Fluxgate probe based on ferrous amorphous alloy magnetic core and method for making fluxgate probe

An iron-based amorphous alloy and iron-based amorphous technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of material composition segregation, micropores, etc., and achieve the effect of low cost, simple operation, and enhanced stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

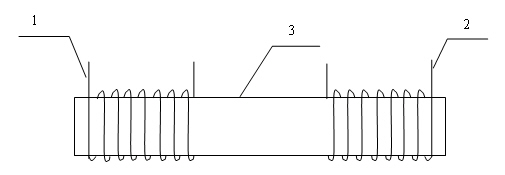

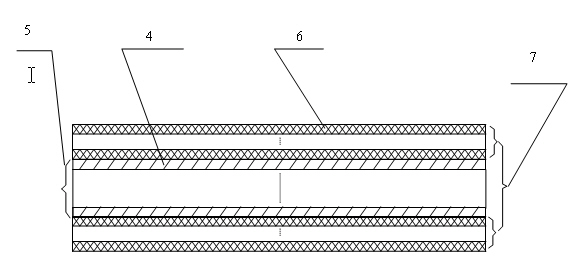

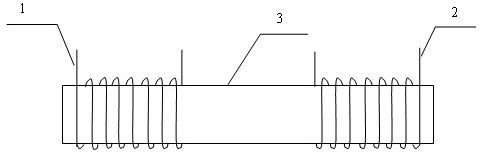

[0024] The structure diagram of the present invention is as figure 1 , 2 As shown, the fluxgate probe based on the iron-based amorphous alloy magnetic core of the present invention includes a magnetic core main shaft 3 and an excitation coil 1 and a detection coil 2 respectively wound on both ends of the magnetic core main shaft 3, wherein the magnetic core main shaft 3 includes There is a magnetic core 5 made of iron-based amorphous foil strip 4 and a jacket 7 wrapped around the outer side of the magnetic core 5 .

[0025] In this embodiment, the above-mentioned magnetic core 5 is made of a layer of iron-based amorphous foil tape 4, or formed by laminating and bonding multiple layers of iron-based amorphous foil tape 4. The cross-sectional shape of the magnetic core 5 is rectangle.

[0026] In this embodiment, the iron-based amorphous foil strip 4 has undergone partial nanocrystallization heat treatment. The thickness of the iron-based amorphous foil strip 4 is 0.03-0.04 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com