6, the slider 6 is arranged on the upper part of the adjustment base plate 5, and the slider 6 is a raised cuboid; the drive unit 3 is composed of a drive device 7 , roller 8, clamping wheel 9, roller support 10, clamping wheel support 11, chute 12, baffle plate 16, the driving device 7 is arranged on the left side, and the right side of the driving device 7 is provided with a roller support Seat 10, the roller support seat 10 is a lying 7-shaped, and the shorter side of the roller support seat 10 is fixedly connected with the driving device 7; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com