Steel wire ring positioning clamping rotating device of steel wire ring winding machine

A wire ring winding machine, positioning and clamping technology, applied in the direction of manufacturing rings from wires, other household appliances, household appliances, etc., to achieve the effect of not easy to be damaged, easy to produce and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation manners are given, but the protection scope of the present invention is not limited to the following embodiments.

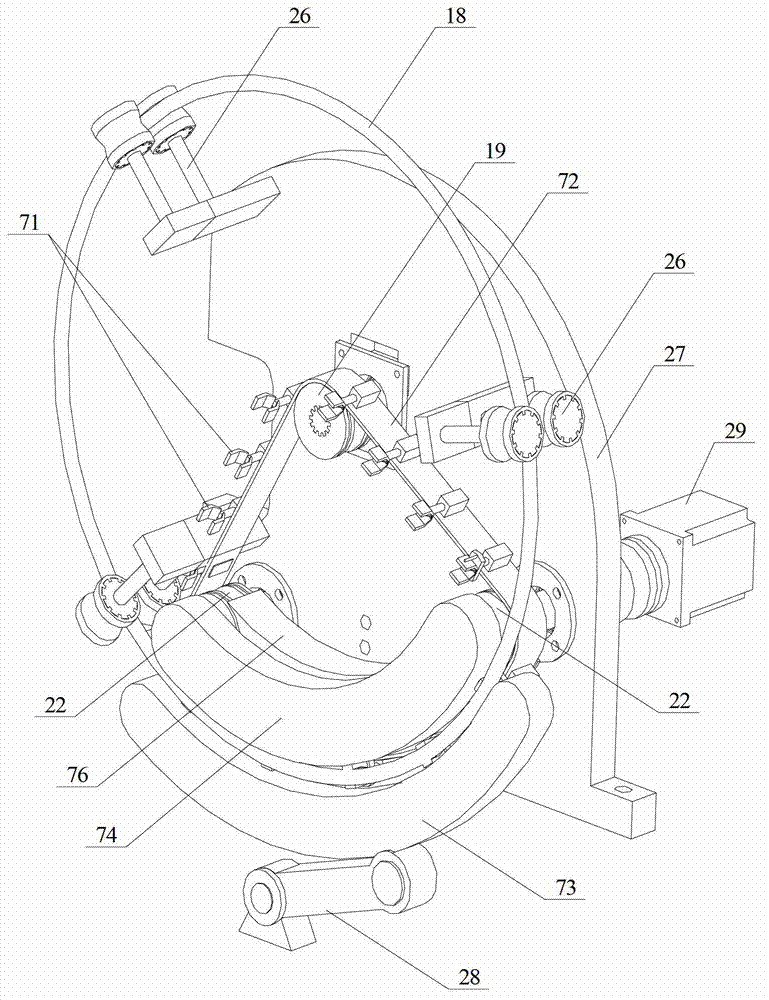

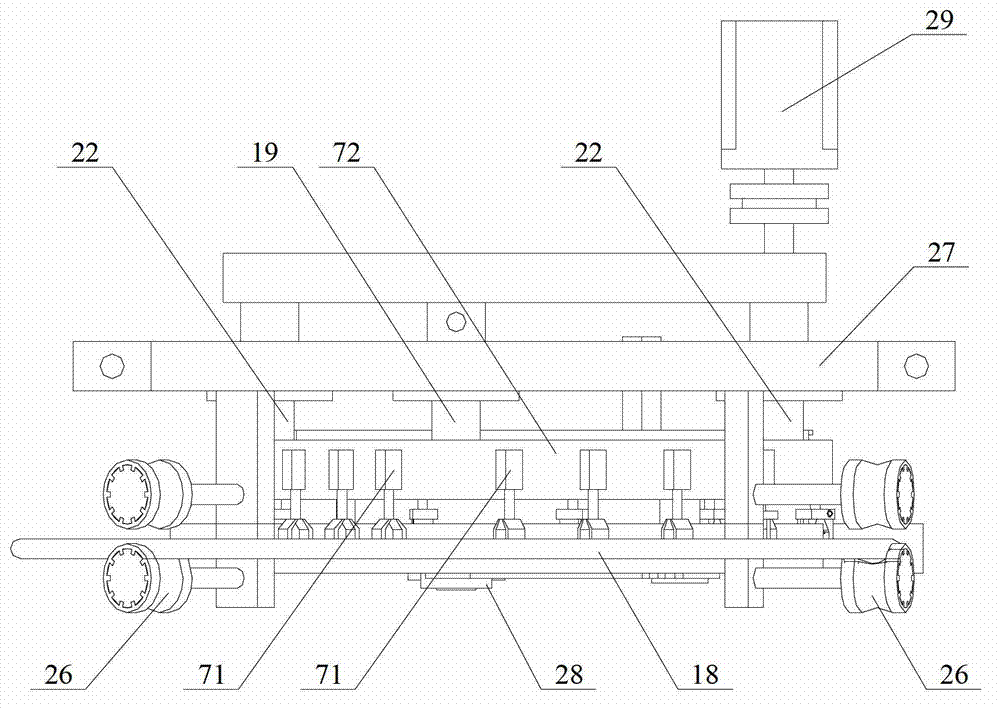

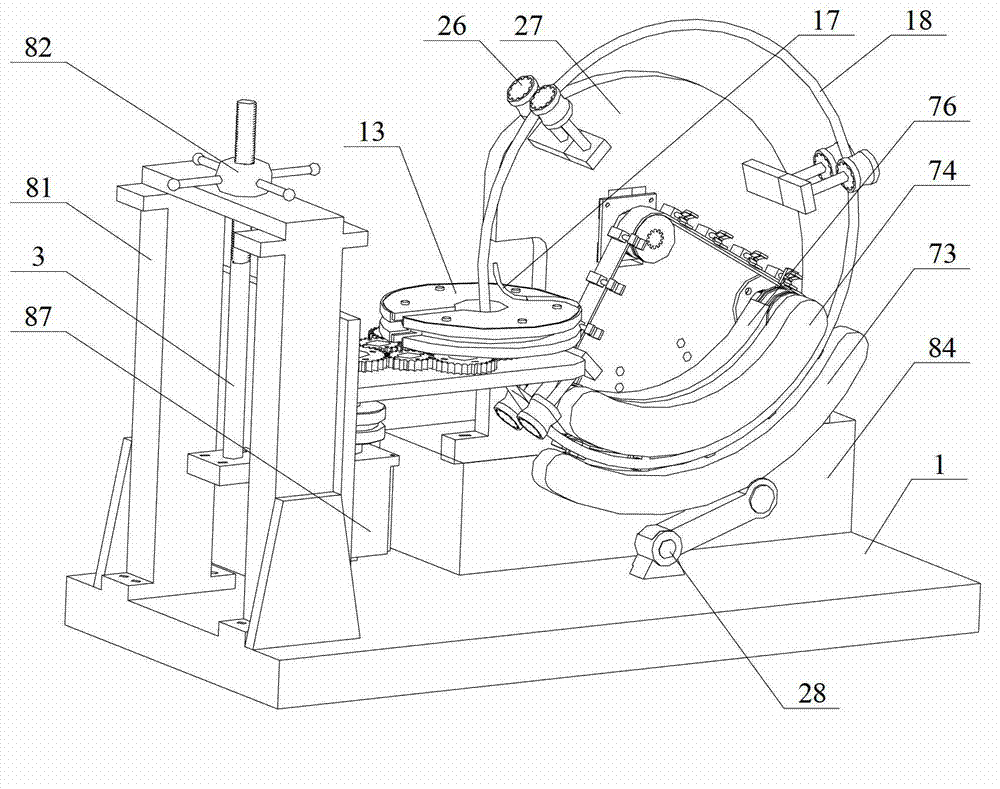

[0017] Such as figure 1 with figure 2 As shown, the traveler positioning, clamping and rotating device of the traveler winding machine involved in this embodiment includes: a central roller 19, two driving rollers 22, three pairs of auxiliary rollers 26, a rear machine plate 27, and a hydraulic cylinder 28 , Drive roller drive motor 29, mechanical claw 71, steel belt 72, lower guide steel plate 73, upper guide steel plate 74 and support steel plate 76. The three pairs of auxiliary rollers 26 are arranged on the rear machine plate 27, and the support steel plate 76 is fixed at the back At the lower part of the front side of the machine plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com