Full-automatic looping and butt-welding integrated machine

An all-in-one, fully automatic technology, applied in welding equipment, resistance welding equipment, applications, etc., can solve problems such as difficulty in meeting high standards of industrial production, uneven alignment of welding ports, and inaccurate welding positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

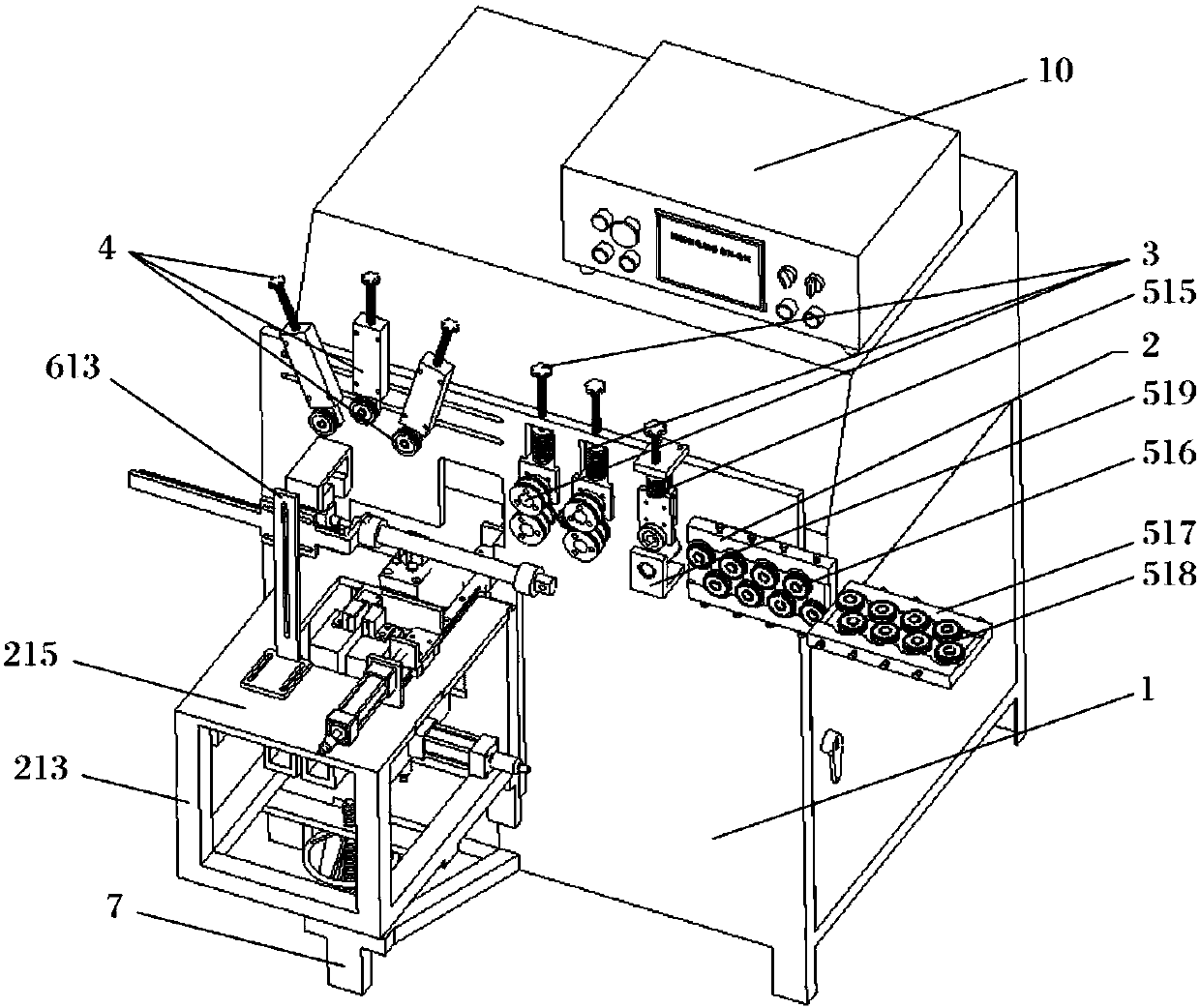

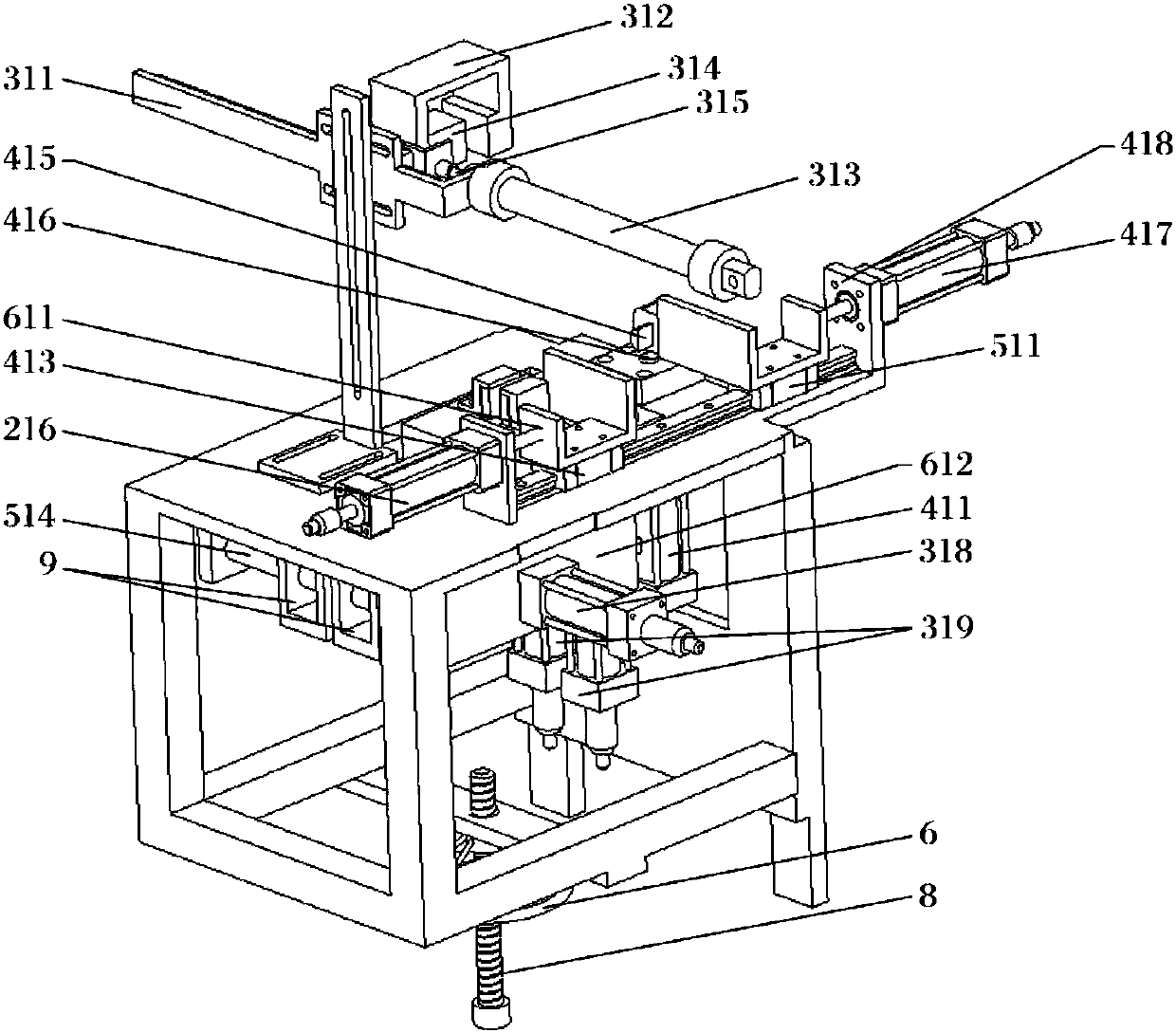

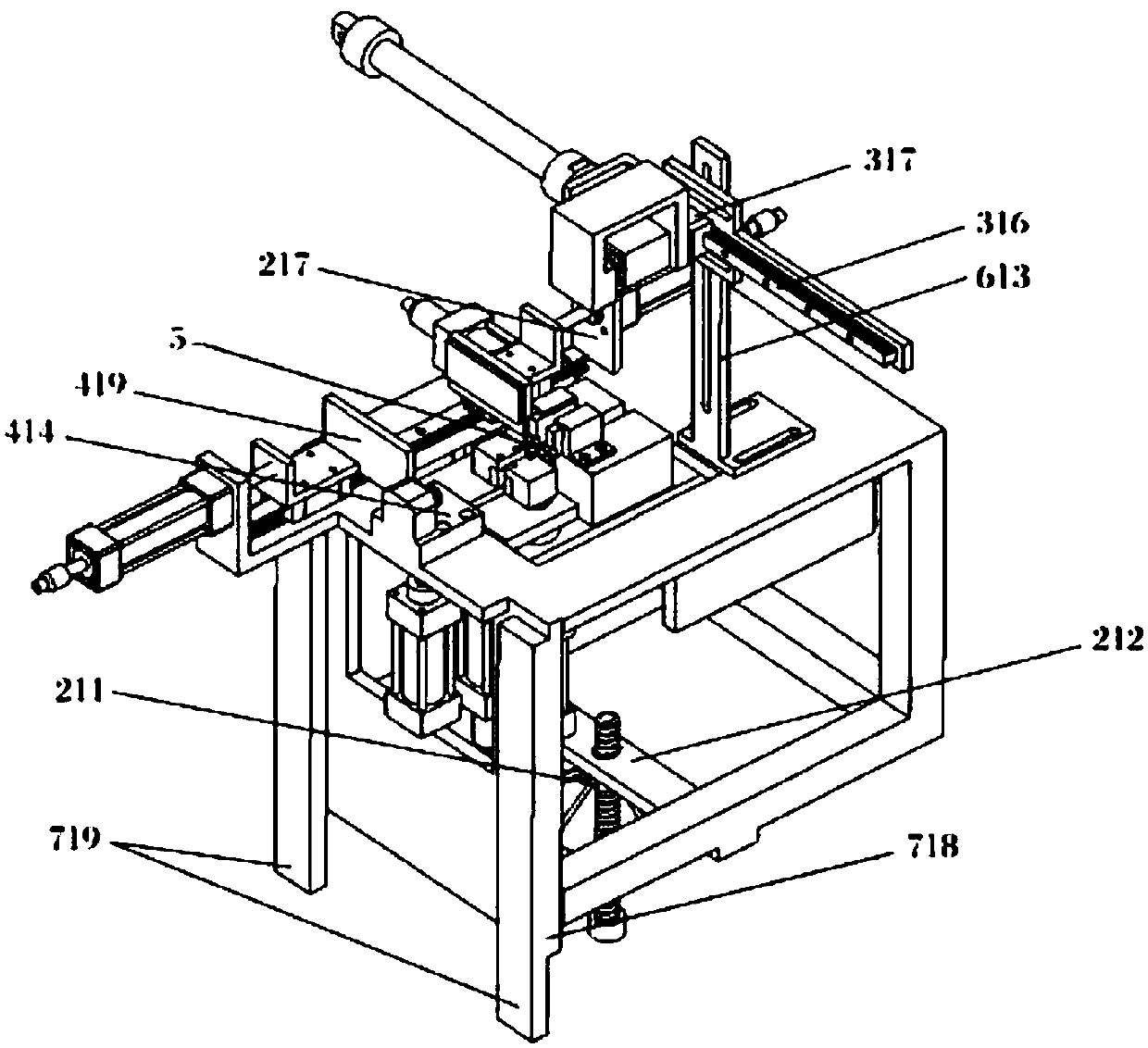

[0050] In order to fully understand the purpose, features and effects of the present invention, the following will be combined with the attached figure 1 -5 is further described to design of the present invention, specific structure and the technical effect that produce.

[0051] Such as figure 1 — Figure 5 The fully automatic loop making and butt welding all-in-one machine of the present invention shown as shown includes: a welding platform 215; a clamping module that moves forward and backward is set on the welding platform 215; a loop sending module that moves forward and backward is set on the welding platform 215 and is matched with the clamping ring module; two iron ring clamping mechanism sliders 9 that move relative to each other are arranged in parallel and facing each other; 9 fixed connection; two clamping ring lower dies 616 are set up and down relative to the clamping ring upper die 615 and are respectively connected up and down with an iron ring clamping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com