Apparatus for making metallic wire binding parts

A metal wire and binding technology, which is applied in the directions of binding, making rings from wires, and applications, can solve the problems of time-consuming, uneconomical production of small print volumes, etc., and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

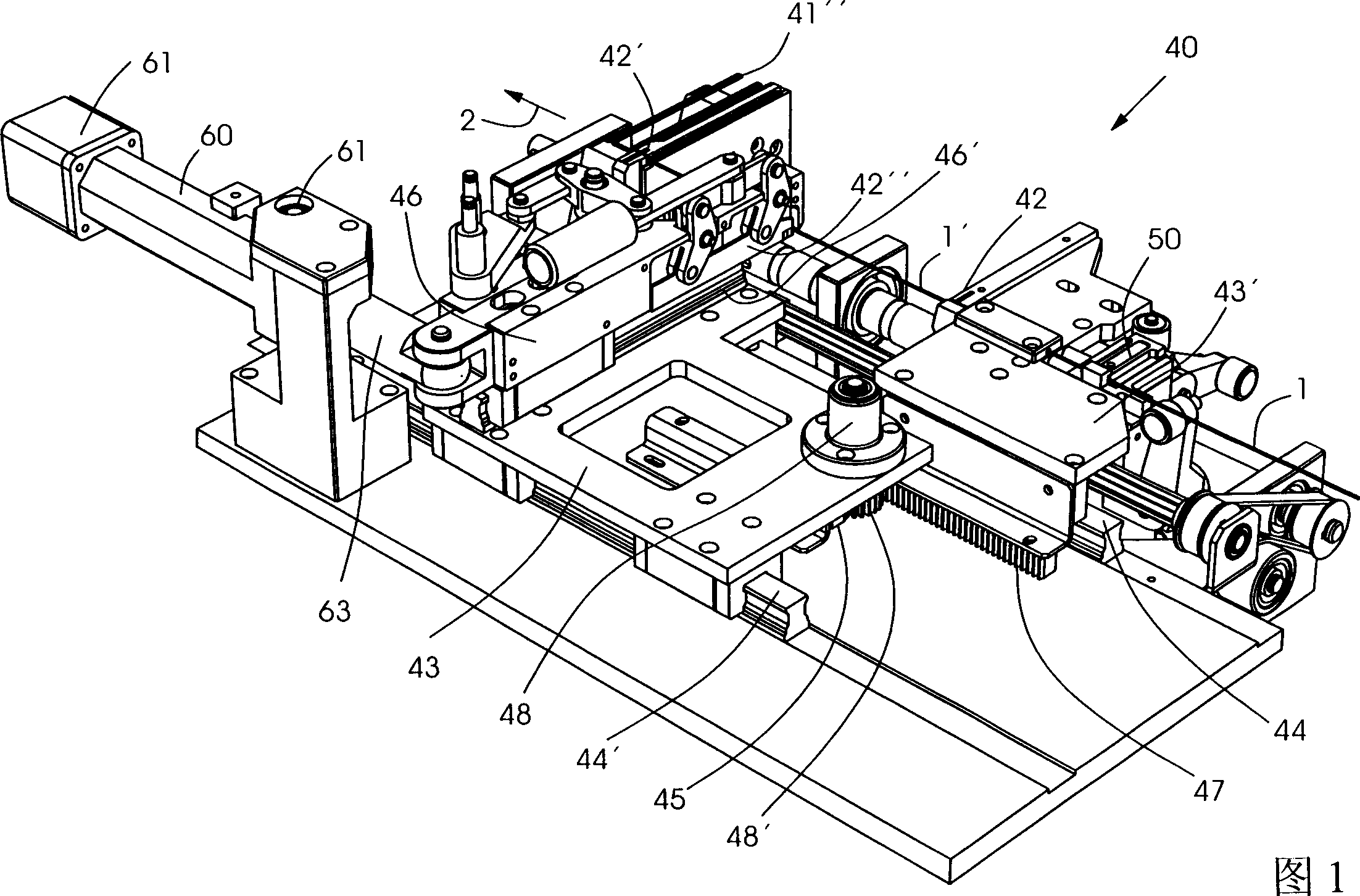

[0059] Figure 1 shows an inventive device, represented by symbol 40, for the flexible manufacture of wire binders for binding booklets of any size and thickness by means of a wire comb binder, in which only or The main building blocks of the invention are described. Other drives and / or guides and cams which are generally known and are required for the operation of the device are only schematically drawn or described in general form.

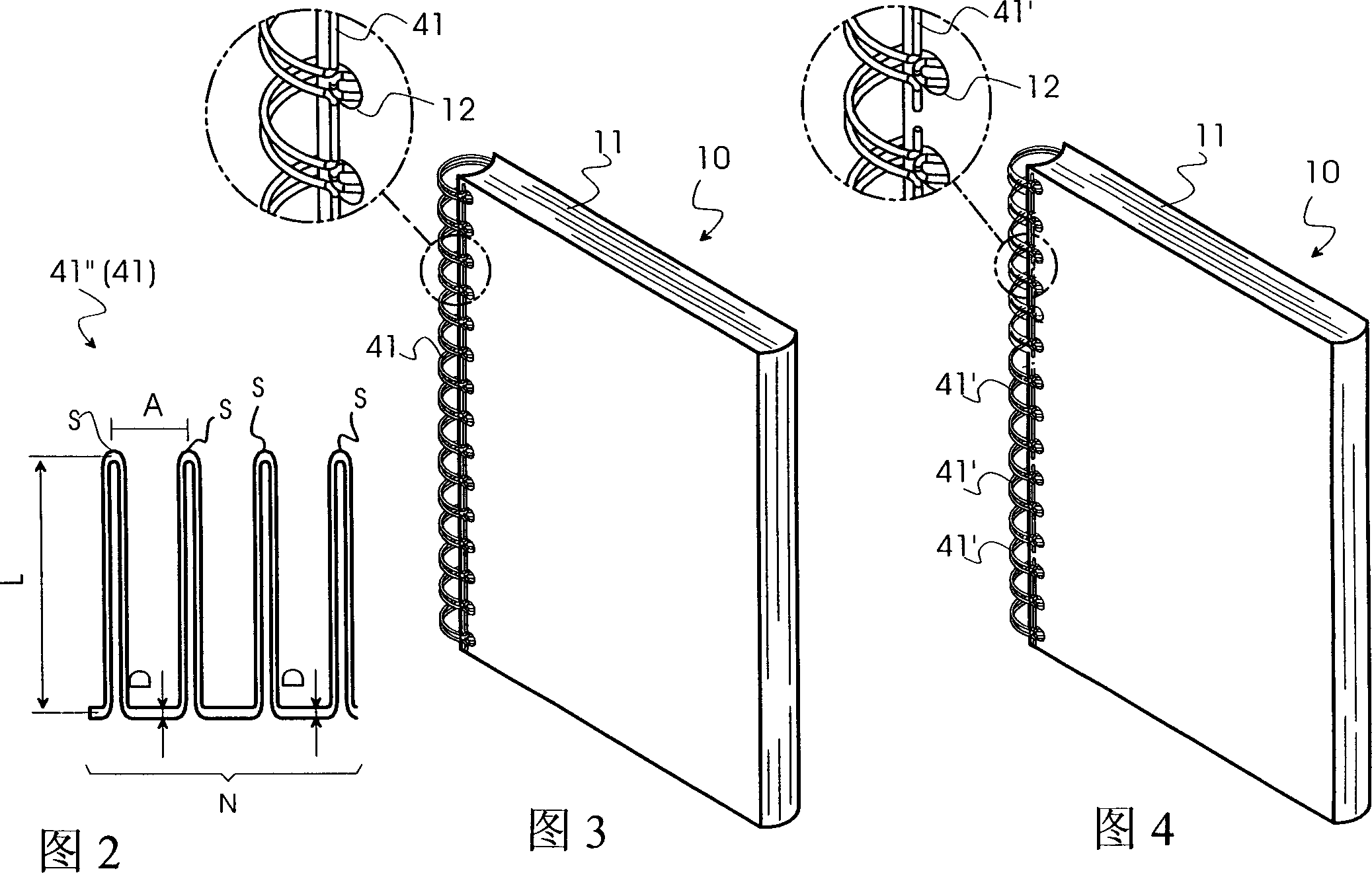

[0060] When there are more than two loops, the wire bindings 41, 41', 41", which are also referred to as wire plates 41", as shown in Figure 2, have a loop length of L, loop spacing of A, metal A loop S with a wire diameter D and a loop number N.

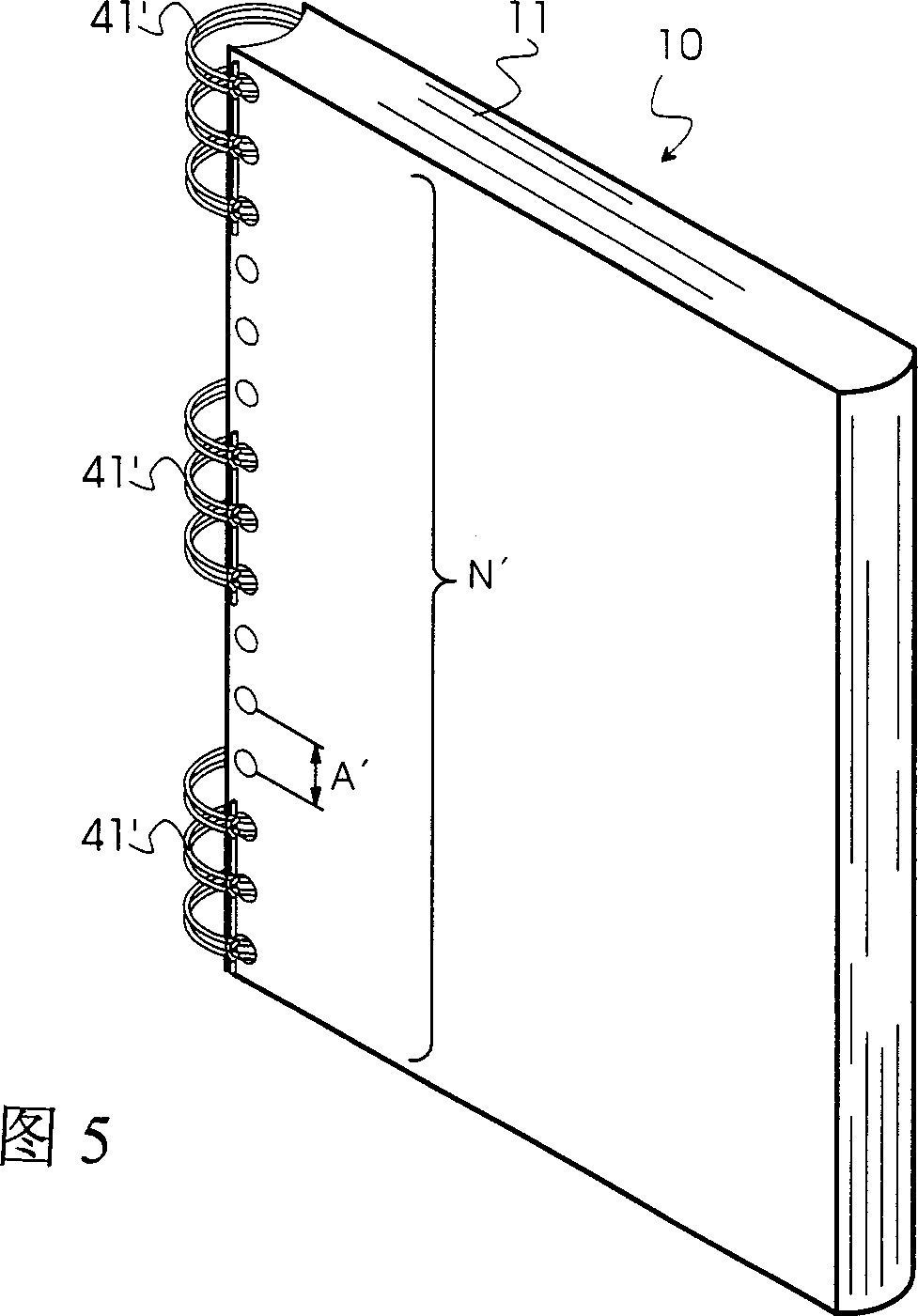

[0061] FIG. 3 shows a bound booklet 10 which has a continuous binding structure. A single binding structure is shown in FIG. 4, which consists of wire binding elements 41', which each have only a single loop and use a wire binding for each hole 12 in the printing carrier. Part 41'. FIG. 5 shows a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com